Why Benchmarking is Crucial in the PCB Industry

In the rapidly evolving printed circuit board (PCB) industry, staying competitive requires more than just keeping pace with the latest technologies and trends. To truly excel, companies must adopt a proactive approach to innovation, leveraging tools like competitive analysis and benchmarking to drive growth and improvement. One key strategy for achieving this is through the implementation of PCB competitive analysis and benchmarking innovation strategies.

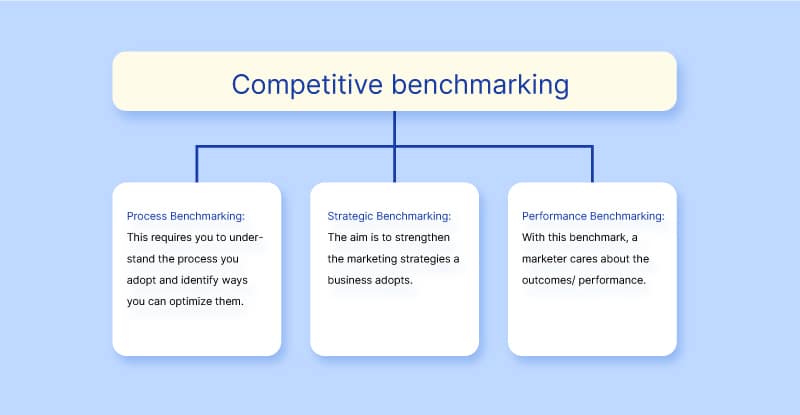

By conducting regular benchmarking exercises, PCB manufacturers can identify gaps in their processes, improve efficiency, and drive innovation. This, in turn, enables them to stay ahead of the competition and capitalize on emerging opportunities. Benchmarking also facilitates the identification of best practices, allowing companies to adopt and integrate these into their own operations.

The benefits of benchmarking in the PCB industry are numerous. For instance, it enables companies to assess their performance relative to industry peers, identify areas for improvement, and develop targeted strategies for addressing these gaps. By adopting a data-driven approach to decision-making, PCB manufacturers can optimize their operations, reduce costs, and enhance overall competitiveness.

In addition to driving innovation and improvement, benchmarking also plays a critical role in facilitating collaboration and knowledge-sharing within the industry. By sharing best practices and lessons learned, companies can work together to address common challenges and drive progress. This, in turn, contributes to the advancement of the industry as a whole, ultimately benefiting all stakeholders.

As the PCB industry continues to evolve, the importance of benchmarking and competitive analysis will only continue to grow. By embracing these strategies, companies can position themselves for success, drive innovation, and stay ahead of the competition in an increasingly complex and dynamic market.

Conducting a Comprehensive Competitive Analysis for PCB Innovation

To stay ahead of the competition in the rapidly evolving printed circuit board (PCB) industry, companies must conduct regular competitive analyses to identify areas for improvement and inform innovation strategies. A comprehensive competitive analysis involves several key steps, including identifying key competitors, analyzing their strengths and weaknesses, and assessing market trends.

Identifying key competitors is a critical first step in conducting a competitive analysis. This involves researching companies that offer similar products or services, as well as those that are pushing the boundaries of innovation in the industry. By analyzing the strengths and weaknesses of these competitors, companies can identify gaps in the market and opportunities for differentiation.

One effective tool for analyzing competitors is the SWOT analysis framework. This involves identifying the strengths, weaknesses, opportunities, and threats associated with each competitor, as well as the company’s own position in the market. By using this framework, companies can gain a deeper understanding of the competitive landscape and identify areas for improvement.

In addition to analyzing competitors, companies must also assess market trends to inform their innovation strategies. This involves researching emerging technologies, industry reports, and market research studies to identify areas of growth and opportunity. By staying up-to-date with the latest trends and developments, companies can position themselves for success and drive innovation in the PCB industry.

Reputable sources such as IPC reports and academic research papers can provide valuable insights into market trends and competitor activity. By leveraging these sources, companies can gain a deeper understanding of the competitive landscape and identify opportunities for innovation and growth.

By conducting a comprehensive competitive analysis, companies can inform their PCB competitive analysis and benchmarking innovation strategies and drive growth and improvement in the industry. This involves identifying areas for improvement, analyzing competitor activity, and assessing market trends to position the company for success.

