Understanding the Importance of Electric Motor Testing and Validation

Electric vehicles (EVs) are becoming increasingly popular, and their reliability and performance are crucial for widespread adoption. One critical aspect of ensuring EV reliability and performance is electric motor testing and validation. Electric motor testing and validation standards are essential for guaranteeing the safety, efficiency, and customer satisfaction of EVs. These standards provide a framework for manufacturers to test and validate their electric motors, ensuring they meet the required specifications and performance criteria.

The importance of electric motor testing and validation cannot be overstated. A faulty or underperforming electric motor can lead to reduced vehicle efficiency, increased energy consumption, and compromised safety. Moreover, electric motor failures can result in costly repairs, damage to the vehicle’s electrical system, and even accidents. Therefore, it is essential to conduct thorough testing and validation of electric motors to ensure they meet the required standards.

Electric motor testing and validation standards, such as those set by the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE), provide a comprehensive framework for testing and validating electric motors. These standards cover various aspects of electric motor performance, including efficiency, power output, and durability. By adhering to these standards, manufacturers can ensure their electric motors meet the required specifications and performance criteria, reducing the risk of failures and ensuring customer satisfaction.

In addition to ensuring safety and performance, electric motor testing and validation standards also play a critical role in reducing energy consumption and environmental impact. By optimizing electric motor efficiency, manufacturers can reduce energy consumption, lower emissions, and minimize the environmental footprint of EVs. This is particularly important, as the demand for EVs continues to grow, and the need for sustainable and environmentally friendly transportation solutions becomes increasingly pressing.

In conclusion, electric motor testing and validation standards are essential for ensuring the reliability and performance of electric vehicles. By adhering to these standards, manufacturers can guarantee the safety, efficiency, and customer satisfaction of their EVs, while also reducing energy consumption and environmental impact. As the EV market continues to evolve, the importance of electric motor testing and validation standards will only continue to grow.

Key Standards for Electric Motor Testing and Validation

Electric motor testing and validation standards play a crucial role in ensuring the reliability and performance of electric vehicles. These standards provide a framework for manufacturers to test and validate their electric motors, ensuring they meet the required specifications and performance criteria. Several organizations, including the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE), have established standards for electric motor testing and validation.

The IEC has published several standards related to electric motor testing and validation, including IEC 60034-1, which outlines the general requirements for electric motors, and IEC 60034-2, which provides guidelines for the testing and validation of electric motors. The SAE has also published standards, such as SAE J240, which provides guidelines for the testing and validation of electric motors for electric vehicles.

These standards cover various aspects of electric motor performance, including efficiency, power output, and durability. They also provide guidelines for testing and validation procedures, including environmental testing, vibration testing, and electromagnetic compatibility (EMC) testing. By adhering to these standards, manufacturers can ensure their electric motors meet the required specifications and performance criteria, reducing the risk of failures and ensuring customer satisfaction.

In addition to the IEC and SAE standards, other organizations, such as the American National Standards Institute (ANSI) and the European Committee for Electrotechnical Standardization (CENELEC), have also published standards related to electric motor testing and validation. These standards provide a comprehensive framework for manufacturers to test and validate their electric motors, ensuring they meet the required specifications and performance criteria.

Compliance with electric motor testing and validation standards is essential for ensuring the reliability and performance of electric vehicles. Manufacturers must ensure their electric motors meet the required specifications and performance criteria, as outlined in the relevant standards. This includes conducting thorough testing and validation procedures, including environmental testing, vibration testing, and EMC testing.

By adhering to electric motor testing and validation standards, manufacturers can ensure their electric motors meet the required specifications and performance criteria, reducing the risk of failures and ensuring customer satisfaction. This is particularly important, as the demand for electric vehicles continues to grow, and the need for reliable and efficient electric motors becomes increasingly pressing.

