What is PCB Manufacturing and Why is it Important?

Printed Circuit Board (PCB) manufacturing is the process of creating the backbone of modern electronics, from smartphones and laptops to medical devices and automotive systems. The PCB serves as the foundation for mounting and connecting electronic components, enabling the flow of electrical signals and power. As the demand for innovative and sophisticated electronics continues to grow, the importance of PCB manufacturing has never been more pronounced.

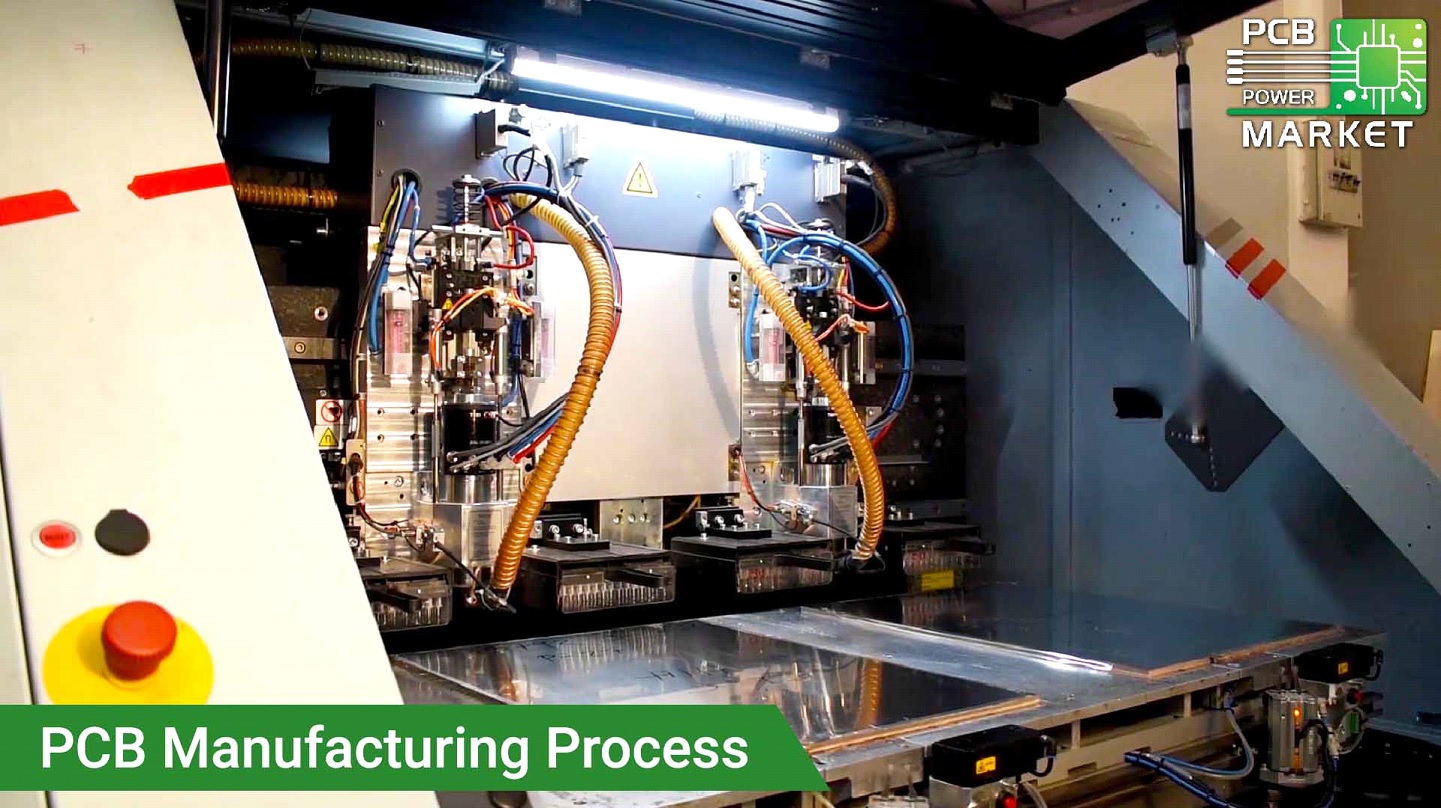

The PCB manufacturing process involves several stages, including design, prototyping, production, and testing. Each stage requires specialized equipment and expertise, making it a complex and challenging process. However, the end result is a critical component that enables the functioning of modern electronics.

