The Rise of PCB Prototyping and Development Startups

The electronics industry has witnessed a significant transformation in recent years, driven by the emergence of PCB prototyping and development startups. These innovative companies have revolutionized the way electronic products are designed, developed, and manufactured, offering a range of benefits that are transforming the industry. By leveraging advanced technologies, such as computer-aided design (CAD) software, 3D printing, and automated manufacturing, PCB prototyping and development startups are enabling rapid prototyping, reducing costs, and increasing innovation.

One of the key drivers of this trend is the growing demand for customized and specialized electronic products. As consumers increasingly seek unique and personalized products, manufacturers are turning to PCB prototyping and development startups to meet this demand. These startups offer a range of services, including PCB design, prototyping, and manufacturing, allowing manufacturers to bring their products to market quickly and efficiently.

PCB prototyping and development startups are also driving innovation in the electronics industry. By leveraging emerging technologies, such as artificial intelligence (AI) and the Internet of Things (IoT), these startups are developing new and innovative products that are transforming the way we live and work. For example, AI-powered PCB design tools are enabling the creation of complex and sophisticated electronic products, while IoT-enabled devices are connecting people and devices like never before.

Furthermore, PCB prototyping and development startups are reducing the barriers to entry for new manufacturers. By offering affordable and accessible PCB design and manufacturing services, these startups are enabling small and medium-sized enterprises (SMEs) to compete with larger manufacturers. This is driving competition and innovation in the industry, leading to better products and services for consumers.

In addition, PCB prototyping and development startups are creating new opportunities for collaboration and partnership. By working together with manufacturers, designers, and engineers, these startups are driving the development of new and innovative products. This collaborative approach is leading to the creation of complex and sophisticated electronic products that are transforming the industry.

Overall, the rise of PCB prototyping and development startups is transforming the electronics industry. By offering rapid prototyping, reducing costs, and increasing innovation, these startups are driving the development of new and innovative products. As the industry continues to evolve, it is likely that PCB prototyping and development startups will play an increasingly important role in shaping the future of electronics.

How to Choose the Right PCB Prototyping Startup for Your Project

When it comes to selecting a PCB prototyping and development startup for your project, there are several factors to consider. With the rise of these innovative companies, it can be overwhelming to navigate the options and choose the right one for your needs. In this article, we will provide guidance on how to select the most suitable PCB prototyping startup for your project, including expertise, equipment, and pricing models.

First and foremost, it is essential to assess the startup’s expertise in PCB prototyping and development. Look for companies with a proven track record of delivering high-quality PCBs, and a team of experienced engineers and designers. Check their portfolio and case studies to see if they have worked on projects similar to yours. Additionally, consider their certifications and compliance with industry standards, such as ISO 9001 and IPC-7351.