How to Conduct Thorough Electric Motor Testing and Validation

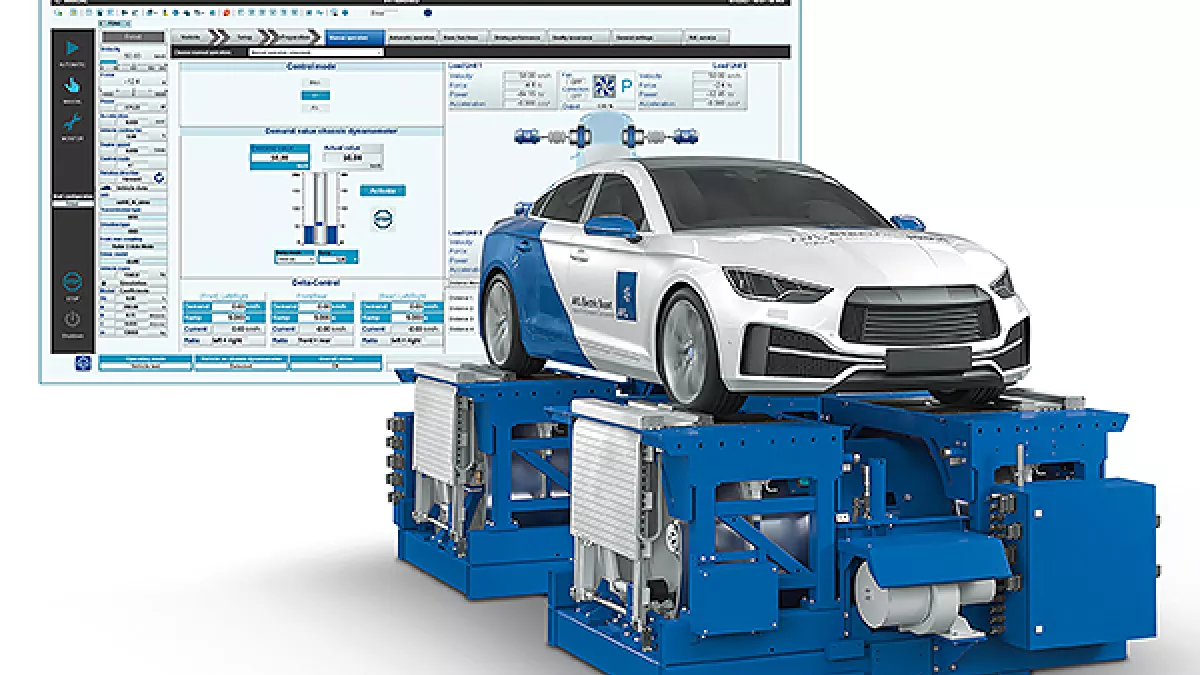

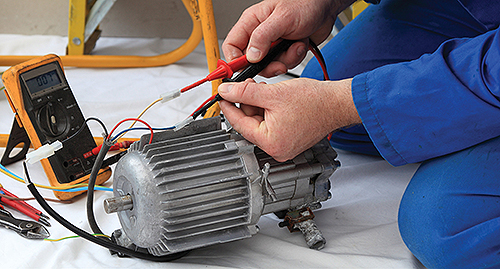

Conducting thorough electric motor testing and validation is crucial to ensure the reliability and performance of electric vehicles. A comprehensive testing and validation process involves several steps, including performance testing, durability testing, and environmental testing. In this section, we will provide a step-by-step guide on how to conduct thorough electric motor testing and validation.

Performance testing is the first step in the testing and validation process. This involves testing the electric motor’s performance under various operating conditions, including speed, torque, and power output. The goal of performance testing is to ensure that the electric motor meets the required specifications and performance criteria.

Durability testing is the next step in the testing and validation process. This involves testing the electric motor’s durability under various operating conditions, including temperature, vibration, and humidity. The goal of durability testing is to ensure that the electric motor can withstand the rigors of real-world operating conditions.

Environmental testing is the final step in the testing and validation process. This involves testing the electric motor’s performance under various environmental conditions, including temperature, humidity, and altitude. The goal of environmental testing is to ensure that the electric motor can operate reliably in a variety of environmental conditions.

In addition to these tests, it is also important to conduct electromagnetic compatibility (EMC) testing and vibration testing. EMC testing ensures that the electric motor does not emit electromagnetic interference that can affect other electrical systems in the vehicle. Vibration testing ensures that the electric motor can withstand the vibrations and shocks that occur during normal vehicle operation.

It is also important to note that electric motor testing and validation should be conducted in accordance with relevant standards and regulations, such as those set by the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE). These standards provide a framework for testing and validation, ensuring that electric motors meet the required specifications and performance criteria.

