What is PCB Manufacturing and Why is it Important?

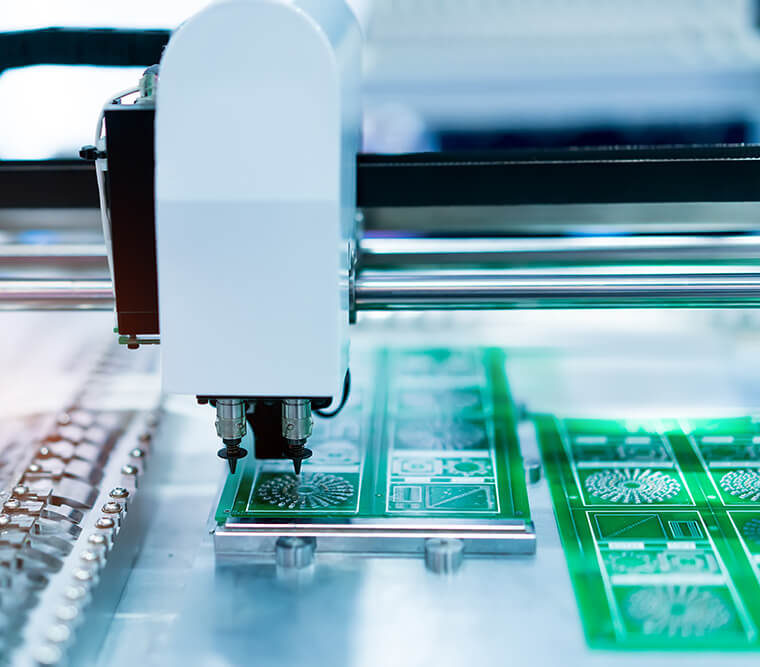

Printed Circuit Board (PCB) manufacturing is the process of creating the backbone of modern electronics, from smartphones and laptops to medical devices and automotive systems. The electronics industry relies heavily on PCBs, which are essentially the foundation of electronic devices, connecting various components and enabling them to function together seamlessly. As the demand for innovative and sophisticated electronic products continues to grow, the need for advanced PCB manufacturing equipment and techniques has become increasingly important.

The significance of PCB manufacturing lies in its ability to enable the mass production of complex electronic devices. By providing a platform for mounting and connecting components, PCBs play a crucial role in determining the performance, reliability, and cost-effectiveness of electronic products. As a result, the PCB manufacturing industry has become a critical component of the global electronics supply chain.

In recent years, the rise of PCB manufacturing equipment startups has transformed the landscape of the industry. These innovative companies are developing cutting-edge solutions that cater to the evolving needs of electronics manufacturers, from improving production efficiency and reducing costs to enhancing product quality and reliability. By leveraging advancements in technology, such as automation, artificial intelligence, and the Internet of Things (IoT), PCB manufacturing equipment startups are revolutionizing the way electronic devices are designed, manufactured, and tested.

As the electronics industry continues to evolve, the importance of PCB manufacturing and the role of innovative startups in driving this evolution will only continue to grow. By providing advanced solutions that address the complex challenges of modern electronics production, PCB manufacturing equipment startups are poised to play a critical role in shaping the future of the industry.

