The Crucial Role of Thermal Management in Electric Vehicles

Electric vehicle thermal management is a critical aspect of EV design and development, playing a vital role in maintaining optimal performance, efficiency, and range. The impact of temperature on battery performance, range, and overall efficiency cannot be overstated. In fact, studies have shown that high temperatures can reduce battery life by up to 50%, while low temperatures can decrease range by as much as 20%. Effective cooling systems can mitigate these effects, ensuring a smoother and more enjoyable driving experience.

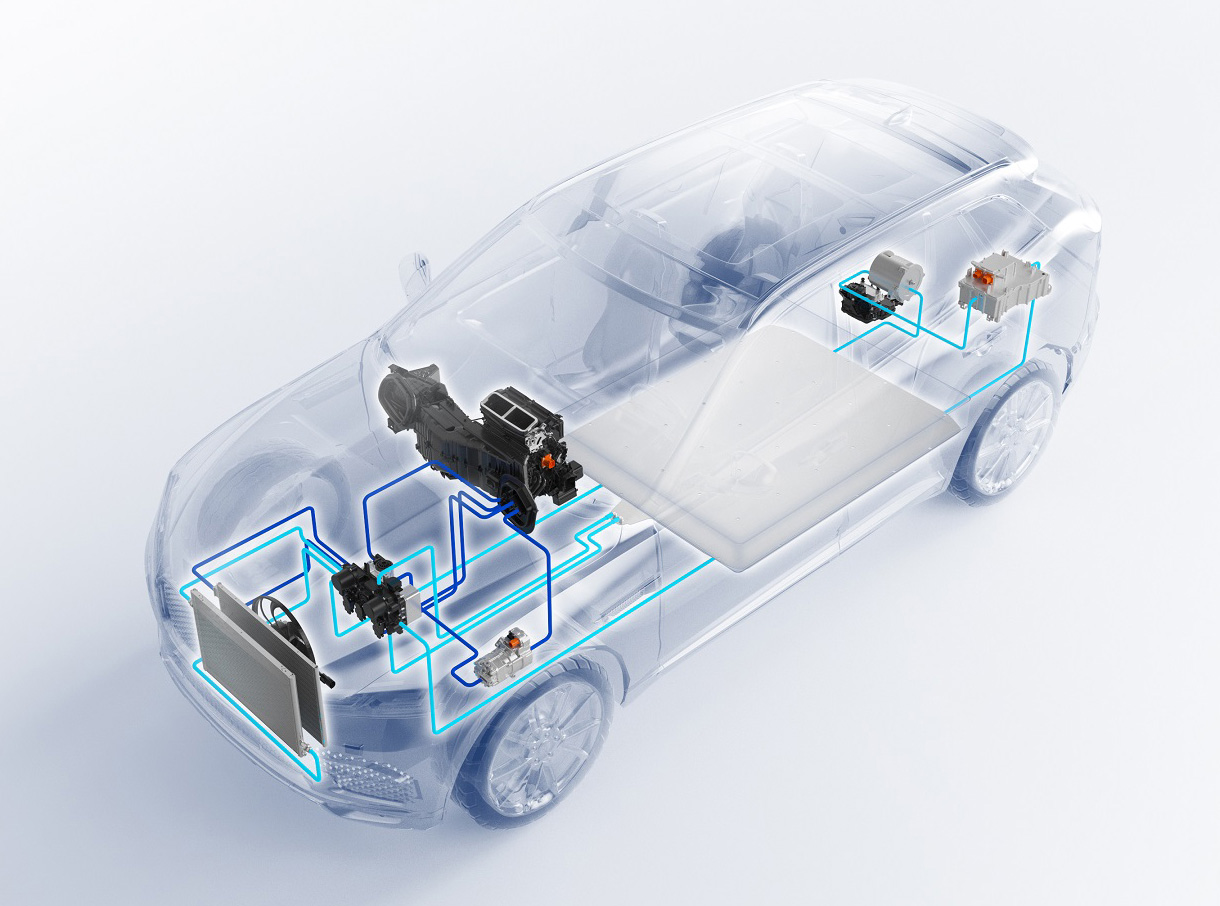

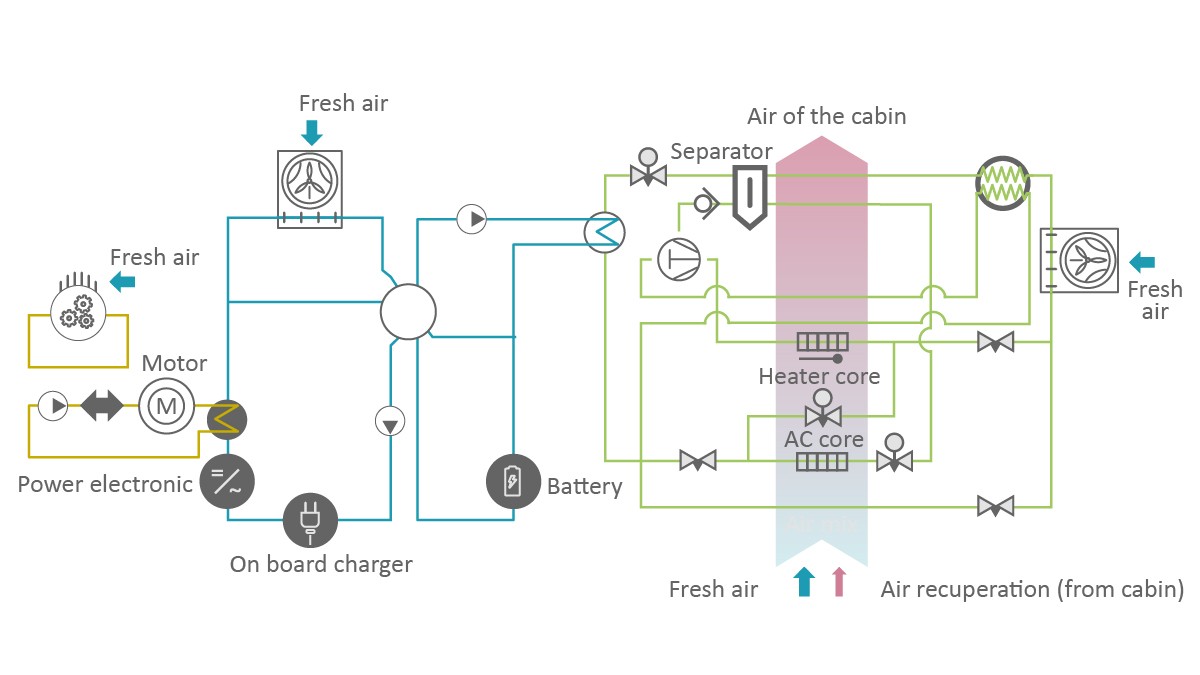

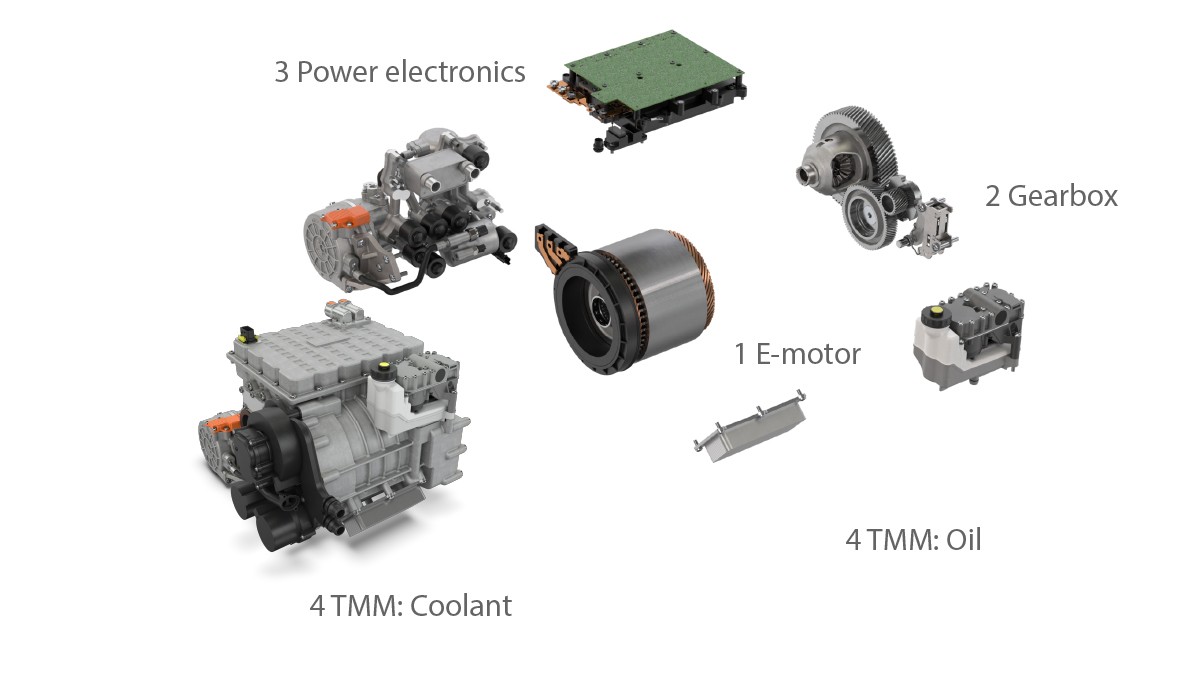

Thermal management systems in electric vehicles are designed to regulate temperature fluctuations, preventing overheating and maintaining optimal operating conditions. This is particularly important for electric motors, batteries, and power electronics, which generate significant amounts of heat during operation. By controlling temperature, EV manufacturers can improve the lifespan of these components, reducing the need for costly repairs and replacements.

In addition to improving performance and efficiency, electric vehicle thermal management systems can also enhance safety. Thermal runaway, a phenomenon where a battery cell overheats and causes a chain reaction, can be catastrophic. Effective cooling systems can prevent thermal runaway, protecting occupants and preventing damage to the vehicle.

