How to Choose the Right PCB Manufacturing Equipment for Your Startup

Selecting the right PCB manufacturing equipment is crucial for startups looking to establish a competitive edge in the market. With a wide range of options available, it can be overwhelming to determine which equipment best suits your needs. To make an informed decision, consider the following factors: budget, production volume, and product complexity.

Firstly, budget is a critical consideration when choosing PCB manufacturing equipment. Startups with limited budgets may need to opt for more affordable options, such as manual or semi-automated equipment. However, it’s essential to weigh the costs against the potential benefits of investing in more advanced equipment, such as automated pick-and-place machines or PCB drills. These machines can significantly improve production efficiency and product quality, but may require a larger upfront investment.

Production volume is another key factor to consider when selecting PCB manufacturing equipment. Startups with high production volumes may require more advanced equipment, such as high-speed pick-and-place machines or PCB assembly lines. On the other hand, startups with lower production volumes may be able to get by with more basic equipment, such as manual assembly tools or small-scale PCB manufacturing machines.

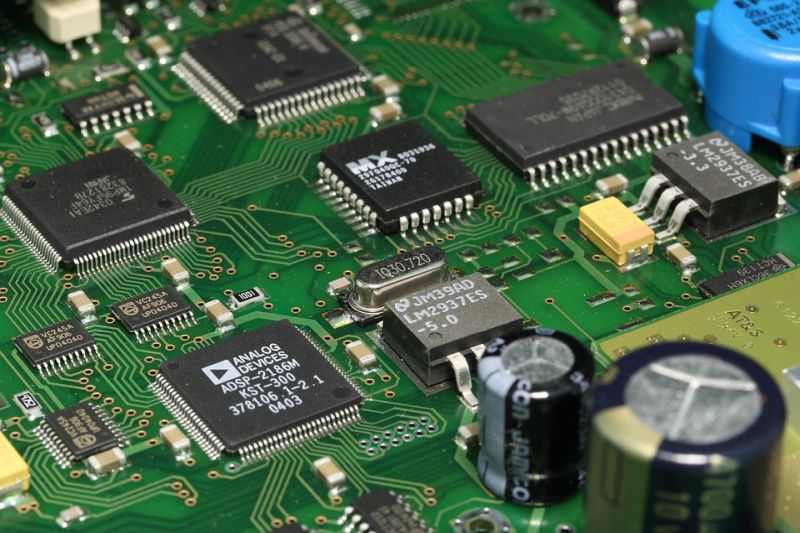

Product complexity is also an essential consideration when choosing PCB manufacturing equipment. Startups producing complex PCBs with multiple layers, fine pitch components, or high-density interconnects may require more advanced equipment, such as 3D printing machines or laser drilling equipment. In contrast, startups producing simpler PCBs may be able to use more basic equipment, such as standard pick-and-place machines or PCB drills.

Some popular PCB manufacturing equipment options for startups include:

- Pick-and-place machines, such as the Juki KE-2080 or the Panasonic NPM-D3

- PCB drills, such as the LPKF ProtoMat S103 or the Excellon HD-5

- PCB assembly lines, such as the Fuji NXT or the Siemens SMT

When evaluating these options, consider factors such as equipment cost, maintenance requirements, and technical support. It’s also essential to assess the equipment’s ability to meet your specific production needs and to ensure that it can be easily integrated into your existing manufacturing workflow.

Key Features to Look for in Modern PCB Manufacturing Equipment

When it comes to selecting the right PCB manufacturing equipment for your startup, there are several key features to look for. Modern PCB manufacturing equipment should possess a combination of automation, precision, and flexibility to ensure high-quality production and efficient workflow.

