What is PCB Assembly and Testing: Understanding the Basics

PCB assembly and testing are critical stages in the electronics manufacturing process. The process involves several stages, including component sourcing, PCB fabrication, assembly, and testing. Component sourcing involves procuring the necessary components, such as resistors, capacitors, and microchips, from reputable suppliers. PCB fabrication involves creating the printed circuit board (PCB) itself, which serves as the foundation for the electronic components.

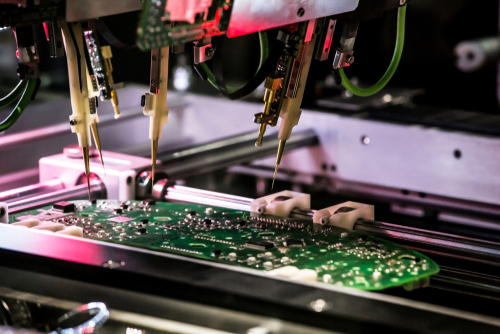

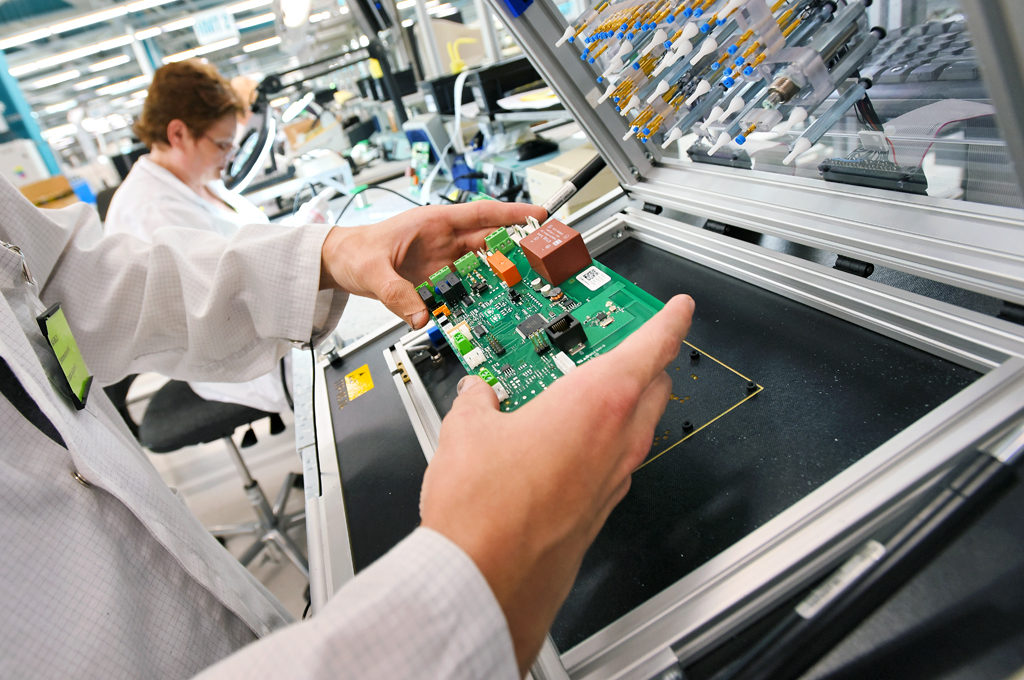

Once the PCB is fabricated, the assembly stage begins. This involves mounting the components onto the PCB using surface mount technology (SMT) or through-hole technology (THT). The assembled PCB is then subjected to various tests to ensure that it functions as intended. These tests may include visual inspections, functional tests, and environmental tests.

PCB assembly and testing are crucial in ensuring the quality and reliability of electronic products. A well-assembled and tested PCB can significantly reduce the risk of product failures, which can lead to costly repairs, recalls, and damage to a company’s reputation. Moreover, PCB assembly and testing startups play a vital role in driving innovation and growth in the electronics manufacturing industry.

These startups specialize in providing PCB assembly and testing services to original equipment manufacturers (OEMs) and original design manufacturers (ODMs). They leverage advanced technologies, such as automation and artificial intelligence, to improve the efficiency and accuracy of the assembly and testing process. By partnering with PCB assembly and testing startups, companies can reduce their production costs, improve product quality, and accelerate their time-to-market.

In addition, PCB assembly and testing startups are driving innovation in the industry by developing new technologies and techniques. For example, some startups are using 3D printing to create complex PCBs with intricate designs. Others are developing advanced testing methods, such as machine learning-based testing, to improve the accuracy and speed of the testing process.

