Navigating the Complexities of the Electric Vehicle Ecosystem

The electric vehicle (EV) industry has experienced rapid growth in recent years, driven by increasing demand for sustainable and environmentally friendly transportation solutions. As the EV market continues to expand, it is essential to develop a comprehensive understanding of the electric motor value chain, a critical component of the EV ecosystem. Electric motor value chain analysis is crucial for stakeholders seeking to navigate and succeed in this complex and rapidly evolving industry. By examining the electric motor value chain, industry players can identify opportunities for innovation, optimize their operations, and make informed strategic decisions.

The electric motor value chain encompasses a range of stakeholders, including manufacturers, suppliers, and customers. Each stakeholder plays a vital role in the design, development, and delivery of electric motors, which are a critical component of EVs. A thorough analysis of the electric motor value chain can provide valuable insights into the EV ecosystem, enabling stakeholders to better understand the complex relationships and dependencies within the industry.

Conducting an electric vehicle and electric motor value chain analysis requires a deep understanding of the EV industry, its stakeholders, and the complex interactions between them. By analyzing the electric motor value chain, industry players can identify areas for improvement, optimize their operations, and develop strategies to stay ahead of the competition. In the following sections, we will delve deeper into the electric motor value chain, exploring its key components, stakeholders, and challenges.

As the EV industry continues to evolve, it is essential to stay up-to-date with the latest developments and trends in the electric motor value chain. By doing so, stakeholders can position themselves for success in this rapidly changing industry, capitalizing on opportunities for growth and innovation. In the next section, we will provide a step-by-step guide on how to conduct a value chain analysis for electric motors, including identifying key stakeholders, assessing their roles and responsibilities, and evaluating the flow of goods, services, and information.

How to Conduct a Value Chain Analysis for Electric Motors

Conducting a value chain analysis for electric motors involves a systematic approach to identifying and evaluating the key stakeholders, activities, and relationships within the electric motor value chain. This analysis is essential for stakeholders seeking to understand the complexities of the electric vehicle ecosystem and the role of electric motors within it. By following these steps, industry players can gain valuable insights into the electric motor value chain and develop strategies to optimize their operations and stay ahead of the competition.

Step 1: Identify Key Stakeholders

The first step in conducting a value chain analysis for electric motors is to identify the key stakeholders involved in the design, development, and delivery of electric motors. These stakeholders may include manufacturers, suppliers, customers, and regulatory bodies. It is essential to understand the roles and responsibilities of each stakeholder and how they interact with one another within the value chain.

Step 2: Assess Roles and Responsibilities

Once the key stakeholders have been identified, the next step is to assess their roles and responsibilities within the electric motor value chain. This involves evaluating the activities and processes performed by each stakeholder and how they contribute to the overall value chain. By understanding the roles and responsibilities of each stakeholder, industry players can identify areas for improvement and optimize their operations.

Step 3: Evaluate the Flow of Goods, Services, and Information

The final step in conducting a value chain analysis for electric motors is to evaluate the flow of goods, services, and information within the value chain. This involves examining the relationships between stakeholders and how they interact with one another. By understanding the flow of goods, services, and information, industry players can identify opportunities for innovation and growth within the value chain.

By following these steps, stakeholders can conduct a comprehensive value chain analysis for electric motors and gain valuable insights into the electric vehicle ecosystem. This analysis is essential for developing strategies to optimize operations, stay ahead of the competition, and succeed in the rapidly evolving electric vehicle industry. In the next section, we will examine the key players in the electric motor value chain and their roles, relationships, and dependencies within the value chain.

Key Players in the Electric Motor Value Chain: A Closer Look

The electric motor value chain is comprised of several key stakeholders, each playing a critical role in the design, development, and delivery of electric motors. These stakeholders can be broadly categorized into three main groups: manufacturers, suppliers, and customers.

Manufacturers are the primary producers of electric motors, responsible for designing, testing, and manufacturing these critical components. They work closely with suppliers to source raw materials, components, and technologies necessary for electric motor production. Suppliers provide a range of goods and services, including rare earth materials, copper, and advanced technologies like power electronics and control systems.

Customers, on the other hand, are the end-users of electric motors, including original equipment manufacturers (OEMs) and aftermarket customers. OEMs integrate electric motors into their products, such as electric vehicles, industrial machinery, and consumer appliances. Aftermarket customers purchase electric motors for replacement or upgrade purposes.