PCB manufacturing equipment startups are playing a crucial role in transforming the sector by introducing innovative solutions, improving efficiency, and reducing costs. These startups are leveraging advancements in technology, such as automation, artificial intelligence, and the Internet of Things (IoT), to develop cutting-edge equipment and software. By doing so, they are enabling PCB manufacturers to produce high-quality boards faster and more cost-effectively, which is essential for meeting the growing demand for electronics.

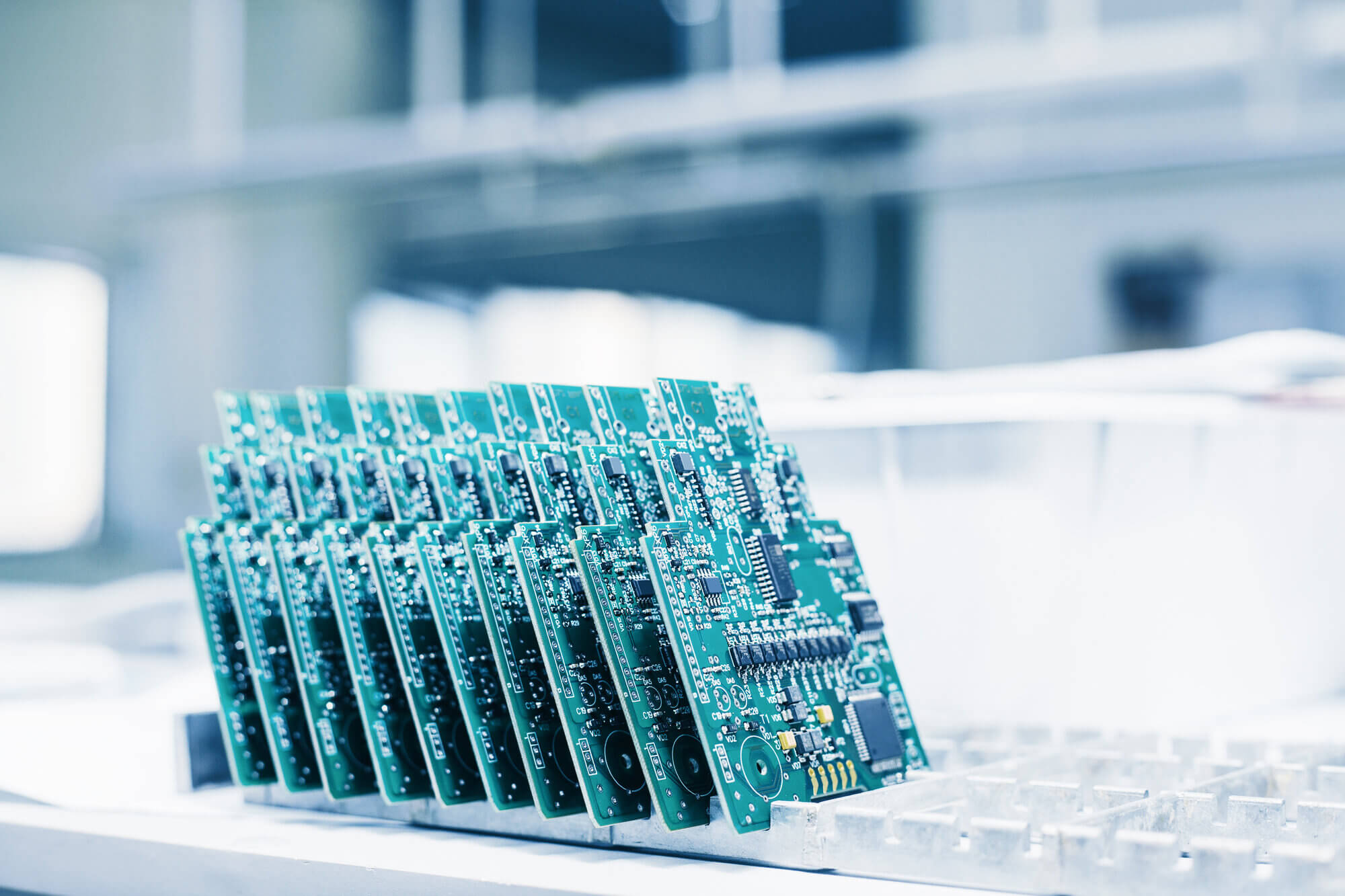

The impact of PCB manufacturing equipment startups can be seen in various industries, from consumer electronics to aerospace and defense. For instance, the development of advanced PCB manufacturing equipment has enabled the production of smaller, more complex boards, which are essential for the creation of smartphones and other portable devices. Similarly, the use of automation and robotics in PCB manufacturing has improved efficiency and reduced labor costs, making it possible for manufacturers to produce high-quality boards at a lower cost.