How to Benchmark Your PCB Design and Manufacturing Processes

Benchmarking is a critical component of PCB competitive analysis and benchmarking innovation strategies, enabling companies to evaluate their design and manufacturing processes and identify areas for improvement. To effectively benchmark these processes, companies must establish clear key performance indicators (KPIs) and track progress over time.

When it comes to PCB design, benchmarking involves evaluating the efficiency and effectiveness of design software, as well as the skills and expertise of design engineers. This may include assessing the time and cost associated with designing and prototyping PCBs, as well as the quality and reliability of the final product.

In terms of manufacturing, benchmarking involves evaluating the efficiency and effectiveness of manufacturing equipment, as well as the supply chain management processes that support production. This may include assessing the yield rates and defect rates associated with different manufacturing processes, as well as the lead times and costs associated with sourcing components and materials.

To establish effective KPIs for benchmarking, companies should consider a range of metrics, including design cycle time, manufacturing yield rates, and supply chain lead times. By tracking these metrics over time, companies can identify areas for improvement and develop targeted strategies for addressing these gaps.

Regular benchmarking also enables companies to stay up-to-date with the latest technologies and trends in PCB design and manufacturing. By evaluating the performance of different design software and manufacturing equipment, companies can identify opportunities for innovation and improvement, and make informed decisions about investments in new technologies and processes.

Furthermore, benchmarking can help companies to identify best practices in PCB design and manufacturing, and to develop strategies for adopting and implementing these practices. By sharing knowledge and expertise with other companies and industry partners, companies can drive innovation and improvement across the industry as a whole.

By incorporating benchmarking into their PCB competitive analysis and benchmarking innovation strategies, companies can drive growth and improvement in the industry, and stay ahead of the competition in a rapidly evolving market.

Leveraging Industry Reports and Research Studies for PCB Innovation

Industry reports and research studies are valuable resources for informing PCB innovation strategies. These reports provide insights into the latest trends and technologies in the industry, as well as analysis of the competitive landscape and market trends. By leveraging these resources, companies can gain a deeper understanding of the industry and identify opportunities for innovation and growth.

One reputable source of industry reports is the IPC (Institute for Printed Circuits). The IPC publishes a range of reports on the PCB industry, including market research studies and technical papers. These reports provide valuable insights into the latest trends and technologies in the industry, as well as analysis of the competitive landscape and market trends.

Academic research papers are another valuable source of information for PCB innovation strategies. These papers provide in-depth analysis of the latest technologies and trends in the industry, as well as insights into the future direction of the industry. By leveraging these resources, companies can gain a deeper understanding of the industry and identify opportunities for innovation and growth.

When using industry reports and research studies to inform PCB innovation strategies, it’s essential to consider the credibility and reliability of the source. Look for reports and studies that are published by reputable organizations and authors, and that are based on rigorous research and analysis.

By leveraging industry reports and research studies, companies can drive innovation and growth in the PCB industry. These resources provide valuable insights into the latest trends and technologies in the industry, as well as analysis of the competitive landscape and market trends. By applying these insights to their PCB competitive analysis and benchmarking innovation strategies, companies can stay ahead of the competition and achieve success in the industry.

Some examples of how industry reports and research studies can be applied to PCB innovation strategies include identifying new technologies and trends, analyzing the competitive landscape, and informing product development and design decisions. By leveraging these resources, companies can drive innovation and growth in the PCB industry and achieve success in the market.

Best Practices for Implementing Innovation Strategies in PCB Design and Manufacturing

Implementing innovation strategies in PCB design and manufacturing requires a structured approach to ensure successful adoption and integration. Here are some best practices to consider when implementing innovation strategies in PCB design and manufacturing.

Adopting agile methodologies is a key best practice for implementing innovation strategies in PCB design and manufacturing. Agile methodologies enable companies to respond quickly to changing market conditions and customer needs, and to iterate and refine their products and processes in real-time.

Encouraging collaboration and knowledge-sharing is another important best practice for implementing innovation strategies in PCB design and manufacturing. By fostering a culture of collaboration and knowledge-sharing, companies can leverage the expertise and insights of their employees to drive innovation and improvement.

