Why Thermal Management Matters in Electric Vehicles

Thermal management is a critical aspect of electric vehicle (EV) design, playing a crucial role in maintaining the performance, efficiency, and longevity of the vehicle. The electric motor and battery are the primary components that generate heat in an EV, and if not managed properly, can lead to reduced performance, decreased range, and even safety issues. Effective thermal management is essential to ensure the optimal operation of the electric motor and battery, thereby enhancing the overall driving experience.

The impact of thermal management on electric vehicle performance cannot be overstated. When the electric motor and battery operate within their optimal temperature ranges, the vehicle achieves better acceleration, improved efficiency, and increased range. Conversely, high temperatures can lead to reduced motor efficiency, decreased battery life, and increased risk of overheating. Furthermore, thermal management also affects the vehicle’s charging system, as high temperatures can slow down the charging process and reduce the overall efficiency of the system.

In addition to its impact on performance, thermal management also plays a critical role in ensuring the safety of the vehicle and its occupants. Overheating can lead to a range of safety issues, including electrical fires, explosions, and even accidents. Therefore, it is essential to implement effective thermal management strategies to prevent such incidents and ensure the safe operation of the vehicle.

Fortunately, advances in electric vehicle and electric motor thermal management have led to the development of innovative solutions that can effectively mitigate the effects of heat on EV performance. These solutions include the use of advanced materials, such as thermal interface materials, and the implementation of sophisticated cooling systems, such as liquid cooling and air cooling. By leveraging these technologies, EV manufacturers can create vehicles that not only perform optimally but also provide a safe and reliable driving experience.

In conclusion, thermal management is a vital aspect of electric vehicle design, and its impact on performance, efficiency, and safety cannot be overstated. By implementing effective thermal management strategies, EV manufacturers can create vehicles that meet the demands of an increasingly environmentally conscious market while also providing a safe and reliable driving experience.

Understanding Electric Motor Thermal Management Systems

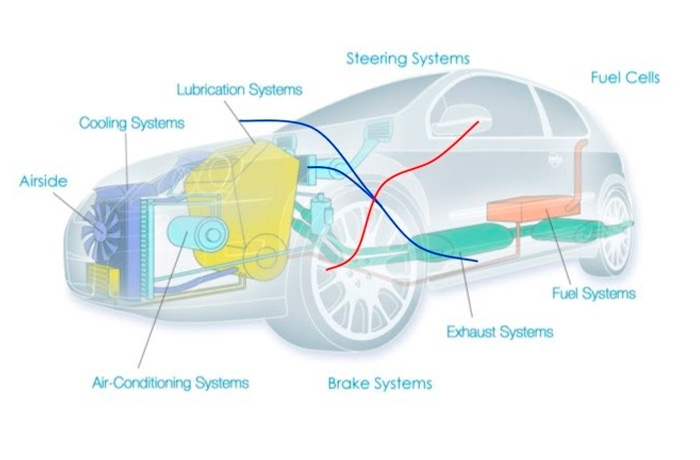

Electric motor thermal management systems are designed to regulate the temperature of the electric motor in electric vehicles, ensuring optimal performance, efficiency, and longevity. There are three primary types of thermal management systems used in electric vehicles: air-cooled, liquid-cooled, and hybrid systems.

Air-cooled systems use air to dissipate heat from the electric motor, typically through the use of heat sinks, fans, or other air-cooling technologies. These systems are relatively simple and cost-effective, but may not be as effective in high-performance or high-temperature applications. The Nissan Leaf, for example, uses an air-cooled thermal management system to regulate its electric motor temperature.

Liquid-cooled systems, on the other hand, use a liquid coolant to absorb heat from the electric motor and transfer it to a heat exchanger, where it is dissipated. These systems are more effective than air-cooled systems, especially in high-performance applications, but are also more complex and expensive. The Tesla Model S, for instance, uses a liquid-cooled thermal management system to regulate its electric motor temperature.

Hybrid systems combine elements of both air-cooled and liquid-cooled systems, using air to dissipate heat from the electric motor and a liquid coolant to absorb heat from the motor and transfer it to a heat exchanger. These systems offer a balance between simplicity and effectiveness, making them suitable for a wide range of applications. The Chevrolet Bolt, for example, uses a hybrid thermal management system to regulate its electric motor temperature.