As the electronics industry continues to evolve, the importance of PCB manufacturing equipment startups will only continue to grow. These startups are driving innovation, improving efficiency, and reducing costs, which is essential for meeting the growing demand for electronics. By providing innovative solutions and equipment, PCB manufacturing equipment startups are playing a critical role in shaping the future of the electronics industry.

How to Choose the Right PCB Manufacturing Equipment for Your Startup

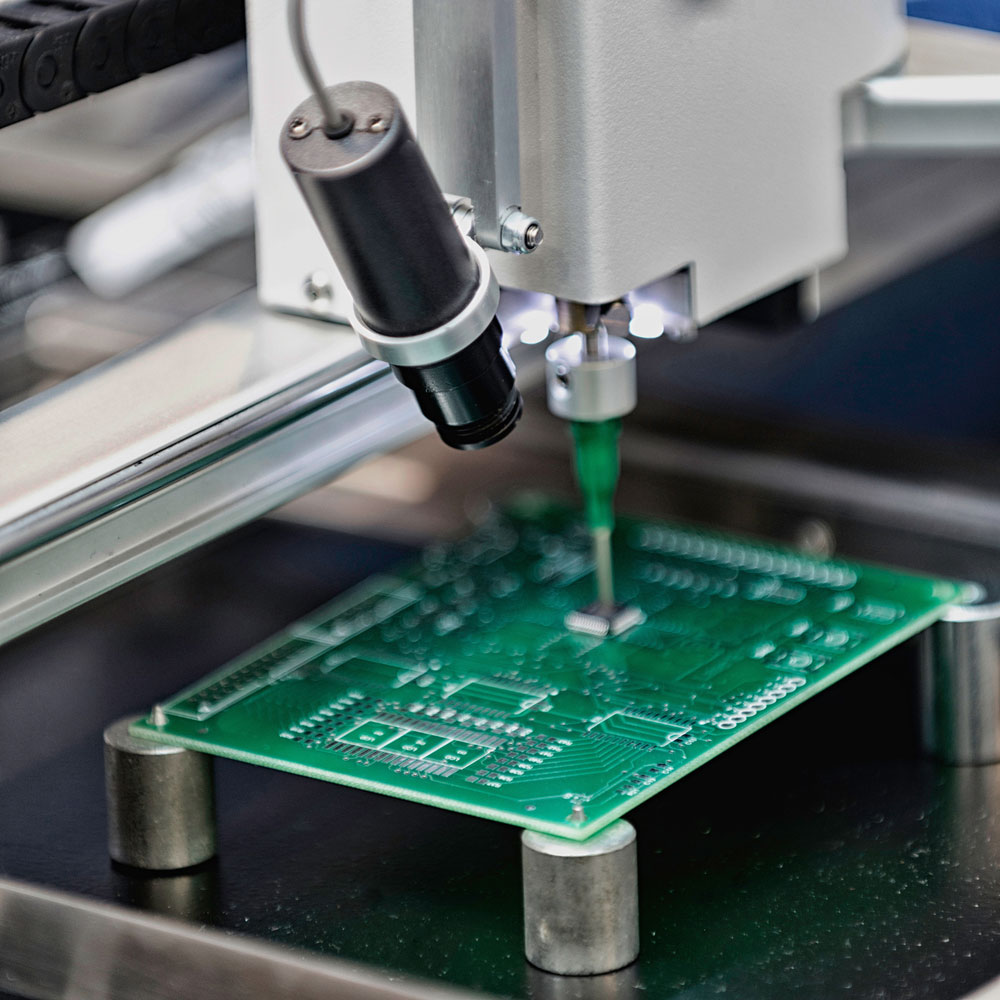

When it comes to selecting the right PCB manufacturing equipment for your startup, there are several factors to consider. The type of equipment needed will depend on the production volume, component complexity, and budget constraints of your operation. For instance, if you’re producing small batches of complex PCBs, you may require a high-precision pick-and-place machine like the Juki FX-3R or the Panasonic NPM-W2. On the other hand, if you’re producing larger volumes of simpler PCBs, a more affordable option like the Neoden 4 pick-and-place machine may be sufficient.

