Understanding the Importance of Electric Motor Supportability Standards

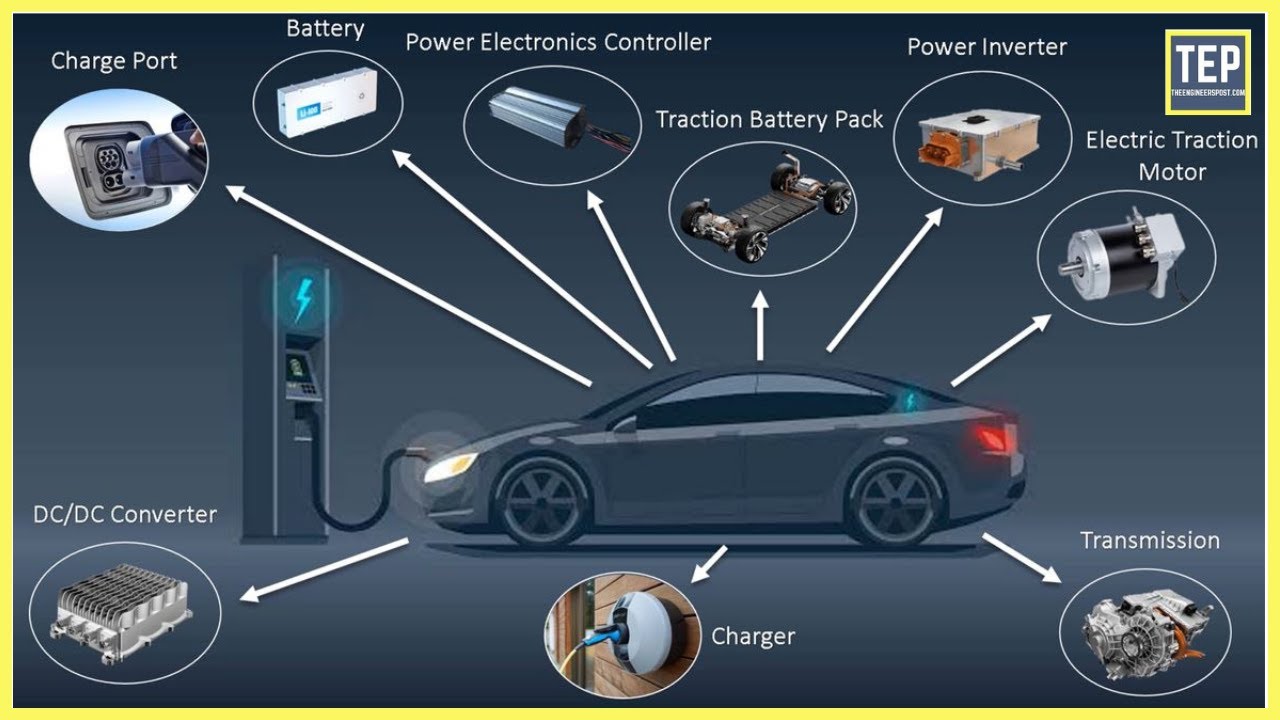

Standardized electric motor supportability standards play a vital role in ensuring the optimal performance, reliability, and safety of electric vehicles. These standards impact the overall efficiency and lifespan of electric motors, which are critical components of electric vehicles. By establishing clear guidelines for electric motor design, testing, and maintenance, manufacturers can minimize the risk of motor failure, reduce downtime, and optimize vehicle performance.

The implementation of electric motor supportability standards also has a significant impact on the environment. By promoting the use of energy-efficient electric motors, these standards contribute to reduced greenhouse gas emissions and a lower carbon footprint. Furthermore, standardized electric motor supportability standards facilitate the development of more sustainable and eco-friendly electric vehicles.

In addition to environmental benefits, electric motor supportability standards also offer economic advantages. By reducing the risk of motor failure and minimizing downtime, manufacturers can lower maintenance costs and improve overall vehicle reliability. This, in turn, leads to increased customer satisfaction and loyalty, as well as improved brand reputation.

Electric vehicle and electric motor supportability standards are essential for ensuring the safe and efficient operation of electric vehicles. By establishing clear guidelines for electric motor design, testing, and maintenance, manufacturers can promote the widespread adoption of electric vehicles and support the transition to a more sustainable transportation sector.