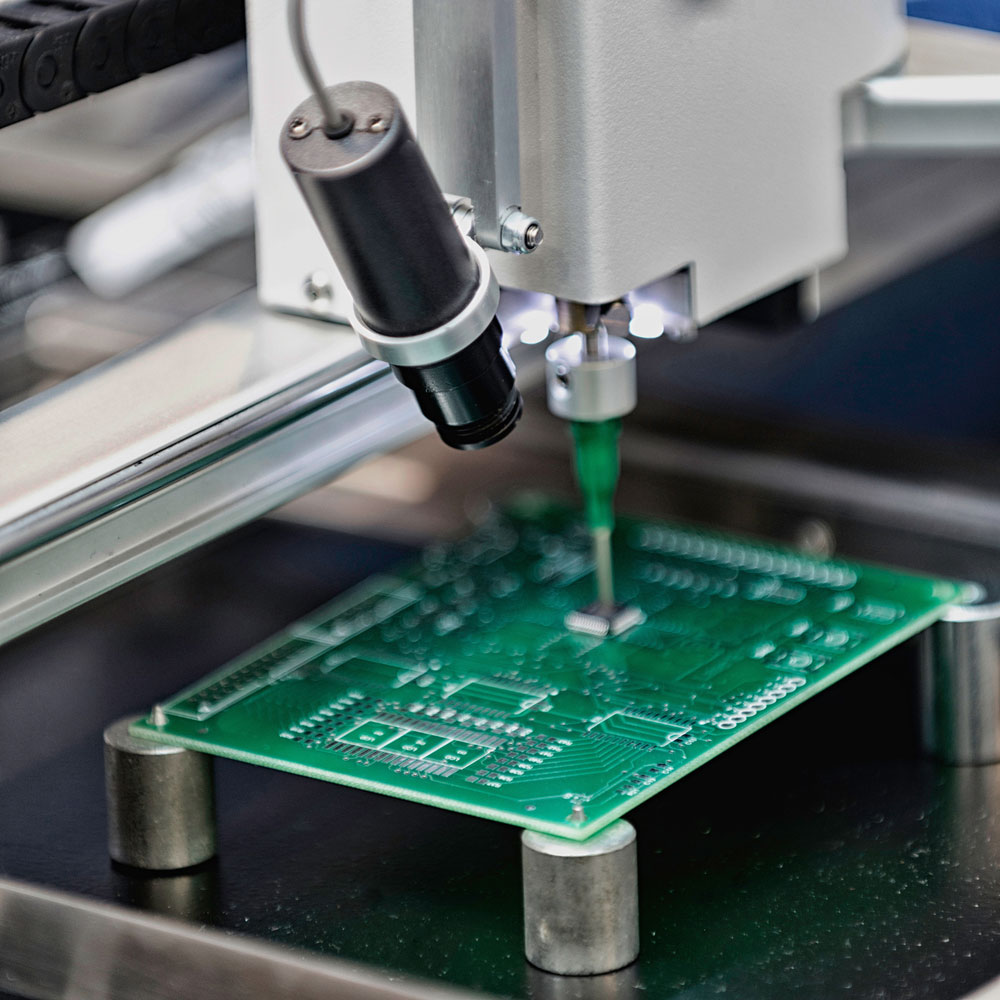

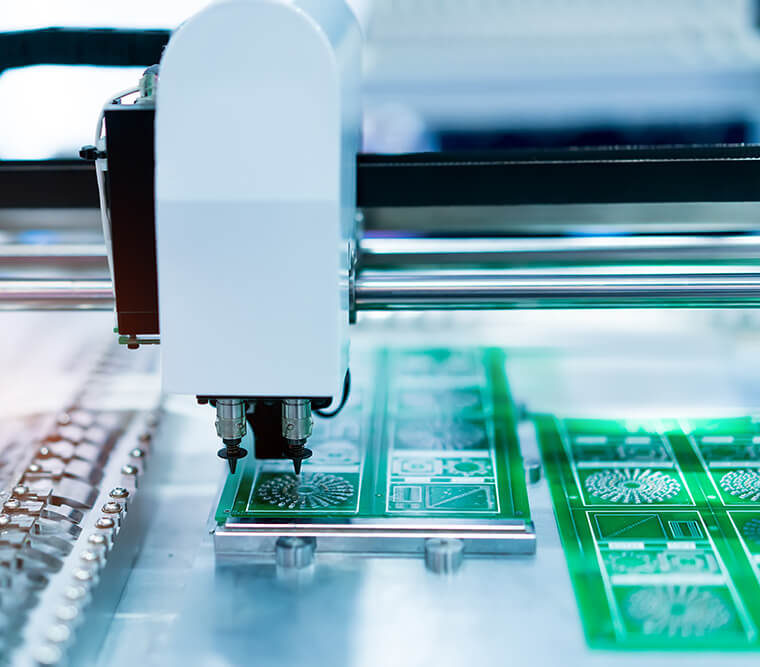

Automation is a critical feature in modern PCB manufacturing equipment. Automated systems can significantly improve production efficiency, reduce labor costs, and minimize the risk of human error. Look for equipment with advanced automation capabilities, such as robotic assembly, automated inspection, and computer-controlled processing.

Precision is another essential feature in PCB manufacturing equipment. Modern PCBs require precise placement of components, accurate drilling, and high-quality soldering. Look for equipment with advanced precision capabilities, such as high-resolution imaging, precise temperature control, and advanced soldering techniques.

Flexibility is also a key feature in modern PCB manufacturing equipment. Startups often need to produce a wide range of PCBs with varying complexities and requirements. Look for equipment that can adapt to different production needs, such as modular designs, interchangeable tooling, and adjustable processing parameters.

Some examples of modern PCB manufacturing equipment that possess these key features include:

- Automated pick-and-place machines, such as the Juki KE-2080 or the Panasonic NPM-D3, which offer high-speed and precise component placement.

- PCB drills, such as the LPKF ProtoMat S103 or the Excellon HD-5, which provide high-precision drilling and milling capabilities.

- PCB assembly lines, such as the Fuji NXT or the Siemens SMT, which offer advanced automation and precision capabilities for high-volume production.

When evaluating these options, consider factors such as equipment cost, maintenance requirements, and technical support. It’s also essential to assess the equipment’s ability to meet your specific production needs and to ensure that it can be easily integrated into your existing manufacturing workflow.

By investing in modern PCB manufacturing equipment with automation, precision, and flexibility, startups can improve production efficiency, reduce costs, and enhance product quality. This can help them stay competitive in the market and achieve long-term success.

Startups Leading the Charge in PCB Manufacturing Innovation

