Why Safety Matters in Electric Vehicle Design

The increasing adoption of electric vehicles (EVs) on roads worldwide has brought attention to the importance of safety in their design. As the automotive industry continues to evolve, electric vehicle and electric motor safety engineering trends are becoming a top priority. One of the primary concerns is the high-voltage electrical system that powers EVs, which poses unique safety challenges. Unlike traditional internal combustion engine vehicles, EVs require specialized safety protocols to protect occupants and bystanders from electrical shock, fires, and other hazards.

According to the National Fire Protection Association (NFPA), electrical fires are a leading cause of vehicle fires, accounting for approximately 20% of all vehicle fires. Furthermore, the high-voltage electrical system in EVs can be particularly hazardous if not designed and manufactured with safety in mind. Therefore, it is crucial to implement robust safety protocols in EV design to minimize the risk of electrical shock, fires, and other safety hazards.

Some of the key safety considerations in EV design include the use of insulation, grounding, and protective devices to prevent electrical shock. Additionally, EV manufacturers must ensure that their vehicles meet strict safety standards, such as those set by the Society of Automotive Engineers (SAE) and the International Electrotechnical Commission (IEC). By prioritizing safety in EV design, manufacturers can help prevent accidents, reduce the risk of injury or death, and protect the environment.

As the demand for EVs continues to grow, it is essential to stay up-to-date with the latest electric vehicle and electric motor safety engineering trends. By doing so, manufacturers can ensure that their vehicles meet the highest safety standards, providing a safe and reliable mode of transportation for drivers and passengers alike.

Advances in Electric Motor Safety Engineering

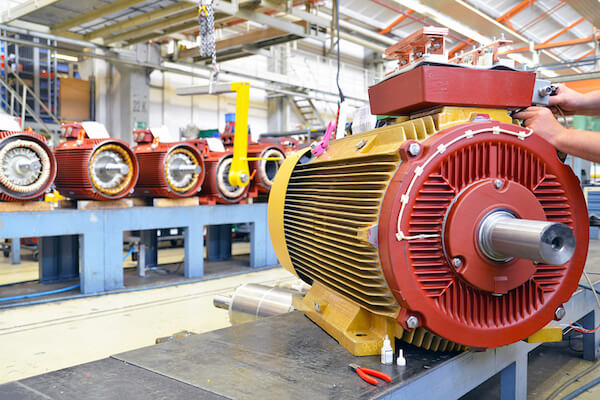

Recent years have seen significant advances in electric motor safety engineering, driven by the growing demand for electric vehicles (EVs) and the need for improved safety standards. One of the key areas of focus has been the development of more efficient and reliable motor designs, which can help to reduce the risk of electrical fires and other safety hazards. For example, the use of permanent magnet motors has become increasingly popular in EVs, due to their high efficiency and reliability.