By following these steps and conducting thorough electric motor testing and validation, manufacturers can ensure that their electric motors meet the required specifications and performance criteria, reducing the risk of failures and ensuring customer satisfaction. This is particularly important, as the demand for electric vehicles continues to grow, and the need for reliable and efficient electric motors becomes increasingly pressing.

In conclusion, conducting thorough electric motor testing and validation is crucial to ensure the reliability and performance of electric vehicles. By following the steps outlined in this section, manufacturers can ensure that their electric motors meet the required specifications and performance criteria, reducing the risk of failures and ensuring customer satisfaction.

Electric Vehicle Testing and Validation: A Holistic Approach

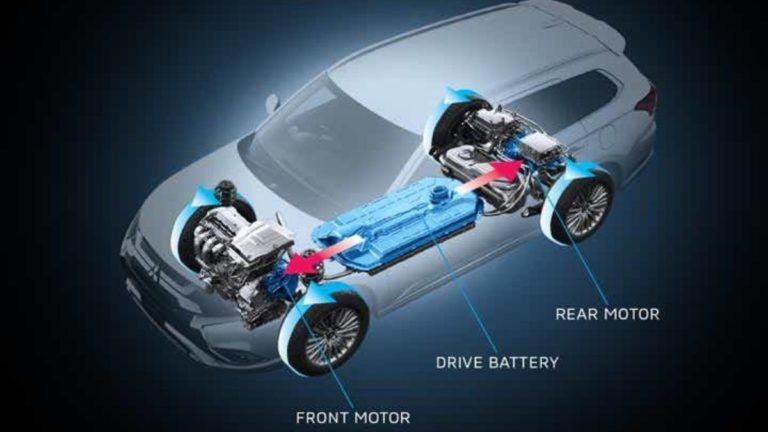

Electric vehicle testing and validation is a complex process that requires a holistic approach to ensure the reliability and performance of the vehicle. A holistic approach involves considering all the components and systems of the vehicle, including the electric motor, battery, charging system, and electrical infrastructure. This approach ensures that the vehicle operates efficiently, safely, and reliably, and meets the required standards and regulations.

One of the key factors to consider in a holistic approach to electric vehicle testing and validation is battery performance. The battery is a critical component of the electric vehicle, and its performance has a significant impact on the overall performance of the vehicle. Battery testing and validation should include tests such as capacity testing, voltage testing, and charging and discharging testing.

Another important factor to consider is the charging system. The charging system should be designed to charge the battery efficiently and safely, and should be tested and validated to ensure that it meets the required standards and regulations. Charging system testing and validation should include tests such as charging speed testing, charging efficiency testing, and safety testing.

Electrical infrastructure is also a critical component of the electric vehicle, and should be tested and validated to ensure that it meets the required standards and regulations. Electrical infrastructure testing and validation should include tests such as electrical safety testing, electrical performance testing, and electromagnetic compatibility (EMC) testing.

In addition to these factors, a holistic approach to electric vehicle testing and validation should also consider the electric motor, transmission, and other components and systems of the vehicle. The electric motor should be tested and validated to ensure that it meets the required standards and regulations, and the transmission should be tested and validated to ensure that it operates efficiently and reliably.

A holistic approach to electric vehicle testing and validation requires a comprehensive testing and validation plan that includes all the components and systems of the vehicle. This plan should include a range of tests and validation procedures, including performance testing, durability testing, and environmental testing. By taking a holistic approach to electric vehicle testing and validation, manufacturers can ensure that their vehicles operate efficiently, safely, and reliably, and meet the required standards and regulations.

By considering all the components and systems of the electric vehicle, a holistic approach to testing and validation can help to identify and address potential issues and problems before they become major concerns. This approach can also help to ensure that the vehicle meets the required standards and regulations, and operates efficiently and reliably in a range of operating conditions.

In conclusion, a holistic approach to electric vehicle testing and validation is essential to ensure the reliability and performance of the vehicle. By considering all the components and systems of the vehicle, manufacturers can ensure that their vehicles operate efficiently, safely, and reliably, and meet the required standards and regulations.