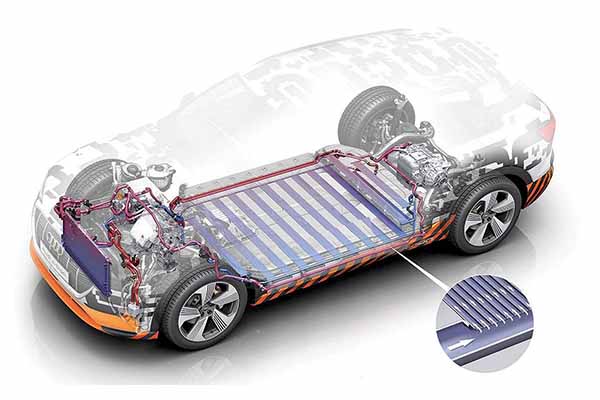

Furthermore, electric vehicle thermal management systems can also play a crucial role in reducing energy consumption. By maintaining optimal temperatures, EVs can optimize energy usage, reducing the strain on the battery and improving overall efficiency. This, in turn, can lead to increased range and reduced charging times.

In conclusion, electric vehicle thermal management is a critical aspect of EV design and development, with a significant impact on performance, efficiency, range, and safety. As the EV industry continues to evolve, the importance of effective thermal management systems will only continue to grow. By prioritizing thermal management, EV manufacturers can create vehicles that are not only environmentally friendly but also provide a superior driving experience.

How to Choose the Right Thermal Management System for Your Electric Vehicle

Selecting the most suitable thermal management system for an electric vehicle is a critical decision that depends on several factors, including climate, driving habits, and vehicle type. A well-designed thermal management system can significantly improve the performance, efficiency, and range of an electric vehicle, while a poorly designed system can lead to reduced battery life, decreased performance, and increased energy consumption.

When choosing a thermal management system, it’s essential to consider the climate in which the vehicle will operate. For example, electric vehicles operating in hot climates may require more advanced cooling systems to prevent overheating, while those operating in cold climates may require more efficient heating systems to maintain optimal battery performance.

Driving habits are also an important consideration when selecting a thermal management system. Aggressive driving, such as rapid acceleration and braking, can generate more heat than moderate driving, requiring a more advanced cooling system. On the other hand, moderate driving habits may allow for a more basic cooling system.

The type of vehicle is also a critical factor in selecting a thermal management system. For example, electric vehicles with large batteries may require more advanced cooling systems to prevent overheating, while those with smaller batteries may require less complex systems.

There are several types of cooling technologies available for electric vehicles, including air-cooled, liquid-cooled, and phase-change materials. Air-cooled systems are the most common and use air to cool the battery and other components. Liquid-cooled systems use a liquid coolant to absorb heat from the battery and other components, and are often more efficient than air-cooled systems. Phase-change materials are a type of advanced cooling technology that use a material that changes phase from solid to liquid as it absorbs heat.