As the demand for electric vehicles continues to grow, the importance of electric motor supportability standards will only continue to increase. By prioritizing the development and implementation of these standards, manufacturers can stay ahead of the curve and establish themselves as leaders in the electric vehicle market.

Key Considerations for Electric Vehicle Manufacturers

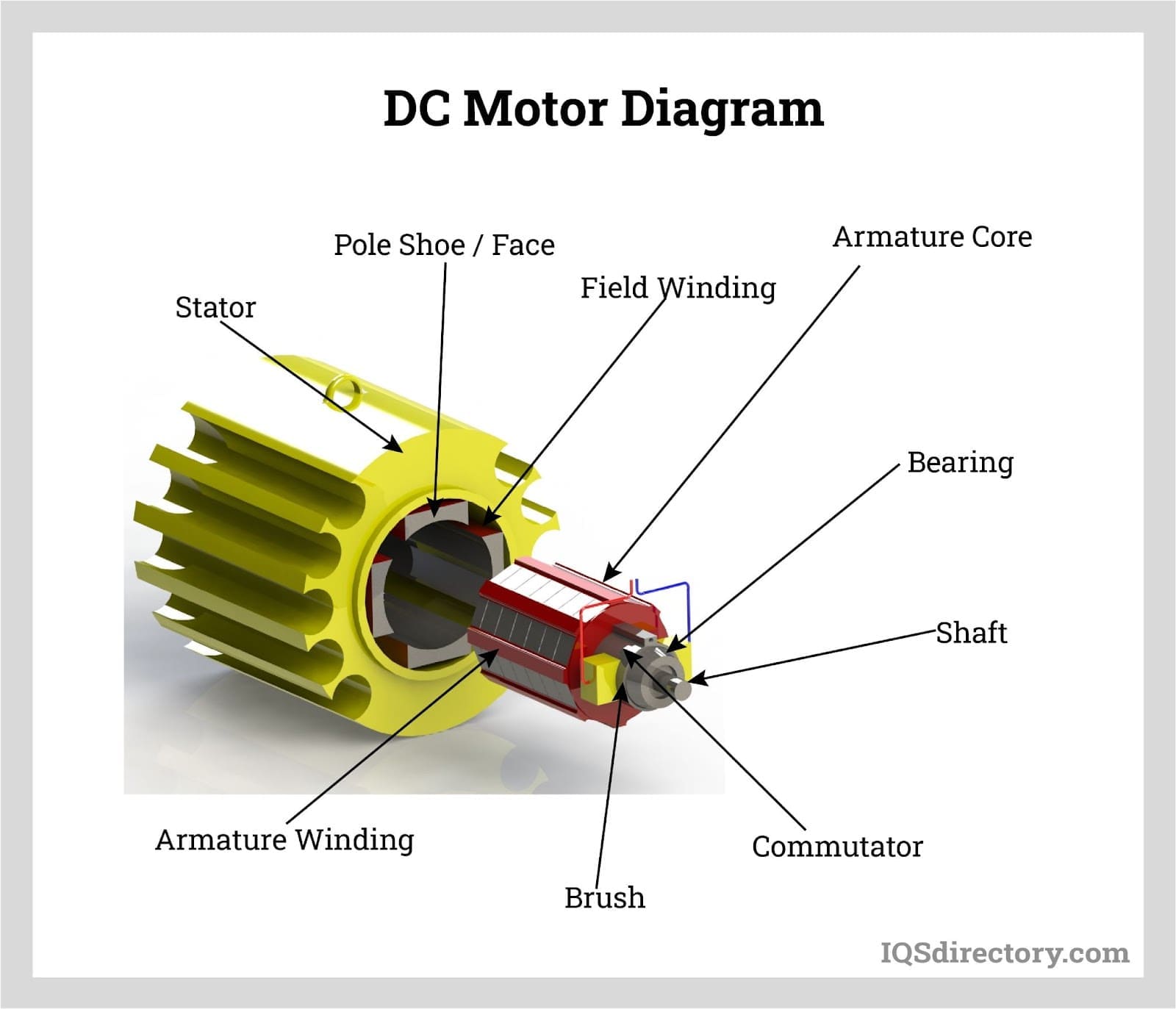

When designing and implementing electric motor supportability standards, electric vehicle manufacturers must consider several crucial factors. One of the most critical aspects is motor design, which plays a significant role in determining the overall efficiency and performance of the electric vehicle. Manufacturers must ensure that their motor designs meet the required standards for power density, efficiency, and reliability.

