Understanding the Importance of Electric Vehicle Safety Standards

The electric vehicle (EV) industry has experienced rapid growth in recent years, with many countries investing heavily in EV infrastructure and incentivizing the adoption of electric vehicles. However, as the number of EVs on the road increases, so does the concern for safety. Electric vehicle and electric motor safety standards trends are becoming increasingly important to ensure the protection of drivers, passengers, and pedestrians. The need for standardized safety protocols is crucial to prevent accidents and ensure the safe operation of EVs.

According to the National Highway Traffic Safety Administration (NHTSA), EVs are subject to the same safety standards as conventional vehicles. However, the unique characteristics of EVs, such as their electric motors and battery systems, require specialized safety standards. The absence of standardized safety protocols can lead to a lack of public trust in EVs, hindering their adoption and the overall growth of the industry.

Electric vehicle and electric motor safety standards trends are evolving to address the unique safety concerns associated with EVs. For instance, the Society of Automotive Engineers (SAE) has developed standards for EV safety, including guidelines for the design and testing of EV batteries and electric motors. Similarly, the International Electrotechnical Commission (IEC) has established standards for the safety of EVs, including requirements for electrical safety and electromagnetic compatibility.

The importance of electric vehicle and electric motor safety standards trends cannot be overstated. As the EV industry continues to grow, it is essential to prioritize safety to ensure public trust and confidence in EVs. By establishing and enforcing standardized safety protocols, the industry can minimize the risk of accidents and ensure the safe operation of EVs.

In conclusion, electric vehicle and electric motor safety standards trends are critical to ensuring the safety of drivers, passengers, and pedestrians. The industry must prioritize safety and establish standardized safety protocols to prevent accidents and ensure public trust in EVs.

How to Identify Safe Electric Vehicles: A Guide to Certification and Compliance

As the electric vehicle (EV) industry continues to grow, it’s essential to ensure that these vehicles meet rigorous safety standards. One way to verify the safety of an EV is to look for certifications from reputable organizations. In this article, we’ll explore the certification process for EVs and provide a guide on how to identify safe electric vehicles.

The certification process for EVs involves a series of tests and evaluations to ensure that the vehicle meets specific safety standards. Regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) and industry organizations like the Society of Automotive Engineers (SAE) play a crucial role in developing and enforcing these standards.

One of the most recognized certifications for EVs is the UL (Underwriters Laboratories) certification. UL is a non-profit organization that tests and certifies products for safety. To obtain UL certification, EV manufacturers must submit their vehicles for testing and evaluation. The testing process includes a series of rigorous tests, including electrical safety, fire resistance, and crashworthiness.

Another important certification for EVs is the ECE (Economic Commission for Europe) R100 certification. This certification is specific to EVs and covers a range of safety aspects, including electrical safety, thermal management, and battery safety. To obtain ECE R100 certification, EV manufacturers must meet specific requirements and undergo testing and evaluation.

In addition to these certifications, EV manufacturers must also comply with national and international safety standards. For example, the National Electric Code (NEC) provides guidelines for the safe installation and maintenance of EV charging systems. Similarly, the International Electrotechnical Commission (IEC) provides standards for the safety of EVs, including requirements for electrical safety and electromagnetic compatibility.

When purchasing an EV, it’s essential to look for these certifications and ensure that the vehicle meets the required safety standards. By doing so, you can have confidence in the safety of your vehicle and enjoy a safe and reliable driving experience.

