Electrifying the Future: The Rise of Electric Vehicles and Safety Concerns

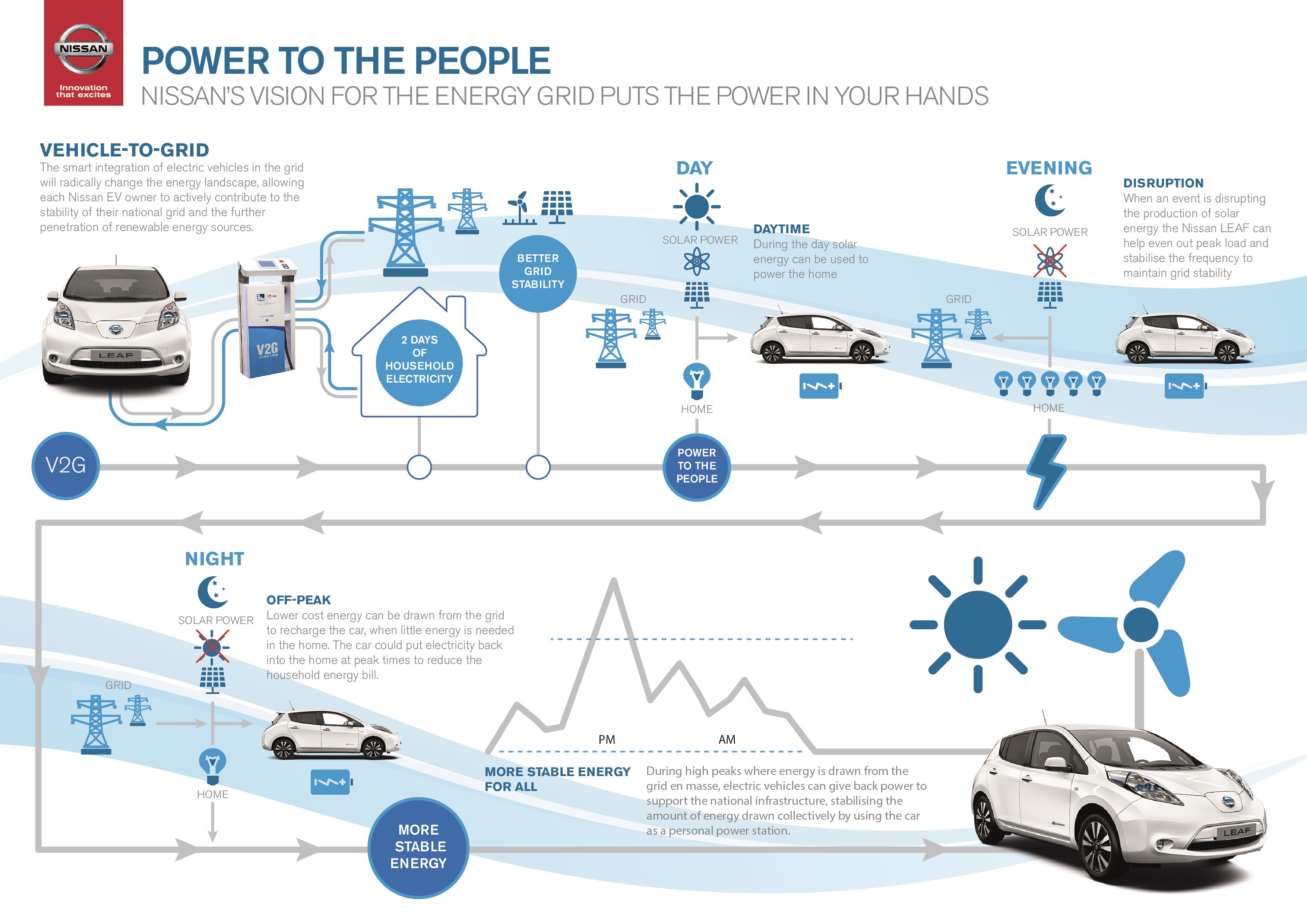

The automotive industry is undergoing a significant transformation with the growing popularity of electric vehicles (EVs). As governments and consumers increasingly focus on sustainable and environmentally friendly transportation options, the demand for EVs is expected to continue its upward trend. However, this shift towards electrification also raises important safety concerns that must be addressed by manufacturers and regulators alike. Electric vehicle and electric motor safety engineering trends are becoming a crucial aspect of the industry, as companies strive to design and develop safe and reliable EVs that meet the needs of consumers while minimizing the risk of accidents and injuries.