How to Choose the Right PCB Manufacturing Equipment for Your Startup

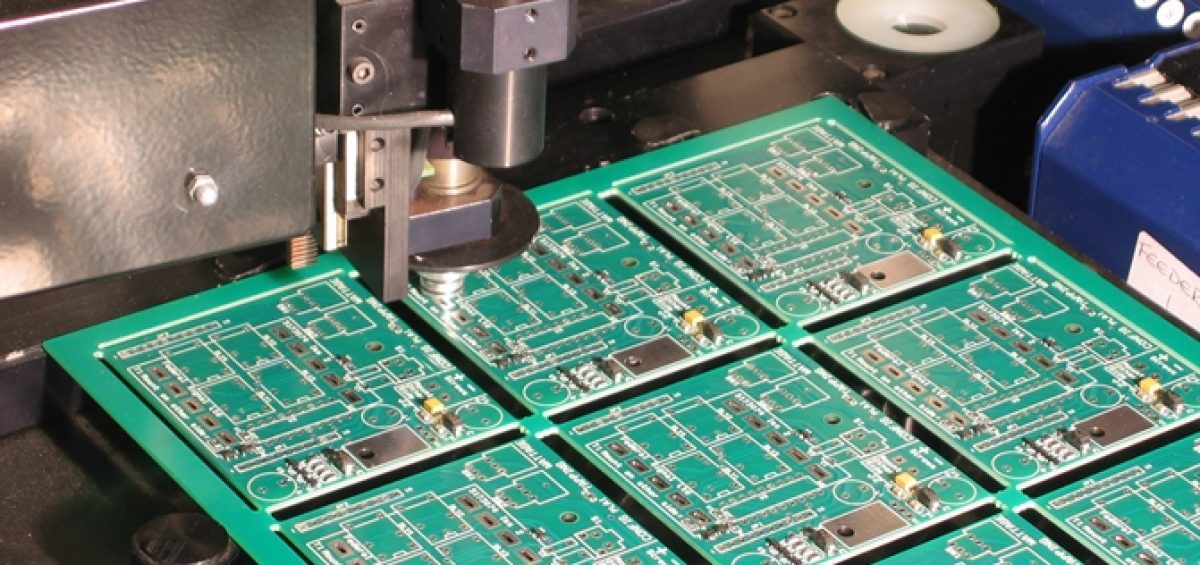

Selecting the right PCB manufacturing equipment is a critical decision for startups, as it can significantly impact production efficiency, product quality, and overall costs. With a wide range of options available, it’s essential to consider several factors before making a decision. One of the primary considerations is production volume. Startups with low to medium production volumes may opt for manual or semi-automatic equipment, such as stencil printers or manual pick-and-place machines. On the other hand, startups with high production volumes may require more advanced automated equipment, such as surface mount technology (SMT) lines or reflow ovens.

Another crucial factor to consider is the type of components being used. For example, startups working with sensitive or high-precision components may require specialized equipment, such as vacuum reflow ovens or precision pick-and-place machines. Additionally, startups with limited budgets may need to consider cost-effective options, such as refurbished or used equipment.

Some popular PCB manufacturing equipment options for startups include:

- Pick-and-place machines, such as the Juki FX-3R or the Panasonic NPM-D3

- Reflow ovens, such as the Heller 1800EXL or the BTU Pyramax

- Stencil printers, such as the DEK Horizon 03iX or the MPM Momentum

When selecting PCB manufacturing equipment, startups should also consider the level of support and service provided by the manufacturer. This includes factors such as training, maintenance, and repair services. By carefully evaluating these factors, startups can ensure that they choose the right equipment for their specific needs and budget.

PCB manufacturing equipment startups, such as those specializing in automation solutions, can provide valuable guidance and support to help startups navigate the equipment selection process. These startups often have extensive experience in the industry and can offer expert advice on the best equipment options for specific production requirements.

The Role of Automation in Modern PCB Manufacturing

Automation has become a crucial aspect of modern PCB manufacturing, enabling companies to increase efficiency, reduce labor costs, and improve product quality. By leveraging advanced automation technologies, PCB manufacturing equipment startups are transforming the industry and setting new standards for production excellence. One of the key benefits of automation in PCB manufacturing is the ability to streamline production processes, reducing the need for manual labor and minimizing the risk of human error.

Automation also enables PCB manufacturers to produce high-quality products at a faster rate, which is essential for meeting the growing demand for electronic devices. Additionally, automation solutions can help reduce waste and energy consumption, making PCB manufacturing more sustainable and environmentally friendly.

Several PCB manufacturing equipment startups are specializing in automation solutions, such as robotic assembly and inspection systems. For example, companies like CyberOptics and Mycronic are developing advanced automation technologies that enable PCB manufacturers to improve production efficiency and product quality.

Some of the key automation technologies being used in PCB manufacturing include:

- Robotic assembly systems, which use robots to assemble and inspect PCBs

- Automated optical inspection (AOI) systems, which use cameras and software to inspect PCBs for defects

- Automated X-ray inspection (AXI) systems, which use X-ray technology to inspect PCBs for internal defects

By adopting automation technologies, PCB manufacturers can improve production efficiency, reduce costs, and enhance product quality. As the demand for electronic devices continues to grow, the role of automation in PCB manufacturing is likely to become even more important, driving innovation and growth in the industry.

PCB manufacturing equipment startups that specialize in automation solutions are well-positioned to capitalize on this trend, providing innovative products and services that meet the evolving needs of the industry. By leveraging automation technologies, these startups can help transform the PCB manufacturing industry, enabling companies to produce high-quality products at a faster rate and lower cost.

Emerging Trends in PCB Manufacturing Equipment: What to Expect

The PCB manufacturing equipment industry is on the cusp of a revolution, driven by emerging trends that are transforming the way electronic devices are designed, manufactured, and tested. One of the most significant trends is the adoption of artificial intelligence (AI) and machine learning (ML) in PCB manufacturing. AI-powered systems can analyze vast amounts of data, identify patterns, and make predictions, enabling PCB manufacturers to optimize their production processes, reduce waste, and improve product quality.

