Understanding the Basics of Electric Vehicle Drive Systems

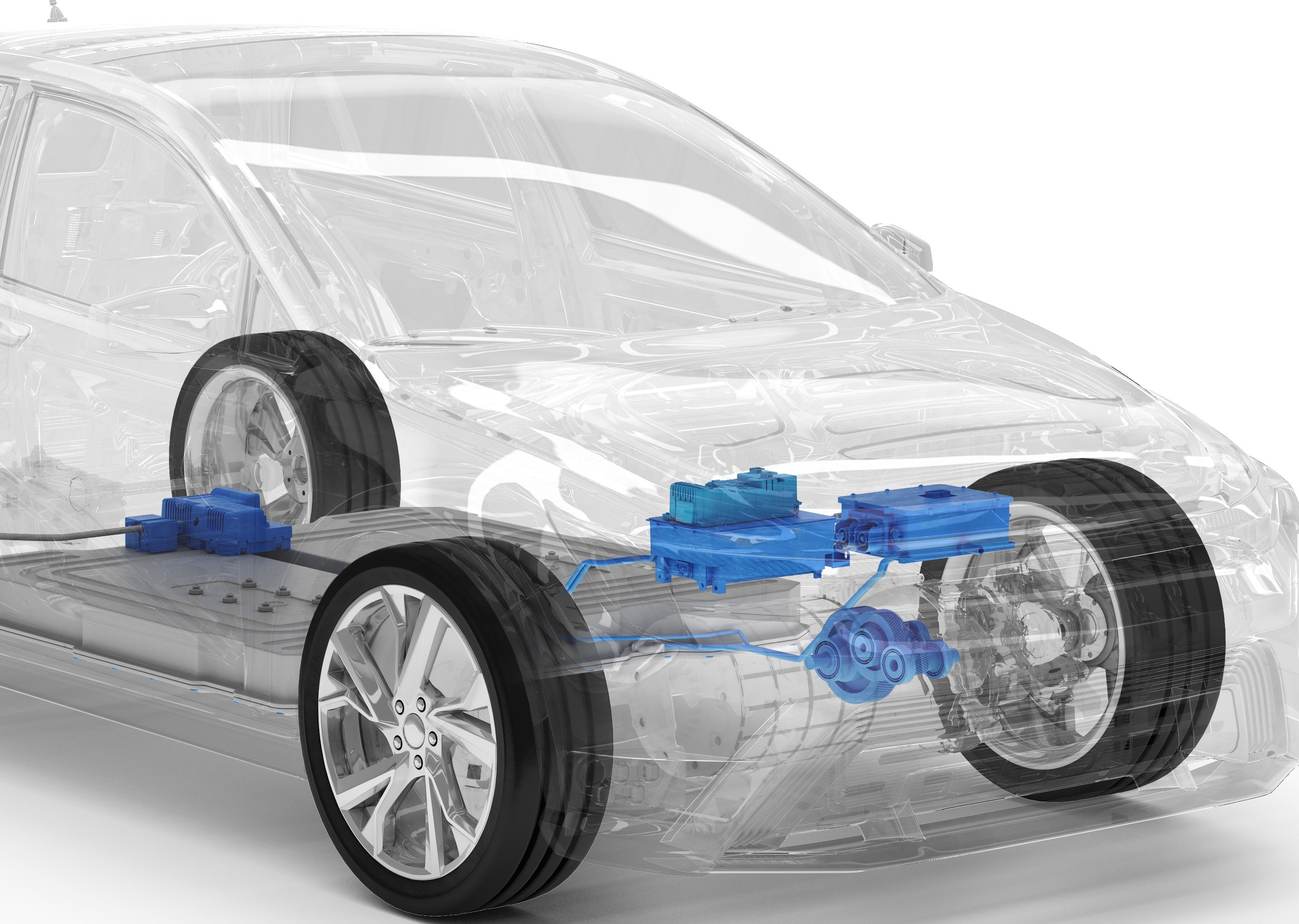

Electric vehicle drive systems are the heart of modern electric vehicles, enabling them to move efficiently and effectively. At its core, an electric vehicle drive system consists of an electric motor, a power electronics controller, and a battery pack. The electric motor converts electrical energy from the battery pack into mechanical energy, propelling the vehicle forward. The power electronics controller manages the flow of electrical energy between the battery pack and the electric motor, ensuring optimal performance and efficiency.

