Understanding the Importance of Electric Vehicle Fault Detection

Electric vehicle fault detection and diagnosis is a critical aspect of ensuring the safe and reliable operation of electric vehicles (EVs). As the world shifts towards a more sustainable and environmentally friendly mode of transportation, the importance of EV fault detection and diagnosis cannot be overstated. The benefits of effective fault detection and diagnosis are numerous, including improved safety, reduced maintenance costs, and enhanced overall performance.

One of the primary concerns with EVs is the risk of electrical shock or fire due to faulty electrical systems. Effective fault detection and diagnosis can help identify potential issues before they become major problems, ensuring the safety of drivers and passengers. Additionally, EVs rely on complex electrical systems, which can be prone to faults and malfunctions. Regular fault detection and diagnosis can help prevent these issues, reducing the need for costly repairs and minimizing downtime.

Furthermore, EV fault detection and diagnosis can also help improve overall performance. By identifying and addressing faults early on, EV owners can ensure that their vehicles are running at optimal levels, which can improve fuel efficiency, reduce emissions, and enhance the overall driving experience. As the demand for EVs continues to grow, the importance of effective fault detection and diagnosis will only continue to increase.

In order to achieve effective fault detection and diagnosis, EV manufacturers and owners must invest in advanced diagnostic tools and technologies. This includes the use of specialized software and hardware, such as multimeters and oscilloscopes, which can help identify faults and malfunctions in EV electrical systems. Additionally, EV owners must also prioritize regular maintenance and inspections, which can help identify potential issues before they become major problems.

By prioritizing electric vehicle fault detection and diagnosis, EV owners and manufacturers can ensure the safe and reliable operation of EVs, while also improving overall performance and reducing maintenance costs. As the world continues to shift towards a more sustainable and environmentally friendly mode of transportation, the importance of effective fault detection and diagnosis will only continue to grow.

Common Electric Vehicle Faults: Identifying the Usual Suspects

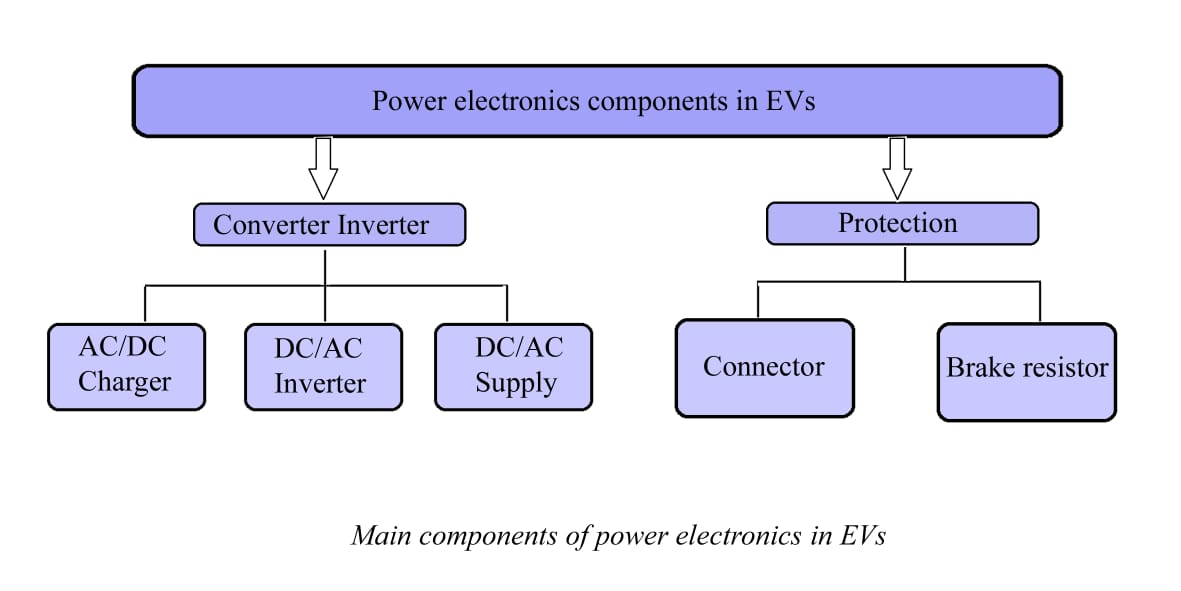

Electric vehicles (EVs) are complex machines that rely on a multitude of electrical and mechanical systems to operate efficiently. However, like any complex system, EVs are not immune to faults and malfunctions. In this section, we will discuss some of the most common electric vehicle faults, including battery management system issues, electrical motor problems, and charging system malfunctions.

