Unlocking the Potential of Electric Vehicles through Efficient Power Management

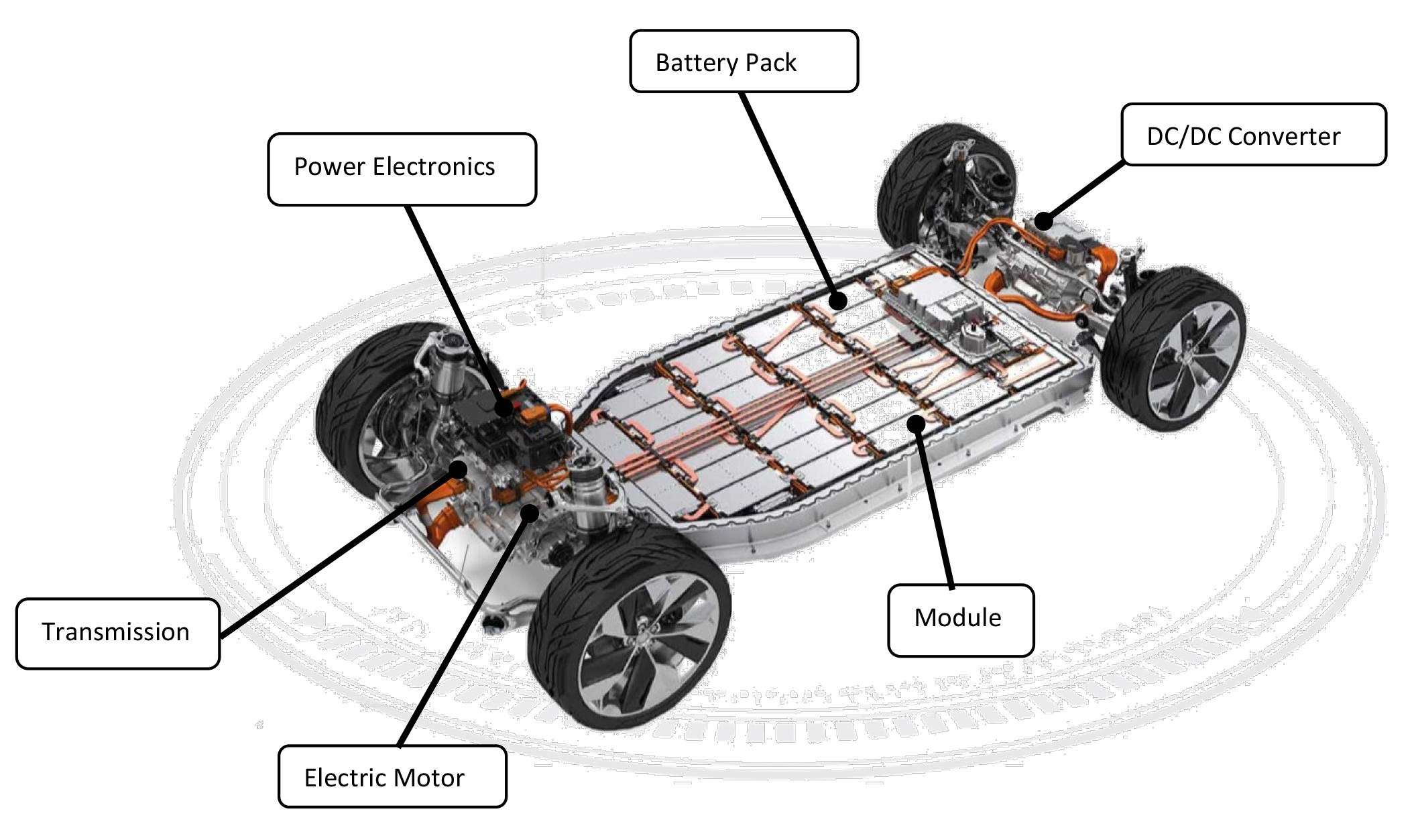

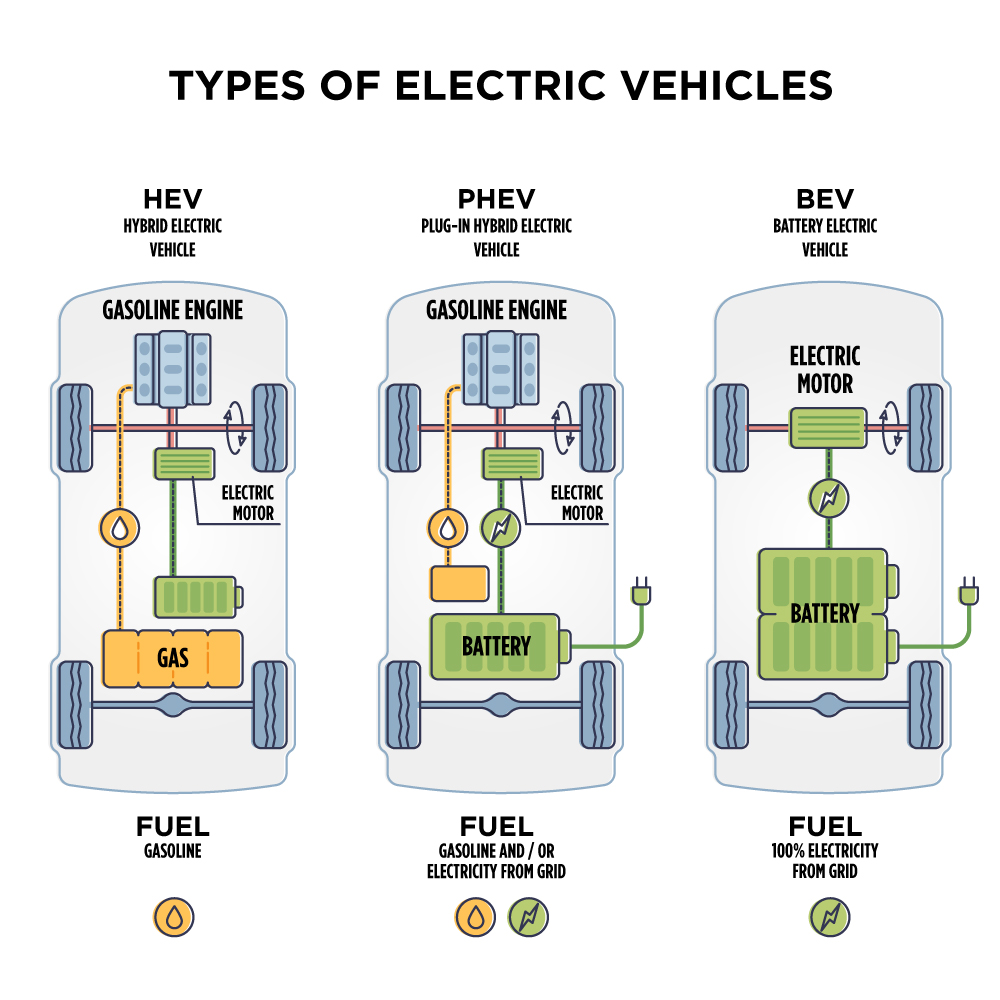

Electric vehicle power electronics play a crucial role in optimizing the performance, efficiency, and overall driving experience of electric vehicles (EVs). As the EV industry continues to grow, advancements in power electronics are transforming the way these vehicles operate. Power electronics are responsible for managing the flow of electrical energy in EVs, enabling the efficient use of battery power, and ensuring a smooth and reliable driving experience.

The impact of power electronics on EV performance cannot be overstated. By optimizing power management, EV manufacturers can improve the range and efficiency of their vehicles, reducing energy consumption and emissions. Additionally, advanced power electronics enable the use of regenerative braking, which captures kinetic energy and converts it into electrical energy, further enhancing efficiency.

The benefits of efficient power management in EVs extend beyond performance and efficiency. By reducing energy consumption, EVs can minimize their environmental impact, making them an attractive option for environmentally conscious consumers. Furthermore, the use of advanced power electronics can improve the overall driving experience, providing a smoother and more responsive ride.