Another trend that is gaining momentum is the Internet of Things (IoT). IoT-enabled PCB manufacturing equipment can communicate with other devices and systems, enabling real-time monitoring, remote control, and predictive maintenance. This can significantly improve production efficiency, reduce downtime, and enhance product quality.

Additionally, the use of robotics and automation in PCB manufacturing is becoming increasingly prevalent. Robotics can perform tasks that are difficult or impossible for humans, such as handling fragile components, inspecting PCBs, and assembling complex devices. Automation can also improve production efficiency, reduce labor costs, and enhance product quality.

Some of the key emerging trends in PCB manufacturing equipment include:

- Artificial intelligence (AI) and machine learning (ML) for predictive maintenance, quality control, and process optimization

- Internet of Things (IoT) for real-time monitoring, remote control, and predictive maintenance

- Robotics and automation for handling fragile components, inspecting PCBs, and assembling complex devices

- 3D printing and additive manufacturing for rapid prototyping and production of complex PCBs

These emerging trends are expected to have a significant impact on the PCB manufacturing equipment industry, enabling companies to produce high-quality products at a faster rate and lower cost. PCB manufacturing equipment startups that specialize in these areas are well-positioned to capitalize on this trend, providing innovative products and services that meet the evolving needs of the industry.

As the demand for electronic devices continues to grow, the need for innovative PCB manufacturing equipment solutions will only continue to increase. By embracing emerging trends and technologies, PCB manufacturing equipment startups can drive innovation, improve efficiency, and reduce costs, ultimately transforming the electronics industry as a whole.

Success Stories: PCB Manufacturing Equipment Startups Making Waves

Several PCB manufacturing equipment startups have made significant strides in the industry, showcasing innovative products, business models, and growth strategies. One such startup is Nano Dimension, an Israeli company that has developed a 3D printed electronics platform for rapid prototyping and production of PCBs. Their innovative approach has attracted significant attention from investors and industry players alike.

Another notable startup is Royal Circuits, a US-based company that offers a range of PCB manufacturing equipment, including pick-and-place machines and reflow ovens. Their focus on providing high-quality, affordable equipment has made them a popular choice among electronics manufacturers.

Mythic, a Swedish startup, has developed an innovative PCB manufacturing platform that utilizes artificial intelligence and machine learning to optimize production processes. Their technology has shown significant improvements in efficiency and product quality, making them an attractive partner for electronics manufacturers.

These startups, among others, are driving innovation in the PCB manufacturing equipment space, offering new and improved solutions that cater to the evolving needs of the electronics industry. By leveraging cutting-edge technologies and business models, they are able to provide more efficient, cost-effective, and sustainable solutions for PCB manufacturing.

One of the key factors contributing to the success of these startups is their ability to identify and address specific pain points in the PCB manufacturing process. By developing targeted solutions, they are able to provide significant value to their customers, setting them apart from traditional industry players.

Furthermore, these startups are often more agile and adaptable than established companies, allowing them to quickly respond to changes in the market and industry trends. This flexibility enables them to stay ahead of the curve and capitalize on emerging opportunities.

The success of these PCB manufacturing equipment startups serves as a testament to the innovative spirit and entrepreneurial drive that is transforming the industry. As the demand for electronic devices continues to grow, the need for efficient, cost-effective, and sustainable PCB manufacturing solutions will only increase, providing a fertile ground for startups to make their mark.

Overcoming Challenges in PCB Manufacturing: Insights from Industry Experts

Despite the growth and innovation in the PCB manufacturing equipment startup space, there are still several challenges that these companies face. To gain a deeper understanding of these challenges and potential solutions, we spoke with industry experts and thought leaders in the field.

One of the biggest challenges facing PCB manufacturing equipment startups is the high cost of research and development. “The cost of developing new PCB manufacturing equipment can be prohibitively expensive, especially for startups with limited resources,” says Dr. Emma Taylor, a leading expert in PCB manufacturing technology. “However, this can be mitigated by partnering with universities, research institutions, or other companies to share the costs and risks associated with R&D.”

Another challenge is the need for highly skilled workers to operate and maintain the equipment. “The PCB manufacturing industry requires a high level of technical expertise, which can be difficult to find, especially in certain regions,” notes John Lee, CEO of a leading PCB manufacturing equipment startup. “To address this, we’ve implemented training programs and partnerships with local educational institutions to develop the skills of our workforce.”

