Streamlining the Electric Motor Supply Chain: Challenges and Opportunities

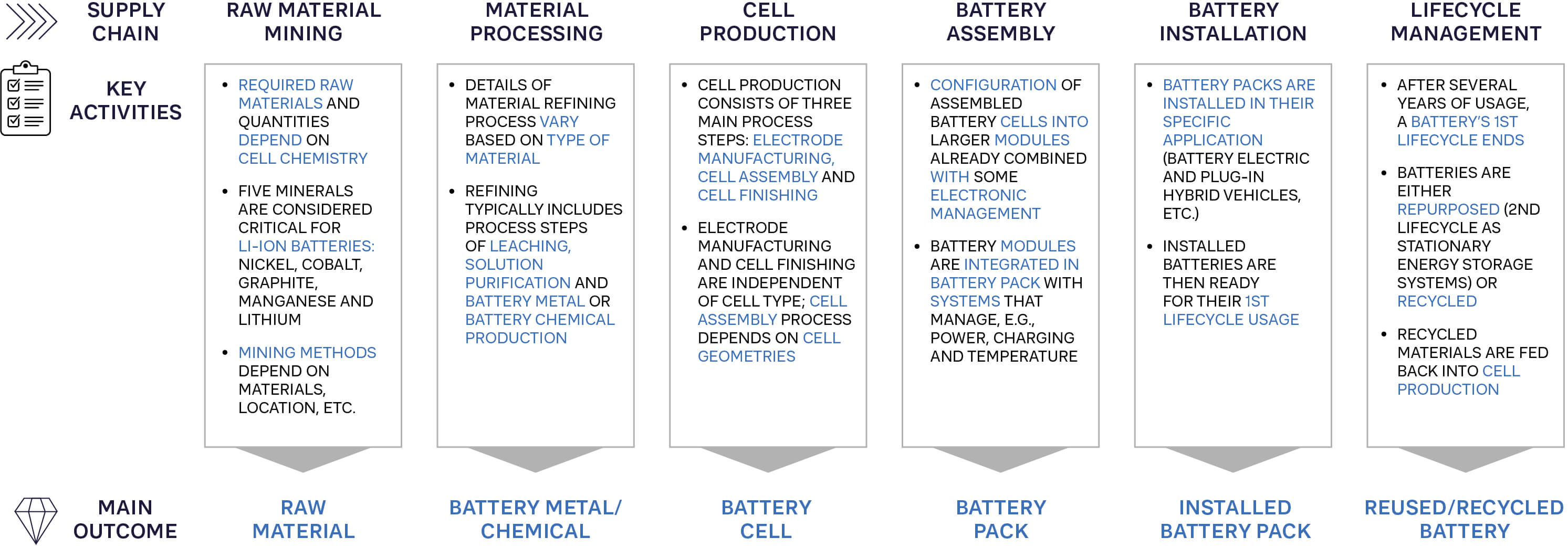

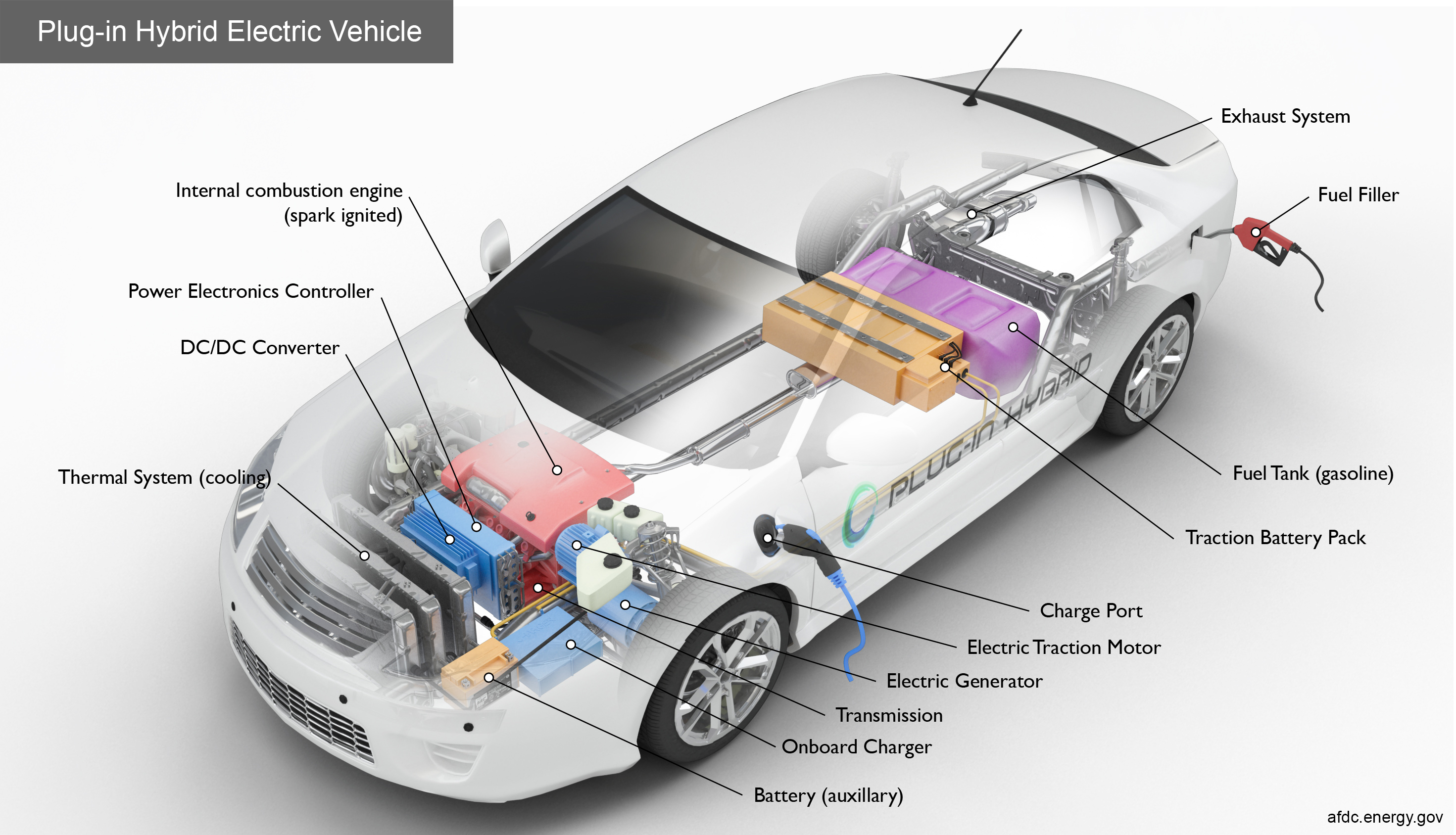

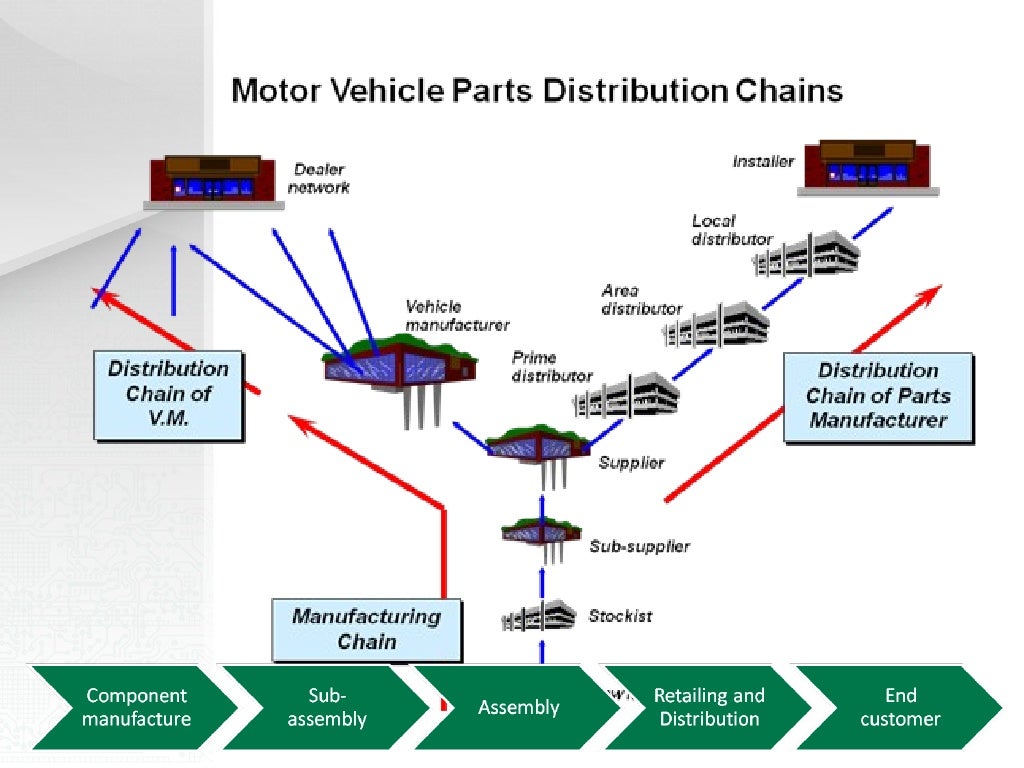

The growing demand for electric vehicles (EVs) has put immense pressure on electric motor supply chains. As the world shifts towards sustainable transportation, manufacturers are facing numerous challenges in meeting the increasing demand for EVs. One of the critical components of EVs is the electric motor, which requires a complex supply chain to produce. The electric motor supply chain involves multiple stakeholders, including component suppliers, manufacturers, and logistics providers.

Component sourcing is one of the significant challenges faced by manufacturers. The electric motor requires a range of components, including rare earth metals, copper, and steel. Sourcing these components from reliable suppliers is crucial to ensure the quality and reliability of the electric motor. However, the global nature of the supply chain makes it challenging to manage and monitor the sourcing process.

Logistics and transportation are another critical aspect of the electric motor supply chain. The components and finished motors need to be transported from suppliers to manufacturers and then to assembly plants. This requires a robust logistics network that can handle the complex transportation requirements. However, the increasing demand for EVs has put pressure on logistics providers, leading to delays and increased costs.

Quality control is also a significant challenge in the electric motor supply chain. The electric motor is a critical component of the EV, and any defects or quality issues can affect the overall performance and safety of the vehicle. Manufacturers need to implement robust quality control measures to ensure that the electric motors meet the required standards. However, this requires significant investment in testing and inspection equipment, as well as training for quality control personnel.