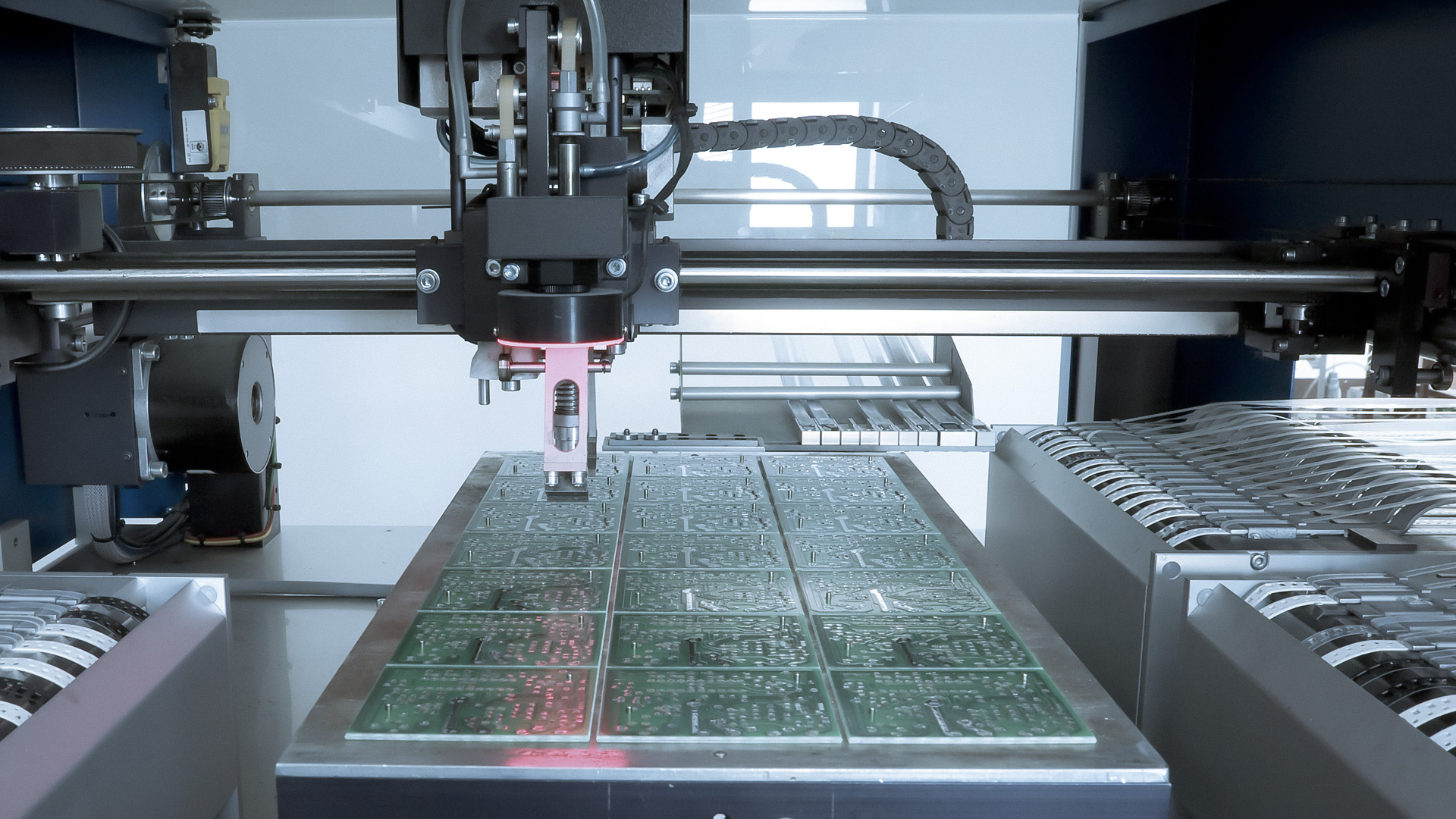

Another critical factor to consider is the startup’s equipment and technology. Look for companies that have invested in state-of-the-art equipment, such as 3D printers, CNC machines, and automated assembly lines. This will ensure that your PCBs are manufactured with precision and accuracy. Additionally, consider their software capabilities, such as CAD design and simulation tools.

Pricing models are also an essential consideration when selecting a PCB prototyping and development startup. Look for companies that offer transparent and competitive pricing, with no hidden fees or charges. Consider their pricing structure, including the cost per unit, and any discounts for large orders. Additionally, ask about their payment terms and any financing options they may offer.

Finally, consider the startup’s communication and collaboration style. Look for companies that have a strong customer support team, with clear and responsive communication channels. Consider their project management approach, including regular updates and milestones. Additionally, ask about their willingness to collaborate with your team, including any necessary design or engineering support.

By considering these factors, you can make an informed decision when selecting a PCB prototyping and development startup for your project. Remember to prioritize expertise, equipment, and pricing models, as well as communication and collaboration style. With the right startup, you can ensure that your PCBs are manufactured with precision and accuracy, and that your project is completed on time and within budget.

Some notable PCB prototyping and development startups that excel in these areas include Fictiv, Xcentric, and Tempo Automation. These companies have demonstrated a strong commitment to quality, innovation, and customer satisfaction, and are well-positioned to support your PCB prototyping and development needs.