Each of these cooling technologies has its pros and cons. Air-cooled systems are simple and inexpensive, but may not be as effective in hot climates. Liquid-cooled systems are more efficient, but may be more complex and expensive. Phase-change materials are highly effective, but may be more expensive and difficult to implement.

Ultimately, the choice of thermal management system will depend on the specific needs and requirements of the electric vehicle. By considering factors such as climate, driving habits, and vehicle type, and evaluating the pros and cons of different cooling technologies, electric vehicle manufacturers can select the most suitable thermal management system for their vehicles.

Heat Generation in Electric Vehicles: Understanding the Sources and Challenges

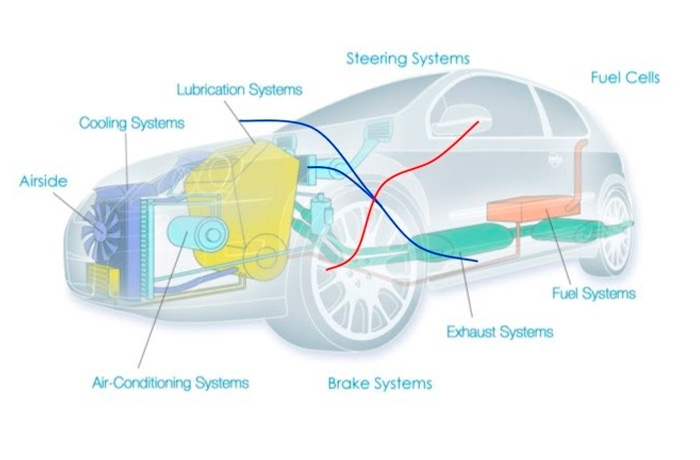

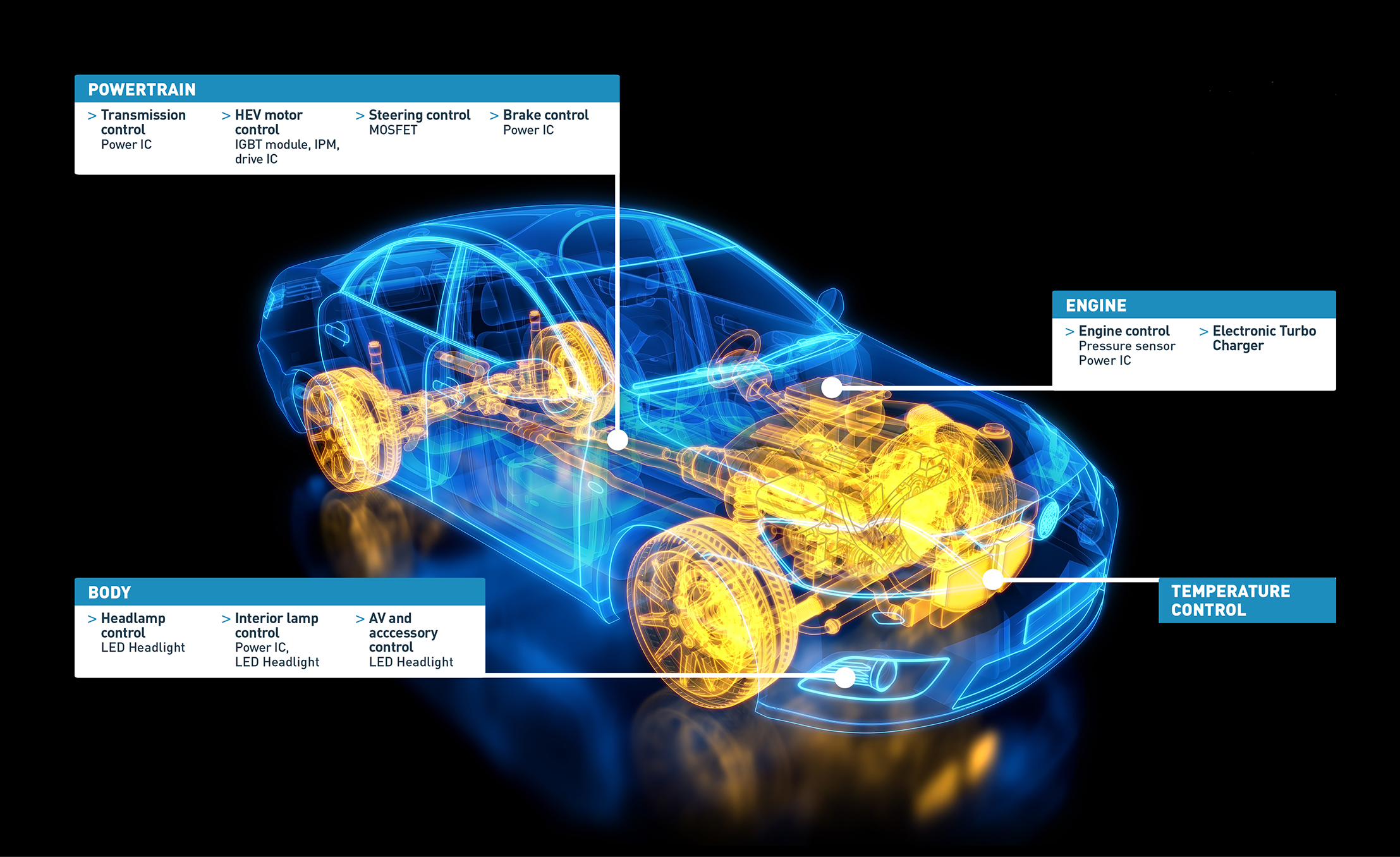

Electric vehicles generate heat from various sources, including the electric motor, battery, and power electronics. Understanding the sources of heat generation is crucial for effective electric vehicle thermal management. The electric motor, for example, generates heat due to electrical resistance and friction, while the battery generates heat due to chemical reactions and electrical resistance.

The power electronics, which include the inverter, converter, and charger, also generate heat due to electrical resistance and switching losses. Additionally, the battery management system, which controls the battery’s state of charge and voltage, can also generate heat.

Managing heat in electric vehicles is challenging due to the high temperatures generated by these components. Thermal runaway, a phenomenon where a battery cell overheats and causes a chain reaction, is a significant concern. Reduced battery performance, decreased range, and increased energy consumption are also consequences of inadequate heat management.

The challenges of managing heat in electric vehicles are further complicated by the need to balance cooling with energy efficiency. Overcooling can lead to reduced efficiency and increased energy consumption, while undercooling can lead to overheating and reduced performance.

Furthermore, electric vehicles have unique thermal management requirements due to their high-power density and compact design. The battery pack, for example, is often located in a confined space, making it difficult to dissipate heat effectively.

Despite these challenges, effective electric vehicle thermal management is crucial for ensuring optimal performance, efficiency, and range. By understanding the sources of heat generation and the challenges of managing heat, electric vehicle manufacturers can design and develop thermal management systems that meet the unique needs of their vehicles.

