Navigating the Complex World of PCB Design and Production

The rapid evolution of electronics has created a complex landscape for PCB design and production. As technology continues to advance at an unprecedented rate, the demand for sophisticated electronic devices has increased exponentially. This, in turn, has placed immense pressure on PCB manufacturers to deliver high-quality, reliable, and cost-effective products that meet the exacting demands of modern electronics.

To stay competitive in this dynamic environment, it is essential for industry stakeholders to stay up-to-date with the latest PCB industry trends and analysis. This includes understanding the impact of emerging technologies, such as the Internet of Things (IoT), artificial intelligence (AI), and 5G, on PCB design and manufacturing. By embracing these trends and investing in research and development, manufacturers can unlock new opportunities for growth, improve efficiency, and enhance their competitive position in the global market.

The importance of adaptability in design and manufacturing cannot be overstated. As the PCB industry continues to evolve, manufacturers must be able to respond quickly to changing market conditions, customer demands, and technological advancements. This requires a deep understanding of the latest PCB industry trends and analysis, as well as the ability to innovate and adapt in response to emerging challenges and opportunities.

How to Leverage Advanced Materials and Technologies for Enhanced PCB Performance

The PCB industry is witnessing a significant shift towards the adoption of advanced materials and technologies, driven by the need for improved performance, reliability, and sustainability. Emerging materials such as graphene, nanomaterials, and advanced ceramics are being increasingly used in PCB manufacturing to enhance thermal management, reduce weight, and improve electrical conductivity.

One of the most promising technologies in this space is 3D printing, which enables the creation of complex PCB geometries and structures that cannot be produced using traditional manufacturing methods. This technology has the potential to revolutionize the PCB industry by enabling the rapid prototyping and production of high-performance PCBs with reduced material waste and energy consumption.

Several companies have already successfully implemented these emerging trends in their PCB manufacturing processes. For example, a leading aerospace company has developed a graphene-based PCB that offers improved thermal management and reduced weight, enabling the creation of more efficient and reliable electronic systems. Another company has used 3D printing to produce complex PCB geometries that cannot be produced using traditional manufacturing methods, reducing production time and costs.

These examples demonstrate the potential of advanced materials and technologies to enhance PCB performance, reliability, and sustainability. As the PCB industry continues to evolve, it is essential for manufacturers to stay up-to-date with the latest trends and technologies, and to invest in research and development to remain competitive in the global market.

The Rise of IoT and Its Impact on PCB Design and Manufacturing

The Internet of Things (IoT) has revolutionized the way we live and work, and its impact on the PCB industry has been significant. The growing demand for IoT devices has led to an increased need for smaller, more complex, and connected PCBs. This has created new challenges for PCB designers and manufacturers, who must balance the need for miniaturization with the requirement for high-performance and reliability.

One of the key trends in IoT-related PCB design is the use of System-in-Package (SiP) technology. This involves integrating multiple components, such as processors, memory, and sensors, into a single package. SiP technology enables the creation of smaller, more complex PCBs that can be used in a wide range of IoT applications, from smart home devices to industrial automation systems.

Another trend in IoT-related PCB manufacturing is the use of flexible PCBs. These PCBs can be bent and folded to fit into small spaces, making them ideal for use in wearable devices and other IoT applications where space is limited. Flexible PCBs also offer improved reliability and durability, as they can withstand the stresses and strains of repeated bending and flexing.

The rise of IoT has also led to an increased focus on connectivity and communication in PCB design. This has driven the development of new technologies, such as wireless charging and Bluetooth Low Energy (BLE), which enable devices to communicate with each other and with the cloud. As the IoT continues to evolve, it is likely that we will see even more innovative technologies emerge, driving further growth and innovation in the PCB industry.

