What is PCB Design and Manufacturing?

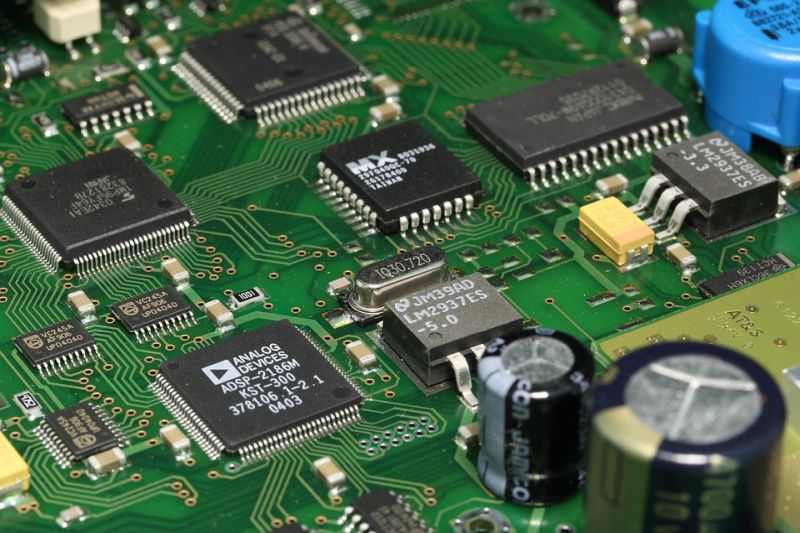

Printed circuit boards (PCBs) are the backbone of modern electronics, serving as the foundation for a wide range of devices, from smartphones and laptops to medical equipment and automotive systems. PCB design and manufacturing startups play a crucial role in bringing these devices to life, leveraging innovative technologies and techniques to create high-quality, reliable, and efficient PCBs.

