What is PCB Manufacturing and Why is it Important?

Printed Circuit Board (PCB) manufacturing is the process of creating the backbone of modern electronics, from smartphones to medical devices, and everything in between. The demand for innovative PCB manufacturing solutions has never been higher, driven by the increasing complexity of electronic devices and the need for faster, smaller, and more efficient products. PCB manufacturing equipment startups are playing a crucial role in shaping the future of this industry, leveraging cutting-edge technologies to improve manufacturing efficiency, reduce costs, and enhance product quality.

The significance of PCB manufacturing lies in its ability to enable the creation of complex electronic systems, which are essential for various industries, including aerospace, automotive, healthcare, and consumer electronics. As the electronics industry continues to evolve, PCB manufacturing equipment startups are developing innovative solutions to address the challenges of traditional manufacturing methods, such as high costs, environmental concerns, and limited design flexibility.

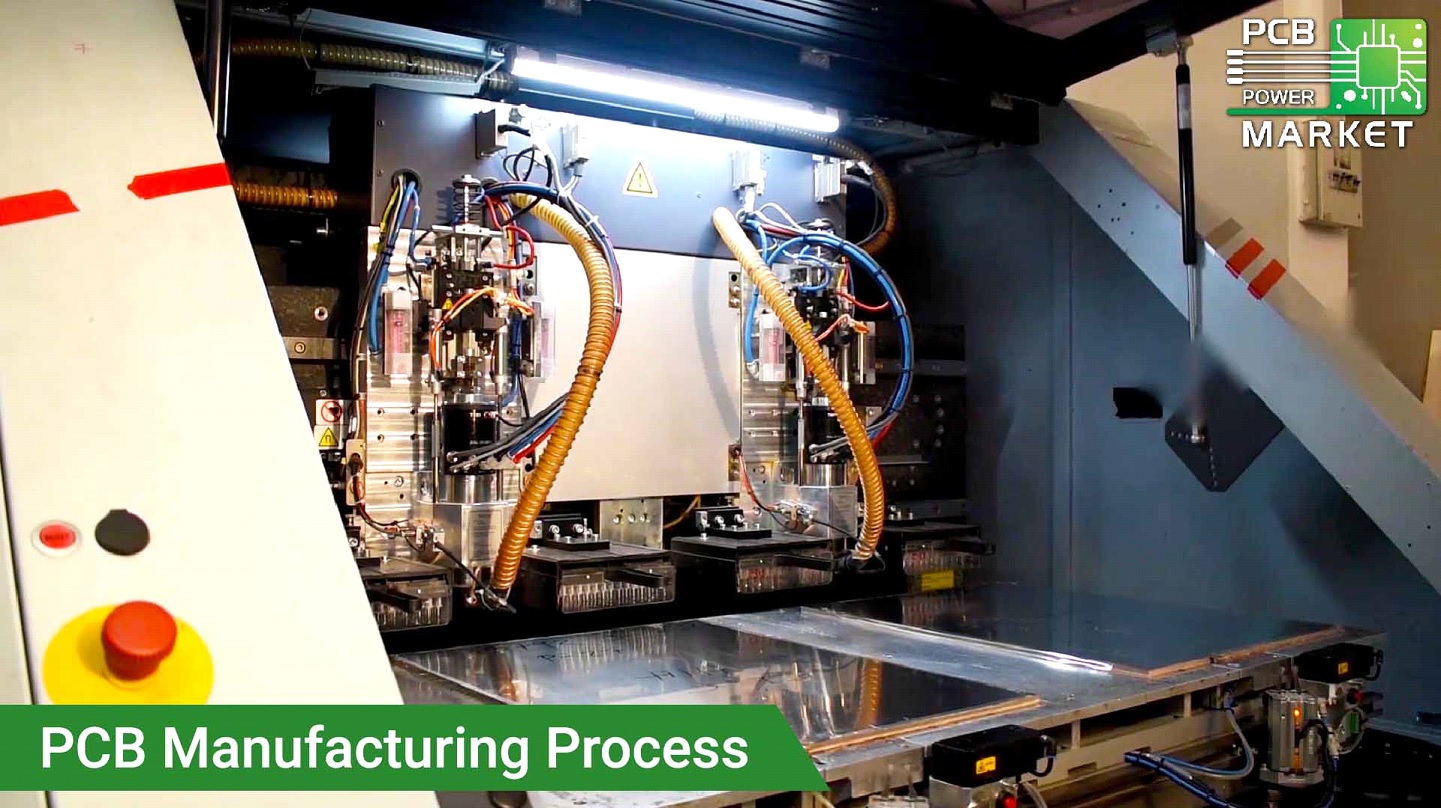

These startups are driving innovation in PCB manufacturing by introducing new technologies, materials, and processes that improve manufacturing efficiency, reduce waste, and enhance product quality. For instance, some startups are developing advanced PCB prototyping tools that enable rapid prototyping and testing, reducing the time and cost associated with traditional prototyping methods. Others are creating innovative PCB manufacturing equipment, such as pick-and-place machines, that can handle complex components and high-volume production.

The impact of PCB manufacturing equipment startups extends beyond the electronics industry, as they contribute to the development of innovative products and solutions that transform various aspects of our lives. From medical devices that improve healthcare outcomes to autonomous vehicles that enhance transportation safety, the innovations driven by PCB manufacturing equipment startups have far-reaching consequences.

As the electronics industry continues to evolve, the demand for innovative PCB manufacturing solutions will only continue to grow. PCB manufacturing equipment startups are well-positioned to capitalize on this trend, driving innovation and growth in the industry while creating new opportunities for entrepreneurs, investors, and consumers alike.

Key Challenges in Traditional PCB Manufacturing and How Startups are Addressing Them

Traditional PCB manufacturing methods have several limitations and challenges that can hinder the production of high-quality PCBs. One of the primary concerns is the high cost associated with traditional manufacturing methods, which can make it difficult for companies to remain competitive in the market. Additionally, traditional PCB manufacturing methods often result in environmental concerns, such as the use of toxic chemicals and the generation of waste.