Battery management system (BMS) issues are a common problem in EVs. The BMS is responsible for monitoring and controlling the battery’s state of charge, voltage, and temperature. However, faults in the BMS can lead to reduced battery performance, decreased range, and even complete system failure. For example, a faulty BMS can cause the battery to overcharge or over-discharge, leading to premature wear and tear.

Electrical motor problems are another common issue in EVs. The electric motor is responsible for propelling the vehicle, and faults in the motor can lead to reduced performance, increased energy consumption, and even complete system failure. For example, a faulty motor can cause the vehicle to vibrate excessively, leading to reduced comfort and increased wear and tear on other components.

Charging system malfunctions are also a common problem in EVs. The charging system is responsible for replenishing the battery’s energy stores, and faults in the charging system can lead to reduced charging efficiency, increased energy consumption, and even complete system failure. For example, a faulty charging system can cause the vehicle to charge slowly or not at all, leading to reduced range and increased downtime.

Real-world examples of these faults can be seen in various EV models. For instance, the Tesla Model S has been known to experience BMS issues, leading to reduced battery performance and decreased range. Similarly, the Nissan Leaf has been known to experience electrical motor problems, leading to reduced performance and increased energy consumption.

It is essential to note that these faults can be prevented or minimized with regular maintenance and inspections. EV owners should prioritize regular checks on their vehicle’s electrical and mechanical systems to identify potential issues before they become major problems. Additionally, EV manufacturers should prioritize the development of robust and reliable systems to minimize the risk of faults and malfunctions.

How to Diagnose Electric Vehicle Faults: A Step-by-Step Approach

Diagnosing electric vehicle faults requires a systematic and structured approach. In this section, we will outline a step-by-step guide to diagnosing electric vehicle faults, including the use of specialized tools and the importance of consulting manufacturer documentation.

Step 1: Gather Information

The first step in diagnosing an electric vehicle fault is to gather information about the problem. This includes collecting data on the vehicle’s performance, such as its speed, acceleration, and battery state of charge. Additionally, it is essential to consult the vehicle’s owner’s manual and manufacturer documentation to understand the vehicle’s systems and components.

Step 2: Use Specialized Tools

Specialized tools, such as multimeters and oscilloscopes, are essential for diagnosing electric vehicle faults. These tools allow technicians to measure and analyze the vehicle’s electrical systems, including the battery, motor, and charging system. For example, a multimeter can be used to measure the voltage and current of the vehicle’s electrical systems, while an oscilloscope can be used to analyze the waveform of the vehicle’s electrical signals.

Step 3: Consult Manufacturer Documentation

Manufacturer documentation is a critical resource for diagnosing electric vehicle faults. This documentation provides detailed information on the vehicle’s systems and components, including troubleshooting guides and repair procedures. Additionally, manufacturer documentation can provide information on the vehicle’s software and firmware, which can be essential for diagnosing complex faults.

Step 4: Perform Visual Inspections

Visual inspections are an essential part of diagnosing electric vehicle faults. Technicians should inspect the vehicle’s electrical systems, including the battery, motor, and charging system, to identify any signs of damage or wear. Additionally, technicians should inspect the vehicle’s software and firmware to identify any errors or anomalies.

Step 5: Analyze Data

Once the data has been collected, it is essential to analyze it to identify patterns and anomalies. This can be done using data analytics software, which can help technicians to identify trends and correlations in the data. Additionally, data analytics can be used to predict potential faults and prevent them from occurring.

By following these steps, technicians can diagnose electric vehicle faults efficiently and effectively. It is essential to remember that diagnosing electric vehicle faults requires a systematic and structured approach, and that specialized tools and manufacturer documentation are essential resources.

The Role of Data Analytics in Electric Vehicle Fault Detection

Data analytics plays a crucial role in electric vehicle fault detection and diagnosis. By analyzing data from various sources, including sensors, logs, and other data points, technicians can identify patterns and anomalies that may indicate a fault. This allows for proactive maintenance and repair, reducing downtime and improving overall vehicle performance.

Machine learning algorithms are a key component of data analytics in electric vehicle fault detection. These algorithms can be trained on large datasets to identify patterns and anomalies, and can even predict potential faults before they occur. For example, a machine learning algorithm can be trained on data from a vehicle’s battery management system to predict when a battery cell may fail.