Real-World Examples: Electric Vehicle Testing and Validation in Practice

Several companies in the electric vehicle industry have successfully implemented electric motor testing and validation standards in their manufacturing processes. Here are a few real-world examples:

Tesla, a leading electric vehicle manufacturer, has implemented a comprehensive testing and validation program for its electric motors. The company uses a combination of simulation tools, testing, and validation to ensure that its electric motors meet the required standards and regulations. Tesla’s testing and validation program includes performance testing, durability testing, and environmental testing, among others.

General Motors, another major electric vehicle manufacturer, has also implemented a robust testing and validation program for its electric motors. The company uses a holistic approach to testing and validation, considering all the components and systems of the vehicle, including the electric motor, battery, charging system, and electrical infrastructure. General Motors’ testing and validation program includes a range of tests, including performance testing, durability testing, and environmental testing.

Nissan, a Japanese electric vehicle manufacturer, has also implemented a comprehensive testing and validation program for its electric motors. The company uses a combination of simulation tools, testing, and validation to ensure that its electric motors meet the required standards and regulations. Nissan’s testing and validation program includes performance testing, durability testing, and environmental testing, among others.

These companies have demonstrated the importance of electric motor testing and validation in ensuring the reliability and performance of electric vehicles. By implementing comprehensive testing and validation programs, they have been able to ensure that their electric motors meet the required standards and regulations, and operate efficiently and reliably in a range of operating conditions.

In addition to these examples, other companies in the electric vehicle industry are also implementing electric motor testing and validation standards in their manufacturing processes. This includes companies such as BMW, Volkswagen, and Hyundai, among others. These companies are using a range of testing and validation methods, including simulation tools, testing, and validation, to ensure that their electric motors meet the required standards and regulations.

By implementing electric motor testing and validation standards, these companies are able to ensure that their electric vehicles operate efficiently and reliably, and meet the required standards and regulations. This is critical for ensuring customer satisfaction, reducing warranty claims, and improving the overall reputation of the company.

In conclusion, electric motor testing and validation is a critical process in the electric vehicle industry. By implementing comprehensive testing and validation programs, companies can ensure that their electric motors meet the required standards and regulations, and operate efficiently and reliably in a range of operating conditions.

Common Challenges and Solutions in Electric Motor Testing and Validation

Electric motor testing and validation can be a complex and challenging process, with several common challenges that need to be addressed. One of the main challenges is ensuring test accuracy and reliability, as electric motors are highly sensitive to environmental and operating conditions. Another challenge is ensuring that the testing and validation process is comprehensive and covers all the necessary aspects of the electric motor’s performance.

One solution to these challenges is to use advanced testing and validation techniques, such as simulation tools and modeling. These techniques can help to ensure that the electric motor is tested and validated under a wide range of operating conditions, and can help to identify potential issues and problems before they become major concerns.

Another solution is to use standardized testing and validation protocols, such as those set by organizations such as the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE). These protocols can help to ensure that the testing and validation process is comprehensive and consistent, and can help to ensure that the electric motor meets the required standards and regulations.

In addition to these solutions, it is also important to ensure that the testing and validation process is well-documented and transparent. This can help to ensure that the results of the testing and validation process are accurate and reliable, and can help to build trust and confidence in the electric motor’s performance.

Another common challenge in electric motor testing and validation is ensuring that the testing and validation process is efficient and cost-effective. One solution to this challenge is to use automated testing and validation tools, which can help to reduce the time and cost of the testing and validation process.

Finally, it is also important to ensure that the testing and validation process is continuous and ongoing, rather than a one-time event. This can help to ensure that the electric motor continues to meet the required standards and regulations over time, and can help to identify potential issues and problems before they become major concerns.

By addressing these common challenges and using the solutions outlined above, electric motor manufacturers can ensure that their products meet the required standards and regulations, and can help to build trust and confidence in the electric motor’s performance.

In conclusion, electric motor testing and validation is a critical process that requires careful attention to detail and a comprehensive approach. By using advanced testing and validation techniques, standardized testing and validation protocols, and automated testing and validation tools, electric motor manufacturers can ensure that their products meet the required standards and regulations, and can help to build trust and confidence in the electric motor’s performance.