Key Players in the PCB Prototyping and Development Startup Ecosystem

The PCB prototyping and development startup ecosystem is comprised of a diverse range of companies, each with their unique value propositions, services, and success stories. In this article, we will showcase some of the notable players in this ecosystem, highlighting their strengths and contributions to the industry.

Fictiv is a leading PCB prototyping and development startup that has gained significant attention in recent years. With a strong focus on rapid prototyping and agile manufacturing, Fictiv has established itself as a go-to partner for companies seeking to bring their products to market quickly and efficiently. Their platform offers a range of services, including PCB design, prototyping, and manufacturing, making it an ideal solution for companies of all sizes.

Xcentric is another notable player in the PCB prototyping and development startup ecosystem. With a strong emphasis on innovation and customer satisfaction, Xcentric has developed a range of cutting-edge services, including 3D printing and IoT-enabled PCBs. Their team of experienced engineers and designers work closely with clients to bring their ideas to life, making them a popular choice for companies seeking to develop complex and sophisticated electronic products.

Tempo Automation is a PCB prototyping and development startup that has gained recognition for its innovative approach to PCB manufacturing. With a focus on automation and efficiency, Tempo Automation has developed a range of services, including rapid prototyping and high-volume manufacturing. Their platform offers a range of benefits, including reduced lead times and increased quality, making it an ideal solution for companies seeking to bring their products to market quickly and efficiently.

Other notable players in the PCB prototyping and development startup ecosystem include MacroFab, a company that specializes in PCB manufacturing and assembly, and Sierra Circuits, a company that offers a range of PCB prototyping and development services, including design, prototyping, and manufacturing.

These companies, along with others, are driving innovation and growth in the PCB prototyping and development startup ecosystem. By offering a range of services and solutions, they are enabling companies to bring their products to market quickly and efficiently, and are playing a critical role in shaping the future of the electronics industry.

The success of these companies can be attributed to their commitment to innovation, customer satisfaction, and quality. By investing in the latest technologies and techniques, they are able to offer a range of benefits, including reduced lead times, increased quality, and improved efficiency. As the electronics industry continues to evolve, it is likely that these companies will play an increasingly important role in shaping its future.

Overcoming Challenges in PCB Prototyping and Development

PCB prototyping and development startups face a range of challenges that can impact their success. From design complexity to material sourcing and regulatory compliance, these challenges can be significant hurdles to overcome. In this article, we will discuss some of the common challenges faced by PCB prototyping and development startups and offer solutions and best practices to overcome these hurdles.