Each type of thermal management system has its advantages and disadvantages, and the choice of system depends on the specific requirements of the electric vehicle. Factors such as performance, efficiency, cost, and packaging constraints must be considered when selecting a thermal management system. By understanding the different types of thermal management systems and their characteristics, electric vehicle manufacturers can design and develop more effective and efficient thermal management solutions.

In addition to the type of thermal management system, other factors such as motor design, winding configuration, and cooling system design also play a crucial role in electric motor thermal management. The use of advanced materials, such as high-temperature superconductors, and innovative cooling technologies, such as spray cooling, can also enhance the effectiveness of thermal management systems.

By optimizing electric motor thermal management, electric vehicle manufacturers can improve the performance, efficiency, and reliability of their vehicles, while also reducing the risk of overheating and increasing the overall driving range.

How to Optimize Electric Vehicle Battery Thermal Management

Optimizing electric vehicle battery thermal management is crucial to ensure the longevity and performance of the battery. A stable battery temperature is essential to maintain the battery’s health, and improper thermal management can lead to reduced battery life, decreased performance, and even safety issues.

One of the most effective ways to optimize electric vehicle battery thermal management is through the use of thermal interface materials (TIMs). TIMs are designed to facilitate heat transfer between the battery cells and the cooling system, ensuring that the battery operates within a safe temperature range. By using high-quality TIMs, electric vehicle manufacturers can improve the overall thermal management of the battery and reduce the risk of overheating.

Battery management systems (BMS) also play a critical role in optimizing electric vehicle battery thermal management. A BMS is responsible for monitoring the battery’s state of charge, voltage, and temperature, and adjusting the charging and discharging rates accordingly. By using advanced BMS algorithms and sensors, electric vehicle manufacturers can optimize the battery’s thermal management and ensure that it operates within a safe temperature range.

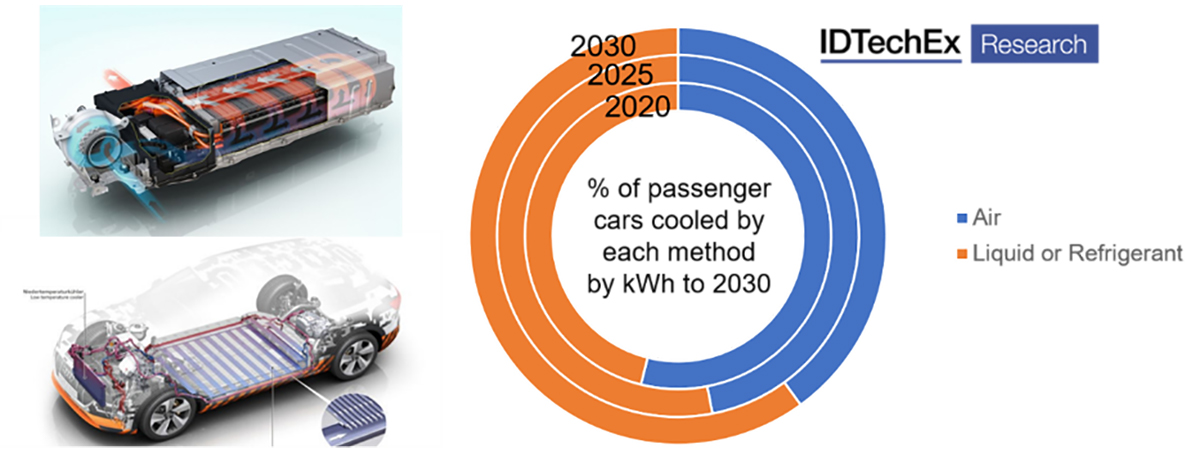

Cooling systems are also essential for optimizing electric vehicle battery thermal management. Liquid cooling systems, for example, can be used to cool the battery cells and maintain a stable temperature. Air cooling systems can also be used, but they may not be as effective in high-performance applications. By selecting the right cooling system and designing it to work in conjunction with the BMS and TIMs, electric vehicle manufacturers can optimize the battery’s thermal management and ensure optimal performance.