The PCB manufacturing industry is witnessing a surge in innovation, driven by startups that are pushing the boundaries of technology and manufacturing processes. These startups are developing cutting-edge solutions that are transforming the way PCBs are designed, manufactured, and tested.

One notable startup in the PCB manufacturing space is Nano Dimension, which is developing advanced 3D printing technologies for PCB production. Their DragonFly 2020 3D printer is capable of producing complex PCBs with high accuracy and speed, making it an attractive solution for startups and established manufacturers alike.

Another startup making waves in the industry is Inspectorio, which is developing AI-powered inspection systems for PCB manufacturing. Their platform uses machine learning algorithms to detect defects and anomalies in PCBs, enabling manufacturers to improve quality control and reduce waste.

Other startups, such as Techniplas and Xcentric Mold & Engineering, are developing innovative solutions for PCB manufacturing, including advanced molding and tooling technologies.

These startups are not only driving innovation in the PCB manufacturing industry but also creating new opportunities for growth and collaboration. By partnering with established manufacturers and suppliers, they are able to bring their innovative solutions to market and make a significant impact on the industry.

The rise of these startups is also driving investment in the PCB manufacturing industry, with venture capital firms and private investors taking notice of the potential for growth and innovation. This influx of capital is enabling startups to scale their operations and develop new technologies, further accelerating the pace of innovation in the industry.

As the PCB manufacturing industry continues to evolve, it’s clear that startups will play a major role in shaping its future. By embracing innovation and collaboration, these startups are empowering PCB manufacturing equipment startups to stay ahead of the curve and drive growth in the industry.

Overcoming Challenges in PCB Manufacturing: Insights from Successful Startups

PCB manufacturing is a complex and challenging process, requiring careful planning, precise execution, and continuous improvement. Startups in the PCB manufacturing industry face unique challenges, including managing supply chains, ensuring quality control, and adapting to changing market demands.