Another significant challenge in traditional PCB manufacturing is the limited design flexibility. Traditional methods often require a significant amount of time and resources to produce a single PCB, making it difficult to accommodate design changes or produce small batches. This can limit the ability of companies to innovate and respond quickly to changing market demands.

PCB manufacturing equipment startups are addressing these challenges by developing innovative solutions that improve efficiency, reduce costs, and enhance design flexibility. For example, some startups are developing advanced PCB prototyping tools that enable rapid prototyping and testing, reducing the time and cost associated with traditional prototyping methods. Others are creating innovative PCB manufacturing equipment, such as pick-and-place machines, that can handle complex components and high-volume production.

Startups are also leveraging automation and artificial intelligence to improve the PCB manufacturing process. For instance, some startups are developing machine learning algorithms that can optimize the PCB manufacturing process, reducing waste and improving quality. Others are creating robotic systems that can automate the assembly and inspection of PCBs, improving efficiency and reducing labor costs.

Furthermore, PCB manufacturing equipment startups are developing sustainable solutions that address the environmental concerns associated with traditional PCB manufacturing methods. For example, some startups are developing lead-free soldering solutions that reduce the use of toxic chemicals, while others are creating biodegradable materials that can replace traditional PCB substrates.

By addressing the challenges of traditional PCB manufacturing, startups are enabling companies to produce high-quality PCBs quickly and efficiently, while also reducing costs and environmental concerns. This is driving innovation in the electronics industry and enabling companies to create new and innovative products that transform various aspects of our lives.

How to Choose the Right PCB Manufacturing Equipment for Your Startup

Selecting the right PCB manufacturing equipment is crucial for startups to ensure efficient and cost-effective production. With a wide range of options available, it can be overwhelming to choose the most suitable equipment for your startup. In this section, we will provide guidance on selecting the right PCB manufacturing equipment, considering factors such as budget, production volume, and design requirements.

One of the most critical factors to consider is the budget. PCB manufacturing equipment can range from a few thousand dollars to hundreds of thousands of dollars, depending on the complexity and capacity of the equipment. Startups should consider their budget and choose equipment that meets their production needs while staying within their budget.