In addition to these technologies, electric vehicle manufacturers can also optimize battery thermal management through innovative design and engineering. For example, some manufacturers are using advanced materials and designs to reduce the thermal resistance of the battery cells and improve heat transfer. Others are using advanced simulation tools to optimize the battery’s thermal management and reduce the risk of overheating.

By optimizing electric vehicle battery thermal management, manufacturers can improve the overall performance and efficiency of the vehicle, while also reducing the risk of safety issues and improving the battery’s longevity. By using a combination of TIMs, BMS, cooling systems, and innovative design and engineering, electric vehicle manufacturers can create vehicles that meet the demands of an increasingly environmentally conscious market.

Furthermore, optimizing electric vehicle battery thermal management can also have a positive impact on the environment. By reducing the risk of overheating and improving the battery’s longevity, electric vehicle manufacturers can reduce the need for replacement batteries and minimize waste. This can help to reduce the environmental impact of electric vehicles and make them a more sustainable option for consumers.

The Role of Electric Motor Design in Thermal Management

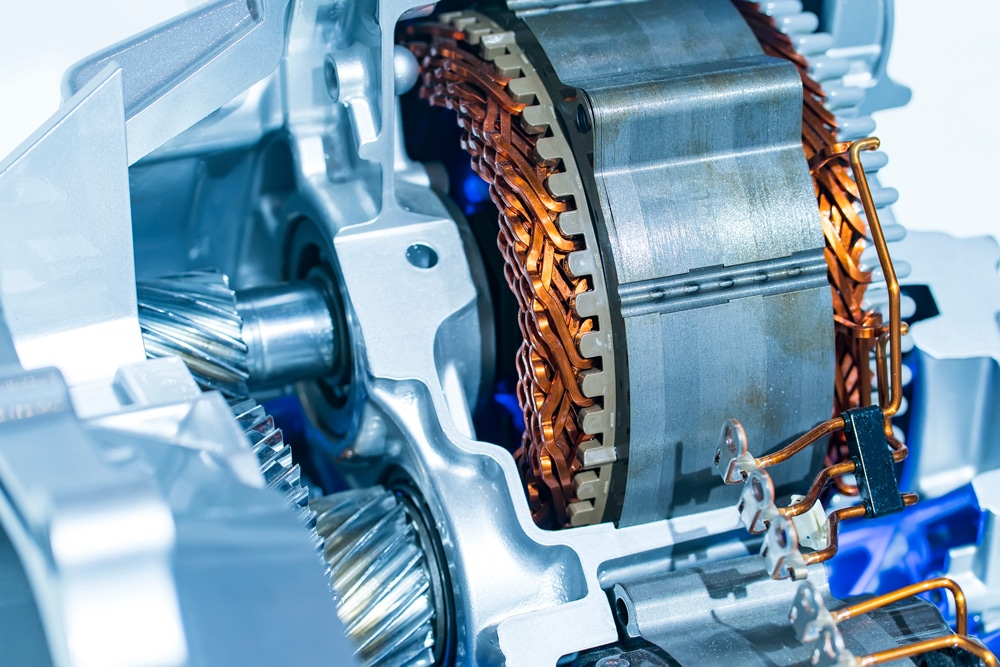

Electric motor design plays a crucial role in thermal management, as it directly affects the motor’s efficiency, power density, and heat generation. The design of the motor can impact the thermal management of the electric vehicle, and therefore, it is essential to consider the thermal aspects of motor design during the development process.

One of the key factors that affect thermal management in electric motor design is the motor topology. Different motor topologies, such as induction motors, permanent magnet motors, and switched reluctance motors, have different thermal characteristics. For example, induction motors tend to generate more heat than permanent magnet motors, due to the presence of a rotor and the resulting friction and windage losses.

Winding configuration is another critical factor that affects thermal management in electric motor design. The winding configuration can impact the motor’s thermal resistance, which is the ability of the motor to dissipate heat. A well-designed winding configuration can help to reduce the motor’s thermal resistance, thereby improving its thermal management.