There are several types of electric vehicle drive systems available, including series, parallel, and combined hybrid systems. Series hybrid systems use a single electric motor, while parallel hybrid systems use multiple electric motors. Combined hybrid systems, on the other hand, use a combination of electric motors and internal combustion engines. Each type of system has its advantages and disadvantages, and the choice of system depends on the specific requirements of the vehicle.

Electric vehicle drive systems offer several benefits over traditional internal combustion engine systems, including improved efficiency, reduced emissions, and lower operating costs. Electric vehicles can achieve efficiency rates of up to 60%, compared to 20% for internal combustion engine vehicles. Additionally, electric vehicles produce zero tailpipe emissions, reducing greenhouse gas emissions and air pollution in urban areas.

However, electric vehicle drive systems also have some limitations. One of the main challenges is the limited range of electric vehicles, which can range from 200 to 300 miles on a single charge. Additionally, charging infrastructure is still in the early stages of development, making it difficult for drivers to find charging stations on long trips.

Despite these challenges, electric vehicle drive systems are rapidly advancing, with new technologies and innovations emerging every year. Advances in battery technology, power electronics, and electric motor design are improving the efficiency, range, and performance of electric vehicles. As the demand for electric vehicles continues to grow, we can expect to see even more innovative solutions in the field of electric vehicle drive systems.

How to Choose the Right Electric Vehicle Drive System for Your Needs

When selecting an electric vehicle drive system, several factors must be considered to ensure optimal performance, efficiency, and cost-effectiveness. One of the most critical factors is power output, which determines the vehicle’s acceleration, top speed, and overall driving experience. Electric vehicle drive systems with higher power output are typically more suitable for larger vehicles or those that require rapid acceleration.

Efficiency is another crucial factor to consider when choosing an electric vehicle drive system. Efficient systems minimize energy losses, reducing the load on the battery pack and increasing the vehicle’s range. Look for systems with high efficiency ratings, typically above 90%, to ensure optimal performance.

Cost is also a significant factor in selecting an electric vehicle drive system. While more expensive systems may offer better performance and efficiency, they may not be feasible for all budgets. Consider the total cost of ownership, including the cost of the system, maintenance, and replacement parts, to ensure the best value for your investment.

Compatibility with different types of electric vehicles is also essential. Ensure the drive system is compatible with your vehicle’s battery pack, power electronics, and other components to avoid compatibility issues and ensure seamless integration.

In addition to these factors, consider the drive system’s reliability, durability, and maintenance requirements. A reliable system with minimal maintenance requirements can reduce downtime and extend the lifespan of the vehicle.

When evaluating electric vehicle drive systems, consider the following key performance indicators (KPIs): power output, efficiency, cost, compatibility, reliability, and maintenance requirements. By carefully evaluating these KPIs, you can select the right electric vehicle drive system for your needs and ensure optimal performance, efficiency, and cost-effectiveness.

Some popular electric vehicle drive systems that balance these factors include the Tesla Model S’s dual-motor system, the Chevrolet Bolt’s single-motor system, and the Nissan Leaf’s e-Powertrain system. Each of these systems offers unique advantages and disadvantages, and the right choice depends on your specific needs and preferences.

