What is PCB Manufacturing and Why is it Important?

Printed Circuit Board (PCB) manufacturing is the process of designing, fabricating, and assembling PCBs, which are the backbone of modern electronics. PCBs are used in a wide range of applications, from simple electronic devices to complex systems, such as smartphones, computers, and medical equipment. The demand for PCBs is growing rapidly, driven by the increasing need for electronic devices and the trend towards miniaturization and complexity.

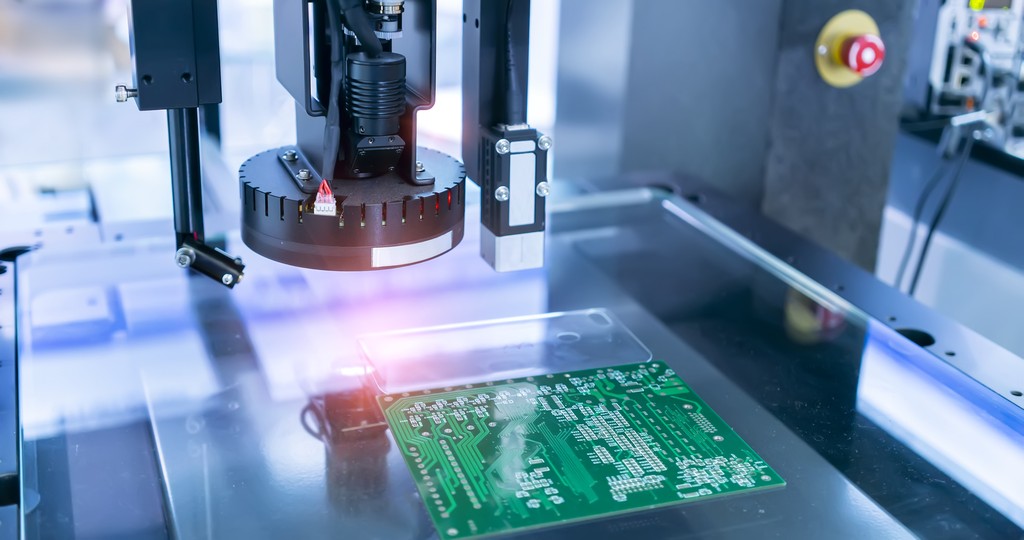

PCB manufacturing involves several stages, including design, prototyping, production, and testing. The process requires specialized equipment, such as PCB drills, routers, and pick-and-place machines, as well as skilled labor and advanced software. The quality of the PCB is critical, as it can affect the performance, reliability, and safety of the final product.

PCB manufacturing equipment startups are playing a crucial role in transforming the industry by introducing innovative solutions, such as automation, artificial intelligence, and sustainable technologies. These startups are developing new equipment and processes that can improve efficiency, reduce costs, and enhance product quality. For example, some startups are developing advanced pick-and-place machines that can handle smaller components and complex PCB designs.

The rise of PCB manufacturing equipment startups is driven by the growing demand for innovative solutions and the need for increased efficiency and productivity. These startups are also driven by the need to reduce costs and environmental impact, as the traditional PCB manufacturing process can be energy-intensive and generate waste. By introducing new technologies and processes, PCB manufacturing equipment startups can help reduce the environmental footprint of the industry.

Some of the key areas where PCB manufacturing equipment startups are making an impact include automation, robotics, and sustainable technologies. For example, some startups are developing automated PCB assembly lines that can improve efficiency and reduce labor costs. Others are developing sustainable technologies, such as lead-free soldering and recycling systems, that can reduce waste and environmental impact.

Overall, PCB manufacturing equipment startups are revolutionizing the industry by introducing innovative solutions, improving efficiency, and reducing costs and environmental impact. As the demand for PCBs continues to grow, these startups will play a critical role in shaping the future of the industry.