Cooling systems are also an essential aspect of electric motor design, as they play a critical role in thermal management. The cooling system can be designed to work in conjunction with the motor’s thermal management system, to ensure that the motor operates within a safe temperature range. For example, some electric motors use a liquid cooling system, which can be designed to circulate a coolant through the motor’s windings and bearings, to absorb and dissipate heat.

The trade-offs between motor efficiency, power density, and thermal management are also important considerations in electric motor design. For example, a motor with a high power density may generate more heat than a motor with a lower power density, due to the increased energy density. Therefore, the designer must balance the competing demands of motor efficiency, power density, and thermal management, to create a motor that meets the requirements of the electric vehicle.

In addition to these factors, the designer must also consider the thermal management of the motor’s bearings and gearbox. The bearings and gearbox can generate heat due to friction and windage losses, and therefore, must be designed to operate within a safe temperature range. This can be achieved through the use of advanced materials and designs, such as ceramic bearings and gearbox cooling systems.

By considering the thermal aspects of electric motor design, designers can create motors that are optimized for thermal management, and therefore, can improve the overall performance and efficiency of the electric vehicle. This can be achieved through the use of advanced materials and designs, such as high-temperature superconductors and advanced cooling systems.

Real-World Examples of Effective Electric Vehicle Thermal Management

The Tesla Model S is a prime example of effective electric vehicle thermal management. The vehicle’s electric motor is cooled by a liquid cooling system, which is designed to maintain a stable temperature even during high-performance driving. The cooling system is also integrated with the vehicle’s battery management system, which helps to regulate the battery’s temperature and optimize its performance.

The Chevrolet Bolt is another example of effective electric vehicle thermal management. The vehicle’s electric motor is cooled by a combination of air and liquid cooling systems, which work together to maintain a stable temperature. The cooling system is also designed to optimize the vehicle’s range and efficiency, by reducing the energy required to cool the motor and battery.

The Nissan Leaf is a third example of effective electric vehicle thermal management. The vehicle’s electric motor is cooled by a liquid cooling system, which is designed to maintain a stable temperature even during high-performance driving. The cooling system is also integrated with the vehicle’s battery management system, which helps to regulate the battery’s temperature and optimize its performance.

In each of these examples, the thermal management system is designed to optimize the vehicle’s performance and efficiency, while also ensuring the safety and reliability of the electric motor and battery. By analyzing these examples, we can gain insights into the strategies and technologies used to achieve effective thermal management in electric vehicles.

One of the key strategies used in these examples is the integration of the thermal management system with the vehicle’s battery management system. This allows the thermal management system to optimize the battery’s temperature and performance, while also ensuring the safety and reliability of the battery.

Another key strategy used in these examples is the use of advanced cooling technologies, such as liquid cooling systems. These systems are designed to maintain a stable temperature even during high-performance driving, and can help to optimize the vehicle’s range and efficiency.

By analyzing these examples, we can also gain insights into the challenges and opportunities associated with electric vehicle thermal management. For example, the need to balance the competing demands of motor efficiency, power density, and thermal management is a key challenge in electric vehicle design.

However, the opportunities associated with electric vehicle thermal management are also significant. By optimizing the thermal management system, electric vehicle manufacturers can improve the vehicle’s performance and efficiency, while also ensuring the safety and reliability of the electric motor and battery.

Thermal Management Challenges in Electric Vehicle Charging Systems

Electric vehicle charging systems pose unique thermal management challenges, particularly when it comes to high-power charging. High-power charging can cause a significant increase in battery temperature, which can impact the battery’s performance, efficiency, and lifespan.

One of the main challenges associated with high-power charging is the need for advanced cooling systems. Traditional cooling systems may not be sufficient to handle the high heat flux generated during high-power charging, and therefore, more advanced cooling systems are required.

Another challenge is the impact of high-power charging on the battery’s state of charge. High-power charging can cause a rapid increase in the battery’s state of charge, which can lead to overheating and reduced battery life.

To address these challenges, electric vehicle manufacturers are developing advanced cooling systems and thermal management strategies. For example, some manufacturers are using liquid cooling systems that can handle high heat flux and maintain a stable battery temperature during high-power charging.