The Role of Electric Motors in Electric Vehicle Drive Systems

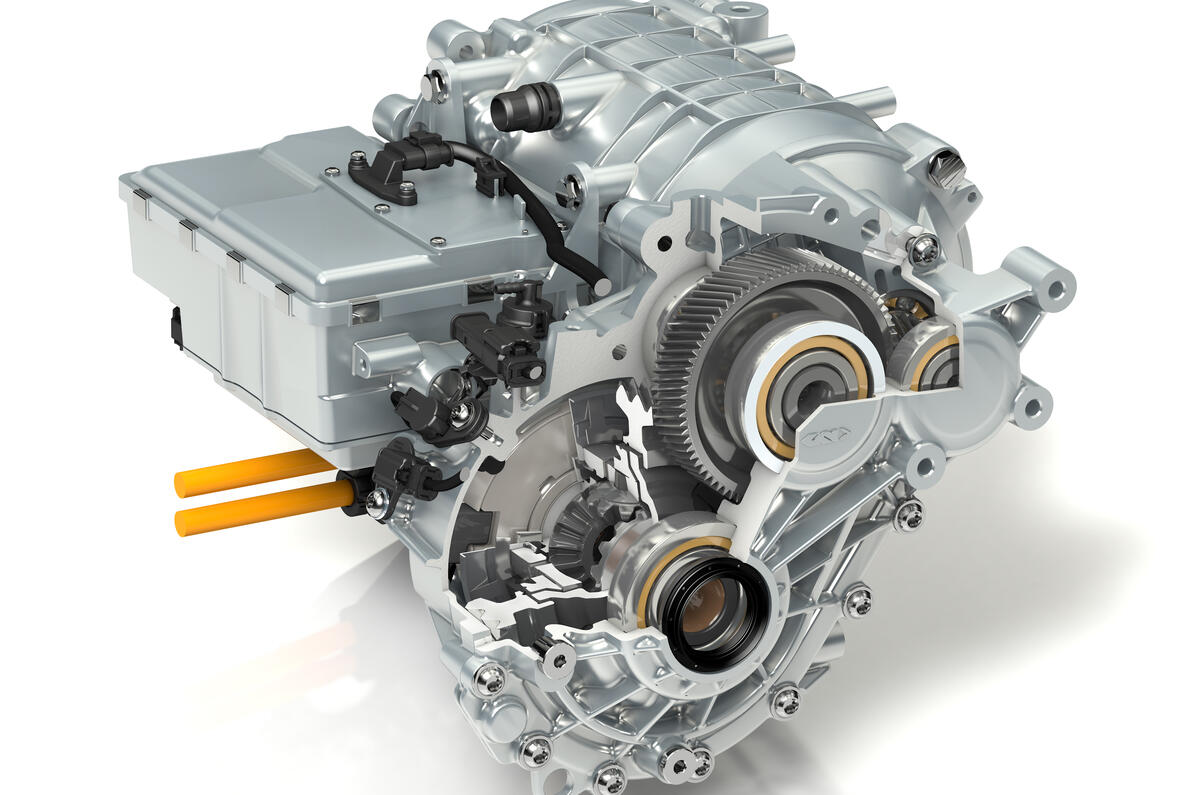

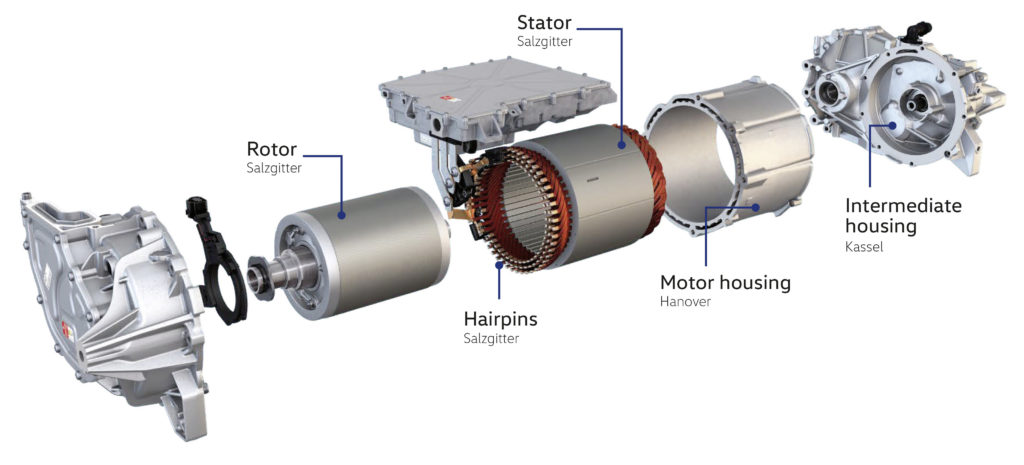

Electric motors are a crucial component of electric vehicle drive systems, responsible for converting electrical energy from the battery pack into mechanical energy that propels the vehicle forward. There are several types of electric motors used in electric vehicle drive systems, each with its own advantages and limitations.

Induction motors are one of the most common types of electric motors used in electric vehicle drive systems. They are relatively simple in design, reliable, and inexpensive to produce. However, they can be less efficient than other types of motors, particularly at low speeds.

Permanent magnet motors, on the other hand, are more efficient and offer better performance than induction motors. They use a permanent magnet as the rotor, which eliminates the need for electrical current to generate the magnetic field. This design makes them more efficient and reliable, but also more expensive to produce.

Switched reluctance motors are another type of electric motor used in electric vehicle drive systems. They are relatively simple in design and offer high efficiency, particularly at high speeds. However, they can be noisy and produce vibrations, which can affect the overall driving experience.

Electric motors play a critical role in the overall performance of electric vehicle drive systems. They must be designed to work efficiently with the battery pack, power electronics, and other components to ensure optimal performance, efficiency, and reliability. Advances in electric motor technology have improved the efficiency, power density, and reliability of electric vehicle drive systems, making them more viable for widespread adoption.

In electric vehicle drive systems, electric motors are typically designed to operate within a specific speed range, typically between 0 and 10,000 rpm. They must also be designed to handle the high currents and voltages required to propel the vehicle forward. The design of the electric motor must also take into account the thermal management system, which is responsible for cooling the motor and other components to prevent overheating.