Advanced cooling technologies, such as heat pipes, thermoelectric coolers, and advanced materials, are being developed to address the thermal management challenges in electric vehicles. These technologies offer improved cooling efficiency, reduced weight, and increased reliability, making them ideal for electric vehicle applications.

In addition to advanced cooling technologies, simulation tools and testing are also essential for optimizing electric vehicle thermal management system performance. By simulating various driving scenarios and testing the thermal management system under different conditions, electric vehicle manufacturers can ensure that their vehicles meet the required performance, efficiency, and safety standards.

Advanced Cooling Technologies for Electric Vehicles: A Review of Current Solutions

Electric vehicle thermal management is a critical aspect of EV design and development, and advanced cooling technologies play a vital role in ensuring optimal performance, efficiency, and range. In this section, we will review current advanced cooling technologies used in electric vehicles, including heat pipes, thermoelectric coolers, and advanced materials.

Heat pipes are a type of advanced cooling technology that uses a sealed tube filled with a working fluid to transfer heat from one location to another. They are highly effective in electric vehicles, where they can be used to cool the battery, electric motor, and power electronics. Heat pipes are also relatively lightweight and compact, making them ideal for EV applications.

Thermoelectric coolers are another type of advanced cooling technology used in electric vehicles. They work by using the Peltier effect to transfer heat from one side of the cooler to the other, and are highly effective in cooling the battery and electric motor. Thermoelectric coolers are also relatively quiet and vibration-free, making them ideal for EV applications.

Advanced materials are also being used in electric vehicle thermal management systems. These materials, such as graphite and carbon fiber, have high thermal conductivity and are lightweight, making them ideal for EV applications. They can be used to cool the battery, electric motor, and power electronics, and are also relatively inexpensive.

Examples of electric vehicles that have successfully implemented advanced cooling technologies include the Tesla Model S and the Chevrolet Bolt. The Tesla Model S uses a combination of heat pipes and thermoelectric coolers to cool the battery and electric motor, while the Chevrolet Bolt uses a advanced material-based cooling system to cool the battery and electric motor.