As the demand for electronic products continues to grow, the importance of PCB assembly and testing startups will only continue to increase. These startups will play a critical role in enabling companies to produce high-quality electronic products quickly and efficiently. By understanding the basics of PCB assembly and testing, companies can better appreciate the value that these startups bring to the table.

How to Choose the Right PCB Assembly and Testing Startup for Your Business

When selecting a PCB assembly and testing startup for your business, there are several factors to consider. Expertise is a crucial aspect, as you want to ensure that the startup has the necessary skills and knowledge to handle your specific PCB assembly and testing needs. Look for startups that have experience working with similar products or technologies.

Equipment is another important consideration. Ensure that the startup has access to state-of-the-art equipment and technology, such as surface mount technology (SMT) machines, automated optical inspection (AOI) systems, and functional testing equipment. This will enable them to produce high-quality PCBs efficiently and effectively.

Certifications are also essential. Look for startups that hold relevant certifications, such as ISO 9001, ISO 13485, or IPC-A-610. These certifications demonstrate that the startup has implemented quality management systems and follows industry standards for PCB assembly and testing.

MacroFab and Screaming Circuits are two examples of PCB assembly and testing startups that specialize in providing high-quality services to businesses. MacroFab offers a range of services, including PCB assembly, testing, and inspection, while Screaming Circuits provides PCB assembly, testing, and design services.

When evaluating PCB assembly and testing startups, it’s also essential to consider their scalability and flexibility. Can they handle large volumes of production? Can they adapt to changes in your product design or production schedule? Look for startups that have a proven track record of delivering high-quality PCBs on time and on budget.

Finally, consider the startup’s customer service and communication. Do they have a responsive and knowledgeable team that can answer your questions and address your concerns? Do they provide regular updates on the status of your project? Good communication is critical to ensuring that your PCB assembly and testing needs are met.

By considering these factors, you can select a PCB assembly and testing startup that meets your business needs and helps you achieve your goals. Remember to research and evaluate several startups before making a decision, and don’t hesitate to ask questions or request references.

The Benefits of Partnering with a PCB Assembly and Testing Startup

Partnering with a PCB assembly and testing startup can bring numerous benefits to businesses. One of the primary advantages is reduced production costs. Startups often have lower overhead costs compared to traditional contract manufacturers, which enables them to offer competitive pricing without compromising on quality.

Increased efficiency is another significant benefit of partnering with a PCB assembly and testing startup. Startups are often more agile and flexible than traditional manufacturers, which allows them to respond quickly to changes in production schedules or design requirements. This can lead to faster time-to-market and improved product quality.

Improved product quality is also a direct result of partnering with a PCB assembly and testing startup. Startups often have a strong focus on quality control and testing, which ensures that products meet the required standards and specifications. This can lead to reduced defect rates, improved reliability, and increased customer satisfaction.

For example, a startup like Tempo Automation has partnered with several established companies to provide PCB assembly and testing services. Tempo Automation’s use of automation and artificial intelligence has enabled it to improve efficiency and reduce production costs, while maintaining high-quality standards.

Similarly, a startup like Fictiv has partnered with companies to provide PCB assembly and testing services, as well as design and engineering support. Fictiv’s use of 3D printing and other advanced technologies has enabled it to produce complex PCBs with high accuracy and speed.

Partnering with a PCB assembly and testing startup can also provide businesses with access to new technologies and innovations. Startups are often at the forefront of adopting new technologies and techniques, which can enable businesses to stay competitive in the market.

Furthermore, partnering with a PCB assembly and testing startup can also provide businesses with increased flexibility and scalability. Startups are often more agile and adaptable than traditional manufacturers, which enables them to respond quickly to changes in production schedules or design requirements.

Overall, partnering with a PCB assembly and testing startup can bring numerous benefits to businesses, including reduced production costs, increased efficiency, improved product quality, and access to new technologies and innovations.

PCB Assembly and Testing Startups to Watch: Innovations and Trends

The PCB assembly and testing industry is rapidly evolving, with new technologies and innovations emerging every day. Startups are at the forefront of this evolution, pushing the boundaries of what is possible in PCB assembly and testing. In this section, we will highlight some of the emerging trends and innovations in PCB assembly and testing, as well as some of the startups that are leading the way.