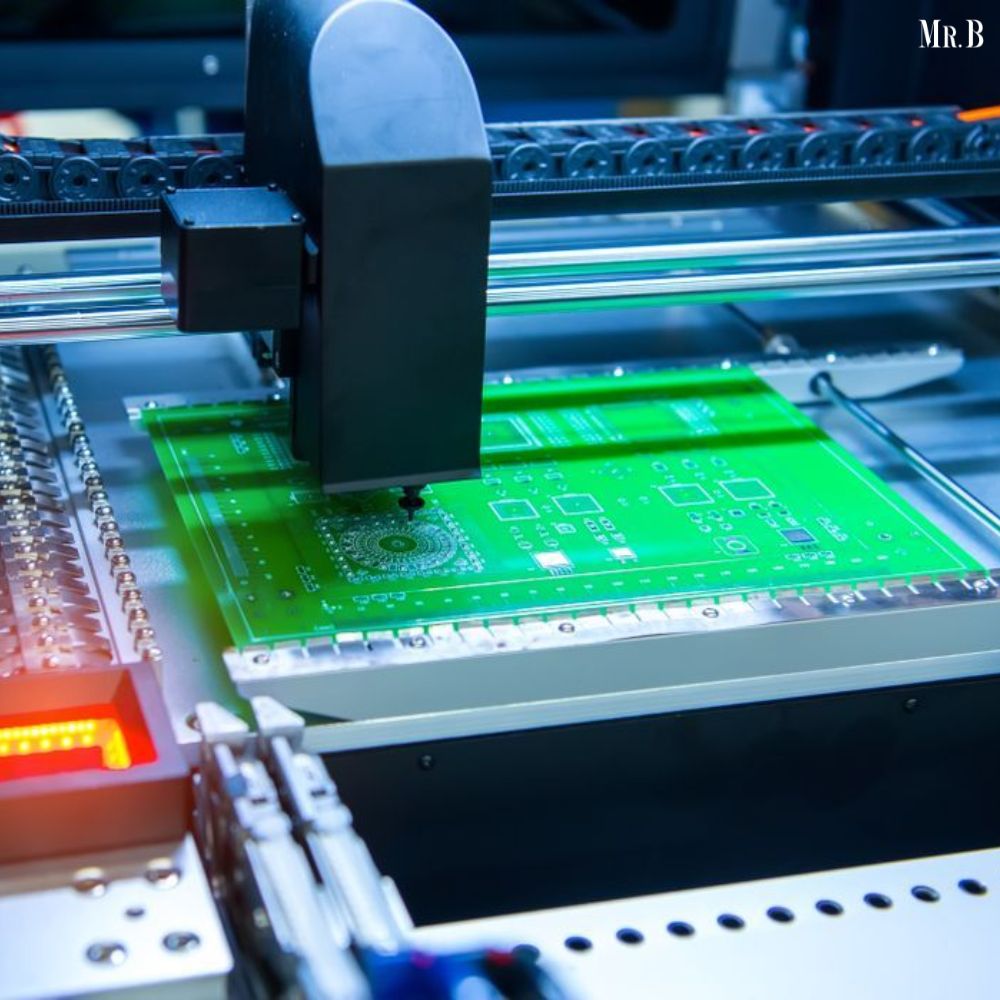

Another essential factor to consider is the production volume. Startups should consider the volume of PCBs they need to produce and choose equipment that can handle that volume. For example, if a startup needs to produce a small batch of PCBs, a pick-and-place machine may be sufficient. However, if the startup needs to produce a large volume of PCBs, a more advanced PCB manufacturing equipment such as a surface mount technology (SMT) machine may be required.

Design requirements are also an essential factor to consider. Startups should consider the complexity of their PCB designs and choose equipment that can handle those designs. For example, if a startup needs to produce PCBs with complex components such as ball grid arrays (BGAs) or quad flat no-leads (QFNs), they may need to choose equipment that can handle those components.

Some popular PCB manufacturing equipment for startups includes pick-and-place machines, PCB prototyping tools, and SMT machines. For example, the Juki FX-3R pick-and-place machine is a popular choice for startups due to its high accuracy and flexibility. The SparkFun PCB Prototyping Tool is another popular choice for startups due to its ease of use and affordability.

When choosing PCB manufacturing equipment, startups should also consider the maintenance and support costs. They should choose equipment that is easy to maintain and has good support from the manufacturer. Additionally, startups should consider the scalability of the equipment, ensuring that it can grow with their business.