The benefits of advanced cooling technologies in electric vehicles are numerous. They can improve performance, efficiency, and range, while also reducing the risk of thermal runaway and improving overall safety. However, there are also challenges associated with implementing these technologies, including high cost and complexity.

Despite these challenges, advanced cooling technologies are expected to play a critical role in the future of electric vehicle thermal management. As the demand for electric vehicles continues to grow, the need for effective and efficient cooling systems will only increase. By investing in advanced cooling technologies, electric vehicle manufacturers can ensure that their vehicles meet the required performance, efficiency, and safety standards.

Thermal Management System Design Considerations for Electric Vehicles

Designing an effective thermal management system for electric vehicles requires careful consideration of several key factors, including packaging, weight, and cost constraints. The thermal management system must be able to efficiently cool the battery, electric motor, and power electronics, while also minimizing weight and cost.

One of the primary design considerations for thermal management systems in electric vehicles is packaging. The thermal management system must be designed to fit within the limited space available in the vehicle, while also providing adequate cooling to the various components. This can be a challenging task, as the thermal management system must be able to cool the battery, electric motor, and power electronics, which are often located in different areas of the vehicle.

Weight is another critical design consideration for thermal management systems in electric vehicles. The thermal management system must be designed to be as lightweight as possible, while still providing adequate cooling to the various components. This can be achieved through the use of lightweight materials, such as aluminum or carbon fiber, and by optimizing the design of the thermal management system to minimize weight.

Cost is also an important design consideration for thermal management systems in electric vehicles. The thermal management system must be designed to be cost-effective, while still providing adequate cooling to the various components. This can be achieved through the use of cost-effective materials and manufacturing processes, and by optimizing the design of the thermal management system to minimize cost.

Simulation tools and testing are also essential for optimizing thermal management system performance in electric vehicles. Simulation tools, such as computational fluid dynamics (CFD) and finite element analysis (FEA), can be used to model the thermal management system and predict its performance under various operating conditions. Testing, such as wind tunnel testing and thermal testing, can be used to validate the performance of the thermal management system and identify areas for improvement.

By carefully considering these design factors and using simulation tools and testing, electric vehicle manufacturers can design and develop thermal management systems that provide optimal cooling to the battery, electric motor, and power electronics, while also minimizing weight and cost.

In addition to these design considerations, electric vehicle manufacturers must also consider the impact of thermal management on the overall performance and efficiency of the vehicle. Effective thermal management can improve the range and efficiency of the vehicle, while also reducing the risk of thermal runaway and improving overall safety.

Overall, designing an effective thermal management system for electric vehicles requires careful consideration of several key factors, including packaging, weight, and cost constraints. By using simulation tools and testing, and by carefully considering these design factors, electric vehicle manufacturers can design and develop thermal management systems that provide optimal cooling to the battery, electric motor, and power electronics, while also minimizing weight and cost.

Real-World Examples of Effective Thermal Management in Electric Vehicles

The Tesla Model S is a prime example of an electric vehicle that has successfully implemented an advanced thermal management system. The Model S uses a combination of air-cooled and liquid-cooled systems to manage the temperature of its battery, electric motor, and power electronics. The vehicle’s thermal management system is designed to maintain a consistent temperature, even in extreme weather conditions, which helps to improve the vehicle’s performance, efficiency, and range.

The Chevrolet Bolt is another example of an electric vehicle that has implemented an effective thermal management system. The Bolt uses a liquid-cooled system to manage the temperature of its battery and electric motor. The vehicle’s thermal management system is designed to optimize the performance and efficiency of the vehicle, while also reducing the risk of thermal runaway and improving overall safety.

Both the Tesla Model S and the Chevrolet Bolt have demonstrated the importance of effective thermal management in electric vehicles. By using advanced cooling technologies and carefully designing their thermal management systems, these vehicles have been able to achieve improved performance, efficiency, and range, while also reducing the risk of thermal runaway and improving overall safety.

Other electric vehicle manufacturers, such as Nissan and BMW, have also implemented advanced thermal management systems in their vehicles. The Nissan Leaf, for example, uses a combination of air-cooled and liquid-cooled systems to manage the temperature of its battery and electric motor. The BMW i3 uses a liquid-cooled system to manage the temperature of its battery and electric motor.