In addition to pick-and-place machines, other essential equipment for PCB manufacturing includes reflow ovens, solder paste printers, and PCB inspection machines. Reflow ovens like the Heller 1800EXL or the BTU Pyramax 100A are crucial for ensuring that solder joints are properly formed and that PCBs are free from defects. Solder paste printers like the DEK Horizon 03iX or the MPM Momentum Elite are necessary for applying the right amount of solder paste to the PCB. PCB inspection machines like the Mirtec MV-3L or the Vi Technology K-series are used to detect defects and ensure that PCBs meet quality standards.

When choosing PCB manufacturing equipment, startups should also consider the cost of ownership, maintenance requirements, and compatibility with existing equipment. It’s essential to research and compare different equipment options to find the best fit for your specific needs and budget. Additionally, startups should consider the scalability of the equipment, as their production needs may change over time.

PCB manufacturing equipment startups are also innovating in the area of equipment selection, offering solutions such as equipment leasing, rental options, and pay-per-use models. These innovative pricing models can help startups reduce their upfront costs and make it more affordable to invest in high-quality equipment.

Ultimately, selecting the right PCB manufacturing equipment is critical to the success of your startup. By considering factors such as production volume, component complexity, and budget constraints, and by researching and comparing different equipment options, startups can make informed decisions that will help them produce high-quality PCBs and stay competitive in the market.

The Role of Automation in Modern PCB Manufacturing

Automation has revolutionized the PCB manufacturing industry, transforming the way PCBs are designed, produced, and tested. By leveraging automation technologies, PCB manufacturing equipment startups can significantly improve efficiency, reduce labor costs, and enhance product quality. Automation enables the production of high-quality PCBs at faster speeds, making it possible to meet the growing demand for electronic devices.

One of the key areas where automation is making a significant impact is in the assembly process. Automated pick-and-place machines, such as the Juki FX-3R or the Panasonic NPM-W2, can accurately place components on the PCB at high speeds, reducing the risk of human error. Additionally, automated soldering systems, like the Heller 1800EXL or the BTU Pyramax 100A, can ensure consistent and high-quality solder joints.

Automation also plays a critical role in PCB inspection and testing. Automated optical inspection (AOI) systems, such as the Mirtec MV-3L or the Vi Technology K-series, can detect defects and irregularities on the PCB, ensuring that only high-quality products are shipped to customers. Furthermore, automated testing systems, like the Teradyne FLEX or the Keysight i3070, can quickly and accurately test PCBs, reducing the time and cost associated with manual testing.

PCB manufacturing equipment startups are pioneering automation solutions in the industry. For example, startups like NovaSparks and Ficontec are developing innovative automation technologies that enable the production of high-quality PCBs at faster speeds and lower costs. These startups are leveraging advancements in robotics, artificial intelligence, and machine learning to create intelligent automation systems that can adapt to changing production requirements.

The adoption of automation in PCB manufacturing has numerous benefits, including increased productivity, improved quality, and reduced labor costs. By automating repetitive and time-consuming tasks, PCB manufacturing equipment startups can free up resources to focus on higher-value tasks, such as design, engineering, and innovation. Moreover, automation enables the production of complex PCBs with high accuracy and precision, making it possible to meet the growing demand for advanced electronic devices.

As the PCB manufacturing industry continues to evolve, automation will play an increasingly important role in shaping the future of the sector. PCB manufacturing equipment startups that invest in automation technologies will be well-positioned to capitalize on emerging trends and opportunities, driving innovation and growth in the industry.

Key Challenges Faced by PCB Manufacturing Equipment Startups

PCB manufacturing equipment startups face a range of challenges that can impact their success and growth. One of the most significant challenges is intense competition from established players in the industry. Large, well-established companies have significant resources and market share, making it difficult for startups to compete. Additionally, the high development costs associated with creating innovative PCB manufacturing equipment can be a significant barrier to entry for startups.