According to a report by the International Energy Agency (IEA), the number of EVs on the road is projected to reach 140 million by 2030, up from just 2 million in 2016. This rapid growth is driven by declining battery costs, improving charging infrastructure, and increasing government support for EV adoption. However, as the number of EVs on the road increases, so does the risk of accidents and injuries related to electrical and thermal hazards.

Electric vehicle and electric motor safety engineering trends are focused on addressing these risks through the development of innovative safety features and technologies. For example, many EV manufacturers are incorporating advanced thermal management systems to prevent overheating and reduce the risk of battery fires. Additionally, companies are investing in the development of more robust electrical insulation and fault detection systems to prevent electrical shocks and short circuits.

Despite these efforts, there is still much work to be done to ensure the safety of EVs. Regulators and industry stakeholders must continue to work together to develop and implement effective safety standards and guidelines for EV design and development. By prioritizing electric vehicle and electric motor safety engineering trends, the industry can help to build consumer trust and confidence in EVs, ultimately driving the widespread adoption of sustainable and environmentally friendly transportation options.

Understanding Electric Motor Safety: Key Challenges and Opportunities

Electric motor safety is a critical aspect of electric vehicle (EV) design and development, as it directly impacts the overall safety and reliability of the vehicle. The unique challenges posed by high-voltage systems in EVs require innovative safety engineering solutions to mitigate the risks of electrical shock, thermal overload, and other hazards. In this context, electric vehicle and electric motor safety engineering trends are focused on developing advanced safety features and technologies to ensure the safe operation of EV motors.

One of the key challenges in EV motor safety is thermal management. High-voltage systems can generate excessive heat, which can lead to reduced motor efficiency, increased risk of electrical shock, and even fires. To address this challenge, manufacturers are developing advanced thermal management systems, including liquid cooling systems, air cooling systems, and thermal interface materials. These systems help to regulate motor temperature, reduce heat-related stress, and prevent overheating.