Despite these challenges, there are opportunities for manufacturers to optimize their electric motor supply chain management. By implementing robust supply chain management systems, manufacturers can improve the efficiency and reliability of their supply chain. This can be achieved through the use of technology, such as blockchain and IoT, which can provide real-time tracking and monitoring of the supply chain.

In addition, manufacturers can benefit from collaborating with suppliers and logistics providers to improve the overall efficiency of the supply chain. This can be achieved through the implementation of just-in-time (JIT) production systems, which can reduce inventory levels and improve the responsiveness of the supply chain.

By addressing the challenges and opportunities in the electric motor supply chain, manufacturers can improve the efficiency and reliability of their supply chain management. This can help to reduce costs, improve quality, and increase the overall competitiveness of the business. As the demand for EVs continues to grow, manufacturers that can optimize their electric motor supply chain management will be well-positioned to take advantage of the opportunities in this rapidly growing market.

How to Implement a Robust Electric Motor Supply Chain Management System

Implementing a robust electric motor supply chain management system is crucial for manufacturers to ensure efficient and reliable production of electric vehicles. A well-designed system can help manufacturers to streamline their supply chain, reduce costs, and improve quality. Here is a step-by-step guide on implementing a robust electric motor supply chain management system:

Step 1: Supplier Selection

Selecting the right suppliers is critical for ensuring the quality and reliability of the electric motor. Manufacturers should evaluate potential suppliers based on their reputation, quality of products, and ability to meet demand. It is also essential to assess the suppliers’ ability to provide just-in-time (JIT) delivery, as this can help to reduce inventory levels and improve responsiveness.

Step 2: Inventory Management

Effective inventory management is vital for ensuring that the right components are available at the right time. Manufacturers should implement an inventory management system that can track inventory levels in real-time, provide alerts for low stock levels, and automate ordering processes. This can help to reduce inventory costs, minimize stockouts, and improve overall efficiency.

Step 3: Demand Forecasting

Demand forecasting is critical for ensuring that manufacturers can meet changing demand patterns. Manufacturers should use historical data, market trends, and seasonal fluctuations to forecast demand. This can help to ensure that the right components are available at the right time, reducing the risk of stockouts and overstocking.

Step 4: Supply Chain Visibility

Supply chain visibility is essential for ensuring that manufacturers can track components in real-time. Manufacturers should implement a supply chain visibility system that can provide real-time tracking, monitoring, and alerts. This can help to improve responsiveness, reduce lead times, and improve overall efficiency.

Step 5: Continuous Improvement

Continuous improvement is critical for ensuring that the electric motor supply chain management system remains effective and efficient. Manufacturers should regularly review their system, identify areas for improvement, and implement changes as needed. This can help to ensure that the system remains aligned with changing business needs and market trends.