Regulatory compliance is another challenge faced by PCB manufacturing equipment startups. The electronics industry is heavily regulated, and startups must ensure that their equipment meets strict safety and environmental standards. This can be a time-consuming and costly process, requiring significant investment in testing and certification.

Furthermore, PCB manufacturing equipment startups must also navigate the complex and rapidly evolving landscape of the electronics industry. The industry is characterized by rapid technological advancements, changing customer needs, and shifting market trends. Startups must be agile and adaptable to stay ahead of the curve and respond to emerging opportunities and threats.

Despite these challenges, successful PCB manufacturing equipment startups have found ways to overcome them. For example, startups like NovaSparks and Ficontec have leveraged partnerships and collaborations with established players to access new markets and technologies. Others, like Mirtec and Vi Technology, have focused on developing innovative solutions that address specific pain points in the industry.

Another key strategy for overcoming challenges is to focus on niche markets or applications. By targeting specific segments of the market, startups can differentiate themselves from larger competitors and establish a strong foothold. For example, startups like BTU International and Heller Industries have focused on developing equipment for specific industries, such as aerospace or automotive.

Finally, PCB manufacturing equipment startups must also prioritize innovation and R&D. By investing in research and development, startups can stay ahead of the curve and develop new technologies and solutions that meet emerging customer needs. This requires a commitment to continuous learning and improvement, as well as a willingness to take calculated risks and experiment with new ideas.

By understanding the key challenges faced by PCB manufacturing equipment startups, entrepreneurs and innovators can better navigate the complex landscape of the industry. By developing strategies to overcome these challenges, startups can establish themselves as leaders in the industry and drive innovation and growth in the sector.

Emerging Trends in PCB Manufacturing Equipment

The PCB manufacturing equipment sector is witnessing a significant transformation, driven by emerging trends that are revolutionizing the industry. PCB manufacturing equipment startups are at the forefront of this change, leveraging innovative technologies to improve efficiency, reduce costs, and enhance product quality. Some of the key trends shaping the future of PCB manufacturing equipment include:

Artificial Intelligence (AI) and Machine Learning (ML): AI and ML are being increasingly adopted in PCB manufacturing equipment to optimize production processes, predict maintenance needs, and improve product quality. Startups like MachineMetrics and Augury are developing AI-powered solutions to enhance the performance of PCB manufacturing equipment.

Internet of Things (IoT): The IoT is transforming the PCB manufacturing equipment sector by enabling real-time monitoring, remote control, and data analytics. Startups like Seebo and Uptake are developing IoT-based solutions to improve the efficiency and productivity of PCB manufacturing equipment.

Sustainable Manufacturing Practices: The growing demand for eco-friendly products is driving the adoption of sustainable manufacturing practices in the PCB manufacturing equipment sector. Startups like Green Circuits and Zero Waste Systems are developing innovative solutions to reduce waste, energy consumption, and environmental impact.

3D Printing and Additive Manufacturing: 3D printing and additive manufacturing are being increasingly adopted in PCB manufacturing equipment to produce complex components and reduce material waste. Startups like Optomec and Nano Dimension are developing innovative 3D printing solutions for PCB manufacturing.

These emerging trends are creating new opportunities for PCB manufacturing equipment startups to innovate and disrupt the industry. By leveraging these trends, startups can develop innovative solutions that improve efficiency, reduce costs, and enhance product quality, ultimately driving growth and success in the sector.

Success Stories: PCB Manufacturing Equipment Startups Making a Mark

The PCB manufacturing equipment sector is witnessing a surge in innovative startups that are making a significant impact on the industry. These startups are leveraging cutting-edge technologies, innovative business models, and agile development processes to disrupt the traditional PCB manufacturing equipment landscape. Here are a few success stories of PCB manufacturing equipment startups that are making a mark:

Myriad Sensors: Myriad Sensors is a startup that has developed a range of innovative sensors for PCB manufacturing equipment. Their sensors use AI-powered algorithms to detect defects and anomalies in real-time, enabling manufacturers to improve product quality and reduce waste. Myriad Sensors has already partnered with several leading PCB manufacturers and is expanding its customer base rapidly.

PCB Robotics: PCB Robotics is a startup that specializes in developing robotic solutions for PCB manufacturing equipment. Their robots use machine learning algorithms to optimize production processes, improve efficiency, and reduce labor costs. PCB Robotics has already deployed its robots in several PCB manufacturing facilities and is seeing significant interest from other manufacturers.