Overall, electric motors are a critical component of electric vehicle drive systems, and their design and performance have a significant impact on the overall efficiency, reliability, and performance of the vehicle. As electric vehicle technology continues to evolve, advances in electric motor design and performance will play a critical role in shaping the future of electric vehicles.

Real-World Examples: Electric Vehicle Drive Systems in Popular Models

The Tesla Model S is a prime example of a successful electric vehicle drive system. Its dual-motor system, which combines a front and rear motor, provides exceptional acceleration and handling. The Model S’s drive system is powered by a 100 kWh battery pack, which provides an estimated range of up to 373 miles on a single charge.

The Chevrolet Bolt is another popular electric vehicle that features a advanced drive system. Its single-motor system is powered by a 60 kWh battery pack, which provides an estimated range of up to 259 miles on a single charge. The Bolt’s drive system is designed to provide exceptional efficiency and reliability, making it a great option for daily driving.

The Nissan Leaf is a pioneering electric vehicle that has been on the market for over a decade. Its single-motor system is powered by a 40 kWh battery pack, which provides an estimated range of up to 147 miles on a single charge. The Leaf’s drive system is designed to provide exceptional efficiency and reliability, making it a great option for city driving.

These examples demonstrate the diversity of electric vehicle drive systems and their capabilities. Each system is designed to meet the specific needs of the vehicle and its intended use. By understanding the strengths and weaknesses of different drive systems, manufacturers can design and develop more efficient and effective electric vehicles.

In addition to these examples, other manufacturers such as BMW, Volkswagen, and Hyundai are also developing advanced electric vehicle drive systems. These systems are designed to provide exceptional performance, efficiency, and reliability, and are expected to play a major role in the future of electric vehicles.

As the demand for electric vehicles continues to grow, the development of advanced drive systems will become increasingly important. By understanding the capabilities and limitations of different drive systems, manufacturers can design and develop more efficient and effective electric vehicles that meet the needs of consumers.

