How to Choose the Right Machines for Your Startup

When starting a business, selecting the right equipment is crucial for success. The machines you choose can significantly impact your productivity, efficiency, and bottom line. With so many options available, it can be overwhelming to determine which machines to buy to start a business. In this article, we will explore the key factors to consider when choosing the right machines for your startup.

First and foremost, it’s essential to consider your budget. Machines can be a significant investment, and it’s crucial to ensure that you have the necessary funds to purchase and maintain them. Additionally, you should consider the industry you are in and the specific needs of your business. For example, if you are starting a manufacturing business, you may need machines such as CNC machines or 3D printers. On the other hand, if you are starting an e-commerce business, you may need machines such as packaging machines or label makers.

Scalability is another critical factor to consider when choosing machines for your startup. As your business grows, you will need machines that can keep up with increased demand. Look for machines that are flexible and can be easily upgraded or modified as your business evolves. It’s also essential to consider the maintenance and repair costs associated with each machine. Some machines may require more frequent maintenance or repairs, which can impact your bottom line.

Popular machines for startups include 3D printers, CNC machines, and laser cutters. These machines offer a range of benefits, including increased efficiency, improved product quality, and reduced labor costs. However, it’s essential to do your research and choose machines that align with your business goals and objectives. By considering your budget, industry, scalability, and maintenance costs, you can make informed decisions about which machines to buy to start a business.

Ultimately, the right machines can make all the difference in the success of your startup. By choosing machines that meet your specific needs and goals, you can increase productivity, efficiency, and profitability. Remember to do your research, consider your options carefully, and choose machines that will drive growth and success for your business.

Top Machines for Small Businesses: A Review of the Best Options

When it comes to selecting the right machines for a small business, there are several options to consider. In this article, we will review some of the top machines for small businesses, including the Epilog Laser Cutter, the MakerGear M2 3D Printer, and the Haas CNC Mill. These machines are highly regarded for their quality, reliability, and versatility, making them ideal for businesses looking to invest in equipment that will drive growth and success.

The Epilog Laser Cutter is a popular choice among small businesses due to its precision and accuracy. This machine is capable of cutting a wide range of materials, including wood, plastic, and metal, making it an ideal choice for businesses that require custom cutting and engraving. The Epilog Laser Cutter is also relatively affordable, with prices starting at around $10,000.

The MakerGear M2 3D Printer is another top machine for small businesses. This printer is known for its high-quality prints and ease of use, making it an ideal choice for businesses that require rapid prototyping and production. The MakerGear M2 3D Printer is also highly customizable, allowing businesses to print a wide range of materials and objects. Prices for this machine start at around $2,000.

The Haas CNC Mill is a highly advanced machine that is capable of performing a wide range of tasks, including milling, drilling, and tapping. This machine is ideal for businesses that require high-precision machining and is commonly used in industries such as aerospace and automotive. The Haas CNC Mill is a significant investment, with prices starting at around $50,000.

When selecting machines for a small business, it’s essential to consider factors such as budget, industry, and scalability. By choosing machines that meet these needs, businesses can increase productivity, efficiency, and profitability. The machines reviewed in this article are highly regarded for their quality and reliability, making them ideal for businesses looking to invest in equipment that will drive growth and success.

In addition to the machines reviewed in this article, there are many other options available for small businesses. When selecting machines, it’s essential to do your research and choose equipment that aligns with your business goals and objectives. By investing in the right machines, businesses can set themselves up for success and drive growth and profitability.

Industry-Specific Machines: What You Need to Know

When it comes to selecting machines for a business, it’s essential to consider the specific industry and the unique challenges and opportunities that come with it. Different industries require different types of machines, and understanding these requirements is crucial for success. In this article, we will explore the different types of machines required for various industries, including food processing, textile manufacturing, and woodworking.

Food processing is a highly regulated industry that requires machines that can meet strict safety and sanitation standards. Machines such as meat grinders, mixers, and packaging equipment are essential for food processing businesses. These machines must be designed to prevent contamination and ensure the safe handling of food products. For example, a meat grinder must be designed to prevent the growth of bacteria and other microorganisms that can cause foodborne illness.