Another essential consideration is the selection of materials used in the construction of the electric motor. The choice of materials can significantly impact the motor’s performance, durability, and cost. Manufacturers must carefully evaluate the pros and cons of different materials, such as copper, aluminum, and rare earth magnets, to ensure that they meet the required standards for electric motor supportability.

Testing protocols are also a critical aspect of electric motor supportability standards. Manufacturers must develop and implement comprehensive testing protocols to ensure that their electric motors meet the required standards for performance, efficiency, and reliability. This includes testing for parameters such as torque, speed, and temperature, as well as evaluating the motor’s performance under various operating conditions.

In addition to motor design, materials, and testing protocols, manufacturers must also consider the impact of electric motor supportability standards on their overall business operations. This includes evaluating the cost implications of implementing these standards, as well as assessing the potential impact on their supply chain and manufacturing processes.

By carefully considering these key factors, electric vehicle manufacturers can ensure that their electric motors meet the required standards for supportability, which is critical for optimizing the performance, reliability, and safety of their vehicles. By prioritizing electric motor supportability standards, manufacturers can also improve their overall competitiveness in the market and enhance their reputation for producing high-quality electric vehicles.

The implementation of electric motor supportability standards also requires collaboration with industry associations, such as the Society of Automotive Engineers (SAE) and the International Electrotechnical Commission (IEC). These organizations play a crucial role in developing and promoting electric motor supportability standards, and manufacturers must work closely with them to ensure that their products meet the required standards.

How to Ensure Compliance with Electric Motor Supportability Standards

Ensuring compliance with established electric motor supportability standards is crucial for electric vehicle manufacturers to guarantee the optimal performance, reliability, and safety of their vehicles. To achieve compliance, manufacturers must follow a structured approach that involves documentation, testing, and certification processes.

Documentation is a critical aspect of ensuring compliance with electric motor supportability standards. Manufacturers must maintain detailed records of their design, testing, and validation processes, including documentation of motor design specifications, testing protocols, and validation results. This documentation serves as evidence of compliance and facilitates audits and inspections by regulatory bodies.

Testing is another essential aspect of ensuring compliance with electric motor supportability standards. Manufacturers must conduct comprehensive testing of their electric motors to validate their performance, efficiency, and reliability. This includes testing for parameters such as torque, speed, and temperature, as well as evaluating the motor’s performance under various operating conditions.

Certification is the final step in ensuring compliance with electric motor supportability standards. Manufacturers must obtain certification from recognized third-party organizations, such as the International Electrotechnical Commission (IEC) or the Society of Automotive Engineers (SAE). Certification provides assurance that the electric motor meets the required standards for supportability and is safe for use in electric vehicles.