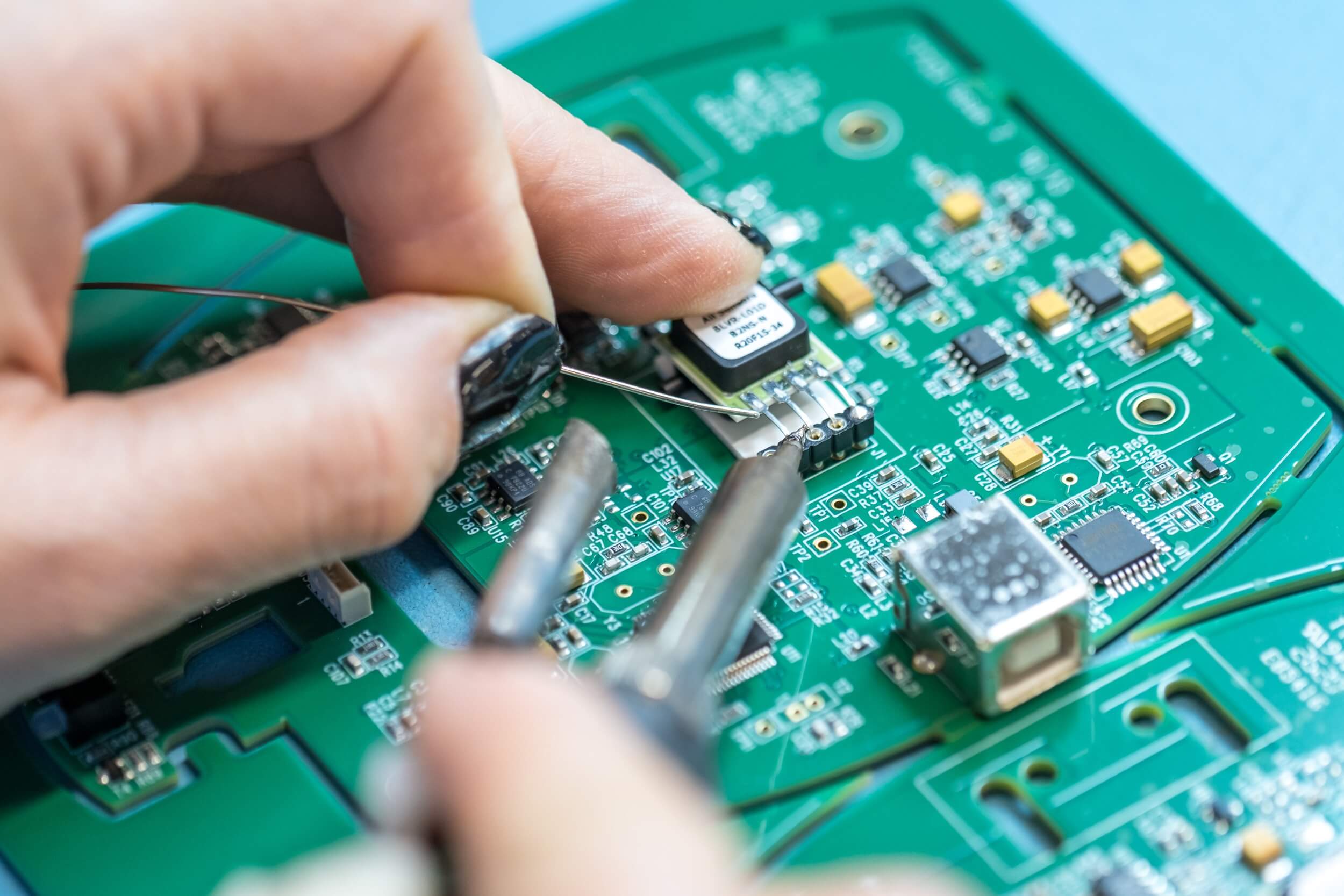

PCB design involves creating a detailed layout of the circuit board, including the placement of components, routing of wires, and selection of materials. This process requires a deep understanding of electronics, materials science, and manufacturing processes. PCB manufacturing, on the other hand, involves transforming the design into a physical product, using techniques such as etching, drilling, and assembly.

The importance of PCB design and manufacturing startups cannot be overstated. These companies are driving innovation in the electronics industry, pushing the boundaries of what is possible with PCB technology. By leveraging advancements in fields like artificial intelligence, robotics, and nanotechnology, PCB design and manufacturing startups are creating new opportunities for device miniaturization, increased performance, and reduced costs.

As the demand for electronic devices continues to grow, the need for high-quality PCBs is becoming increasingly important. PCB design and manufacturing startups are well-positioned to capitalize on this trend, providing innovative solutions that meet the evolving needs of the electronics industry. With their focus on innovation, quality, and efficiency, these startups are revolutionizing the way PCBs are designed and manufactured, and are poised to play a major role in shaping the future of electronics.

How to Bring Your PCB Design to Life: A Guide for Startups

For PCB design and manufacturing startups, bringing a design to life requires careful planning, attention to detail, and a deep understanding of the manufacturing process. To ensure successful production, startups must choose the right design software, select suitable materials, and ensure compliance with industry standards.

Choosing the right design software is critical for PCB design and manufacturing startups. Popular options include Altium Designer, Autodesk Eagle, and KiCad. Each software has its strengths and weaknesses, and startups must carefully evaluate their needs before making a decision. For example, Altium Designer is known for its advanced features and user-friendly interface, while KiCad is a popular open-source option.

Selecting suitable materials is also crucial for PCB design and manufacturing startups. The choice of materials will depend on the specific application and requirements of the PCB. For example, startups may choose from a range of substrates, including FR4, Rogers, and polyimide. Each substrate has its own unique characteristics, and startups must carefully evaluate their options before making a decision.

Ensuring compliance with industry standards is also essential for PCB design and manufacturing startups. Startups must comply with regulations such as RoHS, WEEE, and REACH, which govern the use of hazardous materials in electronic components. Additionally, startups must ensure that their PCBs meet industry standards for quality and reliability, such as ISO 9001.

By following these best practices, PCB design and manufacturing startups can bring their designs to life and ensure successful production. Whether you’re a startup looking to design and manufacture your own PCBs or a established company looking to improve your processes, these tips can help you achieve your goals and stay competitive in the rapidly evolving world of PCB design and manufacturing.

Top PCB Design and Manufacturing Startups to Watch

The PCB design and manufacturing startup landscape is rapidly evolving, with innovative companies emerging to disrupt the industry. Here are a few notable startups to watch:

Tempo Automation, a San Francisco-based startup, is revolutionizing the PCB manufacturing process with its proprietary automation technology. By leveraging machine learning and robotics, Tempo Automation is able to produce high-quality PCBs at unprecedented speeds and costs.