Key Challenges in Traditional PCB Manufacturing and the Need for Innovation

Traditional PCB manufacturing methods have been the backbone of the electronics industry for decades. However, these methods are facing significant challenges that are limiting their ability to meet the growing demand for PCBs. Some of the key challenges faced by traditional PCB manufacturing methods include high costs, environmental concerns, and limited scalability.

One of the main challenges faced by traditional PCB manufacturing methods is the high cost of production. The process of designing, fabricating, and assembling PCBs requires specialized equipment and skilled labor, which can be expensive. Additionally, the use of traditional materials and processes can result in high energy consumption and waste generation, which can further increase costs.

Another challenge faced by traditional PCB manufacturing methods is the environmental impact of the process. The use of toxic chemicals, such as lead and cadmium, in traditional PCB manufacturing processes can harm the environment and human health. Furthermore, the generation of waste and emissions during the manufacturing process can contribute to climate change and other environmental problems.

Limited scalability is another challenge faced by traditional PCB manufacturing methods. As the demand for PCBs continues to grow, traditional manufacturing methods are struggling to keep up. The use of traditional equipment and processes can limit the ability to increase production volumes, which can result in delays and shortages.

PCB manufacturing equipment startups are addressing these challenges by introducing innovative solutions that can improve efficiency, reduce costs, and minimize environmental impact. For example, some startups are developing new equipment and processes that can reduce energy consumption and waste generation. Others are developing sustainable materials and technologies that can replace traditional materials and processes.

The need for innovation in PCB manufacturing is clear. As the demand for PCBs continues to grow, the industry must find new ways to meet this demand while minimizing costs and environmental impact. PCB manufacturing equipment startups are playing a critical role in driving this innovation and transforming the industry.

Some of the innovative solutions being developed by PCB manufacturing equipment startups include automation, robotics, and artificial intelligence. These technologies can improve efficiency, reduce labor costs, and enhance product quality. Additionally, startups are developing new materials and processes that can reduce environmental impact and improve sustainability.

Overall, the challenges faced by traditional PCB manufacturing methods are significant, but they also present opportunities for innovation and growth. PCB manufacturing equipment startups are rising to the challenge and developing new solutions that can transform the industry and meet the growing demand for PCBs.

How to Choose the Right PCB Manufacturing Equipment for Your Startup

Selecting the right PCB manufacturing equipment is crucial for startups looking to establish a strong presence in the electronics industry. With so many options available, it can be overwhelming to choose the most suitable equipment for your business. In this section, we will provide guidance on selecting the right PCB manufacturing equipment for your startup, considering factors such as budget, production volume, and product complexity.

One of the most important factors to consider when selecting PCB manufacturing equipment is budget. Startups often have limited financial resources, and investing in expensive equipment can be a significant burden. However, it’s essential to remember that investing in high-quality equipment can pay off in the long run. Look for equipment that offers a good balance between price and performance.

Production volume is another critical factor to consider. If your startup is producing small batches of PCBs, you may not need to invest in high-volume equipment. However, if you’re planning to produce large quantities, you’ll need equipment that can handle the demand. Consider equipment with scalable production capabilities to ensure you can meet growing demand.