The Evolution of Electric Motor Safety Standards: A Look at Recent Developments

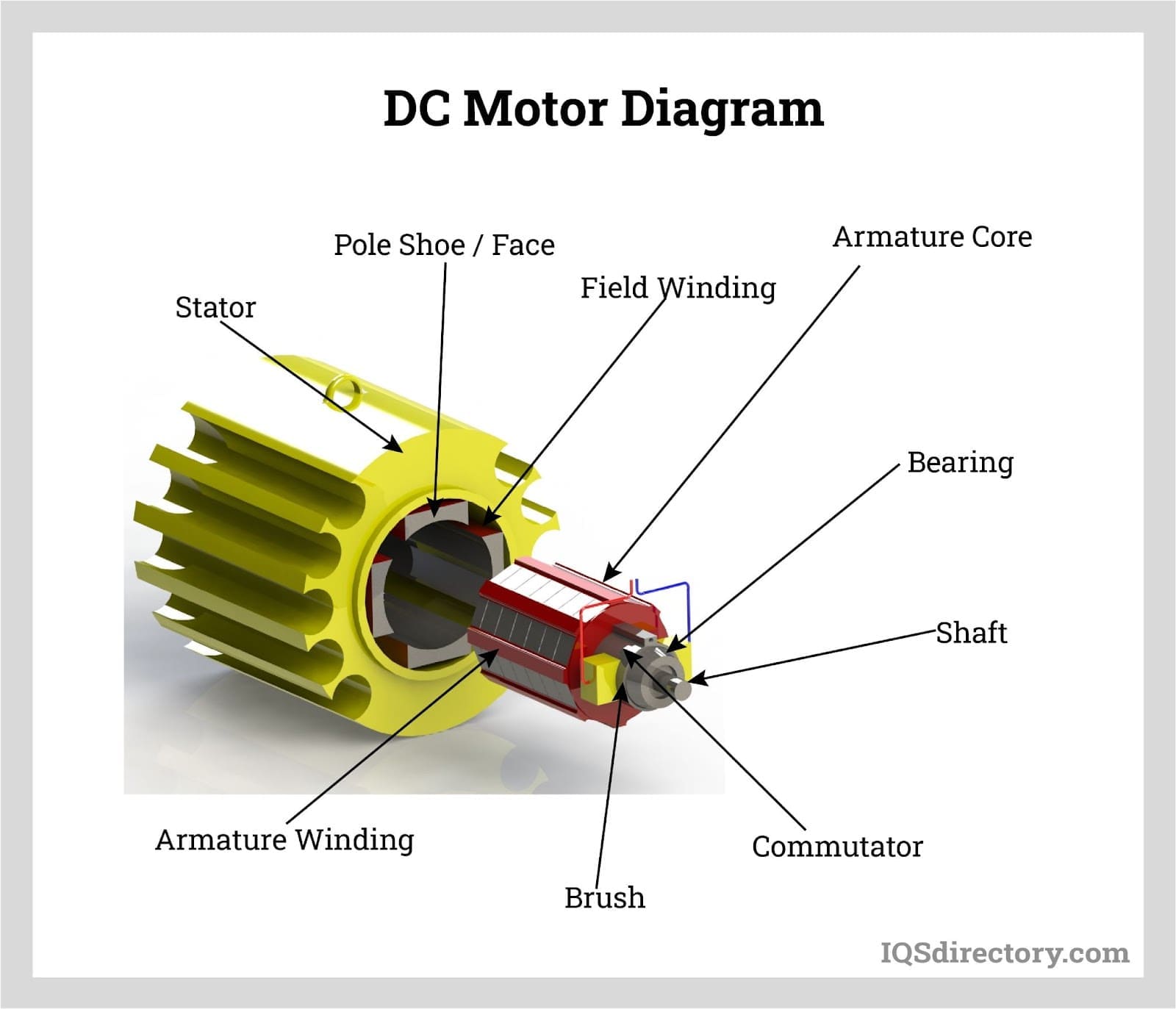

The electric vehicle (EV) industry is rapidly evolving, with advancements in technology and innovations in design. As the industry continues to grow, the need for standardized safety protocols has become increasingly important. One area that has seen significant updates in recent years is electric motor safety standards. In this article, we’ll explore the recent developments in electric motor safety standards and how they impact the design and manufacturing of electric motors.

The National Electric Code (NEC) is a widely recognized standard for electrical safety in the United States. In recent years, the NEC has undergone significant updates to address the unique safety concerns associated with electric motors. For example, the 2020 edition of the NEC includes new requirements for the safe installation and maintenance of electric motors, including guidelines for thermal management and electrical safety.

The International Electrotechnical Commission (IEC) is another organization that plays a critical role in developing safety standards for electric motors. The IEC has established a range of standards for electric motor safety, including requirements for electrical safety, thermal management, and electromagnetic compatibility. In recent years, the IEC has updated its standards to address emerging trends and technologies in the EV industry, such as the use of high-power electric motors and advanced battery systems.

One of the key updates to electric motor safety standards is the increased focus on thermal management. Electric motors can generate significant heat during operation, which can lead to reduced efficiency and increased risk of overheating. To address this concern, the NEC and IEC have established guidelines for thermal management, including requirements for cooling systems and thermal monitoring.

Another important update to electric motor safety standards is the increased focus on electrical safety. Electric motors can pose a risk of electrical shock if not properly designed and manufactured. To address this concern, the NEC and IEC have established guidelines for electrical safety, including requirements for insulation, grounding, and bonding.

The updates to electric motor safety standards have significant implications for the design and manufacturing of electric motors. Manufacturers must ensure that their products meet the latest safety standards, which can require significant investments in research and development. However, the benefits of standardized safety protocols far outweigh the costs, as they help to ensure the safety of drivers, passengers, and pedestrians.

Thermal Management: A Critical Aspect of Electric Motor Safety

Thermal management is a critical aspect of electric motor safety, as it plays a crucial role in preventing overheating and ensuring the efficient operation of electric motors. Electric motors can generate significant heat during operation, which can lead to reduced efficiency, increased risk of overheating, and even electrical fires. In this article, we’ll explore the importance of thermal management in electric motors and discuss how advancements in thermal management are improving electric motor safety and efficiency.