One of the biggest challenges facing PCB manufacturing startups is managing supply chains. With the increasing complexity of PCBs, startups need to ensure that they have a reliable and efficient supply chain in place to meet the demands of their customers. This requires careful planning, coordination, and communication with suppliers, manufacturers, and logistics providers.

Ensuring quality control is another critical challenge for PCB manufacturing startups. With the increasing demand for high-quality PCBs, startups need to ensure that their products meet the highest standards of quality and reliability. This requires implementing robust quality control processes, including inspection, testing, and certification.

Adapting to changing market demands is also a significant challenge for PCB manufacturing startups. With the rapid evolution of technology and changing customer needs, startups need to be agile and responsive to changing market conditions. This requires continuous innovation, improvement, and investment in new technologies and processes.

So, how do successful startups overcome these challenges? Here are some insights from startups that have successfully navigated the challenges of PCB manufacturing:

First, successful startups prioritize supply chain management. They invest in building strong relationships with suppliers, manufacturers, and logistics providers to ensure that they have a reliable and efficient supply chain in place.

Second, successful startups implement robust quality control processes. They invest in inspection, testing, and certification to ensure that their products meet the highest standards of quality and reliability.

Third, successful startups are agile and responsive to changing market conditions. They invest in continuous innovation, improvement, and investment in new technologies and processes to stay ahead of the curve.

Finally, successful startups prioritize customer satisfaction. They invest in building strong relationships with their customers, understanding their needs, and delivering high-quality products and services that meet their expectations.

By following these insights, PCB manufacturing startups can overcome the challenges of the industry and achieve long-term success.

The Future of PCB Manufacturing: Trends and Predictions

The PCB manufacturing industry is on the cusp of a revolution, driven by emerging technologies and trends that are transforming the way PCBs are designed, manufactured, and tested. As the industry continues to evolve, it’s essential to stay ahead of the curve by embracing these trends and predictions.

One of the most significant trends in PCB manufacturing is the increasing use of artificial intelligence (AI). AI-powered inspection systems, for example, can detect defects and anomalies in PCBs with greater accuracy and speed than traditional methods. This trend is expected to continue, with AI-powered manufacturing systems becoming more prevalent in the industry.

Another trend that’s gaining momentum is the Internet of Things (IoT). As more devices become connected, the demand for PCBs that can support IoT applications is increasing. This trend is expected to drive the development of new PCB manufacturing technologies and techniques that can support the production of complex, high-density PCBs.

Sustainable manufacturing practices are also becoming increasingly important in the PCB manufacturing industry. As consumers become more environmentally conscious, manufacturers are under pressure to reduce their environmental impact. This trend is expected to drive the adoption of sustainable manufacturing practices, such as the use of lead-free soldering and recyclable materials.

Other trends that are expected to shape the future of PCB manufacturing include the increasing use of 3D printing, the development of new materials and technologies, and the growing importance of cybersecurity. As the industry continues to evolve, it’s essential to stay ahead of the curve by embracing these trends and predictions.

So, what do these trends and predictions mean for PCB manufacturing equipment startups? They present a range of opportunities and challenges, from the need to develop new technologies and techniques to the importance of staying ahead of the curve in terms of innovation and competitiveness.

By embracing these trends and predictions, PCB manufacturing equipment startups can position themselves for long-term success and growth. This requires a commitment to innovation, a willingness to invest in new technologies and techniques, and a focus on delivering high-quality products and services that meet the evolving needs of the industry.

Investing in the Right PCB Manufacturing Equipment for Long-Term Success

Investing in the right PCB manufacturing equipment is crucial for startups looking to establish a competitive edge in the market. With the rapid evolution of technology and changing customer needs, it’s essential to invest in equipment that can meet the evolving needs of the industry.

When selecting PCB manufacturing equipment, startups should consider factors such as scalability, maintainability, and upgradeability. Scalability is critical, as it enables startups to adapt to changing production volumes and demands. Maintainability is also essential, as it ensures that equipment can be easily serviced and repaired. Upgradeability is also important, as it allows startups to upgrade their equipment to meet changing technology and customer needs.