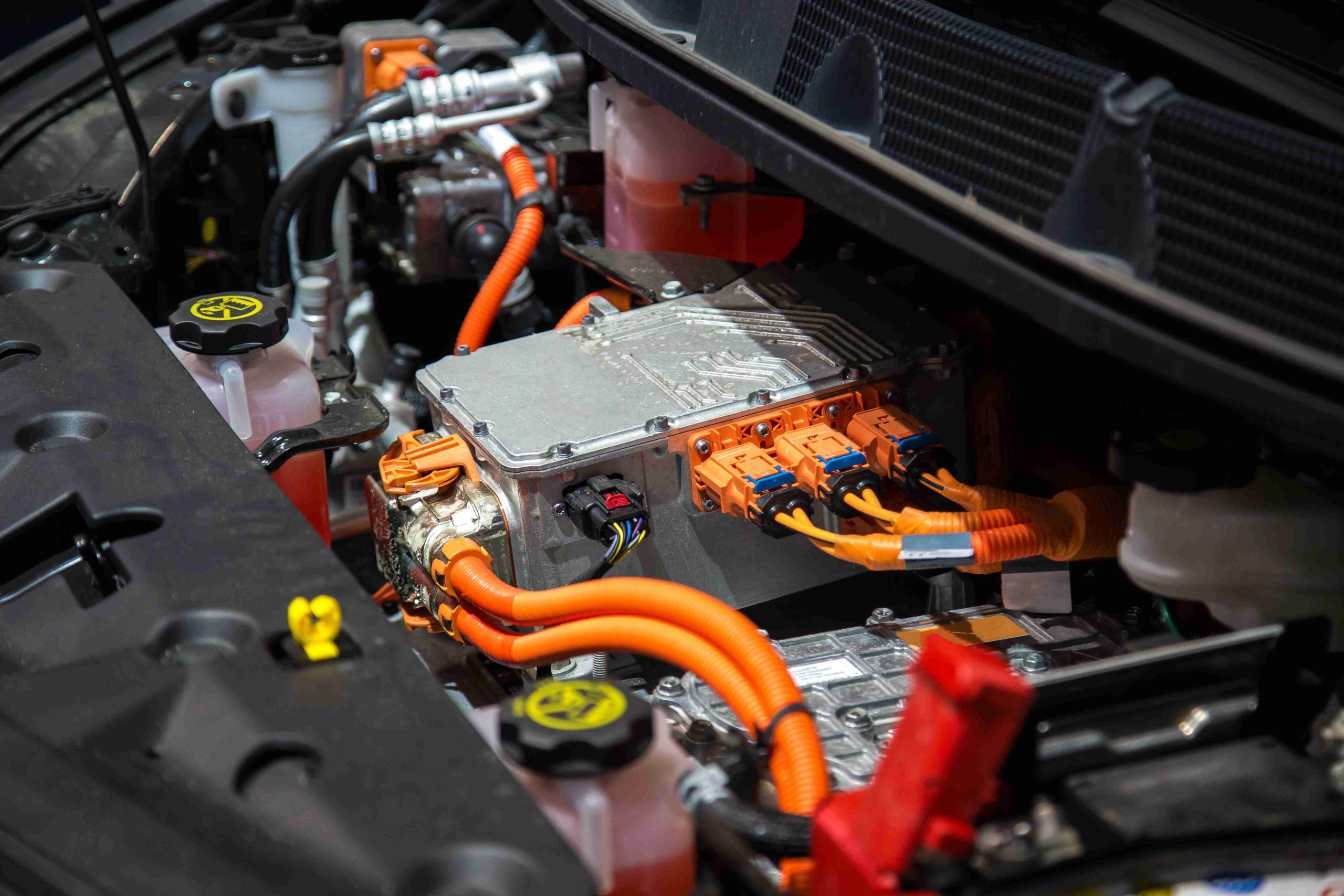

Electrical insulation is another critical aspect of EV motor safety. The high-voltage systems in EVs require specialized insulation materials and designs to prevent electrical shock and short circuits. Manufacturers are developing advanced insulation materials, such as ceramic and glass-based materials, to provide improved electrical insulation and reduce the risk of electrical shock.

Fault detection and protection systems are also essential for EV motor safety. These systems help to detect and prevent faults in the motor and electrical systems, reducing the risk of electrical shock, thermal overload, and other hazards. Manufacturers are developing advanced fault detection and protection systems, including sensors, monitoring systems, and protection circuits, to provide real-time monitoring and protection of EV motors.

By addressing these challenges and opportunities, electric vehicle and electric motor safety engineering trends are helping to improve the overall safety and reliability of EVs. As the industry continues to evolve, we can expect to see even more innovative safety features and technologies emerge, further reducing the risks associated with EVs and promoting widespread adoption of sustainable and environmentally friendly transportation options.

How to Design Safe Electric Vehicle Charging Systems

Designing safe electric vehicle (EV) charging systems is a critical aspect of electric vehicle and electric motor safety engineering trends. As the demand for EVs continues to grow, the need for safe and reliable charging systems has become increasingly important. In this context, it is essential to provide a step-by-step guide on designing safe EV charging systems, including the selection of suitable charging modes, cable management, and protection against electrical shock.