One of the main risks associated with electric motors is overheating. When an electric motor overheats, it can lead to a range of problems, including reduced efficiency, increased risk of electrical fires, and even motor failure. To prevent overheating, electric motor manufacturers use a range of thermal management techniques, including cooling systems, thermal monitoring, and insulation.

Cooling systems are a critical component of thermal management in electric motors. These systems help to dissipate heat generated by the motor, ensuring that it operates within a safe temperature range. There are several types of cooling systems used in electric motors, including air-cooled, liquid-cooled, and hybrid cooling systems. Each type of cooling system has its own advantages and disadvantages, and the choice of cooling system will depend on the specific application and requirements of the motor.

Thermal monitoring is another important aspect of thermal management in electric motors. This involves monitoring the temperature of the motor in real-time, using sensors and other technologies to detect any changes in temperature. By monitoring the temperature of the motor, manufacturers can identify potential problems before they occur, ensuring that the motor operates safely and efficiently.

Advances in thermal management are also improving electric motor safety and efficiency. For example, the development of new materials and technologies, such as advanced insulation materials and thermal interface materials, is helping to improve the thermal performance of electric motors. Additionally, the use of advanced cooling systems, such as liquid-cooled and hybrid cooling systems, is helping to reduce the risk of overheating and improve the overall efficiency of electric motors.

In the context of electric vehicle and electric motor safety standards trends, thermal management is an important consideration. As the demand for electric vehicles continues to grow, the need for safe and efficient electric motors is becoming increasingly important. By prioritizing thermal management, manufacturers can help to ensure that their electric

Thermal Management: A Critical Aspect of Electric Motor Safety

Thermal management is a critical aspect of electric motor safety, as it plays a crucial role in preventing overheating and ensuring the efficient operation of electric motors. Electric motors can generate significant heat during operation, which can lead to reduced efficiency, increased risk of overheating, and even electrical fires. In this article, we’ll explore the importance of thermal management in electric motors and discuss how advancements in thermal management are improving electric motor safety and efficiency.

One of the main risks associated with electric motors is overheating. When an electric motor overheats, it can lead to a range of problems, including reduced efficiency, increased risk of electrical fires, and even motor failure. To prevent overheating, electric motor manufacturers use a range of thermal management techniques, including cooling systems, thermal monitoring, and insulation.

Cooling systems are a critical component of thermal management in electric motors. These systems help to dissipate heat generated by the motor, ensuring that it operates within a safe temperature range. There are several types of cooling systems used in electric motors, including air-cooled, liquid-cooled, and hybrid cooling systems. Each type of cooling system has its own advantages and disadvantages, and the choice of cooling system will depend on the specific application and requirements of the motor.

Thermal monitoring is another important aspect of thermal management in electric motors. This involves monitoring the temperature of the motor in real-time, using sensors and other technologies to detect any changes in temperature. By monitoring the temperature of the motor, manufacturers can identify potential problems before they occur, ensuring that the motor operates safely and efficiently.

Advances in thermal management are also improving electric motor safety and efficiency. For example, the development of new materials and technologies, such as advanced insulation materials and thermal interface materials, is helping to improve the thermal performance of electric motors. Additionally, the use of advanced cooling systems, such as liquid-cooled and hybrid cooling systems, is helping to reduce the risk of overheating and improve the overall efficiency of electric motors.

In the context of electric vehicle and electric motor safety standards trends, thermal management is an important consideration. As the demand for electric vehicles continues to grow, the need for safe and efficient electric motors is becoming increasingly important. By prioritizing thermal management, manufacturers can help to ensure that their electric

Thermal Management: A Critical Aspect of Electric Motor Safety

Thermal management is a critical aspect of electric motor safety, as it plays a crucial role in preventing overheating and ensuring the efficient operation of electric motors. Electric motors can generate significant heat during operation, which can lead to reduced efficiency, increased risk of overheating, and even electrical fires. In this article, we’ll explore the importance of thermal management in electric motors and discuss how advancements in thermal management are improving electric motor safety and efficiency.

One of the main risks associated with electric motors is overheating. When an electric motor overheats, it can lead to a range of problems, including reduced efficiency, increased risk of electrical fires, and even motor failure. To prevent overheating, electric motor manufacturers use a range of thermal management techniques, including cooling systems, thermal monitoring, and insulation.

Cooling systems are a critical component of thermal management in electric motors. These systems help to dissipate heat generated by the motor, ensuring that it operates within a safe temperature range. There are several types of cooling systems used in electric motors, including air-cooled, liquid-cooled, and hybrid cooling systems. Each type of cooling system has its own advantages and disadvantages, and the choice of cooling system will depend on the specific application and requirements of the motor.