Investing in employee training and development is also critical for implementing innovation strategies in PCB design and manufacturing. By providing employees with the skills and knowledge they need to succeed, companies can ensure that their innovation strategies are implemented effectively and efficiently.

Establishing a culture of innovation is also essential for implementing innovation strategies in PCB design and manufacturing. This involves creating an environment that encourages experimentation, risk-taking, and creativity, and that rewards employees for their contributions to innovation and improvement.

Finally, companies should ensure that their innovation strategies are aligned with their overall business goals and objectives. This involves establishing clear metrics and benchmarks for measuring the success of innovation strategies, and ensuring that innovation initiatives are properly resourced and supported.

By following these best practices, companies can ensure that their innovation strategies are implemented effectively and efficiently, and that they achieve their desired outcomes. This is particularly important in the context of PCB competitive analysis and benchmarking innovation strategies, where companies must stay ahead of the competition to succeed.

By adopting these best practices, companies can drive innovation and growth in the PCB industry, and achieve success in the market. This requires a commitment to innovation and improvement, as well as a willingness to invest in the skills and knowledge of employees.

Real-World Examples of Successful PCB Innovation Strategies

Several companies have successfully implemented innovation strategies in PCB design and manufacturing, achieving significant improvements in efficiency, quality, and competitiveness. Here are a few examples of real-world innovation strategies that have driven success in the PCB industry.

Apple, for instance, has been a pioneer in the use of advanced PCB materials and manufacturing processes. The company’s use of high-density interconnect (HDI) technology, for example, has enabled the development of smaller, more complex electronic devices with improved performance and reliability.

Tesla, another company that has successfully implemented innovation strategies in PCB design and manufacturing, has developed innovative manufacturing processes that enable the rapid production of high-quality PCBs. The company’s use of automated manufacturing equipment and advanced quality control systems, for example, has enabled the production of PCBs with improved yield rates and reduced defect rates.

Other companies, such as Google and Amazon, have also implemented innovation strategies in PCB design and manufacturing, achieving significant improvements in efficiency, quality, and competitiveness. These companies have leveraged advanced technologies, such as artificial intelligence and machine learning, to optimize their PCB design and manufacturing processes, and have achieved significant reductions in costs and improvements in quality.

These examples demonstrate the potential of innovation strategies to drive success in the PCB industry. By leveraging advanced technologies and processes, companies can achieve significant improvements in efficiency, quality, and competitiveness, and stay ahead of the competition in a rapidly evolving market.

In the context of PCB competitive analysis and benchmarking innovation strategies, these examples highlight the importance of staying up-to-date with the latest technologies and trends in the industry. By benchmarking their processes and performance against industry leaders, companies can identify areas for improvement and develop targeted strategies for driving innovation and growth.

Overcoming Common Challenges in PCB Innovation and Benchmarking

While innovation and benchmarking are essential for staying competitive in the PCB industry, companies may face several challenges when attempting to implement these strategies. Here are some common challenges that companies may encounter, along with suggestions for overcoming them.

One common challenge is limited resources. Many companies may not have the budget or personnel to dedicate to innovation and benchmarking initiatives. To overcome this challenge, companies can start by identifying areas where they can improve efficiency and reduce costs, and then allocate resources accordingly.

Another common challenge is resistance to change. Companies may be hesitant to adopt new technologies or processes, especially if they have been successful with their current approach. To overcome this challenge, companies can educate their employees on the benefits of innovation and benchmarking, and involve them in the decision-making process.

Difficulty in measuring progress is another common challenge. Companies may struggle to quantify the impact of their innovation and benchmarking initiatives, making it difficult to determine whether they are achieving their goals. To overcome this challenge, companies can establish clear key performance indicators (KPIs) and track progress over time.

In the context of PCB competitive analysis and benchmarking innovation strategies, overcoming these challenges is crucial for achieving success. By identifying areas for improvement, allocating resources effectively, and measuring progress, companies can stay ahead of the competition and drive innovation in the PCB industry.

Additionally, companies can leverage industry reports and research studies to inform their innovation strategies and stay up-to-date with the latest trends and technologies. By applying insights from these sources, companies can develop targeted strategies for driving innovation and growth.

By overcoming common challenges and leveraging industry reports and research studies, companies can unlock the full potential of their PCB innovation strategies and achieve success in the market.