CircuitHub: CircuitHub is a startup that has developed a cloud-based platform for PCB manufacturing equipment. Their platform enables manufacturers to design, prototype, and produce PCBs in a collaborative and agile environment. CircuitHub has already gained significant traction among hobbyists and professionals alike and is expanding its user base rapidly.

Tempo Automation: Tempo Automation is a startup that has developed a range of innovative PCB manufacturing equipment, including pick-and-place machines and reflow ovens. Their equipment uses AI-powered algorithms to optimize production processes and improve product quality. Tempo Automation has already partnered with several leading PCB manufacturers and is expanding its customer base rapidly.

These success stories demonstrate the potential for PCB manufacturing equipment startups to innovate and disrupt the industry. By leveraging cutting-edge technologies, innovative business models, and agile development processes, startups can develop innovative solutions that improve efficiency, reduce costs, and enhance product quality. As the PCB manufacturing equipment sector continues to evolve, it will be exciting to see how these startups and others like them shape the future of the industry.

Future Outlook: Opportunities and Threats for PCB Manufacturing Equipment Startups

The future of PCB manufacturing equipment startups looks promising, with several opportunities for growth and innovation. However, there are also potential threats and disruptions that startups need to be aware of in order to navigate this evolving landscape. Here are some of the key opportunities and threats that PCB manufacturing equipment startups should consider:

Opportunities for Growth:

The increasing demand for IoT devices, electric vehicles, and renewable energy systems is driving the growth of the PCB manufacturing equipment market. Startups that can develop innovative solutions to meet this demand will have a significant opportunity for growth. Additionally, the adoption of Industry 4.0 technologies such as AI, robotics, and data analytics will create new opportunities for startups to develop smart and connected PCB manufacturing equipment.

Emerging Threats:

The PCB manufacturing equipment market is highly competitive, and startups will face intense competition from established players. Additionally, the increasing complexity of PCB designs and the need for high-speed and high-frequency manufacturing will require startups to invest in research and development to stay ahead of the curve. Furthermore, the trade tensions and tariffs imposed by governments on imported electronics components may impact the supply chain and profitability of PCB manufacturing equipment startups.

Potential Disruptions:

The rise of additive manufacturing and 3D printing technologies may disrupt the traditional PCB manufacturing equipment market. Startups that can develop innovative solutions that integrate these technologies will have a significant advantage. Additionally, the increasing focus on sustainability and environmental responsibility may lead to new regulations and standards that PCB manufacturing equipment startups will need to comply with.

To navigate this evolving landscape, PCB manufacturing equipment startups should focus on developing innovative solutions that meet the changing needs of the market. They should also invest in research and development to stay ahead of the curve and be prepared to adapt to new technologies and trends. By doing so, startups can capitalize on the opportunities for growth and minimize the risks associated with the potential threats and disruptions.

Conclusion: The Future of PCB Manufacturing Equipment is in the Hands of Startups

In conclusion, the future of PCB manufacturing equipment is indeed in the hands of startups. These innovative companies are driving the transformation of the sector, leveraging cutting-edge technologies, and pioneering new business models. As the demand for electronics continues to grow, PCB manufacturing equipment startups are poised to play a critical role in shaping the future of the industry.

Throughout this article, we have explored the significance of PCB manufacturing, the importance of selecting the right equipment, and the impact of automation on the sector. We have also examined the emerging trends in PCB manufacturing equipment, including the adoption of AI, IoT, and sustainable manufacturing practices. Additionally, we have showcased successful startups that are making a mark in the industry and analyzed the future prospects for PCB manufacturing equipment startups.

As the PCB manufacturing equipment sector continues to evolve, it is clear that startups will be at the forefront of innovation. These companies are agile, adaptable, and willing to take risks, which enables them to develop innovative solutions that meet the changing needs of the market. As entrepreneurs and innovators, it is essential to seize the opportunities in this exciting and rapidly evolving sector.

By embracing the latest technologies, adopting sustainable manufacturing practices, and developing innovative solutions, PCB manufacturing equipment startups can drive growth, improve efficiency, and reduce costs. As the industry continues to transform, it is clear that the future of PCB manufacturing equipment is bright, and startups are leading the way.