Thermal monitoring is another important aspect of thermal management in electric motors. This involves monitoring the temperature of the motor in real-time, using sensors and other technologies to detect any changes in temperature. By monitoring the temperature of the motor, manufacturers can identify potential problems before they occur, ensuring that the motor operates safely and efficiently.

Advances in thermal management are also improving electric motor safety and efficiency. For example, the development of new materials and technologies, such as advanced insulation materials and thermal interface materials, is helping to improve the thermal performance of electric motors. Additionally, the use of advanced cooling systems, such as liquid-cooled and hybrid cooling systems, is helping to reduce the risk of overheating and improve the overall efficiency of electric motors.

In the context of electric vehicle and electric motor safety standards trends, thermal management is an important consideration. As the demand for electric vehicles continues to grow, the need for safe and efficient electric motors is becoming increasingly important. By prioritizing thermal management, manufacturers can help to ensure that their electric

Thermal Management: A Critical Aspect of Electric Motor Safety

Thermal management is a critical aspect of electric motor safety, as it plays a crucial role in preventing overheating and ensuring the efficient operation of electric motors. Electric motors can generate significant heat during operation, which can lead to reduced efficiency, increased risk of overheating, and even electrical fires. In this article, we’ll explore the importance of thermal management in electric motors and discuss how advancements in thermal management are improving electric motor safety and efficiency.

One of the main risks associated with electric motors is overheating. When an electric motor overheats, it can lead to a range of problems, including reduced efficiency, increased risk of electrical fires, and even motor failure. To prevent overheating, electric motor manufacturers use a range of thermal management techniques, including cooling systems, thermal monitoring, and insulation.

Cooling systems are a critical component of thermal management in electric motors. These systems help to dissipate heat generated by the motor, ensuring that it operates within a safe temperature range. There are several types of cooling systems used in electric motors, including air-cooled, liquid-cooled, and hybrid cooling systems. Each type of cooling system has its own advantages and disadvantages, and the choice of cooling system will depend on the specific application and requirements of the motor.

Thermal monitoring is another important aspect of thermal management in electric motors. This involves monitoring the temperature of the motor in real-time, using sensors and other technologies to detect any changes in temperature. By monitoring the temperature of the motor, manufacturers can identify potential problems before they occur, ensuring that the motor operates safely and efficiently.

Advances in thermal management are also improving electric motor safety and efficiency. For example, the development of new materials and technologies, such as advanced insulation materials and thermal interface materials, is helping to improve the thermal performance of electric motors. Additionally, the use of advanced cooling systems, such as liquid-cooled and hybrid cooling systems, is helping to reduce the risk of overheating and improve the overall efficiency of electric motors.

In the context of electric vehicle and electric motor safety standards trends, thermal management is an important consideration. As the demand for electric vehicles continues to grow, the need for safe and efficient electric motors is becoming increasingly important. By prioritizing thermal management, manufacturers can help to ensure that their electric

Thermal Management: A Critical Aspect of Electric Motor Safety

Thermal management is a critical aspect of electric motor safety, as it plays a crucial role in preventing overheating and ensuring the efficient operation of electric motors. Electric motors can generate significant heat during operation, which can lead to reduced efficiency, increased risk of overheating, and even electrical fires. In this article, we’ll explore the importance of thermal management in electric motors and discuss how advancements in thermal management are improving electric motor safety and efficiency.

One of the main risks associated with electric motors is overheating. When an electric motor overheats, it can lead to a range of problems, including reduced efficiency, increased risk of electrical fires, and even motor failure. To prevent overheating, electric motor manufacturers use a range of thermal management techniques, including cooling systems, thermal monitoring, and insulation.

Cooling systems are a critical component of thermal management in electric motors. These systems help to dissipate heat generated by the motor, ensuring that it operates within a safe temperature range. There are several types of cooling systems used in electric motors, including air-cooled, liquid-cooled, and hybrid cooling systems. Each type of cooling system has its own advantages and disadvantages, and the choice of cooling system will depend on the specific application and requirements of the motor.

Thermal monitoring is another important aspect of thermal management in electric motors. This involves monitoring the temperature of the motor in real-time, using sensors and other technologies to detect any changes in temperature. By monitoring the temperature of the motor, manufacturers can identify potential problems before they occur, ensuring that the motor operates safely and efficiently.

Advances in thermal management are also improving electric motor safety and efficiency. For example, the development of new materials and technologies, such as advanced insulation materials and thermal interface materials, is helping to improve the thermal performance of electric motors. Additionally, the use of advanced cooling systems, such as liquid-cooled and hybrid cooling systems, is helping to reduce the risk of overheating and improve the overall efficiency of electric motors.

In the context of electric vehicle and electric motor safety standards trends, thermal management is an important consideration. As the demand for electric vehicles continues to grow, the need for safe and efficient electric motors is becoming increasingly important. By prioritizing thermal management, manufacturers can help to ensure that their electric