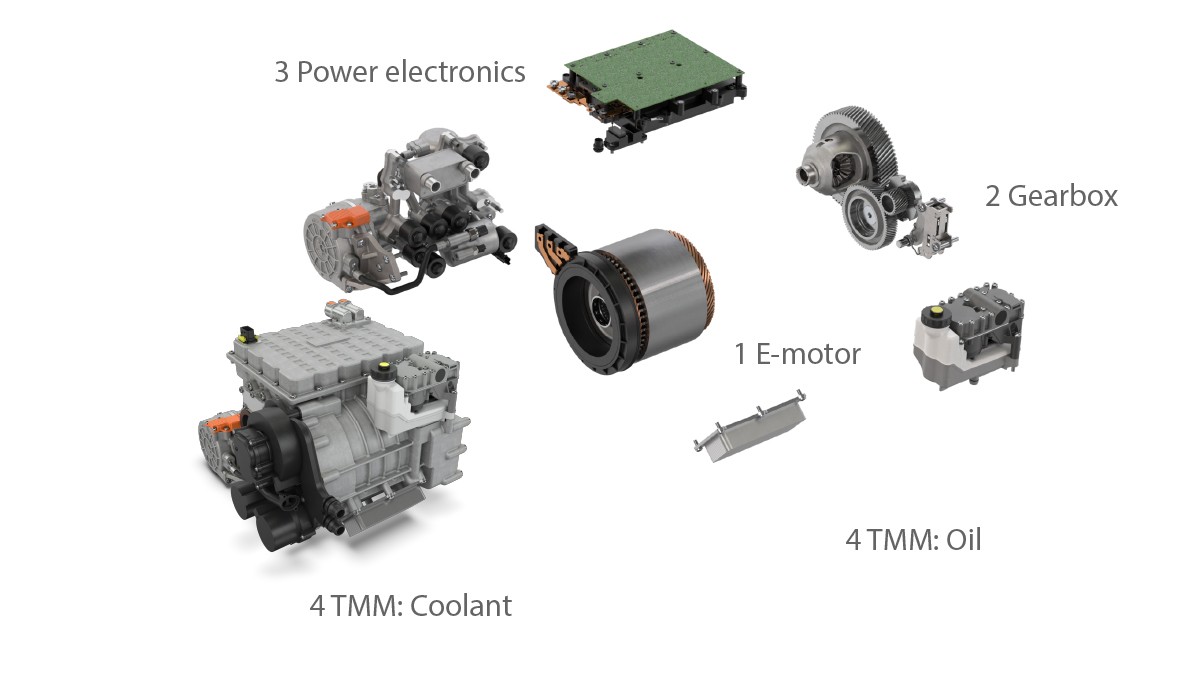

Another important area of advancement has been the development of improved thermal management systems, which are critical for maintaining the safety and performance of EV motors. These systems use advanced materials and cooling technologies to prevent overheating, which can help to reduce the risk of electrical fires and other safety hazards. Additionally, the use of thermal sensors and monitoring systems can help to detect potential problems before they become major issues.

Enhanced fault detection and protection mechanisms are also being developed to improve the safety of EV motors. These mechanisms use advanced algorithms and sensors to detect potential faults and take corrective action to prevent damage or injury. For example, some EVs are equipped with systems that can detect electrical faults and automatically shut down the motor to prevent further damage.

These advances in electric motor safety engineering are helping to drive the growth of the EV market, by providing consumers with safer and more reliable vehicles. As the demand for EVs continues to grow, it is likely that we will see even more innovative solutions to the challenges of electric motor safety engineering. By staying up-to-date with the latest electric vehicle and electric motor safety engineering trends, manufacturers can ensure that their vehicles meet the highest safety standards, providing a safe and reliable mode of transportation for drivers and passengers alike.

The use of advanced materials and technologies, such as silicon carbide (SiC) and gallium nitride (GaN), is also

How to Mitigate Electrical Shock Risks in EVs

Electrical shock is a significant risk in electric vehicles (EVs), particularly when it comes to high-voltage electrical systems. To mitigate this risk, EV manufacturers and owners can take several steps to ensure safe operation and maintenance. One of the most effective ways to prevent electrical shock is through the use of insulation, grounding, and protective devices.

Insulation is a critical component in preventing electrical shock, as it helps to prevent electrical currents from flowing through the body. EV manufacturers can use advanced insulation materials, such as ceramic or glass, to ensure that electrical components are properly isolated. Additionally, grounding systems can be used to direct electrical currents safely to the ground, reducing the risk of electrical shock.

Protective devices, such as fuses and circuit breakers, can also be used to prevent electrical shock. These devices can detect electrical faults and automatically shut off power to prevent damage or injury. EV owners can also take steps to prevent electrical shock, such as avoiding contact with electrical components and following proper maintenance and repair procedures.

Best practices for maintenance and repair are also essential in preventing electrical shock. EV owners should only use authorized repair personnel and follow recommended maintenance schedules to ensure that electrical systems are functioning properly. Additionally, EV owners should be aware of the risks associated with electrical shock and take steps to prevent it, such as avoiding contact with electrical components and following proper safety procedures.

By following these guidelines and staying up-to-date with the latest electric vehicle and electric motor safety engineering trends, EV owners and manufacturers can help to prevent electrical shock and ensure safe operation and maintenance. This is particularly important as the demand for EVs continues to grow, and the need for safe and reliable vehicles becomes increasingly important.

Furthermore, the use of advanced technologies, such as smart charging systems and battery management systems, can also help to mitigate electrical shock risks. These systems can detect electrical faults and automatically shut off power to prevent damage or injury. By incorporating these technologies into EV design, manufacturers can help to ensure safe and reliable operation, and reduce the risk of electrical shock.

The Role of Functional Safety in EV Development

Functional safety is a critical aspect of electric vehicle (EV) development, as it ensures that the vehicle’s systems and components operate safely and reliably. In the context of EVs, functional safety refers to the ability of the vehicle’s electrical and electronic systems to perform their intended functions without posing a risk to occupants or bystanders.