As the demand for EVs continues to grow, the importance of power electronics will only continue to increase. Manufacturers are investing heavily in research and development, driving innovation in power electronics and enabling the creation of more efficient and effective EVs. With the potential for significant improvements in performance, efficiency, and environmental sustainability, electric vehicle power electronics are poised to play a critical role in shaping the future of the EV industry.

How to Choose the Right Power Electronics for Your Electric Vehicle

Selecting the most suitable power electronics for an electric vehicle is a critical decision that can significantly impact the vehicle’s performance, efficiency, and overall driving experience. With the numerous options available, it can be challenging to determine which power electronics solution is best suited for a particular EV. In this section, we will provide guidance on selecting the right power electronics for an electric vehicle, considering factors such as power density, efficiency, and thermal management.

When choosing power electronics for an EV, it is essential to consider the vehicle’s specific requirements and operating conditions. For example, if the vehicle is designed for high-performance applications, it may require power electronics with high power density and efficiency. On the other hand, if the vehicle is designed for urban mobility, it may require power electronics with high efficiency and low thermal management requirements.

Several popular power electronics solutions are used in EVs, including those from Infineon and Texas Instruments. Infineon’s power electronics solutions, such as their IGBT modules and power MOSFETs, are widely used in EVs due to their high power density and efficiency. Texas Instruments’ power electronics solutions, such as their power management ICs and motor drivers, are also popular in EVs due to their high efficiency and reliability.

When evaluating power electronics solutions for an EV, it is crucial to consider the following factors: power density, efficiency, thermal management, and reliability. Power density refers to the amount of power that can be delivered per unit area, while efficiency refers to the ability of the power electronics to minimize energy losses. Thermal management refers to the ability of the power electronics to dissipate heat generated during operation, while reliability refers to the ability of the power electronics to operate continuously without failure.

By considering these factors and evaluating the various power electronics solutions available, EV manufacturers can select the most suitable power electronics for their vehicles, ensuring optimal performance, efficiency, and reliability.