By considering these factors, startups can choose the right PCB manufacturing equipment for their business, ensuring efficient and cost-effective production. This will enable them to produce high-quality PCBs quickly and efficiently, giving them a competitive edge in the market.

The Role of Automation in Modern PCB Manufacturing: Trends and Innovations

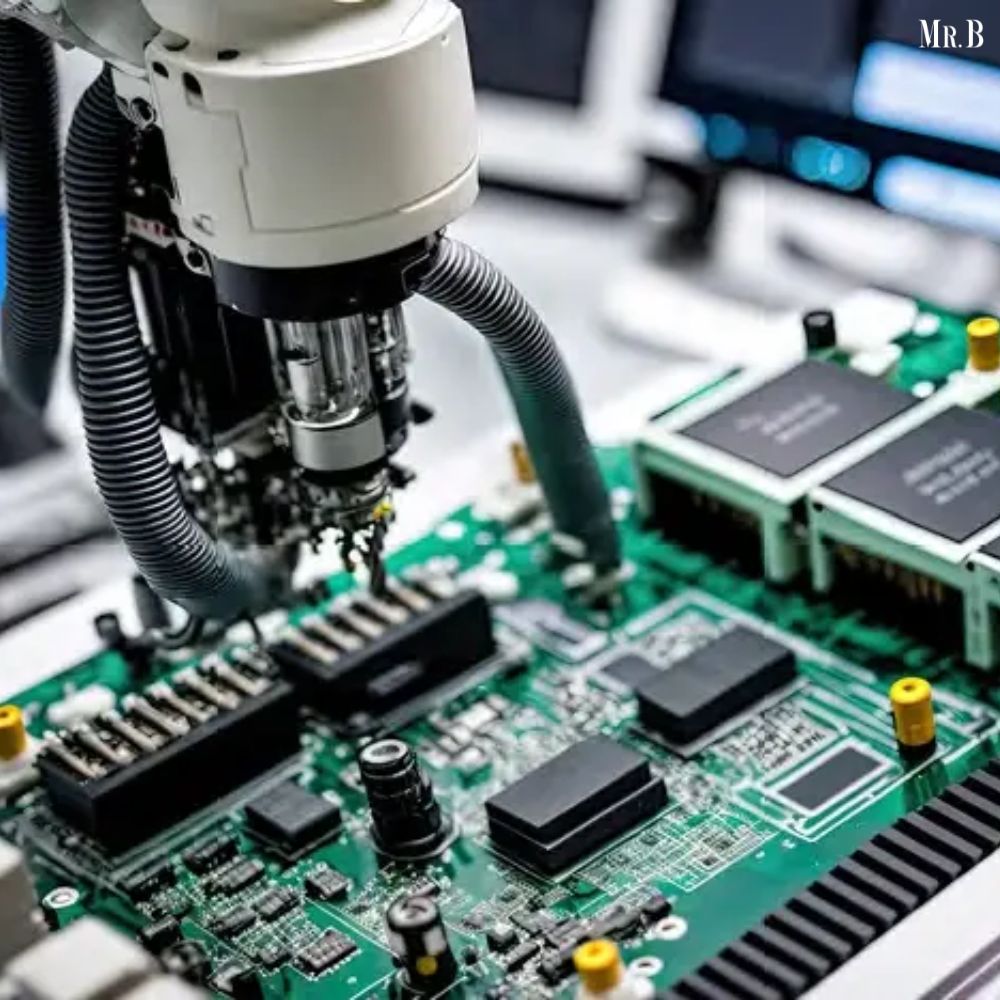

Automation is transforming the PCB manufacturing industry, enabling startups to improve efficiency, quality, and productivity. The use of robotics, artificial intelligence, and machine learning is becoming increasingly prevalent in modern PCB manufacturing, and startups are at the forefront of this trend.

One of the key areas where automation is making a significant impact is in the assembly process. Robotics and machine learning algorithms are being used to optimize the assembly process, reducing the risk of human error and improving the overall quality of the PCBs. For example, startups like KUKA and ABB are developing robotic systems that can handle complex assembly tasks with high precision and accuracy.

