Unlocking the Potential of Electric Motors: Technical Standards to Watch

The electric vehicle (EV) industry has experienced rapid growth in recent years, driven by increasing demand for sustainable and environmentally friendly transportation solutions. As the sector continues to evolve, the need for standardized technical specifications has become more pressing. Electric motor technical standards play a crucial role in ensuring the safety, efficiency, and interoperability of EVs. In this article, we will explore the key technical standards that govern EV technology, including those related to electric motors, and examine the trends shaping the industry.

Electric motor technical standards are essential for ensuring the reliable and efficient operation of EVs. These standards cover various aspects, including motor design, performance, and testing. The International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) are two prominent organizations that develop and publish technical standards for the EV industry. For instance, the IEC 60364 standard provides guidelines for the design and testing of electric motors for EVs, while the SAE J3016 standard specifies the requirements for EV charging systems.

The importance of electric motor technical standards cannot be overstated. These standards help ensure that EVs meet the required safety and performance criteria, which is critical for consumer adoption and regulatory compliance. Moreover, standardized technical specifications facilitate the development of interoperable EV systems, enabling seamless communication between different components and manufacturers. As the EV industry continues to grow, the need for standardized technical specifications will only become more pressing.

Emerging trends in electric motor technology are also driving the development of new technical standards. Advances in materials science and manufacturing techniques have led to the creation of more efficient and compact electric motors. For example, the use of rare-earth magnets has enabled the development of high-performance electric motors with improved power density and efficiency. As these technologies continue to evolve, new technical standards will be needed to ensure their safe and efficient deployment in EVs.

In conclusion, electric motor technical standards are a critical component of the EV industry, ensuring the safety, efficiency, and interoperability of EVs. As the sector continues to evolve, the need for standardized technical specifications will only become more pressing. By understanding the key technical standards that govern EV technology, industry stakeholders can better navigate the complex landscape of electric motor technical standards trends.

How to Choose the Right Electric Motor for Your EV Application

Selecting the most suitable electric motor for a specific electric vehicle (EV) application can be a daunting task, given the numerous options available. However, by considering key factors such as power density, efficiency, and thermal management, engineers and manufacturers can make informed decisions that optimize EV performance and efficiency. In this section, we will explore the popular electric motor types used in EV applications and provide guidance on choosing the right motor for your needs.

Induction motors, permanent magnet motors, and switched reluctance motors are among the most commonly used electric motor types in EV applications. Induction motors, for instance, offer high power density and efficiency, making them suitable for high-performance EVs. Permanent magnet motors, on the other hand, provide high torque and efficiency, making them ideal for EVs that require high acceleration and hill-climbing capabilities. Switched reluctance motors, meanwhile, offer high efficiency and reliability, making them suitable for EVs that require high mileage and low maintenance.

When selecting an electric motor for your EV application, it is essential to consider the specific requirements of your vehicle. For example, if your EV requires high acceleration and hill-climbing capabilities, a permanent magnet motor may be the best choice. However, if your EV requires high mileage and low maintenance, a switched reluctance motor may be more suitable. Additionally, factors such as thermal management, noise reduction, and electromagnetic compatibility must also be considered to ensure optimal motor performance and efficiency.

In recent years, advancements in electric motor design have led to the development of more efficient and compact motors. For example, the use of new materials and manufacturing techniques has enabled the creation of high-performance electric motors with improved power density and efficiency. As the EV industry continues to evolve, the importance of selecting the right electric motor for your application will only become more critical.

By understanding the different electric motor types and their characteristics, engineers and manufacturers can make informed decisions that optimize EV performance and efficiency. Additionally, by considering the specific requirements of their vehicle and the latest advancements in electric motor design, they can ensure that their EV meets the highest standards of performance, efficiency, and reliability.