The Role of Power Electronics in Electric Vehicle Charging Systems

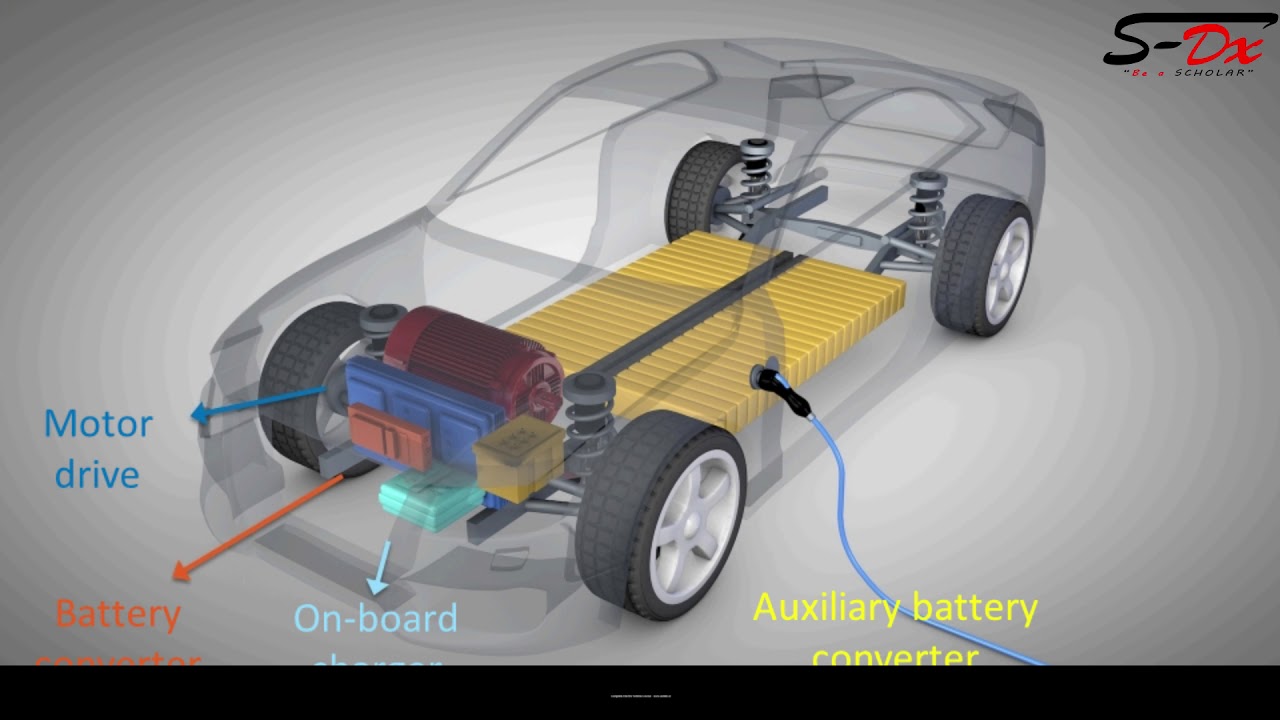

Electric vehicle charging systems rely heavily on power electronics to manage the flow of electrical energy between the grid, the vehicle’s battery, and the charging infrastructure. The primary function of power electronics in EV charging systems is to convert AC power from the grid to DC power, which is then stored in the vehicle’s battery. This process is crucial for efficient and safe charging, as it enables the vehicle to recharge its battery quickly and reliably.

Power electronics play a critical role in managing charging speeds, which is essential for fast-charging systems. Fast-charging systems require high-power electronics that can handle the increased current and voltage requirements. Advanced power electronics, such as those using wide bandgap semiconductors (e.g., SiC and GaN), are being developed to enable faster and more efficient charging.

The benefits of advanced power electronics in fast-charging systems are numerous. They enable faster charging times, which can reduce the time spent at charging stations and increase the overall efficiency of the charging process. Additionally, advanced power electronics can improve the reliability and safety of the charging system, reducing the risk of overheating and electrical shock.

Examples of advanced power electronics used in EV charging systems include the use of insulated gate bipolar transistors (IGBTs) and power MOSFETs. These devices enable high-power and high-frequency switching, which is essential for efficient and fast charging. Additionally, the use of advanced power electronics can enable the development of more compact and lightweight charging systems, which can reduce the overall size and weight of the vehicle.

In conclusion, power electronics play a vital role in electric vehicle charging systems, enabling efficient and safe charging, and managing charging speeds. The development of advanced power electronics is critical for the widespread adoption of fast-charging systems, which will enable the widespread adoption of electric vehicles.

Advancements in Electric Vehicle Power Electronics: Trends and Innovations

The electric vehicle (EV) industry is experiencing rapid growth, driven by increasing demand for sustainable and environmentally friendly transportation solutions. As the industry continues to evolve, advancements in electric vehicle power electronics are playing a critical role in shaping the future of EVs. In this section, we will explore the latest trends and innovations in electric vehicle power electronics, including the adoption of wide bandgap semiconductors and the development of more efficient power modules.

One of the most significant trends in electric vehicle power electronics is the adoption of wide bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN). These materials offer several advantages over traditional silicon-based semiconductors, including higher power density, faster switching speeds, and improved thermal management. As a result, wide bandgap semiconductors are being increasingly used in EV power electronics, enabling the development of more efficient and compact power modules.

Another trend in electric vehicle power electronics is the development of more efficient power modules. These modules are designed to optimize power conversion efficiency, reducing energy losses and improving overall system performance. Advanced power modules, such as those using insulated gate bipolar transistors (IGBTs) and power MOSFETs, are being developed to enable faster and more efficient charging, as well as improved motor control and efficiency.

The potential impact of these advancements on EV performance and efficiency is significant. By enabling faster and more efficient charging, advanced power electronics can reduce charging times and improve overall system efficiency. Additionally, the development of more efficient power modules can improve motor control and efficiency, enabling EVs to achieve better range and performance.

Examples of companies that are driving innovation in electric vehicle power electronics include Infineon, Texas Instruments, and STMicroelectronics. These companies are investing heavily in research and development, driving the adoption of wide bandgap semiconductors and the development of more efficient power modules.