Advancements in Electric Vehicle Drive System Technology

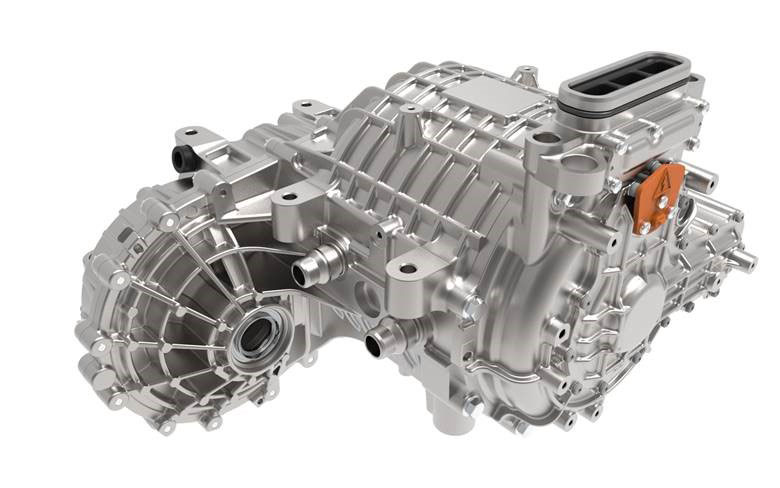

Recent advancements in electric vehicle drive system technology have significantly improved the performance, efficiency, and cost-effectiveness of electric vehicles. One of the most notable advancements is the development of more efficient electric motors, which have increased the range and performance of electric vehicles.

Another significant advancement is the development of advanced power electronics, which have improved the efficiency and reliability of electric vehicle drive systems. These advancements have enabled the widespread adoption of electric vehicles, making them a viable alternative to traditional internal combustion engine vehicles.

Improvements in battery technology have also played a crucial role in the advancement of electric vehicle drive systems. The development of more efficient and cost-effective battery chemistries, such as lithium-ion and solid-state batteries, has increased the range and performance of electric vehicles.

Additionally, advancements in thermal management systems have improved the efficiency and reliability of electric vehicle drive systems. These systems have enabled the development of more efficient and cost-effective cooling systems, which have increased the range and performance of electric vehicles.

These advancements in electric vehicle drive system technology are expected to continue, with emerging trends such as solid-state batteries and advanced power electronics expected to play a major role in the future of electric vehicles. As the demand for electric vehicles continues to grow, the development of more efficient and cost-effective drive systems will become increasingly important.

Manufacturers such as Tesla, General Motors, and Volkswagen are already investing heavily in the development of advanced electric vehicle drive systems. These investments are expected to pay off in the coming years, with the widespread adoption of electric vehicles expected to drive growth in the industry.

As the electric vehicle industry continues to evolve, it is likely that we will see even more innovative and efficient drive systems emerge. The development of advanced electric vehicle drive systems will play a crucial role in shaping the future of the industry, and it will be exciting to see what the future holds.

Challenges and Limitations of Electric Vehicle Drive Systems

Despite the many advantages of electric vehicle drive systems, there are also several challenges and limitations that must be addressed. One of the main challenges is thermal management, which is critical to ensuring the reliability and efficiency of the drive system. Electric vehicle drive systems generate a significant amount of heat, which can affect the performance and lifespan of the system.

Battery durability is another challenge facing electric vehicle drive systems. Batteries are a critical component of electric vehicles, and their durability and lifespan can have a significant impact on the overall performance of the vehicle. Manufacturers are working to develop more durable and long-lasting batteries, but this remains a significant challenge.

Charging infrastructure is also a limitation of electric vehicle drive systems. While charging infrastructure is improving, it can still be a challenge to find charging stations, particularly in rural areas. This can make it difficult for drivers to charge their vehicles on long trips, which can limit the adoption of electric vehicles.

Manufacturers and researchers are working to address these challenges and limitations. For example, some manufacturers are developing advanced thermal management systems that can help to reduce the heat generated by electric vehicle drive systems. Others are working on developing more durable and long-lasting batteries.