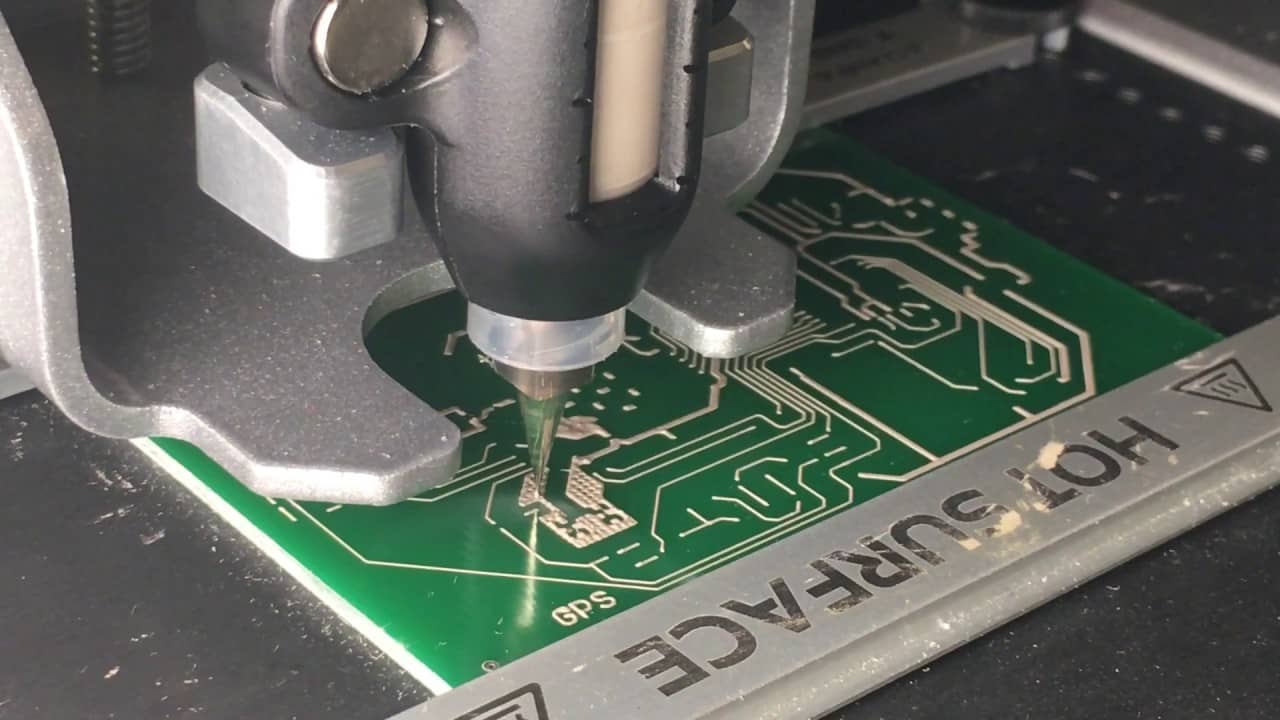

One of the most significant challenges faced by PCB prototyping and development startups is design complexity. As electronic products become increasingly sophisticated, the complexity of PCB designs has also increased. This can make it difficult for startups to design and manufacture PCBs that meet the required specifications. To overcome this challenge, startups can invest in advanced design software and tools, such as computer-aided design (CAD) software and simulation tools. These tools can help startups to design and test PCBs more efficiently and effectively.

Material sourcing is another challenge faced by PCB prototyping and development startups. The availability and cost of materials can impact the success of a startup, particularly if they are working with limited budgets. To overcome this challenge, startups can establish relationships with suppliers and negotiate favorable pricing and delivery terms. They can also consider using alternative materials or sourcing materials from different regions.

Regulatory compliance is also a significant challenge faced by PCB prototyping and development startups. The electronics industry is heavily regulated, and startups must ensure that their products meet the required standards and regulations. To overcome this challenge, startups can invest in regulatory compliance software and tools, such as compliance management software and testing and certification services. They can also establish relationships with regulatory bodies and seek guidance on compliance requirements.

Other challenges faced by PCB prototyping and development startups include manufacturing capacity, quality control, and supply chain management. To overcome these challenges, startups can invest in advanced manufacturing technologies, such as 3D printing and automation. They can also establish relationships with contract manufacturers and suppliers to ensure that their products are manufactured and delivered efficiently and effectively.

Despite these challenges, PCB prototyping and development startups can succeed by adopting best practices and investing in advanced technologies and tools. By overcoming these challenges, startups can bring innovative electronic products to market quickly and efficiently, and establish themselves as leaders in the industry.

Some notable PCB prototyping and development startups that have overcome these challenges include Fictiv, Xcentric, and Tempo Automation. These companies have invested in advanced technologies and tools, established relationships with suppliers and contract manufacturers, and prioritized regulatory compliance and quality control. As a result, they have been able to bring innovative electronic products to market quickly and efficiently, and establish themselves as leaders in the industry.

The Role of Emerging Technologies in PCB Prototyping and Development

Emerging technologies are transforming the PCB prototyping and development process, enabling startups to bring innovative electronic products to market quickly and efficiently. In this article, we will explore the influence of emerging technologies, such as artificial intelligence, 3D printing, and the Internet of Things (IoT), on the PCB prototyping and development process, and their potential to drive innovation and efficiency.