One of the most significant trends in PCB assembly and testing is the use of artificial intelligence (AI) and machine learning (ML). Startups like Tempo Automation and Fictiv are using AI and ML to improve the efficiency and accuracy of their PCB assembly and testing processes. For example, Tempo Automation’s use of AI-powered inspection systems has enabled it to reduce defect rates and improve product quality.

Another trend in PCB assembly and testing is the use of robotics and automation. Startups like MacroFab and Screaming Circuits are using robotics and automation to improve the efficiency and speed of their PCB assembly and testing processes. For example, MacroFab’s use of robotic assembly systems has enabled it to reduce production times and improve product quality.

3D printing is also becoming increasingly popular in PCB assembly and testing. Startups like Fictiv and Tempo Automation are using 3D printing to create complex PCBs with high accuracy and speed. For example, Fictiv’s use of 3D printing has enabled it to create PCBs with intricate designs and complex geometries.

Other startups that are worth watching in the PCB assembly and testing space include:

• PCBWay: A startup that offers PCB assembly and testing services, as well as PCB design and fabrication.

• JLCPCB: A startup that offers PCB assembly and testing services, as well as PCB design and fabrication.

• Seeed Studio: A startup that offers PCB assembly and testing services, as well as PCB design and fabrication.

These startups are just a few examples of the many companies that are innovating in the PCB assembly and testing space. As the industry continues to evolve, we can expect to see even more exciting developments and innovations from these startups and others.

Overcoming Challenges in PCB Assembly and Testing: Lessons from Startups

PCB assembly and testing startups face a range of challenges, from component sourcing and quality control to scalability and customer acquisition. However, many successful startups have overcome these challenges and gone on to achieve significant growth and innovation. In this section, we will explore some of the common challenges faced by PCB assembly and testing startups and share lessons learned from successful startups that have overcome these challenges.

One of the biggest challenges faced by PCB assembly and testing startups is component sourcing. With the increasing complexity of electronic components, it can be difficult for startups to source high-quality components at competitive prices. However, startups like MacroFab and Screaming Circuits have developed strong relationships with component suppliers, enabling them to source high-quality components quickly and efficiently.

Quality control is another significant challenge faced by PCB assembly and testing startups. With the increasing complexity of electronic products, it can be difficult for startups to ensure that their products meet the required quality standards. However, startups like Tempo Automation and Fictiv have developed robust quality control processes, enabling them to detect and correct defects quickly and efficiently.

Scalability is also a major challenge faced by PCB assembly and testing startups. As demand for their products increases, startups must be able to scale their production quickly and efficiently. However, startups like PCBWay and JLCPCB have developed scalable production processes, enabling them to meet increasing demand without compromising on quality.

Customer acquisition is another challenge faced by PCB assembly and testing startups. With the increasing competition in the electronics manufacturing industry, it can be difficult for startups to attract and retain customers. However, startups like Seeed Studio and Adafruit have developed strong relationships with their customers, enabling them to build a loyal customer base and drive growth.

So what can we learn from these successful startups? Firstly, the importance of developing strong relationships with suppliers and customers cannot be overstated. By building strong relationships, startups can ensure that they have access to high-quality components and can meet increasing demand quickly and efficiently.

Secondly, the importance of developing robust quality control processes cannot be overstated. By detecting and correcting defects quickly and efficiently, startups can ensure that their products meet the required quality standards and build a reputation for quality and reliability.

Finally, the importance of scalability cannot be overstated. By developing scalable production processes, startups can meet increasing demand without compromising on quality and drive growth and innovation.

The Future of PCB Assembly and Testing: Predictions and Opportunities

The future of PCB assembly and testing is exciting and full of opportunities. As the electronics manufacturing industry continues to evolve, we can expect to see new technologies and innovations emerge that will shape the future of PCB assembly and testing. In this section, we will explore some of the predictions and opportunities for the future of PCB assembly and testing.

One of the biggest trends that is expected to shape the future of PCB assembly and testing is the increasing use of artificial intelligence (AI) and machine learning (ML). AI and ML are already being used in various aspects of PCB assembly and testing, such as inspection and testing, and we can expect to see even more widespread adoption in the future.

Another trend that is expected to shape the future of PCB assembly and testing is the increasing use of robotics and automation. Robotics and automation are already being used in various aspects of PCB assembly and testing, such as assembly and inspection, and we can expect to see even more widespread adoption in the future.