Textile manufacturing is another industry that requires specialized machines. Machines such as looms, knitting machines, and textile cutters are essential for textile manufacturing businesses. These machines must be designed to handle the unique properties of textiles, such as their flexibility and fragility. For example, a loom must be designed to weave fabric without causing damage or distortion.

Woodworking is an industry that requires machines that can handle the unique properties of wood. Machines such as table saws, drill presses, and sanders are essential for woodworking businesses. These machines must be designed to handle the hardness and density of wood, as well as its tendency to splinter and crack. For example, a table saw must be designed to make precise cuts without causing the wood to splinter or crack.

In addition to these industries, there are many other industries that require specialized machines. For example, the aerospace industry requires machines that can handle the unique properties of metals and other materials used in aircraft manufacturing. The automotive industry requires machines that can handle the high-speed production of vehicle parts. By understanding the unique requirements of each industry, businesses can select the right machines to meet their needs and drive growth and success.

When selecting machines for a business, it’s essential to consider the specific industry and the unique challenges and opportunities that come with it. By choosing machines that meet the specific needs of the industry, businesses can increase productivity, efficiency, and profitability. Whether it’s food processing, textile manufacturing, woodworking, or another industry, the right machines can make all the difference in the success of a business.

The Benefits of Investing in Automated Machinery

Automating business processes with machines can have a significant impact on the success of a company. By investing in automated machinery, businesses can increase efficiency, reduce labor costs, and improve product quality. In this article, we will explore the benefits of automating business processes with machines and provide examples of businesses that have successfully implemented automation.

One of the primary benefits of automating business processes with machines is increased efficiency. Machines can perform tasks faster and more accurately than humans, which can lead to significant productivity gains. For example, a manufacturing company that automates its production line with machines can produce more products in less time, which can lead to increased revenue and competitiveness.

Another benefit of automating business processes with machines is reduced labor costs. Machines can perform tasks that would otherwise require human labor, which can lead to significant cost savings. For example, a company that automates its packaging process with machines can reduce its labor costs by eliminating the need for human packers.

Improved product quality is another benefit of automating business processes with machines. Machines can perform tasks with a high degree of accuracy and precision, which can lead to improved product quality. For example, a company that automates its quality control process with machines can detect defects and irregularities more accurately than human inspectors.

There are many examples of businesses that have successfully implemented automation. For example, Amazon has automated its warehouses with robots and machines, which has improved efficiency and reduced labor costs. Similarly, companies like Tesla and General Motors have automated their manufacturing processes with machines, which has improved product quality and reduced production costs.

When considering automating business processes with machines, it’s essential to weigh the costs and benefits. While machines can provide significant benefits, they can also be expensive to purchase and maintain. However, with the right machines and implementation strategy, businesses can achieve significant returns on investment and drive growth and success.

In conclusion, automating business processes with machines can have a significant impact on the success of a company. By increasing efficiency, reducing labor costs, and improving product quality, businesses can drive growth and success. Whether it’s manufacturing, packaging, or quality control, machines can provide significant benefits and help businesses achieve their goals.

