What are Electric Vehicle Technical Standards and Why are They Important?

Electric vehicle technical standards play a crucial role in ensuring the safety, efficiency, and interoperability of electric vehicles (EVs) and their components, including electric motors. These standards provide a common framework for manufacturers to design, test, and validate their products, facilitating the widespread adoption of EVs. The benefits of standardization in the EV industry are numerous, including improved safety, reduced costs, and increased consumer confidence.

Electric vehicle technical standards cover a wide range of aspects, from the design and testing of electric motors to the safety and performance of charging systems. These standards are developed by organizations such as the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE), which bring together experts from industry, government, and academia to create consensus-based standards.

The importance of electric vehicle technical standards cannot be overstated. By providing a common language and set of requirements, these standards enable manufacturers to develop products that are compatible with different charging systems, communication protocols, and safety features. This, in turn, facilitates the creation of a seamless and efficient EV ecosystem, where vehicles can be charged, maintained, and repaired with ease.

Furthermore, electric vehicle technical standards help to ensure that EVs meet the required safety and performance standards, reducing the risk of accidents and injuries. By specifying requirements for electric motor design, testing, and validation, these standards help to prevent electrical shocks, fires, and other hazards associated with EVs.

In addition to safety and performance, electric vehicle technical standards also play a critical role in promoting the efficiency and sustainability of EVs. By specifying requirements for energy efficiency, emissions, and environmental impact, these standards help to minimize the environmental footprint of EVs and promote sustainable transportation solutions.

In conclusion, electric vehicle technical standards are essential for ensuring the safety, efficiency, and interoperability of EVs and their components. By providing a common framework for manufacturers to design, test, and validate their products, these standards facilitate the widespread adoption of EVs and promote sustainable transportation solutions.

How to Choose the Right Electric Motor for Your Vehicle: A Guide to Technical Specifications

When selecting an electric motor for a vehicle, it is essential to consider several key technical specifications to ensure optimal performance, efficiency, and safety. The electric motor is a critical component of an electric vehicle (EV), and its specifications can significantly impact the overall performance and range of the vehicle.

One of the most critical specifications to consider is the power output of the electric motor. This is typically measured in kilowatts (kW) and determines the motor’s ability to propel the vehicle. A higher power output generally results in faster acceleration and better performance, but it also increases the energy consumption and reduces the vehicle’s range.

Another important specification is the torque output of the electric motor. Torque is a measure of the motor’s rotational force and is typically measured in newton-meters (Nm). A higher torque output generally results in better acceleration and towing capacity, but it also increases the energy consumption and reduces the vehicle’s range.

Efficiency is also a critical specification to consider when selecting an electric motor. This is typically measured as a percentage and determines the motor’s ability to convert electrical energy into mechanical energy. A higher efficiency generally results in better range and reduced energy consumption.

In addition to these specifications, it is also essential to consider the motor’s compatibility with the vehicle’s electrical system and charging infrastructure. The motor should be designed to work seamlessly with the vehicle’s battery management system, power electronics, and charging system to ensure optimal performance and safety.

To match motor specifications to vehicle requirements, it is essential to consider the vehicle’s intended use, range, and performance requirements. For example, a vehicle designed for long-distance driving may require a motor with a higher power output and efficiency, while a vehicle designed for city driving may require a motor with a lower power output and higher torque.

By considering these technical specifications and matching them to the vehicle’s requirements, manufacturers can ensure that their electric vehicles meet the relevant electric vehicle and electric motor technical standards, providing optimal performance, efficiency, and safety for drivers.

IEC and SAE Standards for Electric Vehicles: A Comparative Analysis

The International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) are two of the most prominent organizations developing technical standards for electric vehicles (EVs). Both organizations have developed comprehensive standards for EVs, including electric motor technical standards, charging systems, and safety requirements.

The IEC has developed a range of standards for EVs, including IEC 62196, which specifies the requirements for EV charging systems, and IEC 60364, which covers the safety requirements for EVs. The IEC standards are widely adopted globally and provide a framework for manufacturers to design and test their EVs.