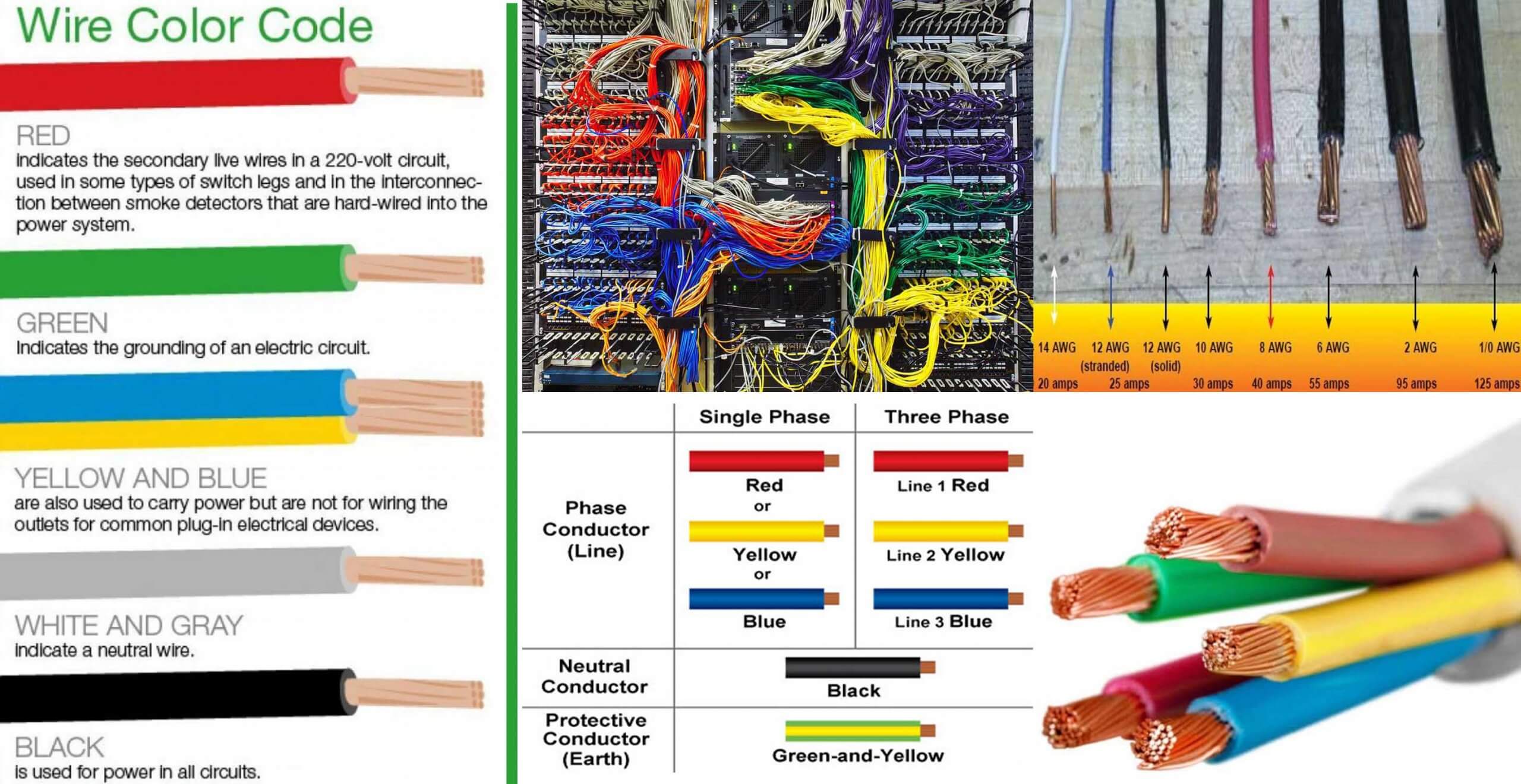

In addition to documentation, testing, and certification, manufacturers must also ensure that their electric motors are designed and manufactured in accordance with established industry standards. This includes adhering to standards for motor design, materials, and testing protocols, as well as ensuring that the motor is compatible with the vehicle’s electrical architecture.

By following a structured approach to ensuring compliance with electric motor supportability standards, electric vehicle manufacturers can guarantee the optimal performance, reliability, and safety of their vehicles. This, in turn, enhances the overall driving experience for electric vehicle owners and operators, while also reducing the risk of accidents and injuries.

The implementation of electric motor supportability standards also has a positive impact on the environment. By promoting the use of energy-efficient electric motors, these standards contribute to reduced greenhouse gas emissions and a lower carbon footprint. Furthermore, standardized electric motor supportability standards facilitate the development of more sustainable and eco-friendly electric vehicles.

Real-World Examples of Electric Motor Supportability in Action

Tesla’s Model S and Chevrolet’s Bolt EV are two notable examples of electric vehicle manufacturers that have successfully implemented electric motor supportability standards. These vehicles have demonstrated exceptional performance, reliability, and safety, thanks in part to the implementation of standardized electric motor supportability standards.

Tesla’s Model S, for instance, features a high-performance electric motor that is designed to meet the company’s stringent standards for efficiency, reliability, and safety. The motor is built with high-quality materials and is subjected to rigorous testing protocols to ensure that it meets the required standards for electric motor supportability.

Chevrolet’s Bolt EV, on the other hand, features a compact and efficient electric motor that is designed to provide exceptional performance and range. The motor is built with advanced materials and is designed to meet the company’s standards for electric motor supportability, including testing protocols for efficiency, reliability, and safety.