Machines for E-commerce and Online Businesses

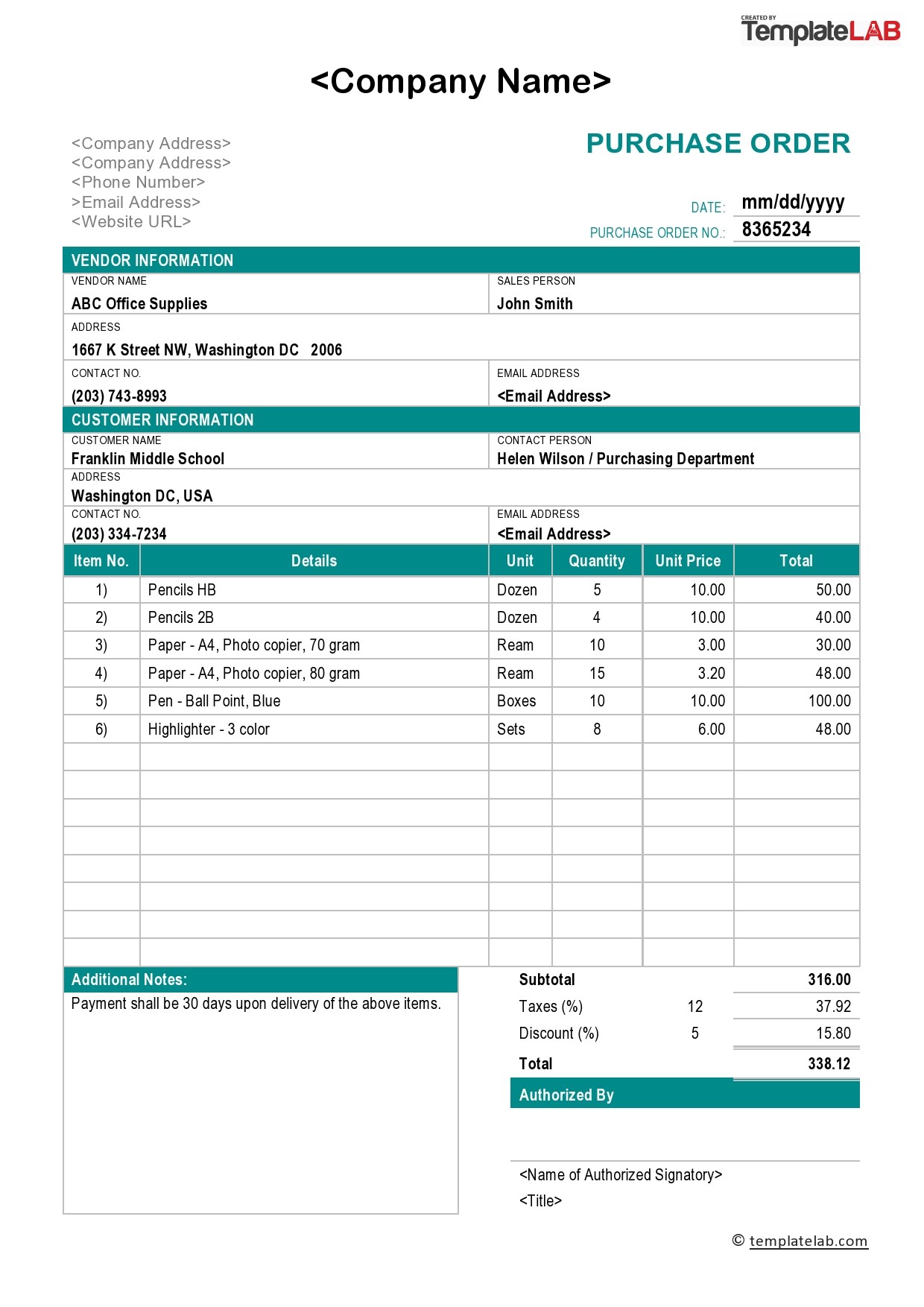

E-commerce and online businesses require specialized machines to streamline order fulfillment and shipping processes. In this article, we will explore the machines required for e-commerce and online businesses, including packaging machines, label makers, and shipping scales.

Packaging machines are essential for e-commerce and online businesses, as they enable efficient and cost-effective packaging of products. These machines can automate tasks such as boxing, bagging, and labeling, which can save time and reduce labor costs. For example, a packaging machine can package up to 100 orders per hour, which can significantly increase productivity and efficiency.

Label makers are another important machine for e-commerce and online businesses. These machines enable businesses to print labels quickly and efficiently, which can save time and reduce errors. Label makers can also print labels with barcodes, which can help businesses track inventory and shipments more effectively.

Shipping scales are also crucial for e-commerce and online businesses, as they enable businesses to accurately weigh and measure packages. This can help businesses calculate shipping costs more accurately and avoid overcharging or undercharging customers. Shipping scales can also help businesses track inventory and shipments more effectively.

In addition to these machines, e-commerce and online businesses may also require other specialized equipment, such as conveyor belts, sorting machines, and automated storage and retrieval systems. These machines can help businesses streamline their order fulfillment and shipping processes, which can improve efficiency and reduce costs.

When selecting machines for e-commerce and online businesses, it’s essential to consider factors such as cost, efficiency, and scalability. Businesses should also consider the specific needs of their business, such as the type of products they sell and the volume of orders they receive. By selecting the right machines, e-commerce and online businesses can improve efficiency, reduce costs, and increase customer satisfaction.