Artificial intelligence (AI) is one of the most significant emerging technologies impacting the PCB prototyping and development process. AI-powered design tools are enabling startups to design and optimize PCBs more efficiently, reducing the risk of errors and improving overall quality. Additionally, AI-powered testing and validation tools are enabling startups to test and validate PCBs more quickly and accurately, reducing the time and cost associated with traditional testing methods.

3D printing is another emerging technology that is transforming the PCB prototyping and development process. 3D printing enables startups to create complex PCBs with intricate designs and geometries, which cannot be produced using traditional manufacturing methods. Additionally, 3D printing reduces the time and cost associated with traditional manufacturing methods, enabling startups to bring products to market more quickly and efficiently.

The Internet of Things (IoT) is also having a significant impact on the PCB prototyping and development process. IoT-enabled PCBs are enabling startups to create connected devices that can communicate with other devices and systems, enabling new applications and use cases. Additionally, IoT-enabled PCBs are enabling startups to collect and analyze data from devices, enabling them to optimize performance and improve overall efficiency.

Other emerging technologies, such as augmented reality (AR) and virtual reality (VR), are also being used in the PCB prototyping and development process. AR and VR enable startups to design and test PCBs in a virtual environment, reducing the risk of errors and improving overall quality. Additionally, AR and VR enable startups to collaborate more effectively with stakeholders, enabling them to bring products to market more quickly and efficiently.

PCB prototyping and development startups that are leveraging emerging technologies are experiencing significant benefits, including improved efficiency, reduced costs, and increased innovation. For example, Fictiv, a PCB prototyping and development startup, is using AI-powered design tools to design and optimize PCBs more efficiently. Additionally, Xcentric, a PCB prototyping and development startup, is using 3D printing to create complex PCBs with intricate designs and geometries.

As emerging technologies continue to evolve and improve, it is likely that they will play an increasingly important role in the PCB prototyping and development process. Startups that are able to leverage these technologies effectively will be well-positioned to bring innovative electronic products to market quickly and efficiently, and to establish themselves as leaders in the industry.