Another area where automation is being used is in the inspection process. Machine learning algorithms are being used to analyze images of PCBs and detect defects, reducing the need for manual inspection and improving the overall quality of the PCBs. Startups like ViTrox and CyberOptics are developing advanced inspection systems that use machine learning algorithms to detect defects and improve the overall quality of the PCBs.

Artificial intelligence is also being used in PCB manufacturing to optimize the production process. AI algorithms are being used to analyze data from various sources, such as sensors and machines, to optimize the production process and improve the overall efficiency of the factory. Startups like Siemens and GE Digital are developing AI-powered solutions that can optimize the production process and improve the overall efficiency of the factory.

The use of automation in PCB manufacturing is not only improving the efficiency and quality of the production process, but it is also enabling startups to innovate and disrupt the industry. For example, startups like Flex and Jabil are using automation to develop new business models, such as contract manufacturing and design for manufacturability.

As the use of automation in PCB manufacturing continues to grow, startups are well-positioned to take advantage of this trend and innovate and disrupt the industry. With the use of robotics, artificial intelligence, and machine learning, startups can improve the efficiency, quality, and productivity of the production process, and develop new business models that can transform the industry.

Sustainable PCB Manufacturing: Eco-Friendly Solutions for a Greener Future

The electronics industry is facing increasing pressure to reduce its environmental footprint, and PCB manufacturing is no exception. Traditional PCB manufacturing methods have significant environmental concerns, including the use of toxic chemicals, energy consumption, and waste generation. However, PCB manufacturing equipment startups are developing innovative solutions to address these concerns and create a more sustainable future for the industry.

One of the key areas where startups are making a significant impact is in the development of lead-free soldering solutions. Lead-free soldering is a critical step in the PCB manufacturing process, and startups like Kester and Indium Corporation are developing innovative lead-free soldering solutions that reduce the environmental impact of the process.

Another area where startups are making a significant impact is in the development of biodegradable materials. Biodegradable materials are being used to replace traditional PCB substrates, reducing the environmental impact of the manufacturing process. Startups like Ecovative and Biome Bioplastics are developing innovative biodegradable materials that are being used in PCB manufacturing.

Energy-efficient equipment is also a key area where startups are making a significant impact. Energy-efficient equipment reduces the energy consumption of the manufacturing process, reducing the environmental impact of the industry. Startups like Siemens and GE Digital are developing energy-efficient equipment that is being used in PCB manufacturing.

Startups are also developing innovative recycling solutions to reduce waste generation in the PCB manufacturing process. Recycling solutions like PCB recycling machines and e-waste recycling facilities are being developed to reduce the environmental impact of the industry.

The development of sustainable PCB manufacturing solutions is not only good for the environment, but it is also good for business. Companies that adopt sustainable PCB manufacturing solutions can reduce their costs, improve their brand reputation, and increase their competitiveness in the market.

As the demand for sustainable PCB manufacturing solutions continues to grow, startups are well-positioned to take advantage of this trend and innovate and disrupt the industry. With the development of lead-free soldering solutions, biodegradable materials, energy-efficient equipment, and recycling solutions, startups are creating a more sustainable future for the PCB manufacturing industry.

Success Stories: PCB Manufacturing Equipment Startups Making Waves in the Industry

The PCB manufacturing industry is witnessing a surge in innovative startups that are making significant contributions to the sector. These startups are developing cutting-edge technologies, products, and services that are transforming the way PCBs are designed, manufactured, and tested.

One such startup is Tempo Automation, a company that has developed a revolutionary PCB manufacturing platform that uses artificial intelligence and machine learning to optimize the production process. Tempo’s platform has been adopted by several leading electronics companies, including Google and Microsoft.

Another successful startup is Fictiv, a company that has developed a cloud-based PCB manufacturing platform that enables designers and engineers to design, prototype, and manufacture PCBs quickly and efficiently. Fictiv’s platform has been used by several leading companies, including Apple and Tesla.

Other notable startups in the PCB manufacturing industry include MacroFab, a company that has developed a cloud-based PCB manufacturing platform that enables designers and engineers to design, prototype, and manufacture PCBs quickly and efficiently. MacroFab’s platform has been used by several leading companies, including NASA and Lockheed Martin.