In conclusion, machines play a critical role in e-commerce and online businesses, enabling businesses to streamline order fulfillment and shipping processes. By selecting the right machines, businesses can improve efficiency, reduce costs, and increase customer satisfaction. Whether it’s packaging machines, label makers, or shipping scales, the right machines can help e-commerce and online businesses succeed in a competitive market.

Leasing vs. Buying: Which Option is Best for Your Business?

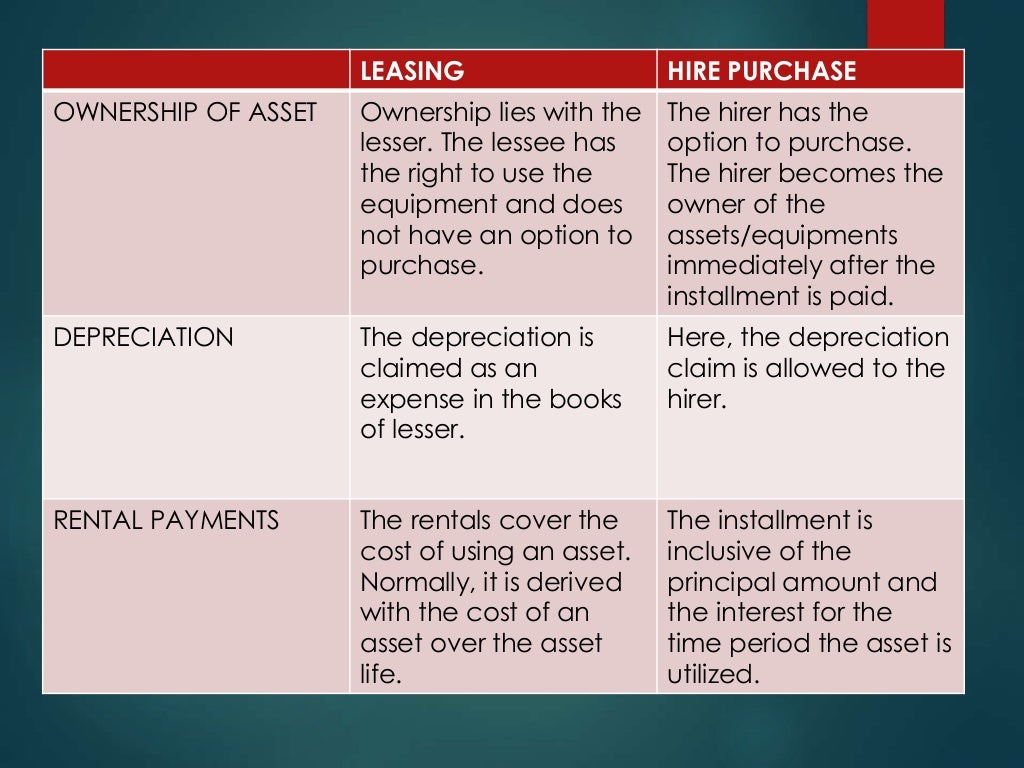

When it comes to acquiring machines for your business, you have two main options: leasing and buying. Both options have their pros and cons, and the right choice for your business depends on several factors. In this article, we will explore the advantages and disadvantages of leasing versus buying machines, and provide guidance on how to make an informed decision.

Leasing machines can be a cost-effective option for businesses that need access to equipment but do not have the upfront capital to purchase it. Leasing allows businesses to use the machine for a set period of time in exchange for monthly payments. This can be beneficial for businesses that need to upgrade their equipment frequently or that have limited budgets.

However, leasing machines also has its drawbacks. For example, businesses may not have ownership of the machine, and may be required to return it at the end of the lease period. Additionally, leasing machines may not provide the same level of customization and control as buying machines.

Buying machines, on the other hand, provides businesses with ownership and control over the equipment. This can be beneficial for businesses that plan to use the machine for an extended period of time and want to customize it to their specific needs. However, buying machines also requires a significant upfront investment, which can be a barrier for some businesses.