Startups should also consider the total cost of ownership (TCO) when selecting PCB manufacturing equipment. TCO includes not only the initial purchase price but also ongoing maintenance, repair, and upgrade costs. By considering TCO, startups can make informed decisions about their equipment investments and ensure that they are getting the best value for their money.

In addition to considering TCO, startups should also evaluate the equipment’s performance, reliability, and compatibility with their existing manufacturing processes. This includes assessing the equipment’s speed, accuracy, and precision, as well as its ability to integrate with other equipment and systems.

Some notable PCB manufacturing equipment startups that are making significant contributions to the industry include:

- Nano Dimension, which is developing advanced 3D printing technologies for PCB production.

- Inspectorio, which is developing AI-powered inspection systems for PCB manufacturing.

- Techniplas, which is developing innovative molding and tooling technologies for PCB manufacturing.

By investing in the right PCB manufacturing equipment, startups can position themselves for long-term success and growth. This requires a commitment to innovation, a willingness to invest in new technologies and techniques, and a focus on delivering high-quality products and services that meet the evolving needs of the industry.

Conclusion: Empowering PCB Manufacturing Startups through Innovation

The PCB manufacturing industry is undergoing a significant transformation, driven by the emergence of innovative equipment startups. These startups are revolutionizing the way PCBs are designed, manufactured, and tested, enabling the production of complex and high-quality boards at a lower cost.

By embracing innovation and investing in high-quality PCB manufacturing equipment, startups can position themselves for long-term success and growth. This requires a commitment to innovation, a willingness to invest in new technologies and techniques, and a focus on delivering high-quality products and services that meet the evolving needs of the industry.

As the PCB manufacturing industry continues to evolve, it’s essential to stay ahead of the curve by embracing emerging technologies and trends. This includes the increasing use of artificial intelligence, the Internet of Things (IoT), and sustainable manufacturing practices.

By investing in the right PCB manufacturing equipment and embracing innovation, startups can overcome the challenges of the industry and achieve long-term success. This includes managing supply chains, ensuring quality control, and adapting to changing market demands.

Ultimately, the future of PCB manufacturing is bright, and innovative equipment startups are leading the charge. By empowering PCB manufacturing startups through innovation, we can drive growth, improve efficiency, and enhance product quality in the industry.

As we look to the future, it’s clear that innovation will continue to play a critical role in shaping the PCB manufacturing industry. By embracing emerging technologies and trends, startups can position themselves for long-term success and growth, and help drive the industry forward.

Conclusion: Empowering PCB Manufacturing Startups through Innovation

In conclusion, the PCB manufacturing industry is undergoing a significant transformation, driven by the emergence of innovative equipment startups. These startups are revolutionizing the way PCBs are designed, manufactured, and tested, enabling the production of complex and high-quality boards at a lower cost.

By embracing innovation and investing in high-quality PCB manufacturing equipment, startups can position themselves for long-term success and growth. This requires a commitment to innovation, a willingness to invest in new technologies and techniques, and a focus on delivering high-quality products and services that meet the evolving needs of the industry.

As the PCB manufacturing industry continues to evolve, it’s essential to stay ahead of the curve by embracing emerging technologies and trends. This includes the increasing use of artificial intelligence, the Internet of Things (IoT), and sustainable manufacturing practices.

By investing in the right PCB manufacturing equipment and embracing innovation, startups can overcome the challenges of the industry and achieve long-term success. This includes managing supply chains, ensuring quality control, and adapting to changing market demands.

Ultimately, the future of PCB manufacturing is bright, and innovative equipment startups are leading the charge. By empowering PCB manufacturing startups through innovation, we can drive growth, improve efficiency, and enhance product quality in the industry.

As we look to the future, it’s clear that innovation will continue to play a critical role in shaping the PCB manufacturing industry. By embracing emerging technologies and trends, startups can position themselves for long-term success and growth, and help drive the industry forward.

Innovative PCB manufacturing equipment startups are revolutionizing the industry, and it’s essential to stay ahead of the curve by embracing emerging technologies and trends. By investing in high-quality PCB manufacturing equipment and embracing innovation, startups can position themselves for long-term success and growth.