Breaking into the Competitive World of PCB Manufacturing

The world of printed circuit board (PCB) manufacturing is a complex and competitive landscape, with numerous established players and a constant influx of new entrants. For PCB startups, breaking into this market can be a daunting task. However, with the growing demand for custom PCBs and the increasing need for innovative solutions, there are opportunities for new businesses to carve out a niche and establish themselves as major players.

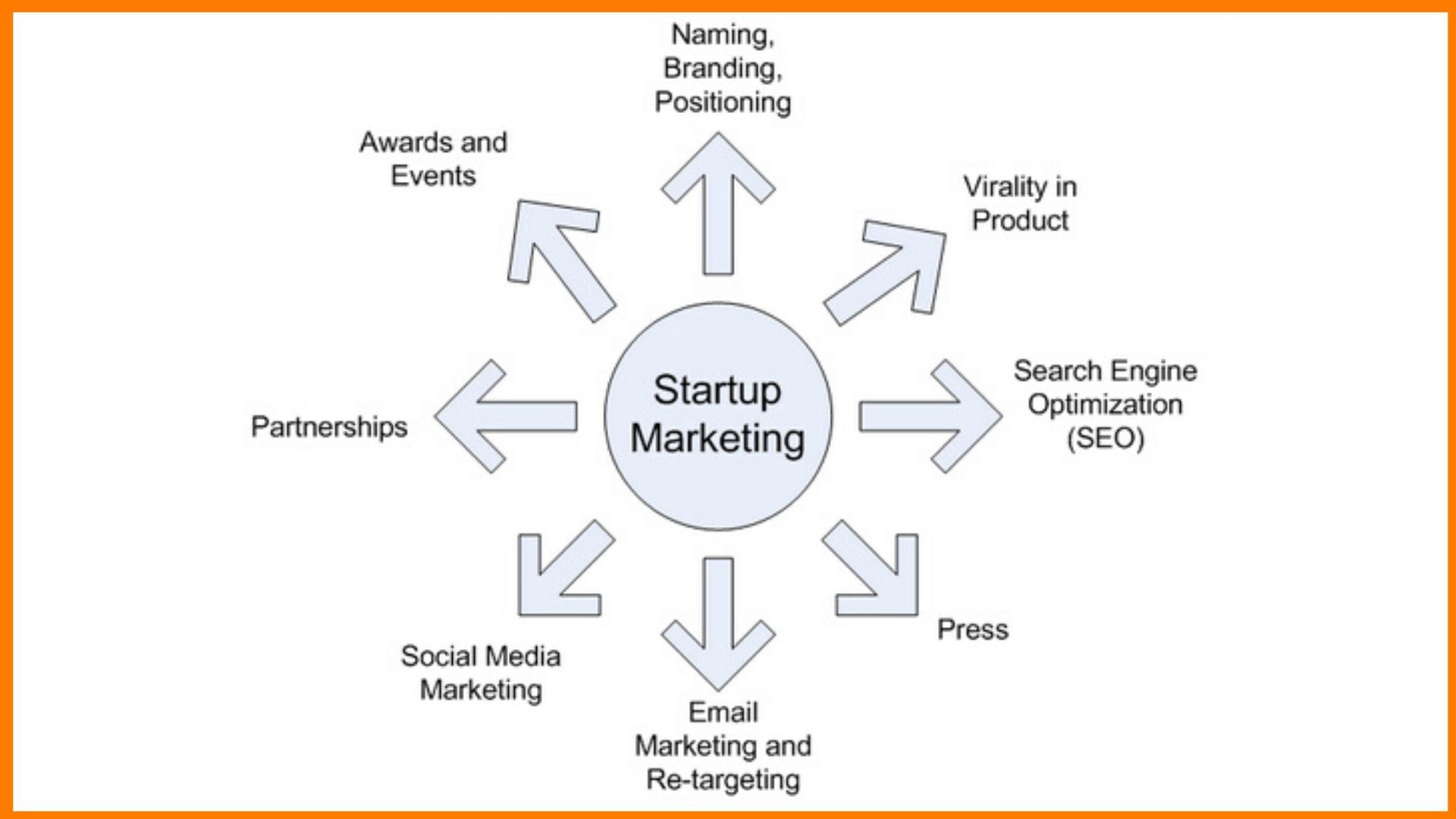

One of the primary challenges facing PCB startups is differentiating themselves in a crowded market. With so many established manufacturers offering similar products and services, it can be difficult for new businesses to stand out and attract customers. To overcome this challenge, PCB startups must focus on developing a unique value proposition (UVP) that sets them apart from the competition.

This UVP can take many forms, such as offering specialized design and manufacturing services, providing exceptional customer support, or developing innovative new products and technologies. By focusing on their strengths and differentiators, PCB startups can establish a strong reputation and attract a loyal customer base.