When deciding between leasing and buying machines, businesses should consider several factors, including their budget, the type of machine they need, and their expected usage. Businesses should also consider the total cost of ownership, including maintenance and repair costs, and the potential for customization and control.

Ultimately, the decision to lease or buy machines depends on the specific needs and goals of your business. By weighing the pros and cons of each option and considering your business’s unique circumstances, you can make an informed decision that will help your business succeed.

In addition to considering the pros and cons of leasing versus buying machines, businesses should also consider the following factors:

– Upfront costs: What is the initial investment required to lease or buy the machine?

– Maintenance and repair costs: What are the ongoing costs associated with maintaining and repairing the machine?

– Customization and control: How much control do you need over the machine, and how much customization is required?

– Expected usage: How often will the machine be used, and for how long?

By considering these factors and weighing the pros and cons of leasing versus buying machines, businesses can make an informed decision that will help them achieve their goals and succeed in their industry.

Maintenance and Repair: Tips for Extending Machine Life

Proper maintenance and repair are crucial for extending the lifespan of machines and preventing downtime. Regular maintenance schedules can help identify potential issues before they become major problems, reducing the risk of machine failure and minimizing repair costs. When selecting machines to buy to start a business, it’s essential to consider the maintenance requirements and costs associated with each piece of equipment.

A well-planned maintenance schedule should include daily, weekly, and monthly tasks to ensure machines are running at optimal levels. Daily tasks may include cleaning and lubricating moving parts, while weekly tasks may involve checking fluid levels and inspecting for signs of wear. Monthly tasks may include performing routine repairs and replacing worn-out parts.

Troubleshooting common issues is also critical for minimizing downtime. By identifying and addressing problems quickly, businesses can reduce the risk of machine failure and prevent costly repairs. Common issues may include faulty sensors, worn-out belts, or clogged filters. By keeping a spare parts inventory and having a plan in place for addressing common issues, businesses can quickly get machines back up and running.

In addition to regular maintenance and troubleshooting, businesses should also consider investing in machine monitoring systems. These systems can provide real-time data on machine performance, allowing businesses to identify potential issues before they become major problems. By leveraging data and analytics, businesses can optimize machine performance, reduce energy consumption, and extend the lifespan of their equipment.

When it comes to repairing machines, it’s essential to work with qualified technicians who have experience with the specific type of equipment. By investing in high-quality repairs and maintenance, businesses can extend the lifespan of their machines and prevent costly replacements. Additionally, many manufacturers offer repair and maintenance services, which can provide businesses with access to specialized expertise and genuine parts.

By prioritizing maintenance and repair, businesses can get the most out of their machines and drive growth and success. Whether you’re looking for machines to buy to start a business or seeking to optimize your existing equipment, a well-planned maintenance and repair strategy is essential for achieving your goals.

Conclusion: Setting Your Business Up for Success with the Right Machines

In conclusion, selecting the right machines for your business is a critical decision that can make or break your success. By considering factors such as budget, industry, and scalability, entrepreneurs can choose the machines that will drive growth and efficiency. Whether you’re looking for machines to buy to start a business or seeking to upgrade your existing equipment, it’s essential to do your research and invest in the right tools for the job.

From 3D printers and CNC machines to packaging machines and label makers, the right equipment can help businesses streamline processes, reduce costs, and improve product quality. By automating business processes and investing in industry-specific machines, entrepreneurs can gain a competitive edge and achieve their goals.

Remember, the key to success lies in choosing the right machines for your business. By weighing the pros and cons of leasing versus buying, prioritizing maintenance and repair, and selecting equipment that meets your unique needs, entrepreneurs can set their businesses up for success. Don’t be afraid to invest in the right machines – with the right equipment, the possibilities are endless.

As you embark on your business journey, keep in mind that the right machines can help you overcome challenges, capitalize on opportunities, and achieve your vision. By making informed decisions about the equipment you use, you can drive growth, increase efficiency, and build a successful business that will thrive for years to come.

In today’s fast-paced business landscape, having the right machines is essential for staying ahead of the curve. By choosing the right equipment and investing in your business, you can unlock your full potential and achieve success. So why wait? Start exploring the machines to buy to start a business and take the first step towards building a thriving enterprise.