Understanding the roles, relationships, and dependencies between these stakeholders is essential for conducting a comprehensive electric vehicle and electric motor value chain analysis. By examining the interactions between manufacturers, suppliers, and customers, industry players can identify opportunities for innovation, optimization, and growth within the value chain.

For instance, manufacturers can work closely with suppliers to develop new technologies and materials that improve electric motor efficiency, reliability, and cost-effectiveness. Customers, in turn, can provide valuable feedback to manufacturers and suppliers, helping to drive innovation and improvement in electric motor design and performance.

By analyzing the key players in the electric motor value chain, industry stakeholders can gain a deeper understanding of the complex relationships and dependencies within the value chain. This knowledge can be used to develop strategies that optimize operations, improve performance, and drive growth in the rapidly evolving electric vehicle industry. In the next section, we will delve into the design and manufacturing process of electric motors, highlighting the importance of efficiency, reliability, and cost-effectiveness.

Electric Motor Design and Manufacturing: A Critical Component of the Value Chain

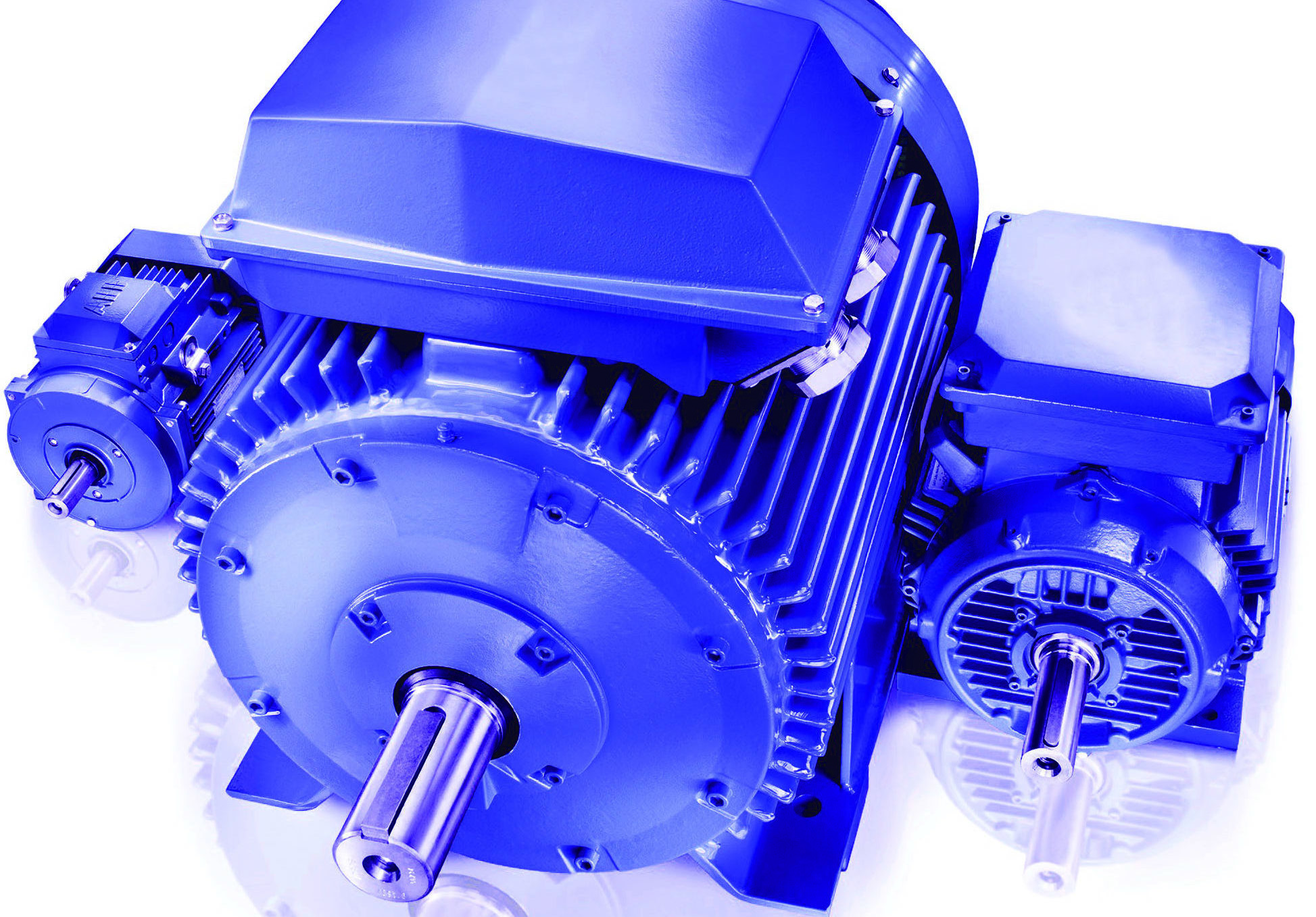

The design and manufacturing of electric motors is a critical component of the electric motor value chain. Electric motors are the heart of electric vehicles, and their performance, efficiency, and reliability are crucial to the overall success of the vehicle. As such, electric motor design and manufacturing is a key area of focus for manufacturers, suppliers, and customers alike.