In addition to developing a UVP, PCB startups must also be aware of the latest trends and innovations in the industry. This includes advancements in materials, design tools, and manufacturing processes, as well as the growing demand for IoT and wearable technology. By staying ahead of the curve and incorporating these trends into their products and services, PCB startups can position themselves for long-term success.

Furthermore, PCB startups must also be mindful of the importance of intellectual property protection, regulatory compliance, and supply chain management. By taking steps to protect their intellectual property, comply with relevant regulations, and establish strong relationships with suppliers, PCB startups can minimize risks and ensure the long-term viability of their business.

Overall, breaking into the competitive world of PCB manufacturing requires a combination of innovative thinking, strategic planning, and a deep understanding of the industry. By focusing on their strengths, staying ahead of the curve, and minimizing risks, PCB startups can establish themselves as major players in the market and achieve long-term success.

How to Develop a Unique Value Proposition for Your PCB Startup

Developing a unique value proposition (UVP) is crucial for PCB startups to differentiate themselves in a crowded market. A UVP is a statement that clearly communicates the benefits and value that your business offers to customers. It’s what sets your business apart from the competition and makes it more attractive to potential customers.

To develop a UVP for your PCB startup, you need to identify your target market and understand their needs. Who are your ideal customers? What are their pain points, and how can your business solve their problems? Conducting market research and gathering feedback from potential customers can help you gain a deeper understanding of their needs and preferences.

Once you have a clear understanding of your target market, you can start developing your UVP. This involves identifying your business’s strengths and competitive advantages. What makes your business unique? What sets you apart from the competition? Is it your expertise in a particular area of PCB design and manufacturing? Is it your commitment to customer service and support?

Your UVP should be clear, concise, and compelling. It should communicate the benefits and value that your business offers to customers in a way that resonates with them. For example, “Our PCB startup offers custom PCB design and manufacturing services that meet the unique needs of our customers. We use state-of-the-art technology and have a team of experienced engineers who can help you bring your product to market quickly and efficiently.”

Having a strong UVP is essential for PCB startups to attract and retain customers. It helps to differentiate your business from the competition and establishes your brand as a trusted and reliable partner in the industry. By developing a UVP that clearly communicates the benefits and value of your business, you can establish a strong foundation for your PCB startup and set yourself up for long-term success.

In addition to developing a UVP, PCB startups should also focus on creating a strong brand identity. This includes developing a unique logo, website, and marketing materials that reflect your business’s values and mission. Consistency is key when it comes to branding, so make sure that all of your marketing materials and communications reflect your UVP and brand identity.

By developing a strong UVP and brand identity, PCB startups can establish themselves as major players in the industry and attract a loyal customer base. Remember to stay focused on your target market and continually evaluate and refine your UVP to ensure that it remains relevant and effective.

Key Considerations for PCB Startup Founders

Launching a successful PCB startup requires careful consideration of several key factors. As a founder, it’s essential to understand the importance of intellectual property protection, regulatory compliance, and supply chain management in the PCB industry.

Intellectual property protection is critical for PCB startups, as it helps to safeguard their designs, trade secrets, and other proprietary information. This can include filing patents, trademarks, and copyrights, as well as implementing non-disclosure agreements (NDAs) and other confidentiality measures. By protecting their intellectual property, PCB startups can prevent competitors from copying their designs and maintain a competitive advantage in the market.

Regulatory compliance is another essential consideration for PCB startups. The PCB industry is subject to various regulations and standards, including those related to environmental sustainability, safety, and quality. PCB startups must ensure that their products and manufacturing processes comply with these regulations, which can include obtaining certifications such as ISO 9001 and RoHS.

Supply chain management is also crucial for PCB startups, as it can impact the quality, cost, and delivery time of their products. PCB startups must carefully select and manage their suppliers, ensuring that they provide high-quality components and materials that meet their specifications. This can include implementing a supplier qualification program, conducting regular audits, and establishing clear communication channels.

In addition to these key considerations, PCB startups must also be aware of the importance of quality management and control. This includes implementing a quality management system (QMS) that ensures the consistent production of high-quality PCBs, as well as conducting regular testing and inspection to detect any defects or issues.

Furthermore, PCB startups must also consider the importance of cybersecurity and data protection. As the use of connected devices and IoT technology continues to grow, PCB startups must ensure that their products and manufacturing processes are secure and protected against cyber threats. This can include implementing robust cybersecurity measures, such as encryption and firewalls, as well as conducting regular security audits and risk assessments.

By carefully considering these key factors, PCB startups can establish a strong foundation for their business and ensure long-term success in the competitive PCB industry.

It’s also important for PCB startups to stay up-to-date with the latest industry trends and developments, including advancements in materials, design tools, and manufacturing processes. By leveraging these developments, PCB startups can stay ahead of the competition and provide innovative solutions to their customers.