Industry experts also highlight the importance of addressing environmental concerns in PCB manufacturing. “The production of PCBs can have a significant environmental impact, from the use of hazardous chemicals to the generation of waste,” says Dr. Maria Rodriguez, a specialist in sustainable PCB manufacturing. “Startups can address this by adopting green technologies and sustainable practices, such as using lead-free soldering or implementing recycling programs.”

Finally, PCB manufacturing equipment startups must navigate the complex regulatory landscape of the industry. “Compliance with regulations such as RoHS, WEEE, and REACH can be a significant challenge for startups, especially those operating in multiple regions,” notes Tom Harris, a regulatory expert in the PCB manufacturing industry. “However, this can be managed by staying up-to-date with the latest regulatory requirements and implementing robust compliance procedures.”

Despite these challenges, the future of PCB manufacturing equipment startups looks bright. By addressing these challenges and leveraging innovative technologies and business models, these companies can drive growth, improve efficiency, and reduce costs in the PCB manufacturing industry.

As the demand for electronic devices continues to grow, the need for innovative PCB manufacturing solutions will only increase. By overcoming the challenges facing the industry, PCB manufacturing equipment startups can play a key role in shaping the future of electronics production.

The Future of PCB Manufacturing: How Startups are Driving Innovation

The future of PCB manufacturing is exciting and rapidly evolving, with startups playing a key role in driving innovation and transforming the industry. As the demand for electronic devices continues to grow, the need for efficient, cost-effective, and sustainable PCB manufacturing solutions will only increase.

One of the key trends shaping the future of PCB manufacturing is the adoption of artificial intelligence (AI) and machine learning (ML) technologies. Startups such as Mythic and Nano Dimension are already leveraging AI and ML to optimize PCB manufacturing processes, improve product quality, and reduce costs.

Another trend is the increasing use of the Internet of Things (IoT) in PCB manufacturing. Startups such as Seeed Studio and Adafruit are developing IoT-enabled PCB manufacturing equipment that can be remotely monitored and controlled, improving efficiency and reducing downtime.

In addition, startups are also driving innovation in sustainable PCB manufacturing practices. Companies such as Royal Circuits and PCB Cart are developing eco-friendly PCB manufacturing solutions that reduce waste, energy consumption, and environmental impact.

The impact of these innovations on the electronics industry as a whole will be significant. With the ability to produce high-quality PCBs more efficiently and sustainably, electronics manufacturers will be able to reduce costs, improve product quality, and increase competitiveness.

Furthermore, the growth of PCB manufacturing equipment startups will also create new opportunities for innovation and entrepreneurship in the electronics industry. As these startups continue to drive innovation and transform the industry, we can expect to see new business models, products, and services emerge that will shape the future of electronics production.

In conclusion, the future of PCB manufacturing is bright, and startups are playing a key role in driving innovation and transforming the industry. As the demand for electronic devices continues to grow, the need for efficient, cost-effective, and sustainable PCB manufacturing solutions will only increase, providing a fertile ground for startups to make their mark.

Conclusion: The Exciting Prospect of PCB Manufacturing Equipment Startups

The rise of PCB manufacturing equipment startups is revolutionizing the electronics industry, bringing innovative solutions, improved efficiency, and reduced costs. As the demand for electronic devices continues to grow, the need for advanced PCB manufacturing equipment will only increase, providing a fertile ground for startups to make their mark.

Throughout this article, we have explored the significance of PCB manufacturing, the importance of automation, and the emerging trends in PCB manufacturing equipment. We have also showcased successful startups that are making waves in the industry and discussed the challenges faced by these companies.

The future of PCB manufacturing is exciting, with startups driving innovation and transforming the industry. As the adoption of artificial intelligence, machine learning, and the Internet of Things (IoT) continues to grow, we can expect to see new business models, products, and services emerge that will shape the future of electronics production.

For entrepreneurs, investors, and industry professionals, the prospect of PCB manufacturing equipment startups is a thrilling one. With the potential for significant growth, innovation, and disruption, this space is ripe for exploration and investment.

In conclusion, the rise of PCB manufacturing equipment startups is a testament to the power of innovation and entrepreneurship in transforming industries. As the electronics industry continues to evolve, we can expect to see these startups play an increasingly important role in shaping the future of PCB manufacturing.

Whether you are an industry expert, a startup founder, or simply someone interested in the latest developments in electronics production, we encourage you to explore this innovative space further. With its potential for growth, innovation, and disruption, the future of PCB manufacturing equipment startups is certainly exciting.