In addition, governments and companies are investing in the development of charging infrastructure. This includes the installation of new charging stations, as well as the development of more efficient and convenient charging systems.

Despite these challenges and limitations, electric vehicle drive systems offer many advantages over traditional internal combustion engine vehicles. They are more efficient, produce fewer emissions, and require less maintenance. As the technology continues to evolve, we can expect to see even more innovative and efficient electric vehicle drive systems emerge.

As the demand for electric vehicles continues to grow, manufacturers and researchers will need to continue to address the challenges and limitations of electric vehicle drive systems. This will require ongoing investment in research and development, as well as collaboration between manufacturers, governments, and other stakeholders.

Electric Vehicle Drive System Maintenance and Repair

Regular maintenance and repair are crucial to ensuring the optimal performance and longevity of electric vehicle drive systems. By following a few simple tips and guidelines, drivers can help to extend the life of their electric vehicle drive system and prevent costly repairs.

One of the most important maintenance tasks for electric vehicle drive systems is to regularly check and maintain the battery pack. This includes checking the battery’s state of charge, ensuring that the battery is properly secured, and keeping the battery clean and free of debris.

Another important maintenance task is to regularly inspect and maintain the electric motor. This includes checking the motor’s bearings, ensuring that the motor is properly lubricated, and keeping the motor clean and free of debris.

In addition to regular maintenance, it’s also important to be aware of common issues that can affect electric vehicle drive systems. For example, overheating can be a major issue for electric vehicle drive systems, particularly in hot weather or during high-performance driving. By being aware of these issues and taking steps to prevent them, drivers can help to extend the life of their electric vehicle drive system.

When it comes to repairing electric vehicle drive systems, it’s often best to seek the advice of a qualified mechanic or technician. These professionals have the training and expertise to diagnose and repair complex issues with electric vehicle drive systems, and can help to ensure that the system is functioning properly and efficiently.

Some common repairs that may be needed for electric vehicle drive systems include replacing worn-out components, such as bearings or seals, and upgrading system performance. By staying on top of maintenance and repairs, drivers can help to ensure that their electric vehicle drive system is running smoothly and efficiently, and can help to prevent costly repairs down the road.

Overall, regular maintenance and repair are crucial to ensuring the optimal performance and longevity of electric vehicle drive systems. By following a few simple tips and guidelines, drivers can help to extend the life of their electric vehicle drive system and prevent costly repairs.

The Future of Electric Vehicle Drive Systems: Trends and Predictions

The future of electric vehicle drive systems is exciting and rapidly evolving. Emerging trends, such as solid-state batteries and advanced power electronics, are expected to play a major role in shaping the future of electric vehicles.

Solid-state batteries, for example, have the potential to significantly improve the range and efficiency of electric vehicles. By replacing the traditional liquid electrolyte with a solid material, solid-state batteries can offer improved safety, energy density, and charging speeds.

Advanced power electronics, on the other hand, are expected to play a critical role in enabling the widespread adoption of electric vehicles. By improving the efficiency and reliability of electric vehicle drive systems, advanced power electronics can help to reduce the cost and complexity of electric vehicles, making them more accessible to a wider range of consumers.

Other emerging trends, such as autonomous driving and vehicle-to-grid (V2G) technology, are also expected to have a significant impact on the future of electric vehicle drive systems. Autonomous driving, for example, has the potential to significantly improve the safety and efficiency of electric vehicles, while V2G technology can enable electric vehicles to act as energy storage devices, providing a new source of revenue for electric vehicle owners.

As the electric vehicle industry continues to evolve, we can expect to see even more innovative and efficient electric vehicle drive systems emerge. By staying on top of the latest trends and developments, manufacturers and consumers can help to ensure that electric vehicles remain a viable and sustainable option for the future of transportation.

Overall, the future of electric vehicle drive systems is bright and exciting. With emerging trends and technologies on the horizon, we can expect to see significant improvements in the efficiency, range, and affordability of electric vehicles. As the electric vehicle industry continues to evolve, it will be interesting to see how these developments shape the future of transportation.