Electric motor design involves a range of considerations, including the type of motor, its power output, efficiency, and reliability. Manufacturers must balance these competing demands to create an electric motor that meets the needs of the vehicle and its intended application. Advanced materials and technologies, such as rare earth magnets and power electronics, play a critical role in shaping the future of electric motor design.

The manufacturing process for electric motors is equally complex, involving a range of steps from material sourcing to final assembly. Manufacturers must ensure that their manufacturing processes are efficient, reliable, and cost-effective, while also meeting the demanding performance and quality standards of the electric vehicle industry.

One of the key challenges facing electric motor manufacturers is the need to balance efficiency, reliability, and cost-effectiveness. Electric motors must be designed to operate efficiently over a wide range of speeds and loads, while also meeting the demanding reliability and durability standards of the electric vehicle industry. At the same time, manufacturers must keep costs under control, as electric motors are a critical component of the overall vehicle cost.

Advanced materials and technologies are playing an increasingly important role in shaping the future of electric motor design and manufacturing. For example, the use of rare earth magnets has enabled the development of more efficient and compact electric motors, while advances in power electronics have improved the performance and reliability of electric motor control systems.

By understanding the design and manufacturing process for electric motors, industry stakeholders can gain a deeper appreciation for the complexities of the electric motor value chain. This knowledge can be used to develop strategies that optimize operations, improve performance, and drive growth in the rapidly evolving electric vehicle industry. In the next section, we will examine the impact of electric vehicle charging infrastructure on the electric motor value chain.

The Impact of Electric Vehicle Charging Infrastructure on the Value Chain

The development of electric vehicle charging infrastructure is a critical component of the electric motor value chain. As the demand for electric vehicles continues to grow, the need for reliable and efficient charging infrastructure becomes increasingly important. The availability and accessibility of charging infrastructure can have a significant impact on the demand for electric motors and the overall electric vehicle ecosystem.

Electric vehicle charging infrastructure can be broadly categorized into two main types: Level 1 (120V) and Level 2 (240V) charging. Level 1 charging uses a standard household outlet and is typically used for overnight charging at home. Level 2 charging, on the other hand, uses a dedicated 240V charging station and is typically used for faster charging at public charging stations.

The development of electric vehicle charging infrastructure is driven by a range of factors, including government policies and regulations, technological advancements, and market demand. Governments around the world are implementing policies and regulations to encourage the adoption of electric vehicles, including investments in charging infrastructure. Technological advancements, such as the development of fast-charging systems, are also driving the growth of charging infrastructure.

The impact of electric vehicle charging infrastructure on the electric motor value chain is significant. The availability and accessibility of charging infrastructure can affect the demand for electric motors, as well as the overall efficiency and reliability of the electric vehicle. Electric motor manufacturers must consider the impact of charging infrastructure on their products, including the design and development of electric motors that can efficiently and reliably operate with different types of charging systems.

In addition, the development of electric vehicle charging infrastructure can also create new opportunities for innovation and growth within the electric motor value chain. For example, the development of fast-charging systems can create new opportunities for electric motor manufacturers to design and develop more efficient and reliable electric motors. Similarly, the growth of public charging infrastructure can create new opportunities for electric motor manufacturers to develop and supply electric motors for use in public charging stations.

By understanding the impact of electric vehicle charging infrastructure on the electric motor value chain, industry stakeholders can gain a deeper appreciation for the complexities of the electric vehicle ecosystem. This knowledge can be used to develop strategies that optimize operations, improve performance, and drive growth in the rapidly evolving electric vehicle industry. In the next section, we will examine Tesla’s electric motor value chain strategy as a case study.