As the EV industry continues to evolve, advancements in electric vehicle power electronics will play a critical role in shaping the future of sustainable transportation. By enabling faster and more efficient charging, improving motor control and efficiency, and reducing energy losses, advanced power electronics will help to drive the widespread adoption of EVs.

Thermal Management in Electric Vehicle Power Electronics: Challenges and Solutions

Thermal management is a critical aspect of electric vehicle power electronics, as it directly impacts the performance, efficiency, and reliability of the vehicle’s powertrain. The power electronics in an electric vehicle generate heat during operation, which can lead to reduced performance, efficiency, and lifespan if not properly managed. In this section, we will discuss the challenges of thermal management in electric vehicle power electronics and present solutions to mitigate these challenges.

One of the primary challenges of thermal management in electric vehicle power electronics is heat generation. The power electronics in an electric vehicle, such as the inverter and motor controller, generate heat during operation due to electrical losses and inefficiencies. If this heat is not properly managed, it can lead to reduced performance, efficiency, and lifespan of the power electronics.

Another challenge of thermal management in electric vehicle power electronics is heat dissipation. The power electronics in an electric vehicle are typically located in a confined space, which can make it difficult to dissipate heat effectively. If the heat is not properly dissipated, it can lead to increased temperatures, reduced performance, and reduced lifespan of the power electronics.

To mitigate the challenges of thermal management in electric vehicle power electronics, several solutions can be employed. One solution is the use of advanced cooling systems, such as liquid cooling or air cooling systems. These systems can effectively dissipate heat from the power electronics, reducing temperatures and improving performance and efficiency.

Another solution is the use of thermal interface materials (TIMs). TIMs are materials that are used to improve the thermal conductivity between the power electronics and the cooling system. By improving the thermal conductivity, TIMs can help to reduce temperatures and improve performance and efficiency.

Examples of companies that are developing advanced thermal management solutions for electric vehicle power electronics include Infineon and Texas Instruments. These companies are developing innovative solutions, such as advanced cooling systems and TIMs, to mitigate the challenges of thermal management in electric vehicle power electronics.

In conclusion, thermal management is a critical aspect of electric vehicle power electronics, and several challenges must be addressed to ensure optimal performance, efficiency, and reliability. By employing advanced cooling systems and TIMs, electric vehicle manufacturers can mitigate the challenges of thermal management and improve the overall performance and efficiency of their vehicles.

Electric Vehicle Power Electronics: A Key Enabler of Autonomous Driving

Autonomous driving is a rapidly evolving technology that is transforming the automotive industry. Electric vehicle power electronics play a critical role in enabling autonomous driving, as they provide the necessary power and control to support the complex systems required for autonomous operation. In this section, we will explore the role of electric vehicle power electronics in autonomous driving and discuss their importance in enabling this technology.

Autonomous driving requires a complex array of sensors, cameras, and other systems to detect and respond to the environment. These systems require significant amounts of power to operate, which is provided by the electric vehicle’s power electronics. The power electronics must be able to supply high levels of power to the autonomous driving systems, while also ensuring efficient and reliable operation.

Electric vehicle power electronics are well-suited to support autonomous driving due to their high power density and efficiency. They can provide the necessary power to support the complex systems required for autonomous operation, while also minimizing energy losses and heat generation. Additionally, electric vehicle power electronics can be designed to provide high levels of reliability and fault tolerance, which is critical for autonomous driving applications.

Examples of electric vehicle power electronics used in autonomous driving include the power modules used in Tesla’s Autopilot system. These power modules provide high levels of power and efficiency, while also ensuring reliable and fault-tolerant operation. Other companies, such as Infineon and Texas Instruments, are also developing power electronics solutions for autonomous driving applications.

The importance of electric vehicle power electronics in autonomous driving cannot be overstated. They provide the necessary power and control to support the complex systems required for autonomous operation, while also ensuring efficient and reliable operation. As autonomous driving technology continues to evolve, the role of electric vehicle power electronics will become increasingly important.