PCB Industry Trends: The Shift towards Automation and Artificial Intelligence

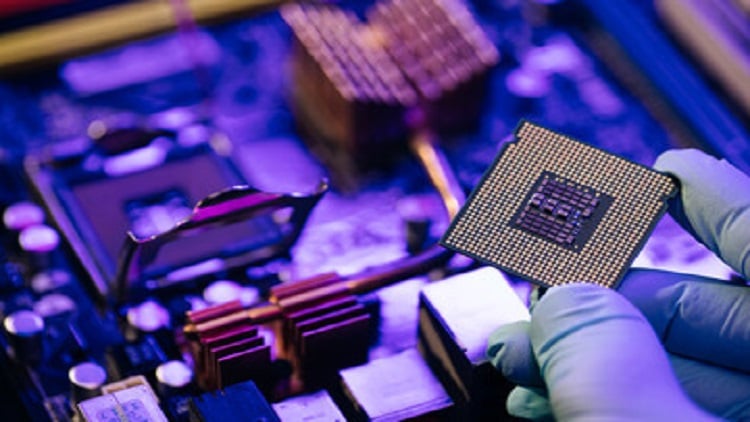

The PCB industry is undergoing a significant transformation, driven by the increasing adoption of automation and artificial intelligence (AI) in manufacturing. This shift is being driven by the need for improved efficiency, reduced errors, and enhanced productivity. By leveraging automation and AI, PCB manufacturers can streamline their production processes, reduce labor costs, and improve product quality.

One of the key trends in PCB automation is the use of machine learning algorithms to optimize production processes. These algorithms can analyze data from various sources, including sensors and production equipment, to identify areas for improvement and optimize production workflows. This can lead to significant reductions in production time and costs, as well as improved product quality.

Another trend in PCB automation is the use of robotics and automated assembly systems. These systems can perform tasks such as component placement, soldering, and inspection, freeing up human workers to focus on higher-value tasks. Robotics and automated assembly systems can also improve product quality and reduce the risk of human error.

The adoption of AI in PCB manufacturing is also on the rise. AI can be used to analyze data from various sources, including production equipment and quality control systems, to identify trends and patterns that can inform production decisions. AI can also be used to optimize production workflows and improve product quality.

As the PCB industry continues to evolve, it is likely that we will see even more innovative applications of automation and AI. By embracing these technologies, PCB manufacturers can stay ahead of the curve and remain competitive in a rapidly changing market.

Environmental Concerns and the Growing Importance of Sustainable PCB Practices

The PCB industry has a significant environmental impact, from the use of hazardous materials to the generation of waste and pollution. As concern for the environment grows, the industry is shifting towards more sustainable practices. This includes the use of eco-friendly materials, reduced waste, and energy-efficient processes.

One of the key trends in sustainable PCB practices is the use of lead-free soldering. This eliminates the use of lead, a toxic substance that can harm human health and the environment. Lead-free soldering also reduces the risk of environmental pollution and promotes a safer working environment.

Another trend in sustainable PCB practices is the use of recyclable materials. This includes the use of recyclable copper, aluminum, and other metals. By using recyclable materials, PCB manufacturers can reduce waste and minimize the environmental impact of their operations.

The use of energy-efficient processes is also becoming increasingly important in the PCB industry. This includes the use of solar-powered equipment, energy-efficient lighting, and other sustainable practices. By reducing energy consumption, PCB manufacturers can minimize their carbon footprint and promote a more sustainable future.

As the PCB industry continues to evolve, it is likely that we will see even more innovative sustainable practices emerge. By embracing these trends, PCB manufacturers can reduce their environmental impact, promote a safer working environment, and contribute to a more sustainable future.

Market Analysis: Identifying Opportunities and Challenges in the Global PCB Industry

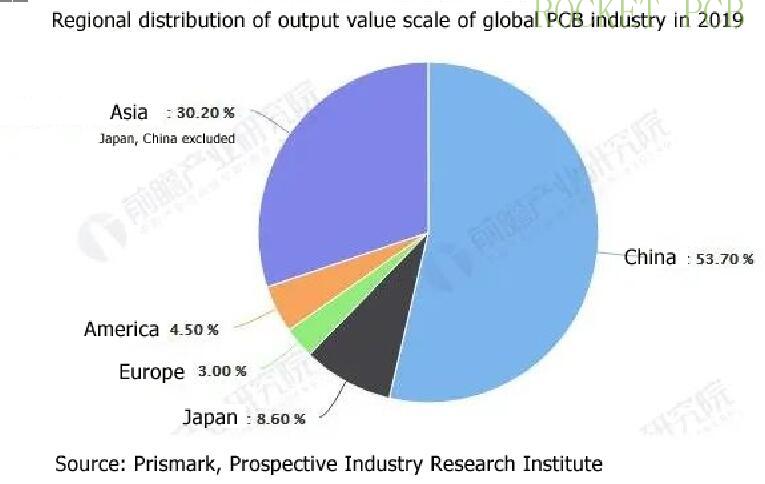

The global PCB market is a complex and dynamic industry, with a wide range of players and stakeholders. To understand the opportunities and challenges in this market, it is essential to conduct a thorough analysis of the current trends and developments.