These startups are not only developing innovative technologies and products but also creating new business models that are disrupting the traditional PCB manufacturing industry. For example, some startups are offering pay-per-part pricing models, which enable customers to pay only for the PCBs they need, rather than having to purchase large quantities.

These success stories demonstrate the potential of PCB manufacturing equipment startups to innovate and disrupt the industry. By developing cutting-edge technologies, products, and services, these startups are transforming the way PCBs are designed, manufactured, and tested, and creating new opportunities for growth and innovation in the sector.

The success of these startups also highlights the importance of innovation and entrepreneurship in the PCB manufacturing industry. By supporting and encouraging startups, the industry can drive growth, innovation, and job creation, and ensure that it remains competitive and relevant in the years to come.

Overcoming Common Challenges in PCB Manufacturing Equipment Startup Development

PCB manufacturing equipment startups face a range of challenges, from funding and talent acquisition to market competition and regulatory compliance. However, with the right strategies and support, these startups can overcome these challenges and achieve success.

One of the biggest challenges faced by PCB manufacturing equipment startups is funding. Many startups struggle to secure the funding they need to develop and launch their products, and this can limit their ability to grow and compete in the market. However, there are a range of funding options available to startups, including venture capital, angel investors, and crowdfunding.

Talent acquisition is another major challenge faced by PCB manufacturing equipment startups. Many startups struggle to attract and retain the skilled engineers and technicians they need to develop and manufacture their products, and this can limit their ability to innovate and compete in the market. However, there are a range of strategies that startups can use to attract and retain talent, including offering competitive salaries and benefits, providing opportunities for professional development, and creating a positive and inclusive company culture.

Market competition is also a major challenge faced by PCB manufacturing equipment startups. Many startups struggle to compete with established companies that have more resources and experience, and this can limit their ability to gain market share and achieve success. However, there are a range of strategies that startups can use to compete in the market, including differentiating their products and services, building strong relationships with customers and partners, and focusing on niche markets or applications.

Regulatory compliance is another challenge faced by PCB manufacturing equipment startups. Many startups struggle to comply with the complex and changing regulatory requirements that apply to the PCB manufacturing industry, and this can limit their ability to operate and grow. However, there are a range of strategies that startups can use to comply with regulatory requirements, including working with regulatory experts, investing in compliance software and systems, and building strong relationships with regulatory agencies.

By understanding and addressing these common challenges, PCB manufacturing equipment startups can overcome the obstacles that stand in their way and achieve success. With the right strategies and support, these startups can innovate and disrupt the PCB manufacturing industry, and create new opportunities for growth and development.

The Future of PCB Manufacturing: Emerging Trends and Opportunities for Startups

The future of PCB manufacturing is exciting and full of opportunities for startups to innovate and disrupt the industry. Emerging trends such as the Internet of Things (IoT), artificial intelligence (AI), and 5G are driving the demand for more complex and sophisticated PCBs, and startups are well-positioned to capitalize on this trend.

One of the key emerging trends in PCB manufacturing is the use of additive manufacturing (AM) technologies, such as 3D printing. AM technologies enable the rapid prototyping and production of complex PCBs, and startups are leveraging these technologies to develop innovative products and services.

Another emerging trend is the use of advanced materials and technologies, such as graphene and nanotechnology. These materials and technologies enable the development of more efficient, reliable, and sustainable PCBs, and startups are at the forefront of this trend.

The increasing demand for IoT devices and 5G networks is also driving the growth of the PCB manufacturing industry. Startups are developing innovative PCBs that can support the high-speed and low-latency requirements of these applications, and this trend is expected to continue in the future.

Furthermore, the use of AI and machine learning (ML) is becoming more prevalent in PCB manufacturing. Startups are leveraging these technologies to develop more efficient and effective manufacturing processes, and to improve the quality and reliability of PCBs.

Overall, the future of PCB manufacturing is bright and full of opportunities for startups to innovate and disrupt the industry. By leveraging emerging trends and technologies, startups can develop innovative products and services that meet the growing demand for more complex and sophisticated PCBs.

As the PCB manufacturing industry continues to evolve, startups will play an increasingly important role in shaping its future. By staying ahead of the curve and leveraging emerging trends and technologies, startups can capitalize on the growing demand for PCBs and establish themselves as leaders in the industry.