One of the key standards for functional safety in EV development is ISO 26262, which provides a framework for ensuring the safety of electrical and electronic systems in vehicles. This standard requires manufacturers to perform hazard analysis and risk assessment to identify potential safety risks and implement measures to mitigate them.

Hazard analysis and risk assessment are critical components of functional safety in EV development. These processes involve identifying potential hazards and evaluating the likelihood and potential impact of each hazard. By performing hazard analysis and risk assessment, manufacturers can identify potential safety risks and implement measures to mitigate them, such as designing safety-critical systems with redundancy and fail-safe defaults.

Functional safety is also closely tied to the concept of safety integrity levels (SILs), which are used to classify the safety criticality of different systems and components. SILs range from 0 (no safety impact) to 4 (extremely high safety impact), and are used to determine the level of safety required for each system or component.

In the context of electric vehicle and electric motor safety engineering trends, functional safety is becoming increasingly important as the demand for EVs continues to grow. By prioritizing functional safety, manufacturers can ensure that their vehicles operate safely and reliably, reducing the risk of accidents and injuries.

Furthermore, the use of advanced technologies, such as autonomous vehicles and vehicle-to-grid (V2G) technology, is also driving the need for functional safety in EV development. These technologies require sophisticated electrical and electronic systems, which must be designed and tested to ensure safe and reliable operation.

Thermal Management Systems for EV Safety

Thermal management systems play a critical role in maintaining the safety of electric vehicles (EVs). These systems are designed to regulate the temperature of the vehicle’s electrical and electronic components, preventing overheating and electrical fires. In the context of electric vehicle and electric motor safety engineering trends, thermal management systems are becoming increasingly important as the demand for EVs continues to grow.

One of the key components of thermal management systems is cooling systems. These systems use a combination of air and liquid cooling to regulate the temperature of the vehicle’s electrical and electronic components. For example, some EVs use a liquid cooling system to cool the electric motor and battery pack, while others use a combination of air and liquid cooling to regulate the temperature of the vehicle’s electrical and electronic components.

Thermal sensors are also an important component of thermal management systems. These sensors monitor the temperature of the vehicle’s electrical and electronic components, providing real-time data on the temperature of the vehicle’s systems. This data can be used to adjust the cooling system, ensuring that the vehicle’s electrical and electronic components are operating within a safe temperature range.

Advanced materials are also being used to improve the safety and efficiency of thermal management systems. For example, some EVs use advanced materials such as graphite and carbon fiber to improve the thermal conductivity of the vehicle’s electrical and electronic components. These materials can help to reduce the risk of overheating and electrical fires, improving the overall safety of the vehicle.

In addition to cooling systems, thermal sensors, and advanced materials, thermal management systems also rely on sophisticated software and algorithms to regulate the temperature of the vehicle’s electrical and electronic components. These software and algorithms use real-time data from the thermal sensors to adjust the cooling system, ensuring that the vehicle’s electrical and electronic components are operating within a safe temperature range.

By incorporating these advanced technologies and materials, thermal management systems can play a critical role in maintaining the safety of EVs. As the demand for EVs continues to grow, it is likely that we will see even more innovative solutions to the challenges of thermal management, driving the development of safer and more efficient EVs.

Ensuring Safe Charging and Discharging of EV Batteries

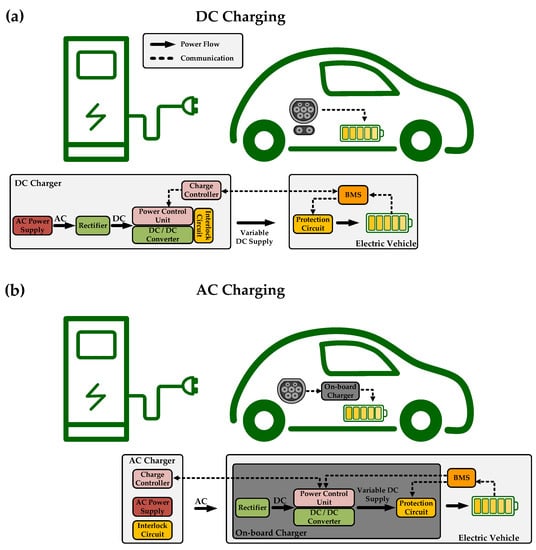

The safe charging and discharging of electric vehicle (EV) batteries is a critical aspect of electric vehicle and electric motor safety engineering trends. As the demand for EVs continues to grow, it is essential to ensure that the charging and discharging processes are safe and efficient. This requires the use of smart charging systems, battery management systems, and protective devices to prevent electrical shock and fires.