Case Study: Tesla’s Electric Motor Value Chain Strategy

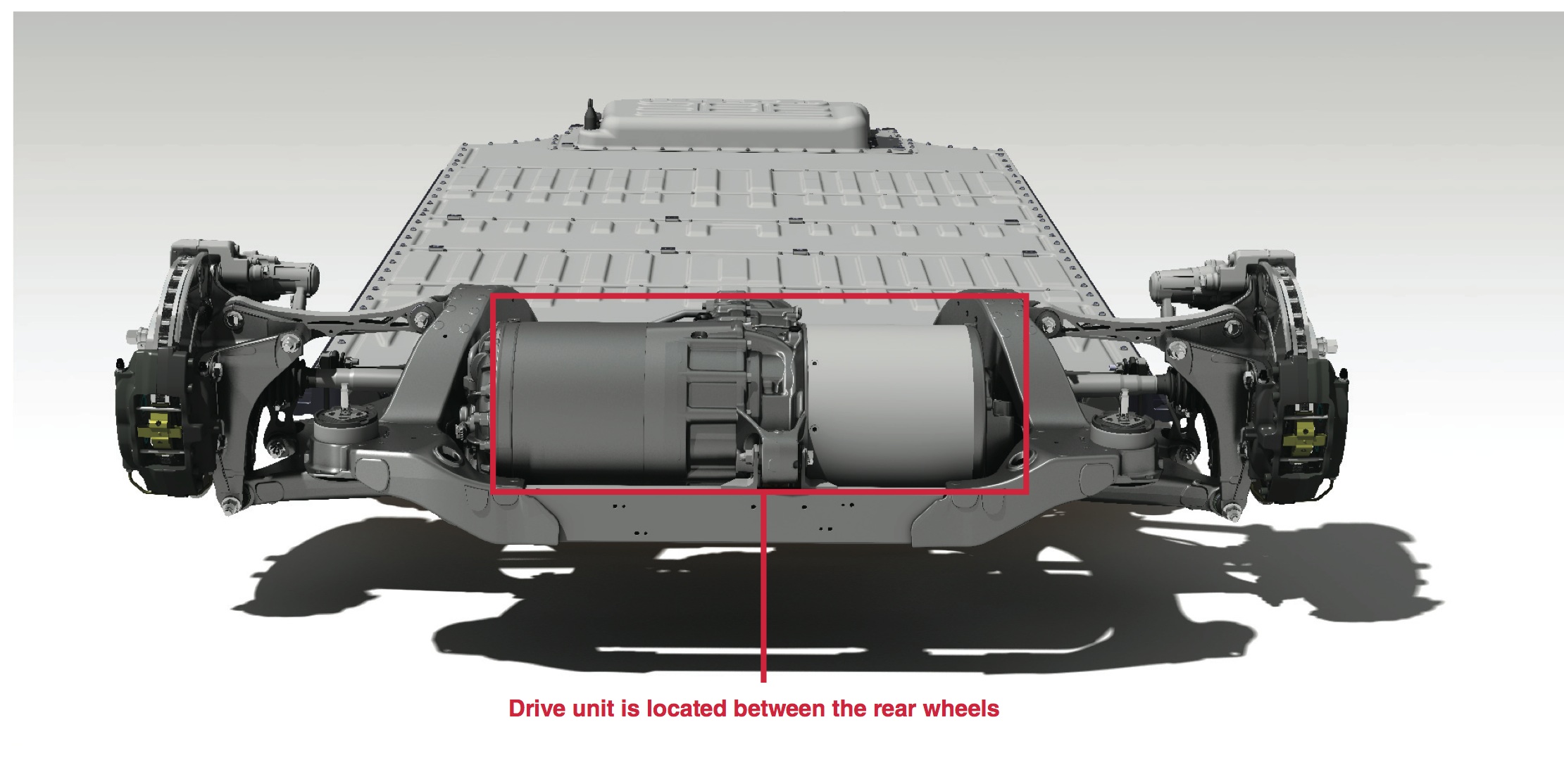

Tesla, Inc. is a leading player in the electric vehicle (EV) industry, and its electric motor value chain strategy is a key component of its success. Tesla’s approach to electric motor design, manufacturing, and supply chain management is highly integrated, with a focus on vertical integration and control over the entire value chain.

Tesla’s electric motor design is centered around its proprietary technology, which includes a unique combination of permanent magnet and induction motor designs. This approach allows Tesla to achieve high efficiency and performance, while also reducing costs and improving reliability. Tesla’s electric motors are designed and manufactured in-house, with a focus on high-volume production and economies of scale.