By following these steps, manufacturers can implement a robust electric motor supply chain management system that can help to improve efficiency, reduce costs, and improve quality. This can help to ensure that electric vehicles are produced efficiently and reliably, meeting the growing demand for sustainable transportation.

In the context of electric vehicle and electric motor supply chain management, a robust system can help to ensure that manufacturers can meet the growing demand for electric vehicles while minimizing costs and improving quality. By implementing a robust system, manufacturers can improve their competitiveness, reduce their environmental impact, and contribute to a more sustainable future.

The Role of Technology in Electric Motor Supply Chain Optimization

Technology plays a vital role in optimizing electric motor supply chain management. The use of advanced technologies such as blockchain, IoT, and AI can help to improve transparency, efficiency, and responsiveness in the supply chain. In the context of electric vehicle and electric motor supply chain management, technology can help to streamline processes, reduce costs, and improve quality.

Blockchain technology, for example, can be used to create a transparent and tamper-proof record of transactions and data exchanges between suppliers, manufacturers, and logistics providers. This can help to improve trust and collaboration in the supply chain, reduce the risk of counterfeiting and errors, and improve overall efficiency.

IoT technology can be used to track and monitor components and finished goods in real-time, providing manufacturers with real-time visibility into their supply chain. This can help to improve responsiveness, reduce lead times, and improve overall efficiency. IoT sensors can also be used to monitor the condition of components and finished goods, helping to improve quality and reduce waste.

AI technology can be used to analyze data and predict demand patterns, helping manufacturers to optimize their production and inventory management. AI can also be used to identify potential risks and disruptions in the supply chain, allowing manufacturers to take proactive steps to mitigate these risks.

The use of advanced technologies such as blockchain, IoT, and AI can help to optimize electric motor supply chain management, improving transparency, efficiency, and responsiveness. By leveraging these technologies, manufacturers can improve their competitiveness, reduce their environmental impact, and contribute to a more sustainable future.

In addition to these technologies, other innovations such as 3D printing and autonomous vehicles are also expected to have a significant impact on electric motor supply chain management. 3D printing, for example, can be used to produce complex components and finished goods on demand, reducing lead times and improving responsiveness. Autonomous vehicles can be used to transport components and finished goods, improving efficiency and reducing costs.

Overall, the use of technology is critical to optimizing electric motor supply chain management. By leveraging advanced technologies such as blockchain, IoT, and AI, manufacturers can improve transparency, efficiency, and responsiveness in their supply chain, reducing costs and improving quality.

In the context of electric vehicle and electric motor supply chain management, technology can help to streamline processes, reduce costs, and improve quality. By embracing these technologies, manufacturers can improve their competitiveness, reduce their environmental impact, and contribute to a more sustainable future.

Case Study: Tesla’s Electric Motor Supply Chain Strategy

Tesla, a leading electric vehicle manufacturer, has implemented a unique approach to electric motor supply chain management. Tesla’s strategy is centered around vertical integration, where the company controls and manages a significant portion of its supply chain. This approach has allowed Tesla to improve efficiency, reduce costs, and increase quality in its electric motor production.

Tesla’s vertical integration strategy involves the company owning and operating several key components of its supply chain, including its battery production facility, motor manufacturing plant, and assembly lines. This approach allows Tesla to have greater control over the quality and reliability of its components, as well as the ability to respond quickly to changes in demand.

In addition to vertical integration, Tesla has also established partnerships with key suppliers to ensure a stable and reliable supply of critical components. These partnerships allow Tesla to work closely with its suppliers to develop and implement new technologies, improve quality, and reduce costs.

One of the benefits of Tesla’s approach to electric motor supply chain management is its ability to improve efficiency and reduce costs. By controlling and managing a significant portion of its supply chain, Tesla is able to reduce its reliance on third-party suppliers and minimize the risk of disruptions and delays.

Another benefit of Tesla’s approach is its ability to improve quality and reliability. By owning and operating its own manufacturing facilities, Tesla is able to ensure that its components meet the highest standards of quality and reliability. This approach has allowed Tesla to establish a reputation for producing high-quality electric vehicles that are reliable and efficient.

However, Tesla’s approach to electric motor supply chain management also has its challenges. One of the challenges is the high upfront cost of establishing and maintaining a vertically integrated supply chain. This approach requires significant investment in manufacturing facilities, equipment, and personnel, which can be a barrier to entry for smaller companies.