Smart charging systems are designed to optimize the charging process, taking into account factors such as the battery’s state of charge, temperature, and charging speed. These systems can help to prevent overcharging, which can lead to electrical fires and other safety hazards. Additionally, smart charging systems can communicate with the grid and other charging infrastructure to ensure that the charging process is safe and efficient.

Battery management systems (BMS) are also critical for ensuring the safe charging and discharging of EV batteries. A BMS monitors the battery’s state of charge, voltage, and temperature, and can detect potential safety hazards such as overcharging or overheating. If a safety hazard is detected, the BMS can take corrective action, such as reducing the charging speed or disconnecting the battery from the charging circuit.

Protective devices, such as fuses and circuit breakers, are also essential for ensuring the safe charging and discharging of EV batteries. These devices can detect electrical faults and disconnect the battery from the charging circuit, preventing electrical shock and fires. Additionally, protective devices can help to prevent overcharging, which can lead to electrical fires and other safety hazards.

In addition to smart charging systems, BMS, and protective devices, it is also essential to follow best practices for charging and discharging EV batteries. This includes using approved charging equipment, following the manufacturer’s instructions, and monitoring the battery’s state of charge and temperature. By following these best practices, EV owners can help to ensure the safe charging and discharging of their batteries, reducing the risk of electrical shock and fires.

As the demand for EVs continues to grow, it is likely that we will see even more innovative solutions to the challenges of safe charging and discharging. For example, the use of advanced materials and technologies, such as graphene and supercapacitors, may help to improve the safety and efficiency of EV batteries. Additionally, the development of vehicle-to-grid (V2G) technology may enable EVs to supply energy back to the grid, reducing the strain on the electrical infrastructure and improving the overall safety and efficiency of the charging and discharging process.

Real-World Examples of Safe EV Design: Lessons from the Tesla Model 3

The Tesla Model 3 is a prime example of a safe electric vehicle (EV) design, incorporating advanced safety features and a robust electrical architecture. One of the key safety features of the Model 3 is its Autopilot system, which uses a combination of sensors and software to enable semi-autonomous driving. This system has been designed with safety in mind, with multiple redundancies and fail-safes to prevent accidents.

In addition to Autopilot, the Model 3 also features a robust electrical architecture, designed to prevent electrical shock and fires. The vehicle’s electrical system is protected by multiple layers of insulation and grounding, and the battery pack is designed to prevent overheating and electrical fires. The Model 3 also features a advanced battery management system, which monitors the battery’s state of charge and temperature, and can detect potential safety hazards.

The Tesla Model 3 is also a great example of how electric vehicle and electric motor safety engineering trends are driving innovation in the industry. The vehicle’s advanced safety features and robust electrical architecture have set a new standard for the industry, and have helped to drive the development of safer and more efficient EVs.

Another important aspect of the Model 3’s safety design is its use of advanced materials and technologies. The vehicle’s body is made from a combination of steel and aluminum, which provides excellent strength and crashworthiness. The Model 3 also features a advanced airbag system, which can detect the severity of a crash and deploy the airbags accordingly.

The Tesla Model 3 is a great example of how safe EV design can be achieved through a combination of advanced safety features, robust electrical architecture, and innovative use of materials and technologies. As the demand for EVs continues to grow, it is likely that we will see even more innovative solutions to the challenges of safe EV design, driving the development of safer and more efficient vehicles.

Furthermore, the Tesla Model 3 is also a great example of how electric vehicle and electric motor safety engineering trends are driving innovation in the industry. The vehicle’s advanced safety features and robust electrical architecture have set a new standard for the industry, and have helped to drive the development of safer and more efficient EVs.

Future Directions in EV Safety Engineering

As the demand for electric vehicles (EVs) continues to grow, it is likely that we will see significant advancements in EV safety engineering. One area that is expected to see significant development is the use of advanced materials, such as graphene and nanomaterials, to improve the safety and efficiency of EV batteries and electrical systems.