Data visualization techniques are also essential in electric vehicle fault detection. By visualizing data in a clear and concise manner, technicians can quickly identify trends and patterns that may indicate a fault. For example, a graph showing the voltage and current of a vehicle’s electrical system can help technicians identify anomalies that may indicate a fault.

Real-world examples of data analytics in electric vehicle fault detection include the use of data analytics platforms such as Splunk or Tableau to analyze data from vehicle sensors and logs. These platforms can help technicians identify patterns and anomalies in vehicle performance data, and can even predict potential faults before they occur.

Additionally, data analytics can be used to optimize electric vehicle performance and reduce energy consumption. By analyzing data on vehicle performance and energy consumption, technicians can identify areas for improvement and optimize vehicle settings to reduce energy consumption and improve overall performance.

Some of the benefits of using data analytics in electric vehicle fault detection include:

- Improved vehicle performance and reliability

- Reduced downtime and maintenance costs

- Improved safety and reduced risk of accidents

- Optimized energy consumption and reduced environmental impact

Overall, data analytics plays a critical role in electric vehicle fault detection and diagnosis. By analyzing data from various sources and using machine learning algorithms and data visualization techniques, technicians can identify patterns and anomalies that may indicate a fault, and can even predict potential faults before they occur.

Real-World Examples: Electric Vehicle Fault Detection in Action

In this section, we will provide real-world examples of electric vehicle fault detection and diagnosis, including case studies of successful fault detection and repair. These examples will demonstrate the importance of electric vehicle fault detection and diagnosis in ensuring the safe and reliable operation of electric vehicles.

Case Study 1: Tesla Model S Battery Management System Fault

In 2019, a Tesla Model S owner reported a fault with the vehicle’s battery management system. The vehicle’s onboard computer reported a fault code indicating a problem with the battery’s state of charge. The owner took the vehicle to a Tesla service center, where technicians used specialized tools to diagnose the fault. The technicians discovered that a faulty sensor was causing the problem and replaced it with a new one. The vehicle was back on the road within a few hours, and the owner was able to continue driving safely.

Case Study 2: Nissan Leaf Charging System Malfunction

In 2018, a Nissan Leaf owner reported a fault with the vehicle’s charging system. The vehicle’s onboard computer reported a fault code indicating a problem with the charging system’s communication protocol. The owner took the vehicle to a Nissan service center, where technicians used data analytics tools to diagnose the fault. The technicians discovered that a software glitch was causing the problem and updated the vehicle’s software to resolve the issue. The vehicle was back on the road within a few days, and the owner was able to continue driving safely.

These case studies demonstrate the importance of electric vehicle fault detection and diagnosis in ensuring the safe and reliable operation of electric vehicles. By using specialized tools and data analytics techniques, technicians can quickly and accurately diagnose faults and perform repairs, minimizing downtime and ensuring the safety of drivers and passengers.

Other examples of electric vehicle fault detection and diagnosis include:

- The use of machine learning algorithms to predict battery faults in electric vehicles

- The use of data analytics to optimize electric vehicle performance and reduce energy consumption

- The use of advanced sensor technologies to detect faults in electric vehicle electrical systems

These examples demonstrate the potential of electric vehicle fault detection and diagnosis to improve the safety, reliability, and performance of electric vehicles. As the demand for electric vehicles continues to grow, the importance of electric vehicle fault detection and diagnosis will only continue to increase.

Best Practices for Electric Vehicle Maintenance and Repair

Regular maintenance and repair are crucial for ensuring the safe and reliable operation of electric vehicles. In this section, we will provide best practices for electric vehicle maintenance and repair, including tips on how to prevent common faults, how to perform routine maintenance tasks, and how to troubleshoot complex issues.

Preventing Common Faults

One of the best ways to prevent common faults in electric vehicles is to follow the manufacturer’s recommended maintenance schedule. This includes regular checks on the vehicle’s electrical systems, battery, and charging system. Additionally, drivers can take steps to prevent faults by avoiding extreme temperatures, keeping the vehicle’s software up to date, and avoiding deep discharging of the battery.

Performing Routine Maintenance Tasks

Routine maintenance tasks are essential for ensuring the safe and reliable operation of electric vehicles. These tasks include checking the vehicle’s tire pressure, brake pads, and fluid levels. Additionally, drivers should regularly inspect the vehicle’s electrical systems, battery, and charging system for signs of wear or damage.