According to recent market research, the global PCB market is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2028. This growth is driven by the increasing demand for PCBs in various industries, including consumer electronics, automotive, and aerospace.

One of the key opportunities in the global PCB market is the growing demand for high-density interconnect (HDI) PCBs. HDI PCBs are designed to meet the increasing demand for smaller, more complex electronic devices. They offer higher density and faster data transfer rates than traditional PCBs, making them ideal for applications such as smartphones, laptops, and tablets.

Another opportunity in the global PCB market is the increasing adoption of PCBs in the automotive industry. As the automotive industry continues to evolve, there is a growing demand for PCBs that can meet the high-performance and reliability requirements of modern vehicles. This includes the use of PCBs in advanced driver-assistance systems (ADAS), autonomous vehicles, and electric vehicles.

However, the global PCB market also faces several challenges, including trade tensions, supply chain disruptions, and emerging competitors. The ongoing trade tensions between the US and China have had a significant impact on the global PCB market, with many manufacturers facing increased costs and uncertainty.

To stay ahead of the curve in the global PCB market, it is essential for manufacturers to stay up-to-date with the latest trends and developments. This includes investing in research and development, adopting new technologies and materials, and building strong relationships with suppliers and customers.

Case Study: Successful Implementation of Emerging Trends in PCB Manufacturing

Company X, a leading manufacturer of PCBs, has successfully implemented emerging trends in PCB manufacturing to stay ahead of the competition. One of the key trends they have adopted is the use of automation and artificial intelligence (AI) in their manufacturing process.

Company X has invested heavily in automation and AI, including the use of robotic assembly lines and machine learning algorithms to optimize production. This has resulted in significant improvements in efficiency, reduced errors, and enhanced productivity.

Another trend that Company X has adopted is the use of sustainable practices in their manufacturing process. They have implemented a range of initiatives, including the use of eco-friendly materials, reduced waste, and energy-efficient processes. This has not only reduced their environmental impact but also improved their bottom line.

Company X has also invested in research and development, including the use of emerging materials and technologies such as graphene and nanomaterials. This has enabled them to develop new and innovative products that meet the changing needs of their customers.

The benefits of adopting emerging trends in PCB manufacturing have been significant for Company X. They have seen a significant increase in productivity, reduced costs, and improved product quality. They have also been able to stay ahead of the competition and maintain their position as a leading manufacturer of PCBs.

The challenges of adopting emerging trends in PCB manufacturing have also been significant for Company X. They have had to invest heavily in new equipment and training, and have had to adapt to new and changing technologies. However, the benefits have far outweighed the challenges, and they continue to be a leader in the industry.

Future-Proofing Your Business: Strategies for Thriving in a Rapidly Evolving PCB Industry

To stay ahead of the curve in the rapidly evolving PCB industry, businesses must be proactive and adaptable. This requires a deep understanding of the latest PCB industry trends and analysis, as well as a willingness to invest in innovation and collaboration.

One key strategy for future-proofing your business is to invest in research and development. This includes staying up-to-date with the latest emerging materials and technologies, such as graphene, nanomaterials, and 3D printing. By investing in R&D, businesses can develop new and innovative products that meet the changing needs of their customers.

Another key strategy is to focus on sustainability. This includes adopting eco-friendly materials, reducing waste, and implementing energy-efficient processes. By prioritizing sustainability, businesses can reduce their environmental impact, improve their bottom line, and enhance their reputation.

Collaboration is also essential for success in the PCB industry. This includes partnering with suppliers, customers, and other stakeholders to stay ahead of the curve. By working together, businesses can share knowledge, resources, and expertise to drive innovation and growth.

Finally, businesses must be adaptable and agile in response to changing market conditions. This includes being prepared to pivot quickly in response to new trends and technologies, as well as being open to new opportunities and challenges.

By following these strategies, businesses can future-proof themselves and thrive in the rapidly evolving PCB industry. This requires a commitment to innovation, collaboration, and adaptability, as well as a deep understanding of the latest PCB industry trends and analysis.