Staying Ahead of the Curve: Future-Proofing Your PCB Innovation Strategies

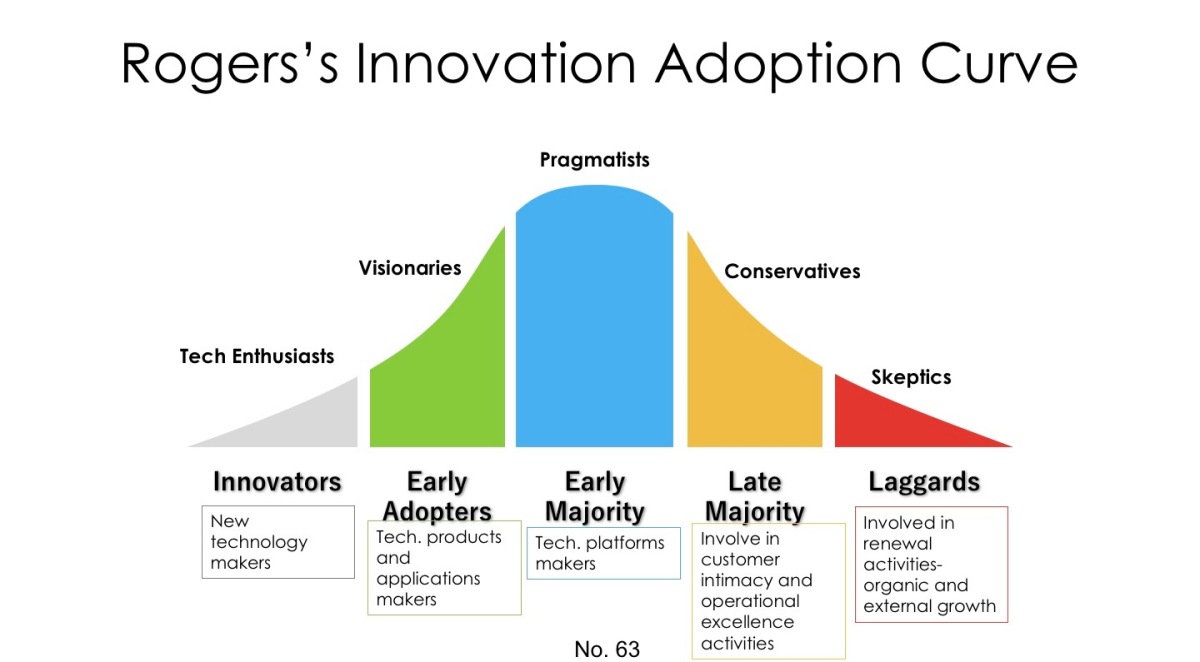

In today’s rapidly evolving PCB industry, staying ahead of the curve requires more than just keeping pace with the latest trends and technologies. To truly future-proof their innovation strategies, companies must anticipate and prepare for the challenges and opportunities that lie ahead.

One key area of focus for future-proofing PCB innovation strategies is emerging trends and technologies, such as artificial intelligence, 5G, and the Internet of Things (IoT). These technologies have the potential to transform the PCB industry, enabling new applications, improving efficiency, and driving innovation.

To stay ahead of the curve, companies must invest in research and development, leveraging these emerging trends and technologies to drive innovation and growth. This may involve partnering with technology leaders, investing in new equipment and processes, and developing new skills and expertise.

Another key area of focus for future-proofing PCB innovation strategies is sustainability and environmental responsibility. As concern for the environment continues to grow, companies must prioritize sustainability and environmental responsibility in their innovation strategies, reducing waste, conserving resources, and minimizing their environmental footprint.

In the context of PCB competitive analysis and benchmarking innovation strategies, future-proofing is crucial for achieving long-term success. By anticipating and preparing for emerging trends and technologies, and prioritizing sustainability and environmental responsibility, companies can stay ahead of the competition and drive innovation in the PCB industry.

By future-proofing their innovation strategies, companies can unlock new opportunities for growth and success, and stay ahead of the curve in a rapidly evolving market. This requires a commitment to ongoing research and development, a focus on sustainability and environmental responsibility, and a willingness to adapt and evolve in response to changing market conditions.