These real-world examples demonstrate the importance of effective thermal management in electric vehicles. By using advanced cooling technologies and carefully designing their thermal management systems, electric vehicle manufacturers can improve the performance, efficiency, and range of their vehicles, while also reducing the risk of thermal runaway and improving overall safety.

In addition to these examples, there are many other electric vehicles that have implemented advanced thermal management systems. The use of these systems is becoming increasingly common in the electric vehicle industry, as manufacturers recognize the importance of effective thermal management in achieving improved performance, efficiency, and range.

Overall, the use of advanced thermal management systems in electric vehicles is a critical aspect of achieving improved performance, efficiency, and range. By using these systems, electric vehicle manufacturers can improve the overall performance and safety of their vehicles, while also reducing the risk of thermal runaway and improving overall efficiency.

Future Directions in Electric Vehicle Thermal Management: Emerging Trends and Technologies

The electric vehicle industry is constantly evolving, and thermal management is no exception. Emerging trends and technologies are being developed to improve the efficiency, performance, and range of electric vehicles. In this section, we will explore some of the emerging trends and technologies in electric vehicle thermal management.

Advanced materials are being developed to improve the thermal management of electric vehicles. These materials, such as graphene and nanomaterials, have high thermal conductivity and are lightweight, making them ideal for electric vehicle applications. They can be used to improve the cooling efficiency of heat exchangers, reduce the weight of thermal management systems, and improve the overall performance of electric vehicles.

Nanotechnology is also being used to improve the thermal management of electric vehicles. Nanomaterials, such as nanoparticles and nanotubes, can be used to improve the thermal conductivity of materials, reduce the weight of thermal management systems, and improve the overall performance of electric vehicles.

Artificial intelligence (AI) is also being used to improve the thermal management of electric vehicles. AI can be used to optimize the thermal management system, predict thermal behavior, and improve the overall performance of electric vehicles. AI can also be used to develop more efficient thermal management systems, reduce the weight of thermal management systems, and improve the overall performance of electric vehicles.

Other emerging trends and technologies in electric vehicle thermal management include the use of phase-change materials, thermoelectric coolers, and advanced heat exchangers. These technologies have the potential to improve the efficiency, performance, and range of electric vehicles, and are being developed and implemented by electric vehicle manufacturers.

The potential benefits of these emerging trends and technologies are significant. They can improve the efficiency, performance, and range of electric vehicles, reduce the weight of thermal management systems, and improve the overall safety of electric vehicles. However, there are also challenges associated with implementing these technologies, including high cost, complexity, and limited availability.

Despite these challenges, the future of electric vehicle thermal management looks promising. Emerging trends and technologies have the potential to improve the efficiency, performance, and range of electric vehicles, and are being developed and implemented by electric vehicle manufacturers. As the electric vehicle industry continues to evolve, we can expect to see more innovative and effective thermal management solutions.

Conclusion: The Importance of Thermal Management in Electric Vehicle Design and Development

In conclusion, thermal management is a critical aspect of electric vehicle design and development. Effective thermal management can improve the performance, efficiency, and range of electric vehicles, while also reducing the risk of thermal runaway and improving overall safety.

As we have seen, there are many different cooling technologies and strategies that can be used to manage heat in electric vehicles. From air-cooled and liquid-cooled systems to phase-change materials and advanced heat exchangers, the options are numerous and varied.

However, regardless of the specific cooling technology or strategy used, the importance of thermal management in electric vehicle design and development cannot be overstated. By prioritizing thermal management, electric vehicle manufacturers can create vehicles that are not only environmentally friendly but also provide a superior driving experience.

In addition to the benefits of improved performance, efficiency, and range, effective thermal management can also help to reduce the risk of thermal runaway and improve overall safety. This is particularly important in electric vehicles, where the high voltage and current of the electrical system can create a significant risk of thermal runaway if not properly managed.

As the electric vehicle industry continues to evolve, we can expect to see even more innovative and effective thermal management solutions. From the use of advanced materials and nanotechnology to the development of more efficient heat exchangers and cooling systems, the future of electric vehicle thermal management looks bright.

In summary, thermal management is a critical aspect of electric vehicle design and development, and effective thermal management can improve the performance, efficiency, and range of electric vehicles while also reducing the risk of thermal runaway and improving overall safety. By prioritizing thermal management, electric vehicle manufacturers can create vehicles that are not only environmentally friendly but also provide a superior driving experience.