Another challenge is the risk of supply chain disruptions and delays. While Tesla’s approach to electric motor supply chain management allows the company to have greater control over its supply chain, it also increases the risk of disruptions and delays if something goes wrong. This risk can be mitigated through the implementation of contingency plans and risk management strategies.

Overall, Tesla’s approach to electric motor supply chain management is a unique and innovative approach that has allowed the company to improve efficiency, reduce costs, and increase quality in its electric motor production. While there are challenges associated with this approach, the benefits of improved efficiency, reduced costs, and increased quality make it a viable strategy for electric vehicle manufacturers.

Managing Risk in the Electric Motor Supply Chain

Risk management is a critical aspect of electric motor supply chain management. The electric motor supply chain is vulnerable to various risks, including component shortages, supplier insolvency, and natural disasters. These risks can have a significant impact on the production and delivery of electric vehicles, leading to delays, cost overruns, and reputational damage.

Component shortages are a common risk in the electric motor supply chain. The demand for electric vehicles is increasing rapidly, leading to a surge in demand for electric motor components. However, the supply of these components is often limited, leading to shortages and delays. To mitigate this risk, manufacturers can diversify their supplier base, implement just-in-time inventory management, and invest in component manufacturing.

Supplier insolvency is another risk that can have a significant impact on the electric motor supply chain. Suppliers may experience financial difficulties, leading to insolvency and disruption to the supply chain. To mitigate this risk, manufacturers can conduct regular supplier assessments, implement contingency plans, and diversify their supplier base.

Natural disasters are also a risk that can impact the electric motor supply chain. Natural disasters such as earthquakes, hurricanes, and floods can damage manufacturing facilities, disrupt logistics, and impact component supply. To mitigate this risk, manufacturers can implement business continuity plans, invest in disaster recovery systems, and diversify their supplier base.

To manage these risks, manufacturers can implement various strategies, including:

Diversifying suppliers: By diversifying their supplier base, manufacturers can reduce their dependence on a single supplier and mitigate the risk of supplier insolvency.

Implementing contingency plans: Manufacturers can implement contingency plans to mitigate the impact of natural disasters and component shortages.

Investing in component manufacturing: Manufacturers can invest in component manufacturing to reduce their dependence on external suppliers and mitigate the risk of component shortages.

Conducting regular supplier assessments: Manufacturers can conduct regular supplier assessments to identify potential risks and implement mitigation strategies.

Implementing just-in-time inventory management: Manufacturers can implement just-in-time inventory management to reduce inventory levels and mitigate the risk of component shortages.

By implementing these strategies, manufacturers can manage the risks associated with the electric motor supply chain and ensure the efficient production and delivery of electric vehicles.

Sustainable Electric Motor Supply Chain Management: Best Practices

Sustainability is a critical aspect of electric motor supply chain management. As the demand for electric vehicles continues to grow, manufacturers must prioritize sustainability to reduce their environmental impact and improve their social responsibility. In this article, we will explore the importance of sustainability in electric motor supply chain management and provide best practices for implementing sustainable supply chain management.

Reducing carbon emissions is a key aspect of sustainable electric motor supply chain management. Manufacturers can reduce their carbon footprint by implementing energy-efficient manufacturing processes, using renewable energy sources, and reducing waste. Additionally, manufacturers can work with suppliers to reduce their carbon emissions and implement sustainable practices throughout the supply chain.

Waste reduction is another important aspect of sustainable electric motor supply chain management. Manufacturers can reduce waste by implementing recycling programs, reducing packaging, and using sustainable materials. Additionally, manufacturers can work with suppliers to reduce waste and implement sustainable practices throughout the supply chain.

Responsible sourcing is also a critical aspect of sustainable electric motor supply chain management. Manufacturers must ensure that their suppliers are operating in a responsible and sustainable manner. This includes ensuring that suppliers are complying with labor laws, environmental regulations, and human rights standards.

Best practices for implementing sustainable electric motor supply chain management include:

Conducting regular sustainability assessments: Manufacturers should conduct regular sustainability assessments to identify areas for improvement and implement sustainable practices throughout the supply chain.

Implementing sustainable manufacturing processes: Manufacturers should implement energy-efficient manufacturing processes, use renewable energy sources, and reduce waste to reduce their environmental impact.

Working with sustainable suppliers: Manufacturers should work with suppliers who are operating in a responsible and sustainable manner to ensure that the entire supply chain is sustainable.

Reducing packaging: Manufacturers should reduce packaging to minimize waste and reduce their environmental impact.

Implementing recycling programs: Manufacturers should implement recycling programs to reduce waste and promote sustainability throughout the supply chain.