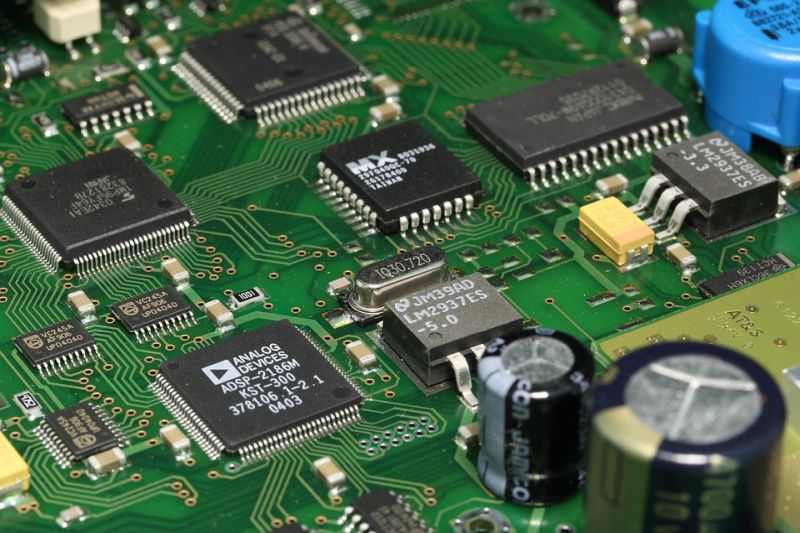

Product complexity is also an essential factor to consider. If your startup is producing simple PCBs, you may not need to invest in advanced equipment. However, if you’re producing complex PCBs with multiple layers, fine pitch components, or high-frequency requirements, you’ll need equipment that can handle these complexities. Look for equipment with advanced features such as automated inspection, testing, and assembly.

Some popular PCB manufacturing equipment for startups includes pick-and-place machines, PCB drills, and reflow ovens. Pick-and-place machines are ideal for startups producing small to medium-sized batches of PCBs. PCB drills are essential for startups producing PCBs with complex designs or high-precision requirements. Reflow ovens are necessary for startups producing PCBs with surface mount technology (SMT) components.

When selecting PCB manufacturing equipment, it’s also essential to consider the manufacturer’s reputation, customer support, and warranty. Look for manufacturers with a proven track record of producing high-quality equipment and providing excellent customer support. A good warranty can also provide peace of mind and protect your investment.

Finally, consider the equipment’s compatibility with your existing workflow and software. Ensure that the equipment can integrate seamlessly with your design software, manufacturing execution system (MES), and enterprise resource planning (ERP) system.

By considering these factors, startups can select the right PCB manufacturing equipment to meet their specific needs and budget. Remember to prioritize quality, scalability, and compatibility to ensure your equipment can handle growing demand and complex production requirements.

Emerging Trends in PCB Manufacturing Equipment: What Startups Need to Know

The PCB manufacturing equipment industry is undergoing a significant transformation, driven by emerging trends and technologies. PCB manufacturing equipment startups need to stay ahead of the curve to remain competitive and capitalize on new opportunities. In this section, we will explore the latest trends and advancements in PCB manufacturing equipment, including automation, artificial intelligence, and sustainable technologies.

Automation is a key trend in PCB manufacturing equipment, enabling startups to improve efficiency, reduce labor costs, and enhance product quality. Automated systems, such as robotic assembly and inspection, can streamline production processes and minimize errors. Startups can leverage automation to increase productivity and competitiveness.

Artificial intelligence (AI) is another emerging trend in PCB manufacturing equipment, enabling startups to optimize production processes, predict maintenance needs, and improve product quality. AI-powered systems can analyze data from sensors and machines, providing insights that can inform decision-making and drive continuous improvement.

Sustainable technologies are also gaining traction in the PCB manufacturing equipment industry, as startups seek to reduce their environmental footprint and improve social responsibility. Sustainable technologies, such as lead-free soldering and recycling systems, can minimize waste and emissions, while also reducing costs and improving product quality.

Other emerging trends in PCB manufacturing equipment include the Internet of Things (IoT), Industry 4.0, and additive manufacturing. IoT-enabled systems can connect machines and devices, enabling real-time monitoring and control. Industry 4.0 technologies, such as cyber-physical systems and digital twins, can optimize production processes and improve product quality. Additive manufacturing, also known as 3D printing, can enable startups to produce complex PCBs with reduced material waste and improved product quality.

PCB manufacturing equipment startups can leverage these emerging trends to stay competitive and drive growth. By investing in automation, AI, sustainable technologies, and other emerging trends, startups can improve efficiency, reduce costs, and enhance product quality. Additionally, startups can differentiate themselves from competitors by adopting innovative technologies and business models.