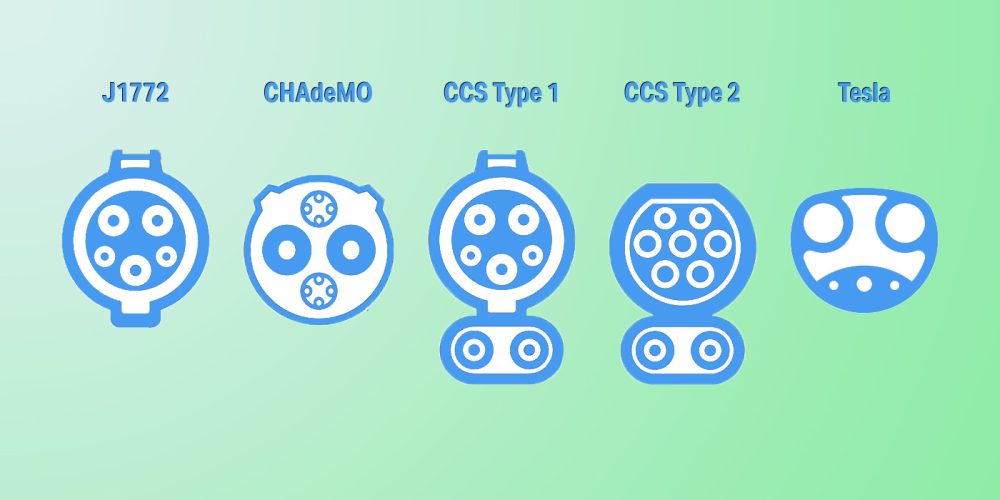

The SAE, on the other hand, has developed standards specifically for the North American market. SAE J1772, for example, specifies the requirements for EV charging systems in North America, while SAE J3016 covers the safety requirements for EVs. The SAE standards are widely adopted in North America and provide a framework for manufacturers to design and test their EVs for the local market.

A comparative analysis of the IEC and SAE standards reveals both similarities and differences. Both standards emphasize the importance of safety, efficiency, and interoperability in EV design and testing. However, the IEC standards tend to be more comprehensive and detailed, covering a wider range of topics, including electromagnetic compatibility and environmental testing.

The SAE standards, on the other hand, are more focused on the specific requirements of the North American market, including the use of specific charging connectors and communication protocols. The SAE standards also tend to be more flexible, allowing for more variation in EV design and testing.

Despite these differences, both the IEC and SAE standards play a critical role in ensuring that EVs meet the relevant electric vehicle and electric motor technical standards, providing a safe and efficient driving experience for consumers. By understanding the similarities and differences between these standards, manufacturers can design and test their EVs to meet the requirements of different markets and regions.

In conclusion, the IEC and SAE standards provide a framework for manufacturers to design and test their EVs, ensuring that they meet the relevant technical standards for safety, efficiency, and interoperability. By understanding the similarities and differences between these standards, manufacturers can navigate the complex regulatory landscape and bring safe and efficient EVs to market.

Understanding Electric Vehicle Charging Systems: Technical Requirements and Safety Standards

Electric vehicle (EV) charging systems are a critical component of the EV ecosystem, enabling drivers to recharge their vehicles quickly and efficiently. However, the technical requirements and safety standards for EV charging systems are complex and multifaceted, requiring careful consideration to ensure safe and efficient operation.

There are several key technical requirements for EV charging systems, including charging modes, connectors, and safety features. Charging modes refer to the different ways in which an EV can be charged, including Level 1 (120V), Level 2 (240V), and DC Fast Charging. Connectors refer to the physical interface between the EV and the charging station, and must be designed to ensure safe and efficient energy transfer.

Safety features are also a critical component of EV charging systems, and must be designed to prevent electrical shock, fires, and other hazards. These features may include ground fault protection, overcurrent protection, and thermal monitoring. The importance of adhering to safety standards for charging systems cannot be overstated, as failure to do so can result in serious injury or death.

The International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) have developed technical standards for EV charging systems, including IEC 62196 and SAE J1772. These standards provide a framework for manufacturers to design and test their charging systems, ensuring that they meet the necessary technical requirements and safety standards.

In addition to these standards, there are also several industry-led initiatives aimed at promoting the adoption of EVs and the development of EV charging infrastructure. For example, the Charging Interface Initiative (CharIN) is a global industry association that aims to promote the adoption of EVs and the development of EV charging infrastructure.

By understanding the technical requirements and safety standards for EV charging systems, manufacturers can design and develop safe and efficient charging solutions that meet the needs of EV drivers. This, in turn, can help to promote the adoption of EVs and reduce greenhouse gas emissions from transportation.

In the context of electric vehicle and electric motor technical standards, the development of EV charging systems is a critical component of the overall EV ecosystem. By ensuring that EV charging systems meet the necessary technical requirements and safety standards, manufacturers can help to promote the adoption of EVs and reduce greenhouse gas emissions from transportation.

Case Study: Tesla’s Electric Motor Technology and its Compliance with Technical Standards

Tesla is a leading manufacturer of electric vehicles (EVs) and has developed a range of innovative electric motor technologies. In this case study, we will examine Tesla’s electric motor technology and its compliance with relevant technical standards.