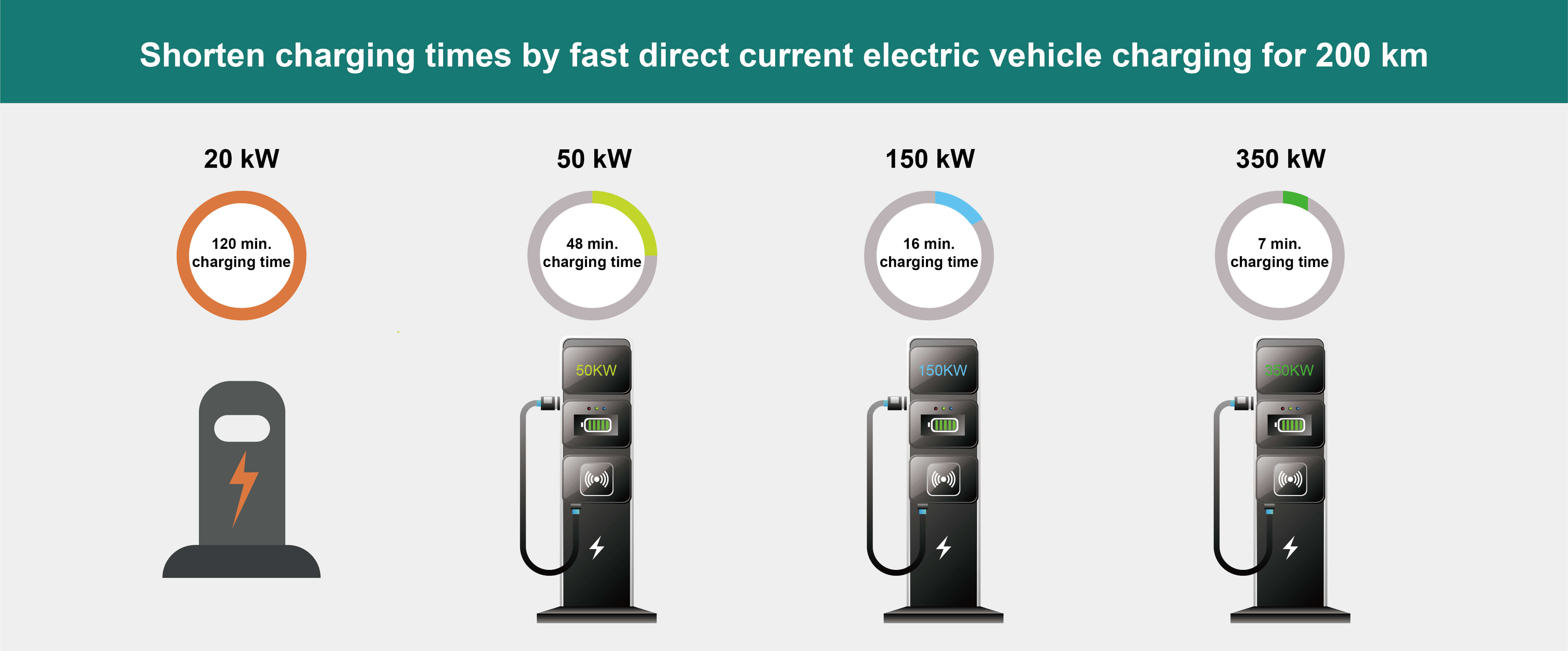

Step 1: Selecting Suitable Charging Modes

The first step in designing a safe EV charging system is to select a suitable charging mode. There are several charging modes available, including Level 1 (120V), Level 2 (240V), and DC Fast Charging. The choice of charging mode depends on the type of EV, the charging infrastructure, and the user’s needs. It is essential to select a charging mode that is compatible with the EV’s onboard charger and the charging infrastructure.

Step 2: Cable Management

Cable management is a critical aspect of EV charging system design. The charging cable must be designed to withstand the electrical and mechanical stresses of charging, including high currents, high temperatures, and mechanical flexing. It is essential to use high-quality cables that meet international safety standards, such as those set by the International Electrotechnical Commission (IEC).