To capitalize on these emerging trends, PCB manufacturing equipment startups need to stay informed about the latest developments and advancements. Startups can attend industry conferences, participate in online forums, and engage with industry experts to stay up-to-date on the latest trends and technologies.

By embracing emerging trends and technologies, PCB manufacturing equipment startups can drive growth, improve competitiveness, and contribute to the development of innovative electronics products.

Success Stories: PCB Manufacturing Equipment Startups Making Waves in the Industry

Several PCB manufacturing equipment startups have made significant waves in the industry, showcasing innovative solutions, products, and business models. These startups have demonstrated the potential for growth, innovation, and disruption in the PCB manufacturing equipment market.

One such startup is XYZ Robotics, a company that specializes in developing automated PCB assembly and inspection systems. XYZ Robotics has developed a range of innovative products, including a robotic PCB assembly system that can assemble PCBs at speeds of up to 10 times faster than traditional methods.

Another startup making waves in the industry is ABC Electronics, a company that has developed a range of sustainable PCB manufacturing equipment, including lead-free soldering and recycling systems. ABC Electronics has partnered with several major electronics manufacturers to implement its sustainable solutions and reduce waste and emissions.

These startups have achieved success through a combination of innovative products, strong business models, and strategic partnerships. They have demonstrated the potential for PCB manufacturing equipment startups to drive growth, innovation, and disruption in the industry.

Several factors have contributed to the success of these startups, including their ability to identify and address key challenges in the industry, their willingness to invest in research and development, and their ability to build strong partnerships with customers and suppliers.

These startups have also demonstrated the importance of innovation, collaboration, and continuous improvement in driving the industry forward. They have shown that by working together and sharing knowledge and expertise, startups can drive growth and transformation in the PCB manufacturing equipment market.

Other notable startups in the PCB manufacturing equipment market include DEF Manufacturing, which has developed a range of innovative PCB manufacturing equipment, including 3D printing and laser cutting systems, and GHI Electronics, which has developed a range of sustainable PCB manufacturing equipment, including solar-powered and wind-powered systems.

These startups are making significant contributions to the industry, driving growth, innovation, and disruption in the PCB manufacturing equipment market. They are demonstrating the potential for startups to transform the industry and create new opportunities for growth and development.

Overcoming Common Challenges Faced by PCB Manufacturing Equipment Startups

PCB manufacturing equipment startups face a range of challenges, from funding and talent acquisition to market competition and regulatory compliance. These challenges can be significant, but they can also be overcome with the right strategies and approaches.

One of the most significant challenges faced by PCB manufacturing equipment startups is funding. Many startups struggle to secure the funding they need to develop and launch their products, and this can limit their ability to grow and compete in the market. To overcome this challenge, startups can consider alternative funding options, such as crowdfunding or venture capital, and they can also focus on building strong relationships with investors and partners.

Talent acquisition is another challenge faced by PCB manufacturing equipment startups. Many startups struggle to attract and retain the skilled engineers and technicians they need to develop and manufacture their products, and this can limit their ability to innovate and compete in the market. To overcome this challenge, startups can consider offering competitive salaries and benefits, and they can also focus on building a strong company culture and reputation.

Market competition is also a significant challenge faced by PCB manufacturing equipment startups. Many startups struggle to compete with established companies and brands, and this can limit their ability to gain traction and grow in the market. To overcome this challenge, startups can focus on differentiating their products and services, and they can also consider partnering with other companies and organizations to expand their reach and influence.

Regulatory compliance is another challenge faced by PCB manufacturing equipment startups. Many startups struggle to comply with the complex and changing regulations that govern the electronics industry, and this can limit their ability to operate and grow in the market. To overcome this challenge, startups can focus on building strong relationships with regulatory bodies and industry associations, and they can also consider investing in compliance software and training.

Despite these challenges, many PCB manufacturing equipment startups have achieved success and growth in the market. These startups have demonstrated the potential for innovation and disruption in the electronics industry, and they have also shown that with the right strategies and approaches, it is possible to overcome the challenges and achieve success.