Both Tesla and Chevrolet have demonstrated a commitment to implementing electric motor supportability standards in their vehicles, and the results are evident in the exceptional performance and reliability of their electric vehicles. By prioritizing electric motor supportability standards, these manufacturers have been able to create vehicles that are not only environmentally friendly but also safe and reliable.

The implementation of electric motor supportability standards has also had a positive impact on the overall driving experience for electric vehicle owners and operators. By ensuring that electric motors are designed and built to meet rigorous standards for efficiency, reliability, and safety, manufacturers can provide a more enjoyable and stress-free driving experience.

In addition to the benefits for electric vehicle owners and operators, the implementation of electric motor supportability standards has also had a positive impact on the environment. By promoting the use of energy-efficient electric motors, these standards contribute to reduced greenhouse gas emissions and a lower carbon footprint.

Overall, the implementation of electric motor supportability standards is a critical aspect of ensuring the optimal performance, reliability, and safety of electric vehicles. By prioritizing these standards, manufacturers can create vehicles that are not only environmentally friendly but also safe and reliable, providing a more enjoyable and stress-free driving experience for electric vehicle owners and operators.

The Role of Industry Associations in Shaping Electric Motor Supportability Standards

Industry associations play a crucial role in shaping electric motor supportability standards for electric vehicles. Organizations such as the Society of Automotive Engineers (SAE) and the International Electrotechnical Commission (IEC) have been instrumental in developing and promoting standards for electric motor supportability.

The SAE, for example, has developed a range of standards for electric motor supportability, including standards for motor design, testing, and validation. These standards provide a framework for electric vehicle manufacturers to ensure that their electric motors meet the required standards for performance, efficiency, and reliability.

The IEC, on the other hand, has developed international standards for electric motor supportability, including standards for motor design, materials, and testing protocols. These standards provide a global framework for electric vehicle manufacturers to ensure that their electric motors meet the required standards for performance, efficiency, and reliability.

Industry associations also provide a platform for electric vehicle manufacturers to collaborate and share best practices in electric motor supportability. This collaboration enables manufacturers to stay up-to-date with the latest developments in electric motor technology and to ensure that their electric motors meet the required standards for performance, efficiency, and reliability.

In addition to developing and promoting standards, industry associations also provide training and education programs for electric vehicle manufacturers. These programs enable manufacturers to develop the skills and knowledge needed to design and implement electric motor supportability standards.

Overall, industry associations play a critical role in shaping electric motor supportability standards for electric vehicles. By developing and promoting standards, providing a platform for collaboration, and offering training and education programs, industry associations enable electric vehicle manufacturers to ensure that their electric motors meet the required standards for performance, efficiency, and reliability.

The influence of industry associations in shaping electric motor supportability standards has a positive impact on the overall performance and reliability of electric vehicles. By promoting standardized electric motor supportability standards, industry associations enable electric vehicle manufacturers to create vehicles that are not only environmentally friendly but also safe and reliable.

Overcoming Common Challenges in Electric Motor Supportability

Electric vehicle manufacturers face several challenges when implementing electric motor supportability standards. One of the most significant challenges is cost constraints. Implementing electric motor supportability standards can be expensive, and manufacturers must balance the cost of implementation with the benefits of improved performance, reliability, and safety.

Another challenge is supply chain complexities. Electric vehicle manufacturers often rely on a complex network of suppliers to provide components and materials for their electric motors. Ensuring that these suppliers meet the required standards for electric motor supportability can be a significant challenge.

To overcome these challenges, electric vehicle manufacturers can adopt several strategies. One approach is to invest in research and development to improve the efficiency and cost-effectiveness of electric motor supportability standards. This can involve developing new technologies and materials that can help reduce the cost of implementation.

Another approach is to collaborate with suppliers and industry partners to ensure that they meet the required standards for electric motor supportability. This can involve providing training and education programs for suppliers, as well as implementing quality control measures to ensure that components and materials meet the required standards.

Electric vehicle manufacturers can also adopt a modular approach to electric motor design, which can help reduce the complexity of supply chain management. This involves designing electric motors with modular components that can be easily sourced from multiple suppliers.

In addition to these strategies, electric vehicle manufacturers can also benefit from the use of advanced technologies such as simulation and modeling tools. These tools can help manufacturers optimize the design and performance of their electric motors, while also reducing the cost and complexity of implementation.