The Internet of Things (IoT) is also expected to have a significant impact on the future of PCB assembly and testing. As more and more devices become connected to the internet, the demand for PCBs that can support IoT applications is expected to increase. This will require PCB assembly and testing startups to develop new technologies and innovations that can support IoT applications.

Industry 4.0 is also expected to have a significant impact on the future of PCB assembly and testing. Industry 4.0 is a term that refers to the fourth industrial revolution, which is characterized by the increasing use of automation, robotics, and AI in manufacturing. As Industry 4.0 continues to evolve, we can expect to see even more widespread adoption of automation, robotics, and AI in PCB assembly and testing.

So what opportunities do these trends present for PCB assembly and testing startups? Firstly, the increasing use of AI and ML presents opportunities for startups to develop new technologies and innovations that can support AI and ML applications. Secondly, the increasing use of robotics and automation presents opportunities for startups to develop new technologies and innovations that can support robotics and automation applications.

Finally, the increasing demand for PCBs that can support IoT applications presents opportunities for startups to develop new technologies and innovations that can support IoT applications. By developing new technologies and innovations that can support these trends, PCB assembly and testing startups can position themselves for success in the future.

Success Stories: PCB Assembly and Testing Startups that Have Made a Mark

There are several PCB assembly and testing startups that have achieved significant growth, innovation, or recognition in the industry. In this section, we will share some of their success stories and analyze the factors that contributed to their success.

One such startup is Tempo Automation, a PCB assembly and testing startup that has developed a unique approach to automation and robotics. Tempo Automation’s use of AI and ML has enabled it to improve the efficiency and accuracy of its PCB assembly and testing processes, making it a leader in the industry.

Another startup that has made a mark in the industry is Fictiv, a PCB assembly and testing startup that has developed a unique approach to 3D printing and additive manufacturing. Fictiv’s use of 3D printing has enabled it to produce complex PCBs with high accuracy and speed, making it a popular choice among electronics manufacturers.

MacroFab is another startup that has achieved significant growth and recognition in the industry. MacroFab’s use of automation and robotics has enabled it to improve the efficiency and accuracy of its PCB assembly and testing processes, making it a leader in the industry.

Screaming Circuits is another startup that has made a mark in the industry. Screaming Circuits’ use of automation and robotics has enabled it to improve the efficiency and accuracy of its PCB assembly and testing processes, making it a popular choice among electronics manufacturers.

So what factors contributed to the success of these startups? Firstly, their ability to innovate and develop new technologies and approaches to PCB assembly and testing was a key factor. Secondly, their focus on quality and customer service was also important. Finally, their ability to scale and grow quickly was also a key factor.

These success stories demonstrate the potential for PCB assembly and testing startups to make a significant impact in the industry. By developing new technologies and approaches, focusing on quality and customer service, and scaling quickly, startups can achieve significant growth and recognition in the industry.

Conclusion: The Role of PCB Assembly and Testing Startups in Shaping the Electronics Manufacturing Industry

PCB assembly and testing startups are playing a crucial role in shaping the electronics manufacturing industry. These startups are driving innovation and growth in the industry by developing new technologies and approaches to PCB assembly and testing. They are also providing businesses with access to high-quality PCBs at competitive prices, which is helping to drive growth and innovation in the industry.

The importance of PCB assembly and testing startups cannot be overstated. They are helping to drive innovation and growth in the industry, and are providing businesses with access to high-quality PCBs at competitive prices. As the industry continues to evolve, it is likely that PCB assembly and testing startups will play an increasingly important role in shaping the future of electronics manufacturing.

However, in order to stay competitive in the global market, it is essential that PCB assembly and testing startups continue to invest in research and development. This will enable them to stay ahead of the curve and develop new technologies and approaches that will help to drive innovation and growth in the industry.

Additionally, it is essential that businesses recognize the importance of PCB assembly and testing startups and provide them with the support and resources they need to succeed. This can include providing funding, mentorship, and access to resources and expertise.

By working together, PCB assembly and testing startups and businesses can help to drive innovation and growth in the electronics manufacturing industry. This will help to ensure that the industry remains competitive in the global market and continues to provide high-quality products and services to consumers.

In conclusion, PCB assembly and testing startups are playing a crucial role in shaping the electronics manufacturing industry. They are driving innovation and growth in the industry, and are providing businesses with access to high-quality PCBs at competitive prices. As the industry continues to evolve, it is likely that PCB assembly and testing startups will play an increasingly important role in shaping the future of electronics manufacturing.