In conclusion, electric vehicle power electronics are a critical component of autonomous driving systems. They provide the necessary power and control to support the complex systems required for autonomous operation, while also ensuring efficient and reliable operation. As autonomous driving technology continues to evolve, the importance of electric vehicle power electronics will only continue to grow.

Power Electronics for Electric Vehicle Motor Control: A Deep Dive

Electric vehicle motor control is a critical aspect of electric vehicle power electronics, as it directly impacts the performance, efficiency, and reliability of the vehicle’s powertrain. In this section, we will provide an in-depth examination of power electronics used in electric vehicle motor control, including their function in controlling torque, speed, and efficiency.

Electric vehicle motor control involves the use of power electronics to control the flow of electrical energy to the motor. This is typically achieved through the use of a power module, which is a compact package of power electronics that includes a power semiconductor device, a gate driver, and a control circuit. The power module is responsible for controlling the flow of electrical energy to the motor, and is typically controlled by a microcontroller or other control device.

The power electronics used in electric vehicle motor control must be able to handle high levels of power and current, while also providing high levels of efficiency and reliability. This is typically achieved through the use of advanced power semiconductor devices, such as insulated gate bipolar transistors (IGBTs) and power MOSFETs. These devices are able to handle high levels of power and current, while also providing high levels of efficiency and reliability.

Advanced motor control strategies, such as field-oriented control (FOC) and direct torque control (DTC), are also used in electric vehicle motor control. These strategies involve the use of advanced algorithms and control techniques to optimize the performance and efficiency of the motor. FOC, for example, involves the use of a mathematical model of the motor to optimize the flow of electrical energy to the motor, while DTC involves the use of a direct torque control algorithm to optimize the torque output of the motor.

Examples of companies that are developing advanced power electronics for electric vehicle motor control include Infineon and Texas Instruments. These companies are developing innovative solutions, such as advanced power modules and motor control algorithms, to optimize the performance and efficiency of electric vehicle motors.

In conclusion, power electronics play a critical role in electric vehicle motor control, and are essential for optimizing the performance and efficiency of electric vehicle powertrains. By using advanced power semiconductor devices and motor control strategies, electric vehicle manufacturers can optimize the performance and efficiency of their vehicles, while also reducing energy losses and improving reliability.

Future Outlook: The Evolution of Electric Vehicle Power Electronics

The future of electric vehicle power electronics is exciting and rapidly evolving. As the demand for electric vehicles continues to grow, the need for more efficient, reliable, and cost-effective power electronics solutions will become increasingly important. In this section, we will offer a forward-looking perspective on the future of electric vehicle power electronics, including potential advancements in materials, designs, and manufacturing processes.

One of the most significant trends in the future of electric vehicle power electronics is the adoption of new materials and technologies. For example, the use of wide bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), is expected to become more widespread. These materials offer several advantages over traditional silicon-based semiconductors, including higher power density, faster switching speeds, and improved thermal management.

Another trend in the future of electric vehicle power electronics is the development of more efficient power modules. These modules will be designed to optimize power conversion efficiency, reduce energy losses, and improve overall system performance. Advanced power modules will also be designed to be more compact and lightweight, making them ideal for use in electric vehicles.

The future of electric vehicle power electronics will also be shaped by advancements in manufacturing processes. For example, the use of 3D printing and other additive manufacturing techniques will enable the creation of complex power electronics components with improved performance and reliability. Additionally, the use of advanced simulation and modeling tools will enable the design and optimization of power electronics systems with improved efficiency and performance.

The implications of these developments for the electric vehicle industry will be significant. As electric vehicle power electronics continue to evolve, they will play an increasingly important role in enabling the widespread adoption of electric vehicles. By providing more efficient, reliable, and cost-effective power electronics solutions, electric vehicle manufacturers will be able to create vehicles that are more appealing to consumers and more competitive in the market.

In conclusion, the future of electric vehicle power electronics is bright and exciting. As the demand for electric vehicles continues to grow, the need for more efficient, reliable, and cost-effective power electronics solutions will become increasingly important. By adopting new materials and technologies, developing more efficient power modules, and advancing manufacturing processes, electric vehicle manufacturers will be able to create vehicles that are more appealing to consumers and more competitive in the market.