MacroFab, a Houston-based startup, is democratizing access to PCB manufacturing with its cloud-based platform. By providing a user-friendly interface and streamlined production process, MacroFab is enabling startups and small businesses to bring their PCB designs to life.

Bay Area Circuits, a California-based startup, is pushing the boundaries of PCB design and manufacturing with its innovative approach to flexible circuits. By leveraging advanced materials and manufacturing techniques, Bay Area Circuits is creating flexible PCBs that are thinner, lighter, and more reliable than traditional rigid PCBs.

These startups, along with others, are driving innovation in the PCB design and manufacturing space. By leveraging cutting-edge technologies and innovative approaches, they are disrupting the industry and creating new opportunities for startups and small businesses to succeed.

As the demand for electronic devices continues to grow, the need for high-quality PCBs is becoming increasingly important. PCB design and manufacturing startups like Tempo Automation, MacroFab, and Bay Area Circuits are well-positioned to capitalize on this trend, providing innovative solutions that meet the evolving needs of the electronics industry.

Overcoming Common Challenges in PCB Design and Manufacturing

PCB design and manufacturing startups often face a range of challenges that can impact the success of their products. Some of the most common pain points include design errors, material sourcing, and production delays.

Design errors can be a major issue for PCB design and manufacturing startups. These errors can occur at any stage of the design process, from schematic capture to layout and routing. To mitigate this risk, startups can use design software that includes built-in checks and validation tools. Additionally, startups can work with experienced designers who have a deep understanding of PCB design principles and best practices.

Material sourcing is another challenge that PCB design and manufacturing startups may face. With the increasing demand for electronic devices, the availability of certain materials can be limited. To overcome this challenge, startups can work with suppliers who have a proven track record of delivering high-quality materials on time. Startups can also consider using alternative materials or designing their products to be more material-efficient.

Production delays can also be a major issue for PCB design and manufacturing startups. These delays can occur due to a range of factors, including equipment failures, staffing issues, and supply chain disruptions. To mitigate this risk, startups can work with contract manufacturers who have a proven track record of delivering high-quality products on time. Startups can also consider implementing lean manufacturing principles and investing in automation technologies to improve efficiency and reduce the risk of delays.

By understanding these common challenges and taking steps to mitigate them, PCB design and manufacturing startups can improve their chances of success and deliver high-quality products to their customers. Whether you’re a startup looking to design and manufacture your own PCBs or a established company looking to improve your processes, being aware of these challenges and taking steps to overcome them is crucial for success in the rapidly evolving world of PCB design and manufacturing.

The Role of Automation in Modern PCB Manufacturing

Automation is playing an increasingly important role in modern PCB manufacturing, enabling PCB design and manufacturing startups to improve efficiency, reduce costs, and enhance product quality. By leveraging robotics, artificial intelligence, and machine learning, startups can automate many aspects of the manufacturing process, from material handling and assembly to testing and inspection.

One of the key benefits of automation in PCB manufacturing is improved efficiency. By automating repetitive tasks, startups can free up staff to focus on higher-value activities, such as design and engineering. Additionally, automation can help to reduce the risk of human error, which can be a major source of defects and quality issues in PCB manufacturing.

Automation can also help to reduce costs in PCB manufacturing. By minimizing the need for manual labor, startups can reduce their labor costs and improve their bottom line. Additionally, automation can help to reduce waste and improve material utilization, which can also help to reduce costs.

Another key benefit of automation in PCB manufacturing is enhanced product quality. By using advanced testing and inspection technologies, startups can ensure that their PCBs meet the highest standards of quality and reliability. Additionally, automation can help to improve the consistency of PCB production, which can be critical for applications where reliability is paramount.

Examples of automation in PCB manufacturing include the use of robotic assembly systems, automated optical inspection (AOI) systems, and machine learning algorithms for predictive maintenance. By leveraging these technologies, PCB design and manufacturing startups can stay ahead of the competition and deliver high-quality products to their customers.