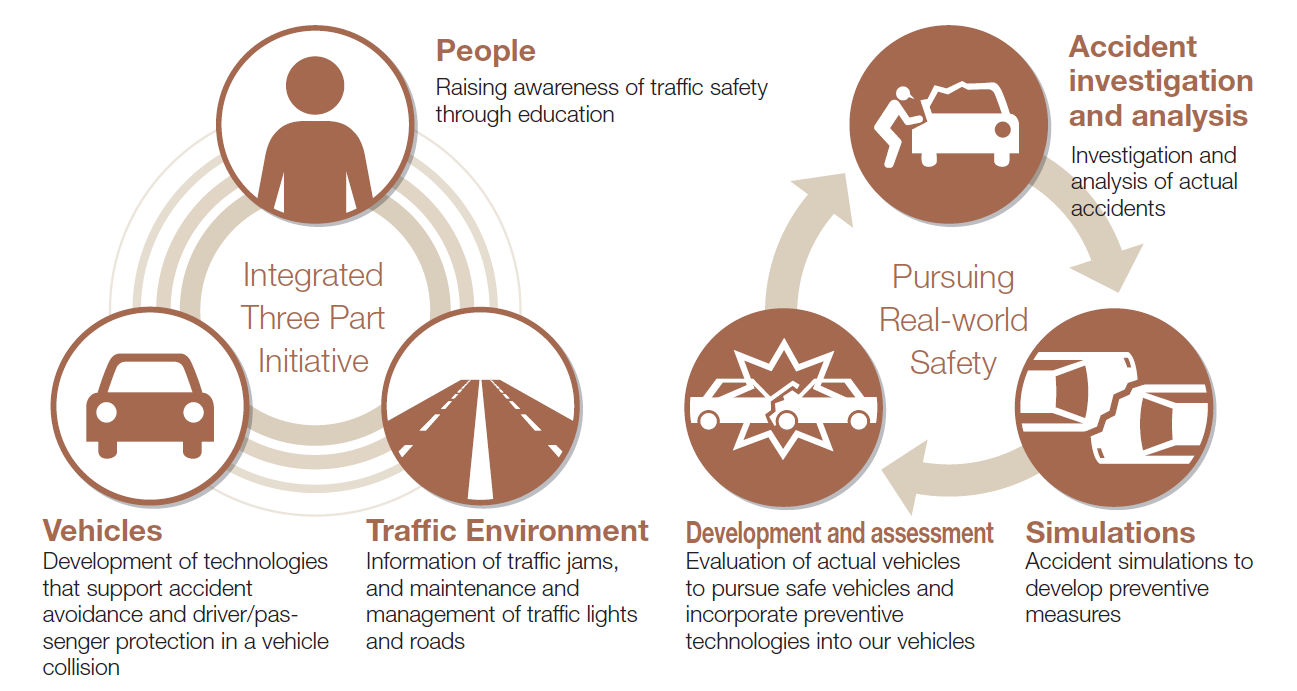

Another area that is expected to see significant development is the use of autonomous vehicles, which are expected to play a major role in improving road safety. Autonomous vehicles use a combination of sensors and software to enable self-driving, and are expected to reduce the risk of accidents caused by human error.

Vehicle-to-grid (V2G) technology is also expected to play a major role in improving EV safety engineering. V2G technology enables EVs to supply energy back to the grid, reducing the strain on the electrical infrastructure and improving the overall safety and efficiency of the charging and discharging process.

In addition to these advancements, it is also likely that we will see significant developments in the use of artificial intelligence (AI) and machine learning (ML) in EV safety engineering. AI and ML can be used to analyze data from EVs and predict potential safety hazards, enabling proactive measures to be taken to prevent accidents.

Furthermore, the use of advanced simulation tools and modeling techniques is also expected to play a major role in improving EV safety engineering. These tools enable engineers to simulate and test different scenarios, reducing the risk of accidents and improving the overall safety and efficiency of EVs.

As the demand for EVs continues to grow, it is likely that we will see even more innovative solutions to the challenges of EV safety engineering. By incorporating advanced materials, autonomous vehicles, V2G technology, AI, ML, and advanced simulation tools, engineers can create safer and more efficient EVs that meet the needs of a rapidly changing transportation landscape.

In the context of electric vehicle and electric motor safety engineering trends, it is clear that the future of EV safety engineering is bright. With the continued development of advanced technologies and innovative solutions, it is likely that we will see significant improvements in EV safety and efficiency, enabling widespread adoption and reducing the environmental impact of transportation.