Best Practices for Successful PCB Prototyping and Development

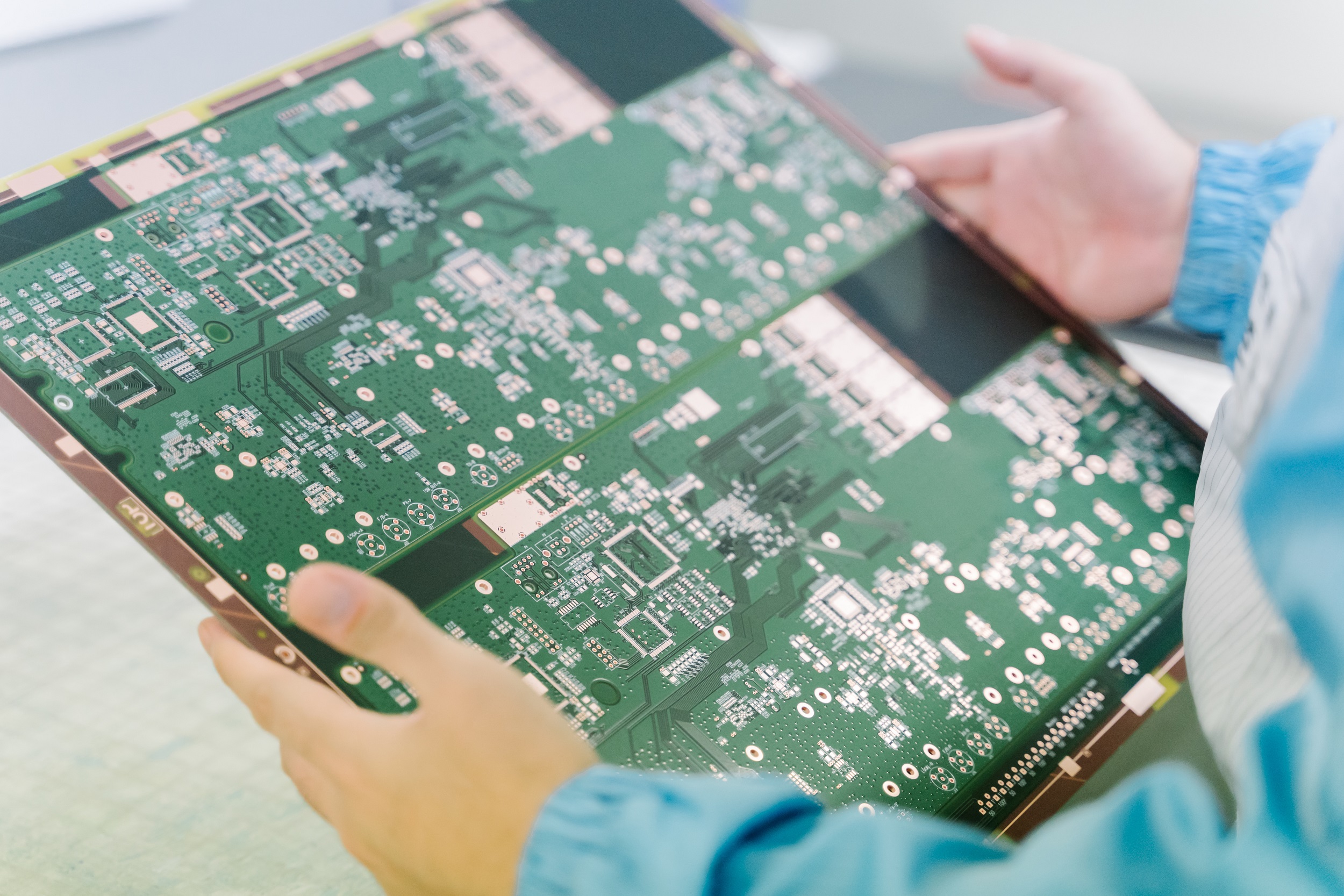

PCB prototyping and development startups are revolutionizing the electronics industry by providing rapid prototyping, reduced costs, and increased innovation. However, to achieve success in this field, it is essential to follow best practices that ensure high-quality PCBs, efficient development processes, and effective collaboration with stakeholders. In this article, we will discuss some of the best practices for successful PCB prototyping and development, including design for manufacturability, testing and validation, and collaboration with contract manufacturers.

Design for manufacturability (DFM) is a critical best practice in PCB prototyping and development. DFM involves designing PCBs with manufacturing considerations in mind, such as component selection, PCB layout, and material selection. By following DFM principles, startups can ensure that their PCBs are manufactured efficiently and effectively, reducing the risk of errors and improving overall quality.

Testing and validation are also essential best practices in PCB prototyping and development. Testing and validation involve verifying that PCBs meet the required specifications and performance standards. By conducting thorough testing and validation, startups can ensure that their PCBs are reliable, efficient, and meet the required standards.

Collaboration with contract manufacturers is another critical best practice in PCB prototyping and development. Contract manufacturers can provide startups with access to advanced manufacturing technologies, expertise, and resources. By collaborating with contract manufacturers, startups can ensure that their PCBs are manufactured efficiently and effectively, reducing the risk of errors and improving overall quality.

Other best practices for successful PCB prototyping and development include using advanced design software, such as computer-aided design (CAD) software, and simulation tools. These tools can help startups to design and optimize PCBs more efficiently, reducing the risk of errors and improving overall quality.

Additionally, startups should prioritize regulatory compliance and quality control. Regulatory compliance involves ensuring that PCBs meet the required standards and regulations, such as RoHS and REACH. Quality control involves ensuring that PCBs are manufactured to the required standards, reducing the risk of errors and improving overall quality.

By following these best practices, PCB prototyping and development startups can ensure that their PCBs are of high quality, efficient, and meet the required standards. This can help startups to establish themselves as leaders in the industry, and to bring innovative electronic products to market quickly and efficiently.