Other manufacturers are developing advanced battery management systems that can optimize the battery’s state of charge and reduce the risk of overheating during high-power charging. These systems use advanced algorithms and sensors to monitor the battery’s temperature and state of charge, and adjust the charging rate accordingly.

In addition to these solutions, researchers are also exploring new materials and technologies that can improve the thermal management of electric vehicle charging systems. For example, some researchers are developing advanced thermal interface materials that can improve the heat transfer between the battery and the cooling system.

Others are exploring the use of phase change materials that can absorb and release heat during the charging process, reducing the risk of overheating and improving the overall efficiency of the charging system.

By addressing the thermal management challenges associated with electric vehicle charging systems, manufacturers can improve the performance, efficiency, and lifespan of their vehicles, and provide a better driving experience for their customers.

Furthermore, the development of advanced thermal management strategies and technologies can also enable the widespread adoption of high-power charging, which is critical for the growth of the electric vehicle market.

Future Directions in Electric Vehicle Thermal Management

The future of electric vehicle thermal management is exciting and rapidly evolving. As the demand for electric vehicles continues to grow, manufacturers are investing heavily in research and development to improve the efficiency, performance, and range of their vehicles.

One of the key areas of focus is the development of new materials and technologies that can improve the thermal management of electric vehicles. For example, researchers are exploring the use of advanced thermal interface materials that can improve the heat transfer between the battery and the cooling system.

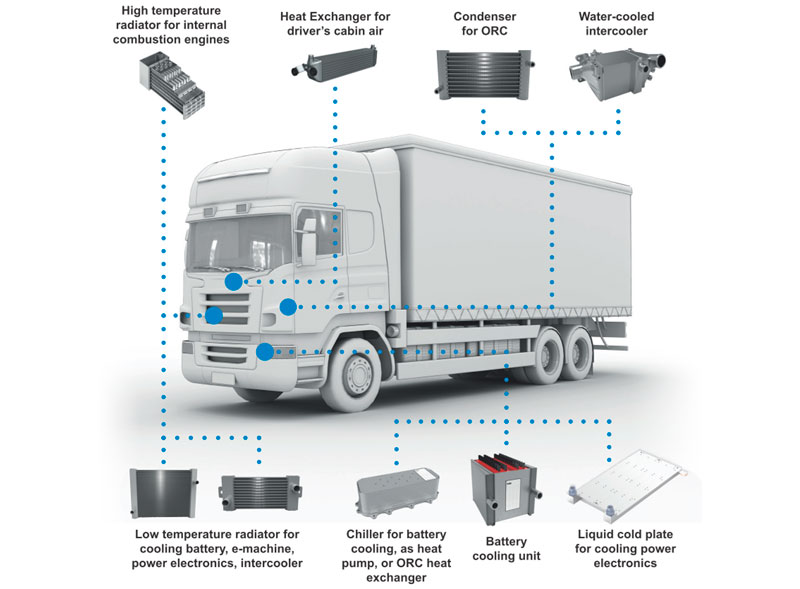

Another area of focus is the development of new system architectures that can optimize the thermal management of electric vehicles. For example, some manufacturers are exploring the use of distributed cooling systems that can cool the battery and electric motor simultaneously.

The use of advanced simulation tools and modeling techniques is also becoming increasingly important in the development of electric vehicle thermal management systems. These tools allow manufacturers to simulate and optimize the thermal management of their vehicles,

Future Directions in Electric Vehicle Thermal Management

The future of electric vehicle thermal management is exciting and rapidly evolving. As the demand for electric vehicles continues to grow, manufacturers are investing heavily in research and development to improve the efficiency, performance, and range of their vehicles.

One of the key areas of focus is the development of new materials and technologies that can improve the thermal management of electric vehicles. For example, researchers are exploring the use of advanced thermal interface materials that can improve the heat transfer between the battery and the cooling system.

Another area of focus is the development of new system architectures that can optimize the thermal management of electric vehicles. For example, some manufacturers are exploring the use of distributed cooling systems that can cool the battery and electric motor simultaneously.

The use of advanced simulation tools and modeling techniques is also becoming increasingly important in the development of electric vehicle thermal management systems. These tools allow manufacturers to simulate and optimize the thermal management of their vehicles,