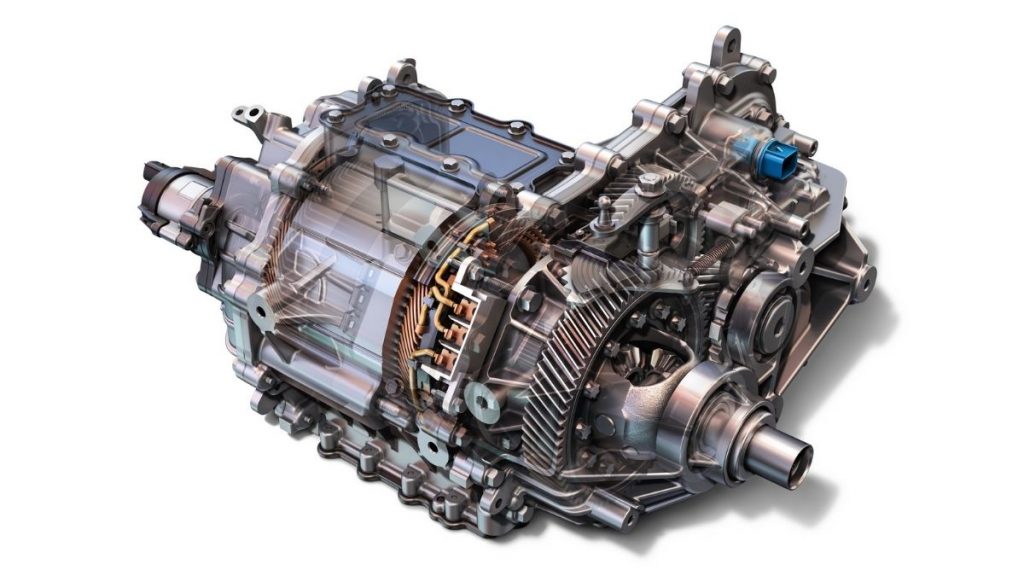

Tesla’s electric motor technology is based on a three-phase, four-pole induction motor design. This design provides high efficiency and reliability, and is well-suited to the demands of EV applications. Tesla’s motors are also designed to be highly scalable, with a range of power outputs available to suit different vehicle applications.

In terms of technical standards, Tesla’s electric motors comply with a range of industry standards, including those developed by the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE). For example, Tesla’s motors meet the requirements of IEC 60034-1, which specifies the safety and performance requirements for electric motors.

Tesla’s approach to electric motor design and manufacturing is also notable for its emphasis on innovation and collaboration. The company has developed a range of partnerships with suppliers and research institutions to advance the development of electric motor technology. This approach has enabled Tesla to stay at the forefront of electric motor innovation and to develop highly efficient and reliable motors.

However, Tesla’s approach to electric motor design and manufacturing is not without its challenges. The company has faced criticism for its use of proprietary technology and its limited disclosure of technical information. This has made it difficult for other manufacturers to develop compatible products and has limited the adoption of Tesla’s technology in other industries.

Despite these challenges, Tesla’s electric motor technology is widely recognized as a benchmark for the industry. The company’s commitment to innovation and collaboration has enabled it to develop highly efficient and reliable motors that meet the demands of EV applications. As the EV industry continues to evolve, it is likely that Tesla’s electric motor technology will play an increasingly important role in shaping the future of transportation.

In the context of electric vehicle and electric motor technical standards, Tesla’s approach to electric motor design and manufacturing is a valuable case study. The company’s emphasis on innovation and collaboration has enabled it to develop highly efficient and reliable motors that meet the demands of EV applications. However, the company’s use of proprietary technology and limited disclosure of technical information has also raised challenges for the industry.

The Role of Testing and Validation in Ensuring Electric Vehicle Technical Standards

Testing and validation are critical components of ensuring that electric vehicles (EVs) meet technical standards. The testing and validation process involves a series of rigorous tests and evaluations to ensure that EVs meet the required safety, performance, and efficiency standards.

There are several types of testing and validation procedures used in the EV industry, including laboratory testing, field testing, and simulation testing. Laboratory testing involves testing EV components and systems in a controlled laboratory environment, while field testing involves testing EVs in real-world driving conditions. Simulation testing involves using computer simulations to test EV performance and behavior.

The testing and validation process is essential for ensuring that EVs meet the required technical standards, including those related to safety, performance, and efficiency. For example, the International Electrotechnical Commission (IEC) has developed a range of standards for EV safety, including IEC 62196, which specifies the safety requirements for EV charging systems.

In addition to ensuring compliance with technical standards, testing and validation also play a critical role in identifying and addressing potential issues and defects in EV design and manufacturing. By identifying and addressing these issues early on, manufacturers can reduce the risk of costly recalls and improve overall vehicle quality.

The testing and validation process also involves collaboration and knowledge-sharing between manufacturers, suppliers, and regulatory bodies. This collaboration is essential for ensuring that EVs meet the required technical standards and for promoting the development of new and innovative technologies.