Some notable PCB prototyping and development startups that are following these best practices include Fictiv, Xcentric, and Tempo Automation. These startups are using advanced design software, simulation tools, and collaboration with contract manufacturers to ensure that their PCBs are of high quality, efficient, and meet the required standards.

Real-World Applications of PCB Prototyping and Development Startups

PCB prototyping and development startups are revolutionizing the electronics industry by providing rapid prototyping, reduced costs, and increased innovation. These startups are being used in a wide range of applications, from medical devices to aerospace systems and consumer electronics. In this article, we will highlight some real-world examples of PCB prototyping and development startups in action.

Medical devices are one of the most significant applications of PCB prototyping and development startups. These startups are being used to develop innovative medical devices, such as portable defibrillators and implantable devices. For example, a startup called Fictiv is working with a medical device company to develop a portable defibrillator that can be used in emergency situations.

Aerospace systems are another significant application of PCB prototyping and development startups. These startups are being used to develop innovative aerospace systems, such as satellite components and navigation systems. For example, a startup called Xcentric is working with a aerospace company to develop a navigation system for a satellite.

Consumer electronics are also a significant application of PCB prototyping and development startups. These startups are being used to develop innovative consumer electronics, such as smart home devices and wearables. For example, a startup called Tempo Automation is working with a consumer electronics company to develop a smart home device that can control lighting and temperature.

Other applications of PCB prototyping and development startups include industrial automation, automotive systems, and renewable energy systems. These startups are being used to develop innovative solutions for these industries, such as control systems and sensor systems.

PCB prototyping and development startups are also being used in research and development applications. These startups are being used to develop innovative solutions for research and development, such as prototyping and testing new materials and technologies.

Some notable PCB prototyping and development startups that are working on real-world applications include Fictiv, Xcentric, and Tempo Automation. These startups are working with a wide range of companies, from medical device companies to aerospace companies and consumer electronics companies.

By highlighting these real-world examples, we can see the significant impact that PCB prototyping and development startups are having on the electronics industry. These startups are revolutionizing the way that electronic products are designed, developed, and manufactured, and are enabling companies to bring innovative products to market quickly and efficiently.

The Future of PCB Prototyping and Development Startups

PCB prototyping and development startups are revolutionizing the electronics industry by providing rapid prototyping, reduced costs, and increased innovation. As the industry continues to evolve, it is likely that these startups will play an increasingly important role in shaping the future of electronics. In this article, we will provide insights into the future of PCB prototyping and development startups, including trends, opportunities, and challenges.

One of the most significant trends in the future of PCB prototyping and development startups is the increasing use of emerging technologies, such as artificial intelligence, 3D printing, and the Internet of Things (IoT). These technologies are enabling startups to develop innovative solutions that are faster, cheaper, and more efficient than traditional methods.

Another trend is the growing demand for PCB prototyping and development services in emerging markets, such as Asia and Latin America. As these markets continue to grow and develop, it is likely that PCB prototyping and development startups will play an increasingly important role in meeting the demand for electronic products.

Despite these trends and opportunities, PCB prototyping and development startups also face significant challenges, such as design complexity, material sourcing, and regulatory compliance. To overcome these challenges, startups must invest in advanced technologies, develop strategic partnerships, and prioritize quality and reliability.

Some notable PCB prototyping and development startups that are well-positioned for success in the future include Fictiv, Xcentric, and Tempo Automation. These startups are leveraging emerging technologies, developing strategic partnerships, and prioritizing quality and reliability to stay ahead of the competition.

As the electronics industry continues to evolve, it is likely that PCB prototyping and development startups will play an increasingly important role in shaping the future of electronics. By leveraging emerging technologies, developing strategic partnerships, and prioritizing quality and reliability, these startups can overcome the challenges of the industry and achieve success.

In conclusion, the future of PCB prototyping and development startups is bright, with significant trends, opportunities, and challenges on the horizon. By understanding these trends and opportunities, and by prioritizing quality and reliability, startups can position themselves for success in the future.