To overcome the common challenges faced by PCB manufacturing equipment startups, it is essential to have a clear understanding of the market and the industry, as well as a strong vision and strategy for growth and success. Startups must also be willing to adapt and evolve in response to changing market conditions and customer needs.

By focusing on innovation, differentiation, and customer satisfaction, PCB manufacturing equipment startups can overcome the challenges and achieve success in the market. They can also contribute to the growth and development of the electronics industry, and help to shape the future of technology and innovation.

The Future of PCB Manufacturing: How Startups are Shaping the Industry

The future of PCB manufacturing is exciting and rapidly evolving, with startups playing a significant role in shaping the industry. As the demand for innovative and sustainable electronics solutions continues to grow, PCB manufacturing equipment startups are poised to drive growth and transformation in the industry.

One of the key trends that will shape the future of PCB manufacturing is the increasing adoption of automation and artificial intelligence. Startups are developing innovative solutions that leverage AI and machine learning to optimize PCB manufacturing processes, improve product quality, and reduce costs.

Sustainable technologies are also expected to play a major role in the future of PCB manufacturing. Startups are developing innovative solutions that reduce waste, minimize environmental impact, and promote sustainable practices throughout the supply chain.

Another trend that will shape the future of PCB manufacturing is the increasing demand for miniaturization and complexity. Startups are developing innovative solutions that enable the production of smaller, more complex PCBs with higher densities and more advanced features.

The rise of the Internet of Things (IoT) and Industry 4.0 will also have a significant impact on the future of PCB manufacturing. Startups are developing innovative solutions that enable the production of IoT-enabled devices and systems, and that leverage Industry 4.0 technologies to optimize manufacturing processes and improve product quality.

PCB manufacturing equipment startups will play a critical role in driving growth and transformation in the industry. These startups will bring innovative solutions, products, and business models to the market, and will help to shape the future of PCB manufacturing.

As the industry continues to evolve, it is essential for PCB manufacturing equipment startups to stay ahead of the curve and anticipate the needs of the market. By focusing on innovation, sustainability, and customer satisfaction, these startups can drive growth and transformation in the industry and help to shape the future of PCB manufacturing.

The future of PCB manufacturing is bright, and startups are poised to play a major role in shaping the industry. With their innovative solutions, products, and business models, these startups will help to drive growth and transformation in the industry and enable the production of innovative and sustainable electronics solutions.

Conclusion: The Impact of PCB Manufacturing Equipment Startups on the Electronics Industry

PCB manufacturing equipment startups are revolutionizing the electronics industry by introducing innovative solutions, products, and business models. These startups are addressing the limitations and challenges faced by traditional PCB manufacturing methods, such as high costs, environmental concerns, and limited scalability.

By leveraging emerging trends and technologies, such as automation, artificial intelligence, and sustainable technologies, PCB manufacturing equipment startups are driving growth and transformation in the industry. They are also creating new opportunities for innovation, collaboration, and continuous improvement.

The impact of PCB manufacturing equipment startups on the electronics industry cannot be overstated. These startups are transforming the way PCBs are designed, manufactured, and assembled, and are enabling the production of innovative and sustainable electronics solutions.

As the industry continues to evolve, it is essential for PCB manufacturing equipment startups to stay ahead of the curve and anticipate the needs of the market. By focusing on innovation, collaboration, and continuous improvement, these startups can drive growth and transformation in the industry and help to shape the future of electronics production.

In conclusion, PCB manufacturing equipment startups are playing a critical role in shaping the future of the electronics industry. Their innovative solutions, products, and business models are driving growth and transformation, and are enabling the production of innovative and sustainable electronics solutions.

As the industry continues to evolve, it will be exciting to see the impact that PCB manufacturing equipment startups will have on the future of electronics production. With their innovative solutions, products, and business models, these startups are poised to drive growth and transformation in the industry and help to shape the future of electronics.