In the context of electric vehicle and electric motor technical standards, testing and validation are critical components of ensuring that EVs meet the required safety, performance, and efficiency standards. By employing rigorous testing and validation procedures, manufacturers can ensure that their EVs meet the required technical standards and provide a safe and efficient driving experience for consumers.

Furthermore, the testing and validation process also provides valuable insights and data that can be used to improve EV design and manufacturing. By analyzing the results of testing and validation, manufacturers can identify areas for improvement and optimize their designs and manufacturing processes to produce higher-quality EVs.

Future Developments in Electric Vehicle Technical Standards: Trends and Challenges

The electric vehicle (EV) industry is rapidly evolving, with new technologies and trends emerging all the time. As the industry continues to grow and mature, it is likely that electric vehicle technical standards will play an increasingly important role in shaping the future of transportation.

One of the key trends in the EV industry is the development of new and innovative battery technologies. Advances in battery technology have the potential to significantly improve the range and efficiency of EVs, making them more viable for widespread adoption. However, these advances also raise new challenges for electric vehicle technical standards, as manufacturers must ensure that their vehicles meet the required safety and performance standards.

Another trend in the EV industry is the increasing focus on autonomous vehicles. Autonomous vehicles have the potential to revolutionize the way we think about transportation, but they also raise new challenges for electric vehicle technical standards. For example, autonomous vehicles require advanced sensors and software systems, which must be designed and tested to meet the required safety and performance standards.

Despite these challenges, the development of electric vehicle technical standards is likely to continue to play a critical role in shaping the future of the EV industry. By establishing clear and consistent standards for safety, performance, and efficiency, manufacturers can ensure that their vehicles meet the required standards and provide a safe and efficient driving experience for consumers.

In the context of electric vehicle and electric motor technical standards, the future developments in the EV industry are likely to be shaped by a range of factors, including advances in technology, changes in consumer demand, and evolving regulatory requirements. By staying ahead of these trends and developments, manufacturers can ensure that their vehicles meet the required technical standards and remain competitive in the market.

Some of the key challenges facing the EV industry in terms of standardization include the need for greater interoperability between different manufacturers and systems, the need for more comprehensive testing and validation procedures, and the need for more effective collaboration and knowledge-sharing between manufacturers, suppliers, and regulatory bodies.

Despite these challenges, the future of electric vehicle technical standards looks bright. By continuing to develop and refine these standards, manufacturers can ensure that their vehicles meet the required safety, performance, and efficiency standards, and provide a safe and efficient driving experience for consumers.

Best Practices for Implementing Electric Vehicle Technical Standards in Manufacturing

Implementing electric vehicle technical standards in manufacturing is crucial to ensure the safety, efficiency, and interoperability of electric vehicles. To achieve this, manufacturers must adopt best practices that prioritize design, testing, and validation. Here are some guidelines to help manufacturers implement electric vehicle technical standards effectively.

Design for Compliance: Manufacturers should design their electric vehicles and electric motors with technical standards in mind. This involves considering factors such as power output, torque, and efficiency to ensure that the vehicle meets the required standards. By designing for compliance, manufacturers can avoid costly rework and ensure that their products meet the necessary technical standards.

Testing and Validation: Thorough testing and validation are critical to ensuring that electric vehicles meet technical standards. Manufacturers should conduct a range of tests, including performance, safety, and durability tests, to validate their products. This helps to identify and address any defects or issues before the vehicle is released to the market.

Collaboration and Knowledge-Sharing: Collaboration and knowledge-sharing are essential in implementing electric vehicle technical standards. Manufacturers should work closely with suppliers, industry associations, and regulatory bodies to stay up-to-date with the latest standards and best practices. This helps to ensure that manufacturers are aware of any changes or updates to technical standards and can implement them effectively.

Training and Education: Manufacturers should provide ongoing training and education to their employees on electric vehicle technical standards. This helps to ensure that employees are aware of the latest standards and best practices and can implement them effectively. Training and education also help to promote a culture of compliance within the organization.

Continuous Improvement: Manufacturers should continuously monitor and improve their processes to ensure that they remain compliant with electric vehicle technical standards. This involves regularly reviewing and updating designs, testing and validation procedures, and manufacturing processes to ensure that they meet the required standards.

By following these best practices, manufacturers can ensure that their electric vehicles meet the necessary technical standards, providing a safe and efficient driving experience for consumers. Implementing electric vehicle technical standards in manufacturing requires a commitment to design, testing, and validation, as well as collaboration, training, and continuous improvement. By prioritizing these factors, manufacturers can stay ahead of the curve and maintain a competitive edge in the market.

:max_bytes(150000):strip_icc()/Typesofvehicleplugs_svetolk_iStock_GettyImagesPlus-5461dcc83ddd4b35b248dcb6a018b559.jpg)