The Role of Industry Standards in Shaping EV Technical Specifications

Industry standards play a crucial role in shaping the technical specifications of electric vehicles (EVs). Organizations such as the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) develop and publish standards that govern various aspects of EV technology, including electric motor technical standards trends. These standards ensure that EVs meet the required safety, efficiency, and interoperability criteria, which is critical for consumer adoption and regulatory compliance.

The IEC, for instance, has developed a range of standards that address various aspects of EV technology, including charging systems, battery management, and electromagnetic compatibility. The IEC 62196 standard, for example, specifies the requirements for EV charging systems, while the IEC 62660 standard addresses the safety and performance of EV batteries. Similarly, the SAE has developed standards such as the SAE J3016, which specifies the requirements for EV charging systems, and the SAE J2954, which addresses the safety and performance of EV batteries.

These industry standards have a significant impact on the development of EV technology, including electric motor technical standards trends. By providing a common framework for the design and testing of EV components, these standards enable manufacturers to develop interoperable systems that meet the required safety and performance criteria. Additionally, these standards facilitate the development of new technologies and innovations, such as advanced battery management systems and high-power charging systems.

The importance of industry standards in shaping EV technical specifications cannot be overstated. By providing a common language and framework for the development of EV technology, these standards enable manufacturers to develop products that meet the required safety, efficiency, and interoperability criteria. As the EV industry continues to evolve, the role of industry standards will only become more critical, driving innovation and growth in the sector.

In the context of electric motor technical standards trends, industry standards play a crucial role in shaping the development of new technologies and innovations. By providing a common framework for the design and testing of electric motors, these standards enable manufacturers to develop products that meet the required safety, efficiency, and interoperability criteria. As the EV industry continues to evolve, the importance of industry standards in shaping electric motor technical standards trends will only become more critical.

Advancements in Electric Motor Design: Trends and Innovations

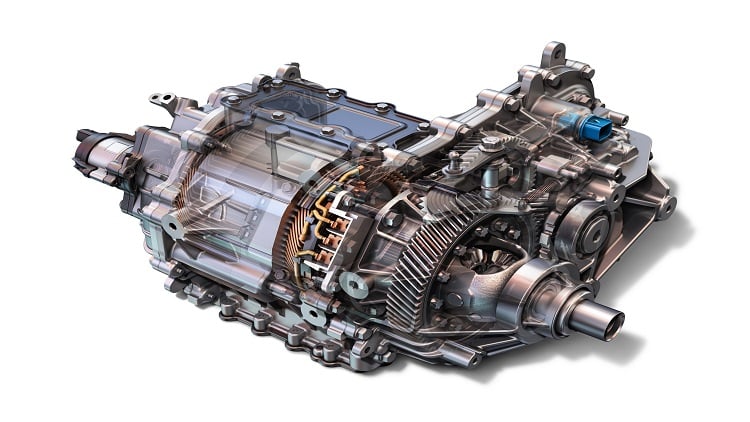

Recent years have seen significant advancements in electric motor design, driven by the growing demand for efficient and sustainable electric vehicles (EVs). The development of new materials, topologies, and manufacturing techniques has enabled the creation of more efficient and compact electric motors, which are critical for improving the performance and range of EVs. In this section, we will explore some of the latest trends and innovations in electric motor design, including the use of axial flux motors and transverse flux motors.

One of the most significant advancements in electric motor design is the development of axial flux motors. These motors use a unique topology that allows for higher power density and efficiency, making them ideal for high-performance EVs. Axial flux motors also offer improved thermal management, which is critical for maintaining the reliability and lifespan of the motor. Companies such as Tesla and Lucid Motors have already adopted axial flux motors in their EVs, demonstrating the potential of this technology.

Another trend in electric motor design is the use of transverse flux motors. These motors use a unique topology that allows for higher torque density and efficiency, making them ideal for EVs that require high acceleration and hill-climbing capabilities. Transverse flux motors also offer improved thermal management and reduced noise, making them a popular choice for EV manufacturers. Companies such as BMW and Volkswagen have already adopted transverse flux motors in their EVs, demonstrating the potential of this technology.