By adopting these strategies, electric vehicle manufacturers can overcome the common challenges associated with implementing electric motor supportability standards. This can help ensure that their electric vehicles meet the required standards for performance, reliability, and safety, while also reducing the cost and complexity of implementation.

The implementation of electric motor supportability standards is a critical aspect of ensuring the optimal performance, reliability, and safety of electric vehicles. By overcoming the common challenges associated with implementation, electric vehicle manufacturers can create vehicles that are not only environmentally friendly but also safe and reliable.

Future Directions for Electric Motor Supportability Standards

The future of electric motor supportability standards is exciting and rapidly evolving. Emerging trends and technologies, such as autonomous vehicles and vehicle-to-grid (V2G) technology, are expected to shape the industry and drive innovation in electric motor design and supportability.

Autonomous vehicles, for example, will require advanced electric motor supportability standards to ensure safe and reliable operation. This will involve the development of new testing protocols and validation procedures to ensure that electric motors can operate safely and efficiently in autonomous vehicles.

V2G technology, on the other hand, will enable electric vehicles to act as energy storage devices and supply electricity back to the grid. This will require advanced electric motor supportability standards to ensure that electric motors can operate efficiently and safely in V2G applications.

Other emerging trends and technologies, such as advanced materials and manufacturing techniques, will also play a critical role in shaping the future of electric motor supportability standards. These advancements will enable the development of more efficient, reliable, and cost-effective electric motors, which will be essential for the widespread adoption of electric vehicles.

The development of electric motor supportability standards will also be influenced by government regulations and industry initiatives. Governments around the world are implementing regulations to promote the adoption of electric vehicles, and industry associations are developing standards and guidelines to support the development of electric motor supportability standards.

As the electric vehicle industry continues to evolve, it is essential that electric motor supportability standards keep pace with emerging trends and technologies. By developing and implementing advanced electric motor supportability standards, the industry can ensure that electric vehicles are safe, reliable, and efficient, and that they meet the needs of consumers and the environment.

The future of electric motor supportability standards is bright, and it is expected that the industry will continue to innovate and develop new technologies and standards to support the widespread adoption of electric vehicles. By staying ahead of the curve and developing advanced electric motor supportability standards, the industry can ensure that electric vehicles are a success and that they play a critical role in reducing greenhouse gas emissions and promoting sustainable transportation.

Best Practices for Electric Vehicle Owners and Operators

Electric vehicle owners and operators play a critical role in maintaining and supporting their vehicles’ electric motors. By following best practices, they can ensure that their electric motors operate efficiently, reliably, and safely.

One of the most important best practices is to follow a regular maintenance schedule. This includes checking the electric motor’s temperature, voltage, and current levels, as well as performing routine cleaning and inspection tasks. By following a regular maintenance schedule, electric vehicle owners and operators can identify and address potential issues before they become major problems.

Another best practice is to troubleshoot and repair issues promptly. Electric vehicle owners and operators should be aware of the common issues that can affect their electric motors, such as overheating, overcharging, and electrical faults. By troubleshooting and repairing issues promptly, they can prevent more serious problems from developing and ensure that their electric motors continue to operate efficiently and reliably.

In addition to maintenance and troubleshooting, electric vehicle owners and operators should also be aware of the importance of proper charging and storage procedures. This includes using the correct charging equipment and following the manufacturer’s recommended charging and storage procedures. By following proper charging and storage procedures, electric vehicle owners and operators can help extend the lifespan of their electric motors and ensure that they operate efficiently and reliably.

Finally, electric vehicle owners and operators should be aware of the importance of keeping their electric motors up-to-date with the latest software and firmware updates. This can help ensure that their electric motors operate efficiently and reliably, and that they are able to take advantage of the latest advancements in electric motor technology.

By following these best practices, electric vehicle owners and operators can help ensure that their electric motors operate efficiently, reliably, and safely. This can help extend the lifespan of their electric motors, reduce maintenance costs, and improve overall vehicle performance.

Electric motor supportability standards play a critical role in ensuring that electric vehicles operate efficiently, reliably, and safely. By following best practices and staying up-to-date with the latest advancements in electric motor technology, electric vehicle owners and operators can help ensure that their electric motors meet the required standards for performance, efficiency, and reliability.