The Future of Electric Vehicle Testing and Validation: Emerging Trends and Technologies

The electric vehicle industry is rapidly evolving, and testing and validation standards are playing a crucial role in ensuring the reliability and performance of electric vehicles. Emerging trends and technologies are transforming the way electric vehicles are tested and validated, and it’s essential to stay ahead of the curve.

One of the most significant emerging trends in electric vehicle testing and validation is the use of simulation tools. Simulation tools allow manufacturers to test and validate electric vehicles in a virtual environment, reducing the need for physical prototypes and minimizing the risk of errors. This approach also enables manufacturers to test and validate electric vehicles under a wide range of operating conditions, including extreme temperatures and weather conditions.

Artificial intelligence (AI) and machine learning (ML) are also being increasingly used in electric vehicle testing and validation. AI and ML algorithms can analyze vast amounts of data generated during testing and validation, identifying patterns and anomalies that may not be apparent to human testers. This enables manufacturers to identify and address potential issues before they become major concerns.

Another emerging trend in electric vehicle testing and validation is the use of advanced testing and validation protocols. These protocols include advanced testing methods such as electromagnetic compatibility (EMC) testing, electromagnetic interference (EMI) testing, and radio-frequency (RF) testing. These tests ensure that electric vehicles meet the required standards and regulations for electromagnetic compatibility and radio-frequency interference.

The use of big data analytics is also becoming increasingly important in electric vehicle testing and validation. Big data analytics enables manufacturers to analyze vast amounts of data generated during testing and validation, identifying trends and patterns that can inform design and development decisions.

In addition to these emerging trends and technologies, there is also a growing focus on cybersecurity in electric vehicle testing and validation. As electric vehicles become increasingly connected, the risk of cyber threats increases, and manufacturers must ensure that their vehicles are secure and protected against potential threats.

Finally, there is a growing trend towards more sustainable and environmentally friendly testing and validation methods. This includes the use of renewable energy sources, such as solar and wind power, to power testing and validation facilities, and the development of more efficient testing and validation protocols that minimize waste and reduce environmental impact.

By embracing these emerging trends and technologies, electric vehicle manufacturers can ensure that their vehicles meet the required standards and regulations, and provide a safe and reliable driving experience for customers.

In conclusion, the future of electric vehicle testing and validation is exciting and rapidly evolving. Emerging trends and technologies are transforming the way electric vehicles are tested and validated, and it’s essential for manufacturers to stay ahead of the curve to remain competitive.

Best Practices for Ensuring Compliance with Electric Motor Testing and Validation Standards

Ensuring compliance with electric motor testing and validation standards is crucial for electric vehicle manufacturers to ensure the reliability and performance of their vehicles. Here are some best practices to follow:

Documentation is key to ensuring compliance with electric motor testing and validation standards. Manufacturers should maintain detailed records of all testing and validation activities, including test results, test procedures, and test equipment used. This documentation should be easily accessible and up-to-date.

Training is also essential to ensure compliance with electric motor testing and validation standards. Manufacturers should provide regular training to their employees on the latest testing and validation procedures, as well as on the use of new technologies and equipment.

Continuous improvement is also critical to ensuring compliance with electric motor testing and validation standards. Manufacturers should regularly review and update their testing and validation procedures to ensure they are aligned with the latest standards and regulations.

In addition to these best practices, manufacturers should also ensure that their testing and validation facilities are equipped with the latest technologies and equipment. This includes the use of advanced testing and validation tools, such as simulation software and data analytics tools.

Manufacturers should also ensure that their testing and validation procedures are aligned with the latest industry standards and regulations. This includes compliance with standards set by organizations such as the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE).

Finally, manufacturers should ensure that their testing and validation procedures are transparent and auditable. This includes maintaining detailed records of all testing and validation activities, as well as providing regular updates to stakeholders on testing and validation progress.

By following these best practices, electric vehicle manufacturers can ensure compliance with electric motor testing and validation standards, and provide a safe and reliable driving experience for their customers.

In conclusion, ensuring compliance with electric motor testing and validation standards is critical for electric vehicle manufacturers. By following best practices such as documentation, training, continuous improvement, and transparency, manufacturers can ensure that their vehicles meet the required standards and regulations, and provide a safe and reliable driving experience for their customers.