In addition to these advancements, researchers are also exploring new materials and manufacturing techniques to improve the efficiency and performance of electric motors. For example, the use of rare-earth magnets has enabled the development of high-performance electric motors with improved power density and efficiency. Similarly, the use of 3D printing and other advanced manufacturing techniques has enabled the creation of complex motor geometries and topologies that were previously impossible to produce.

These advancements in electric motor design are critical for improving the performance and range of EVs, and will play a key role in shaping the future of electric vehicle technology. As the demand for EVs continues to grow, we can expect to see even more innovative and efficient electric motor designs emerge, driving the industry forward and enabling the widespread adoption of sustainable transportation solutions.

Real-World Examples: Electric Vehicles that Showcase Cutting-Edge Motor Technology

The electric vehicle (EV) industry has witnessed significant advancements in motor technology, with several models showcasing cutting-edge innovations. In this section, we will explore some real-world examples of EVs that feature advanced electric motor technology, including the Tesla Model S, the Chevrolet Bolt, and the Nissan Leaf.

The Tesla Model S is a prime example of an EV that features advanced electric motor technology. The vehicle is equipped with a high-performance electric motor that produces 762 horsepower and 723 lb-ft of torque. The motor is designed to provide exceptional acceleration and efficiency, with the vehicle able to go from 0-60 mph in just 2.5 seconds. The Tesla Model S also features advanced thermal management systems, which help to optimize motor performance and efficiency.

The Chevrolet Bolt is another EV that showcases advanced electric motor technology. The vehicle is equipped with a high-performance electric motor that produces 200 horsepower and 266 lb-ft of torque. The motor is designed to provide exceptional efficiency and range, with the vehicle able to travel up to 259 miles on a single charge. The Chevrolet Bolt also features advanced battery management systems, which help to optimize motor performance and efficiency.

The Nissan Leaf is a popular EV that features advanced electric motor technology. The vehicle is equipped with a high-performance electric motor that produces 147 horsepower and 236 lb-ft of torque. The motor is designed to provide exceptional efficiency and range, with the vehicle able to travel up to 147 miles on a single charge. The Nissan Leaf also features advanced thermal management systems, which help to optimize motor performance and efficiency.

These EVs demonstrate the advancements that have been made in electric motor technology, with a focus on efficiency, performance, and range. The use of advanced materials, topologies, and manufacturing techniques has enabled the creation of high-performance electric motors that are critical for the widespread adoption of EVs. As the EV industry continues to evolve, we can expect to see even more innovative and efficient electric motor designs emerge, driving the industry forward and enabling the widespread adoption of sustainable transportation solutions.

Challenges and Opportunities in Electric Motor Standardization

The standardization of electric motor technology is crucial for the widespread adoption of electric vehicles (EVs). However, there are several challenges and opportunities associated with standardizing electric motor technology. In this section, we will discuss the need for harmonization across different industries and regions, and explore the potential benefits of standardization, such as increased efficiency and reduced costs.

One of the main challenges in standardizing electric motor technology is the need for harmonization across different industries and regions. Different countries and regions have different standards and regulations for electric motors, which can create confusion and complexity for manufacturers and consumers. For example, the European Union has its own set of standards for electric motors, while the United States has its own set of standards. This can create challenges for manufacturers who want to sell their products globally.

Another challenge is the need for standardization across different types of electric motors. There are many different types of electric motors, each with its own unique characteristics and requirements. For example, induction motors, permanent magnet motors, and switched reluctance motors all have different design and testing requirements. Standardizing these different types of motors can be a complex and challenging task.

Despite these challenges, there are many opportunities associated with standardizing electric motor technology. One of the main benefits is increased efficiency. Standardized electric motors can be designed and tested to optimize their performance and efficiency, which can lead to cost savings and reduced energy consumption. Another benefit is reduced costs. Standardized electric motors can be manufactured at a lower cost, which can make them more competitive in the market.