By implementing these best practices, manufacturers can ensure that their electric motor supply chain is sustainable and responsible. This will not only reduce their environmental impact but also improve their social responsibility and contribute to a more sustainable future.

Collaboration and Communication in Electric Motor Supply Chain Management

Collaboration and communication are critical components of electric motor supply chain management. Effective collaboration and communication between suppliers, manufacturers, and logistics providers can help to improve efficiency, reduce costs, and increase quality in the supply chain.

One of the key benefits of collaboration and communication in electric motor supply chain management is improved visibility and transparency. By sharing data and information in real-time, suppliers, manufacturers, and logistics providers can gain a better understanding of the supply chain and make more informed decisions.

Another benefit of collaboration and communication is improved responsiveness. By working together, suppliers, manufacturers, and logistics providers can respond more quickly to changes in demand, supply chain disruptions, and other issues that may arise.

Strategies for improving collaboration and communication in electric motor supply chain management include:

Implementing a collaborative planning, forecasting, and replenishment (CPFR) system: This system allows suppliers, manufacturers, and logistics providers to share data and information in real-time, improving visibility and transparency in the supply chain.

Using cloud-based communication platforms: Cloud-based communication platforms can help to facilitate communication and collaboration between suppliers, manufacturers, and logistics providers, improving responsiveness and reducing errors.

Conducting regular meetings and updates: Regular meetings and updates can help to ensure that all parties are informed and aligned, improving collaboration and communication in the supply chain.

Providing training and education: Providing training and education to suppliers, manufacturers, and logistics providers can help to improve their understanding of the supply chain and their roles within it, improving collaboration and communication.

By implementing these strategies, suppliers, manufacturers, and logistics providers can improve collaboration and communication in the electric motor supply chain, leading to improved efficiency, reduced costs, and increased quality.

In the context of electric vehicle and electric motor supply chain management, collaboration and communication are critical for ensuring that the supply chain is efficient, responsive, and sustainable. By working together, suppliers, manufacturers, and logistics providers can help to drive the growth of the electric vehicle market and reduce the environmental impact of the supply chain.

Future-Proofing Electric Motor Supply Chain Management: Trends and Innovations

The electric vehicle (EV) industry is rapidly evolving, and electric motor supply chain management must adapt to stay ahead. Emerging trends and innovations are transforming the way electric motors are designed, manufactured, and distributed. In this article, we will explore the future of electric motor supply chain management and the implications of these trends for the industry.

One of the most significant trends shaping the future of electric motor supply chain management is the adoption of 3D printing. This technology enables the rapid production of complex components, reducing lead times and increasing flexibility. Electric motor manufacturers can use 3D printing to produce customized components, such as motor housings and windings, on demand. This approach can help reduce inventory levels, minimize waste, and improve product quality.

Another trend that is gaining traction is the use of autonomous vehicles in logistics and transportation. Autonomous vehicles can optimize routes, reduce fuel consumption, and improve delivery times. Electric motor manufacturers can leverage autonomous vehicles to streamline their supply chains, reducing costs and improving efficiency. For example, autonomous trucks can be used to transport components and finished goods, reducing the need for human drivers and minimizing the risk of accidents.

Advanced materials are also playing a crucial role in shaping the future of electric motor supply chain management. New materials, such as graphene and nanomaterials, are being developed to improve the performance and efficiency of electric motors. These materials can help reduce weight, increase power density, and improve thermal management. Electric motor manufacturers can work with suppliers to develop new materials and components that meet the evolving needs of the EV industry.

The Internet of Things (IoT) is another trend that is transforming electric motor supply chain management. IoT sensors and devices can be used to track components, monitor inventory levels, and optimize production processes. Electric motor manufacturers can use IoT data to predict maintenance needs, reduce downtime, and improve overall equipment effectiveness.

Finally, the use of artificial intelligence (AI) and machine learning (ML) is becoming increasingly important in electric motor supply chain management. AI and ML algorithms can be used to analyze data, predict demand, and optimize production processes. Electric motor manufacturers can use AI and ML to improve forecasting accuracy, reduce inventory levels, and minimize waste.

In conclusion, the future of electric motor supply chain management is being shaped by emerging trends and innovations. Electric motor manufacturers must adapt to these changes to remain competitive and meet the evolving needs of the EV industry. By embracing 3D printing, autonomous vehicles, advanced materials, IoT, AI, and ML, electric motor manufacturers can future-proof their supply chains and drive growth in the EV market.