Troubleshooting Complex Issues

Troubleshooting complex issues in electric vehicles requires a systematic and structured approach. Drivers should start by consulting the vehicle’s owner’s manual and manufacturer documentation to identify potential causes of the problem. Additionally, drivers can use specialized tools, such as multimeters and oscilloscopes, to diagnose faults in the vehicle’s electrical systems.

Best Practices for Electric Vehicle Maintenance and Repair

Some best practices for electric vehicle maintenance and repair include:

- Following the manufacturer’s recommended maintenance schedule

- Regularly inspecting the vehicle’s electrical systems, battery, and charging system

- Keeping the vehicle’s software up to date

- Avoiding extreme temperatures and deep discharging of the battery

- Using specialized tools, such as multimeters and oscilloscopes, to diagnose faults

By following these best practices, drivers can help ensure the safe and reliable operation of their electric vehicles, and prevent common faults from occurring. Additionally, regular maintenance and repair can help extend the lifespan of the vehicle’s electrical systems, battery, and charging system, and reduce the need for costly repairs.

The Future of Electric Vehicle Fault Detection: Emerging Trends and Technologies

The field of electric vehicle fault detection and diagnosis is rapidly evolving, with emerging trends and technologies that are transforming the way faults are detected and diagnosed. In this section, we will discuss some of the most promising emerging trends and technologies in electric vehicle fault detection, including the use of artificial intelligence, the Internet of Things (IoT), and advanced sensor technologies.

Artificial Intelligence (AI) in Electric Vehicle Fault Detection

AI is being increasingly used in electric vehicle fault detection and diagnosis, with applications such as predictive maintenance and fault detection. AI algorithms can analyze data from various sources, including sensors and logs, to identify patterns and anomalies that may indicate a fault. Additionally, AI can be used to optimize electric vehicle performance and reduce energy consumption.

Internet of Things (IoT) in Electric Vehicle Fault Detection

The IoT is also being used in electric vehicle fault detection and diagnosis, with applications such as remote monitoring and diagnostics. IoT sensors can be used to monitor electric vehicle systems and components, providing real-time data on performance and health. Additionally, IoT can be used to enable remote diagnostics and repair, reducing downtime and improving overall efficiency.

Advanced Sensor Technologies in Electric Vehicle Fault Detection

Advanced sensor technologies, such as lidar and radar, are being used in electric vehicle fault detection and diagnosis, with applications such as collision detection and avoidance. These sensors can provide high-resolution data on the vehicle’s surroundings, enabling advanced safety features and improving overall safety.

Emerging Trends and Technologies in Electric Vehicle Fault Detection

Some emerging trends and technologies in electric vehicle fault detection include:

- The use of blockchain technology to enable secure and transparent data sharing

- The use of 5G networks to enable high-speed data transfer and remote diagnostics

- The use of advanced materials and manufacturing techniques to improve electric vehicle performance and efficiency

These emerging trends and technologies are transforming the field of electric vehicle fault detection and diagnosis, enabling improved safety, efficiency, and performance. As the demand for electric vehicles continues to grow, the importance of electric vehicle fault detection and diagnosis will only continue to increase.

Conclusion: The Importance of Electric Vehicle Fault Detection and Diagnosis

In conclusion, electric vehicle fault detection and diagnosis is a critical aspect of ensuring the safe and reliable operation of electric vehicles. The benefits of improved safety, reduced maintenance costs, and enhanced overall performance make electric vehicle fault detection and diagnosis an essential tool for electric vehicle owners and manufacturers.

Throughout this article, we have discussed the significance of electric vehicle fault detection and diagnosis, common electric vehicle faults, and the role of data analytics in electric vehicle fault detection. We have also provided real-world examples of electric vehicle fault detection and diagnosis, and discussed emerging trends and technologies in this field.

As the demand for electric vehicles continues to grow, the importance of electric vehicle fault detection and diagnosis will only continue to increase. It is essential that electric vehicle owners and manufacturers prioritize electric vehicle fault detection and diagnosis to ensure the safe and reliable operation of electric vehicles.

By investing in electric vehicle fault detection and diagnosis, electric vehicle owners and manufacturers can:

- Improve safety and reduce the risk of accidents

- Reduce maintenance costs and downtime

- Enhance overall performance and efficiency

- Improve customer satisfaction and loyalty

In summary, electric vehicle fault detection and diagnosis is a critical aspect of ensuring the safe and reliable operation of electric vehicles. By prioritizing electric vehicle fault detection and diagnosis, electric vehicle owners and manufacturers can improve safety, reduce maintenance costs, and enhance overall performance.