Standardization can also facilitate the development of new technologies and innovations. By establishing common standards and protocols, manufacturers and researchers can focus on developing new and improved electric motor technologies, rather than spending time and resources on developing proprietary solutions. This can lead to faster innovation and adoption of new technologies.

In conclusion, the standardization of electric motor technology is crucial for the widespread adoption of electric vehicles. While there are challenges associated with standardization, the benefits of increased efficiency, reduced costs, and facilitated innovation make it an important goal for the industry. As the industry continues to evolve, we can expect to see more standardized electric motor technologies emerge, driving the industry forward and enabling the widespread adoption of sustainable transportation solutions.

The Future of Electric Vehicle Technology: Emerging Trends and Predictions

As the electric vehicle (EV) industry continues to evolve, several emerging trends are expected to shape the future of electric motor technical standards. One of the most significant trends is the integration of autonomous driving technology, which will require advanced electric motor designs that can provide high torque density, efficiency, and reliability. Vehicle-to-grid (V2G) technology is another trend that will play a crucial role in the future of EVs, enabling vehicles to act as energy storage devices and supply electricity back to the grid.

Advanced battery management systems will also be essential for the widespread adoption of EVs, as they will enable more efficient charging and discharging of batteries, as well as improved overall vehicle performance. The development of new battery chemistries, such as solid-state batteries, will also have a significant impact on electric motor technical standards, as they will require new designs and configurations to optimize their performance.

In addition to these trends, the increasing focus on sustainability and environmental protection will drive the development of more efficient and environmentally friendly electric motor technologies. This may include the use of new materials, such as rare-earth-free magnets, and the development of more efficient manufacturing processes.

The convergence of these trends will require electric motor technical standards to evolve rapidly to keep pace with the changing needs of the industry. This will involve the development of new standards for autonomous driving, V2G technology, and advanced battery management systems, as well as the revision of existing standards to reflect the latest technological advancements.

As the EV industry continues to grow and evolve, it is essential that electric motor technical standards keep pace with the latest trends and innovations. By doing so, the industry can ensure that EVs are safe, efficient, and environmentally friendly, and that they meet the needs of consumers and businesses alike. The future of electric vehicle technology is exciting and rapidly evolving, and electric motor technical standards will play a critical role in shaping its development.

Conclusion: The Road Ahead for Electric Vehicle Technical Standards

In conclusion, the future of electric vehicle technology is exciting and rapidly evolving, with emerging trends like autonomous driving, vehicle-to-grid (V2G) technology, and advanced battery management systems set to shape the development of electric motor technical standards. As the industry continues to grow and mature, it is essential that technical standards keep pace with the latest innovations and advancements.

The importance of ongoing innovation and standardization in electric vehicle technology cannot be overstated. By working together to develop and implement standardized technical specifications, industry stakeholders can ensure that electric vehicles are safe, efficient, and environmentally friendly, and that they meet the needs of consumers and businesses alike.

As we look to the future, it is clear that electric motor technical standards will play a critical role in shaping the development of the electric vehicle industry. By staying ahead of the curve and anticipating emerging trends and innovations, industry stakeholders can ensure that electric vehicles continue to improve and evolve, and that they remain a viable and sustainable option for transportation.

Ultimately, the widespread adoption of electric vehicles will depend on the development of standardized technical specifications that ensure safety, efficiency, and interoperability. By working together to achieve this goal, industry stakeholders can help to create a more sustainable and environmentally friendly transportation system, and ensure a bright future for electric vehicle technology.

The electric vehicle and electric motor technical standards trends are expected to continue to evolve and improve in the coming years, with new innovations and advancements emerging all the time. As the industry continues to grow and mature, it is essential that technical standards keep pace with the latest developments, and that industry stakeholders work together to ensure a safe, efficient, and sustainable future for electric vehicle technology.