Tesla’s supply chain management is also highly integrated, with a focus on controlling the entire value chain from raw materials to finished goods. Tesla has established partnerships with key suppliers, including battery manufacturers and rare earth material providers, to ensure a stable and reliable supply of critical components. Tesla’s supply chain management is also highly automated, with a focus on using advanced technologies such as artificial intelligence and machine learning to optimize logistics and inventory management.

Tesla’s electric motor value chain strategy has been highly successful, with the company achieving significant cost reductions and improvements in efficiency and performance. Tesla’s approach to vertical integration and control over the entire value chain has also allowed the company to achieve high levels of quality and reliability, which has been critical to its success in the EV market.

However, Tesla’s electric motor value chain strategy is not without its challenges. The company’s focus on vertical integration and control over the entire value chain has led to significant investments in manufacturing and supply chain infrastructure, which can be costly and time-consuming to establish. Additionally, Tesla’s reliance on proprietary technology and partnerships with key suppliers can create risks and uncertainties, particularly if these partnerships are disrupted or if the technology becomes obsolete.

Despite these challenges, Tesla’s electric motor value chain strategy is a highly effective approach to achieving success in the EV market. By controlling the entire value chain and focusing on high-volume production and economies of scale, Tesla has been able to achieve significant cost reductions and improvements in efficiency and performance. As the EV market continues to evolve, Tesla’s approach to electric motor design, manufacturing, and supply chain management is likely to remain a key component of its success.

Challenges and Opportunities in the Electric Motor Value Chain

The electric motor value chain is facing a number of challenges, including supply chain disruptions, technological advancements, and regulatory changes. These challenges can impact the demand for electric motors, the efficiency and reliability of the motors, and the overall profitability of the value chain.

One of the key challenges facing the electric motor value chain is supply chain disruptions. The electric motor value chain is highly dependent on the availability of raw materials, such as rare earth metals and copper. Disruptions to the supply of these materials can impact the production of electric motors and the overall efficiency of the value chain.

Another challenge facing the electric motor value chain is technological advancements. The development of new technologies, such as advanced materials and manufacturing processes, can impact the efficiency and reliability of electric motors. These advancements can also create new opportunities for innovation and growth within the value chain.

Regulatory changes are also a challenge facing the electric motor value chain. Governments around the world are implementing regulations to encourage the adoption of electric vehicles and reduce greenhouse gas emissions. These regulations can impact the demand for electric motors and the overall profitability of the value chain.

Despite these challenges, there are also opportunities for innovation and growth within the electric motor value chain. The development of new technologies and manufacturing processes can create new opportunities for efficiency and reliability improvements. The growth of the electric vehicle market can also create new opportunities for innovation and growth within the value chain.

One of the key opportunities facing the electric motor value chain is the development of advanced materials and manufacturing processes. The use of advanced materials, such as rare earth metals and advanced ceramics, can improve the efficiency and reliability of electric motors. The development of new manufacturing processes, such as 3D printing and additive manufacturing, can also improve the efficiency and reliability of electric motors.

Another opportunity facing the electric motor value chain is the growth of the electric vehicle market. The adoption of electric vehicles is expected to continue to grow in the coming years, driven by government regulations and consumer demand. This growth can create new opportunities for innovation and growth within the value chain.

Conclusion: Harnessing the Power of the Electric Motor Value Chain

In conclusion, the electric motor value chain is a complex and rapidly evolving industry that requires a comprehensive understanding of its various stakeholders, technologies, and trends. By conducting an electric vehicle and electric motor value chain analysis, stakeholders can gain valuable insights into the EV ecosystem and identify opportunities for innovation and growth.

As the demand for electric vehicles continues to grow, the electric motor value chain will play an increasingly important role in shaping the future of the industry. By understanding the key players, technologies, and trends in the electric motor value chain, stakeholders can position themselves for success in this rapidly evolving industry.

Recommendations for stakeholders seeking to navigate and succeed in the electric motor value chain include:

- Conducting a comprehensive electric vehicle and electric motor value chain analysis to gain a deeper understanding of the industry and its various stakeholders.

- Investing in research and development to stay ahead of the curve in terms of technological advancements and innovations.

- Building strong relationships with key stakeholders, including suppliers, manufacturers, and customers, to ensure a stable and reliable supply chain.

- Staying up-to-date with regulatory changes and trends in the industry to ensure compliance and competitiveness.

By following these recommendations and staying informed about the latest developments in the electric motor value chain, stakeholders can harness the power of this complex and rapidly evolving industry and position themselves for success in the years to come.