Step 3: Protection Against Electrical Shock

Protection against electrical shock is a critical aspect of EV charging system design. The charging system must be designed to prevent electrical shock, including shock from high-voltage systems, electrical arcs, and ground faults. It is essential to use protective devices, such as ground fault circuit interrupters (GFCIs) and arc fault circuit interrupters (AFCIs), to prevent electrical shock.

Step 4: Compliance with International Safety Standards

Compliance with international safety standards is essential for ensuring the safety of EV charging systems. The charging system must meet the requirements of international safety standards, such as those set by the IEC and the National Electric Manufacturers Association (NEMA). It is essential to use testing and certification procedures to ensure compliance with these standards.

By following these steps, designers and engineers can create safe and reliable EV charging systems that meet the needs of EV users. As electric vehicle and electric motor safety engineering trends continue to evolve, it is essential to stay up-to-date with the latest developments and innovations in EV charging system design.

Advances in Battery Safety: Thermal Management and Protection Systems

Battery safety is a critical aspect of electric vehicle (EV) design and development, and advances in thermal management and protection systems are playing a crucial role in improving the safety of EV batteries. As electric vehicle and electric motor safety engineering trends continue to evolve, the development of advanced battery safety technologies is becoming increasingly important.

Thermal management systems are designed to regulate the temperature of EV batteries, preventing overheating and reducing the risk of battery fires. These systems typically consist of a combination of cooling and heating elements, such as liquid cooling systems, air cooling systems, and thermal interface materials. By maintaining a stable battery temperature, thermal management systems can help to improve battery performance, increase battery lifespan, and reduce the risk of battery fires.

Protective circuits are another critical component of EV battery safety. These circuits are designed to detect and prevent electrical faults, such as overcharging, over-discharging, and electrical shorts. By detecting and preventing these faults, protective circuits can help to reduce the risk of battery fires and electrical shock.

Advanced materials are also being developed to improve EV battery safety. These materials, such as lithium-ion batteries with built-in safety features, are designed to reduce the risk of battery fires and electrical shock. By incorporating these advanced materials into EV battery design, manufacturers can help to improve the overall safety of their vehicles.

The use of thermal management systems, protective circuits, and advanced materials is contributing to improved safety and reduced risk of battery fires in EVs. As electric vehicle and electric motor safety engineering trends continue to evolve, we can expect to see even more innovative safety features and technologies emerge, further reducing the risks associated with EVs and promoting widespread adoption of sustainable and environmentally friendly transportation options.

Examples of EVs that have incorporated advanced battery safety technologies include the Tesla Model 3, which features a advanced thermal management system, and the Audi e-tron, which features a protective circuit system. These vehicles demonstrate the importance of battery safety in EV design and development, and highlight the need for continued innovation in this area.

The Role of Functional Safety in Electric Vehicle Development

Functional safety is a critical aspect of electric vehicle (EV) development, as it ensures the safe operation of the vehicle and its components. In the context of electric vehicle and electric motor safety engineering trends, functional safety plays a vital role in mitigating the risks associated with EVs. This article will explain the concept of functional safety and its application in EV development, highlighting the importance of hazard analysis, risk assessment, and safety validation in ensuring the safe operation of EVs.

Functional safety is a systematic approach to ensuring the safety of a system or component. It involves identifying potential hazards, assessing the risks associated with those hazards, and implementing measures to mitigate or eliminate those risks. In the context of EV development, functional safety is applied to the design and development of the vehicle’s electrical and electronic systems, including the battery management system, the electric motor, and the charging system.

Hazard analysis is a critical step in the functional safety process. It involves identifying potential hazards associated with the EV’s electrical and electronic systems, such as electrical shock, thermal overload, and battery fires. Once these hazards have been identified, risk assessment is used to determine the likelihood and potential impact of each hazard. This information is then used to develop safety requirements and implement measures to mitigate or eliminate the risks.