As the demand for electronic devices continues to grow, the need for efficient and effective PCB manufacturing processes will become increasingly important. By embracing automation and other advanced technologies, PCB design and manufacturing startups can position themselves for success in this rapidly evolving industry.

Ensuring Quality and Reliability in PCB Design and Manufacturing

Quality and reliability are critical components of PCB design and manufacturing, particularly for startups looking to establish themselves in the industry. To ensure compliance with industry standards, PCB design and manufacturing startups must implement effective testing and inspection protocols, as well as adhere to standards such as ISO 9001.

ISO 9001 is a widely recognized standard for quality management, and it provides a framework for PCB design and manufacturing startups to ensure that their products meet the highest standards of quality and reliability. By implementing ISO 9001, startups can demonstrate their commitment to quality and reliability, and establish trust with their customers.

In addition to ISO 9001, PCB design and manufacturing startups can also implement other quality management systems, such as Six Sigma or Lean manufacturing. These systems provide a framework for continuous improvement, and can help startups to identify and eliminate defects in their products.

Effective testing and inspection protocols are also critical for ensuring quality and reliability in PCB design and manufacturing. Startups can use a variety of testing methods, including functional testing, environmental testing, and reliability testing, to ensure that their products meet the required standards.

Another key aspect of quality and reliability in PCB design and manufacturing is the use of high-quality materials and components. Startups should select materials and components that meet the required standards, and ensure that they are sourced from reputable suppliers.

By prioritizing quality and reliability, PCB design and manufacturing startups can establish themselves as leaders in the industry, and build trust with their customers. By implementing effective testing and inspection protocols, adhering to industry standards, and using high-quality materials and components, startups can ensure that their products meet the highest standards of quality and reliability.

The Future of PCB Design and Manufacturing: Trends and Innovations

The future of PCB design and manufacturing is exciting and rapidly evolving, with emerging trends and innovations that are transforming the industry. One of the most significant trends is the use of flexible circuits, which are being used in a wide range of applications, from wearable devices to medical implants.

Another trend that is gaining momentum is the use of 3D printing in PCB manufacturing. This technology allows for the rapid prototyping and production of complex PCBs, and is being used by a growing number of PCB design and manufacturing startups.

Nanotechnology is also being used in PCB design and manufacturing, with the development of nanoscale materials and components that are being used to create smaller, faster, and more powerful PCBs.

Artificial intelligence and machine learning are also being used in PCB design and manufacturing, with the development of AI-powered design tools and machine learning algorithms that can optimize PCB design and manufacturing processes.

These emerging trends and innovations are transforming the PCB design and manufacturing industry, and are creating new opportunities for startups and established companies alike. By embracing these trends and innovations, PCB design and manufacturing startups can stay ahead of the competition and establish themselves as leaders in the industry.

As the demand for electronic devices continues to grow, the need for innovative and efficient PCB design and manufacturing solutions will become increasingly important. By leveraging emerging trends and innovations, PCB design and manufacturing startups can meet this demand and establish themselves as key players in the industry.

Conclusion: The Exciting World of PCB Design and Manufacturing Startups

The world of PCB design and manufacturing startups is an exciting and rapidly evolving field, full of opportunities and challenges. As we’ve seen in this article, there are many innovative approaches, products, and services being developed by startups in this space, from Tempo Automation’s automated PCB manufacturing to MacroFab’s cloud-based PCB design and manufacturing platform.

Despite the challenges faced by startups in this space, such as design errors, material sourcing, and production delays, there are many strategies that can be employed to mitigate these risks and ensure successful production. By choosing the right design software, selecting suitable materials, and ensuring compliance with industry standards, startups can set themselves up for success.

The future of PCB design and manufacturing is also looking bright, with emerging trends and innovations such as flexible circuits, 3D printing, and nanotechnology set to shape the industry in the coming years. By embracing these trends and innovations, PCB design and manufacturing startups can stay ahead of the competition and establish themselves as leaders in the industry.

In conclusion, the world of PCB design and manufacturing startups is an exciting and rapidly evolving field, full of opportunities and challenges. By understanding the importance of PCB design and manufacturing, the challenges faced by startups in this space, and the emerging trends and innovations that are shaping the industry, readers can gain a deeper appreciation for the complex and fascinating world of PCB design and manufacturing.