Safety validation is another critical step in the functional safety process. It involves testing and verifying that the EV’s electrical and electronic systems meet the safety requirements and are functioning as intended. This includes testing for electrical shock, thermal overload, and other potential hazards, as well as verifying that the vehicle’s safety features, such as airbags and anti-lock braking systems, are functioning correctly.

The application of functional safety in EV development is critical to ensuring the safe operation of EVs. By identifying and mitigating potential hazards, EV manufacturers can reduce the risk of accidents and injuries, and ensure that their vehicles meet the safety standards and regulations set by regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) and the International Electrotechnical Commission (IEC).

In conclusion, functional safety plays a vital role in electric vehicle and electric motor safety engineering trends. By applying a systematic approach to safety, EV manufacturers can ensure the safe operation of their vehicles and reduce the risk of accidents and injuries. As the EV industry continues to evolve, the importance of functional safety will only continue to grow.

Real-World Examples: Safe Electric Vehicle Designs and Technologies

The electric vehicle (EV) industry has made significant strides in recent years, with many manufacturers incorporating advanced safety features and technologies into their vehicles. In this article, we will showcase real-world examples of safe EV designs and technologies, highlighting the innovative safety features and engineering solutions employed in these vehicles.

One example of a safe EV design is the Tesla Model 3’s battery management system. This system is designed to prevent overheating and electrical shock, and features a advanced thermal management system that regulates the temperature of the battery pack. The Tesla Model 3 also features a advanced airbag system, including a driver’s knee airbag and a passenger’s seat cushion airbag, which provides enhanced protection in the event of a collision.

Another example of a safe EV design is the Audi e-tron’s thermal management system. This system is designed to regulate the temperature of the battery pack and electric motor, preventing overheating and electrical shock. The Audi e-tron also features a advanced safety system, including a driver assistance system and a collision avoidance system, which provides enhanced protection in the event of a collision.

The Hyundai

Real-World Examples: Safe Electric Vehicle Designs and Technologies

The electric vehicle (EV) industry has made significant strides in recent years, with many manufacturers incorporating advanced safety features and technologies into their vehicles. In this article, we will showcase real-world examples of safe EV designs and technologies, highlighting the innovative safety features and engineering solutions employed in these vehicles.

One example of a safe EV design is the Tesla Model 3’s battery management system. This system is designed to prevent overheating and electrical shock, and features a advanced thermal management system that regulates the temperature of the battery pack. The Tesla Model 3 also features a advanced airbag system, including a driver’s knee airbag and a passenger’s seat cushion airbag, which provides enhanced protection in the event of a collision.

Another example of a safe EV design is the Audi e-tron’s thermal management system. This system is designed to regulate the temperature of the battery pack and electric motor, preventing overheating and electrical shock. The Audi e-tron also features a advanced safety system, including a driver assistance system and a collision avoidance system, which provides enhanced protection in the event of a collision.

The Hyundai

Real-World Examples: Safe Electric Vehicle Designs and Technologies

The electric vehicle (EV) industry has made significant strides in recent years, with many manufacturers incorporating advanced safety features and technologies into their vehicles. In this article, we will showcase real-world examples of safe EV designs and technologies, highlighting the innovative safety features and engineering solutions employed in these vehicles.

One example of a safe EV design is the Tesla Model 3’s battery management system. This system is designed to prevent overheating and electrical shock, and features a advanced thermal management system that regulates the temperature of the battery pack. The Tesla Model 3 also features a advanced airbag system, including a driver’s knee airbag and a passenger’s seat cushion airbag, which provides enhanced protection in the event of a collision.

Another example of a safe EV design is the Audi e-tron’s thermal management system. This system is designed to regulate the temperature of the battery pack and electric motor, preventing overheating and electrical shock. The Audi e-tron also features a advanced safety system, including a driver assistance system and a collision avoidance system, which provides enhanced protection in the event of a collision.

The Hyundai