In conclusion, launching a successful PCB startup requires careful consideration of several key factors, including intellectual property protection, regulatory compliance, supply chain management, quality management, and cybersecurity. By understanding the importance of these factors and implementing effective strategies, PCB startups can establish a strong foundation for their business and achieve long-term success in the competitive PCB industry.

PCB Design and Manufacturing: Best Practices for Startups

When it comes to PCB design and manufacturing, startups need to ensure that they are following best practices to produce high-quality boards that meet their customers’ needs. In this section, we will discuss some of the key considerations for PCB startups, including design for manufacturability, material selection, and working with contract manufacturers.

Design for manufacturability (DFM) is a critical consideration for PCB startups. This involves designing the PCB with manufacturing in mind, taking into account factors such as component placement, routing, and testing. By designing for manufacturability, startups can reduce the risk of errors and defects during the manufacturing process, which can save time and money in the long run.

Material selection is another important consideration for PCB startups. The type of material used for the PCB can affect its performance, durability, and cost. Startups should consider factors such as the operating temperature, frequency, and power requirements of the board when selecting materials. For example, if the board will be used in a high-temperature environment, a material with high thermal stability may be required.

Working with contract manufacturers is a common practice for PCB startups. Contract manufacturers can provide startups with access to specialized equipment and expertise, which can help to improve the quality and efficiency of the manufacturing process. However, startups need to carefully select and manage their contract manufacturers to ensure that they meet their quality and delivery requirements.

Some of the key benefits of working with contract manufacturers include reduced capital expenditures, improved quality, and increased flexibility. However, startups also need to be aware of the potential risks, such as loss of control over the manufacturing process and potential quality issues.

To mitigate these risks, startups should establish clear communication channels with their contract manufacturers, define clear quality and delivery requirements, and conduct regular audits and inspections. By following these best practices, startups can ensure that their PCBs are manufactured to high standards and meet their customers’ needs.

In addition to these considerations, PCB startups should also be aware of the latest trends and innovations in PCB technology. This includes advancements in materials, design tools, and manufacturing processes, which can help to improve the quality, efficiency, and cost-effectiveness of the manufacturing process.

By staying up-to-date with the latest developments in PCB technology and following best practices for design and manufacturing, startups can produce high-quality PCBs that meet their customers’ needs and stay competitive in the market.

Some of the latest trends in PCB technology include the use of advanced materials such as flexible and rigid-flex PCBs, the adoption of automation and robotics in the manufacturing process, and the use of artificial intelligence and machine learning to improve quality and efficiency.

By leveraging these trends and innovations, PCB startups can improve their competitiveness and stay ahead of the curve in the rapidly evolving PCB industry.

Case Study: Successful PCB Startups and Their Strategies

There are several successful PCB startups that have made a name for themselves in the industry. In this section, we will highlight the stories of a few of these startups, including their business models, marketing strategies, and product development approaches.

One example of a successful PCB startup is Tempo Automation, a company that specializes in rapid PCB prototyping and production. Tempo Automation was founded in 2015 and has since become one of the leading PCB manufacturers in the United States. The company’s success can be attributed to its innovative approach to PCB manufacturing, which includes the use of automation and robotics to improve efficiency and reduce costs.

Another example of a successful PCB startup is MacroFab, a company that offers a range of PCB manufacturing services, including prototyping, production, and assembly. MacroFab was founded in 2013 and has since become one of the leading PCB manufacturers in North America. The company’s success can be attributed to its focus on providing high-quality PCBs at competitive prices, as well as its commitment to customer service and support.

Both Tempo Automation and MacroFab have been successful in the PCB industry due to their innovative approaches to manufacturing and their commitment to customer service and support. These companies have demonstrated that it is possible to succeed in the PCB industry with the right business model, marketing strategy, and product development approach.

Other successful PCB startups include companies such as SparkFun, Adafruit, and Seeed Studio. These companies have all been successful in the PCB industry due to their innovative approaches to product development and their commitment to customer service and support.

SparkFun, for example, is a company that specializes in the development of open-source electronics and PCBs. The company was founded in 2003 and has since become one of the leading providers of open-source electronics and PCBs in the world. SparkFun’s success can be attributed to its innovative approach to product development, which includes the use of open-source hardware and software to improve collaboration and innovation.

Adafruit is another example of a successful PCB startup. The company was founded in 2005 and has since become one of the leading providers of DIY electronics and PCBs in the world. Adafruit’s success can be attributed to its innovative approach to product development, which includes the use of open-source hardware and software to improve collaboration and innovation.

Seeed Studio is a company that specializes in the development of open-source electronics and PCBs. The company was founded in 2008 and has since become one of the leading providers of open-source electronics and PCBs in the world. Seeed Studio’s success can be attributed to its innovative approach to product development, which includes the use of open-source hardware and software to improve collaboration and innovation.

These companies have all been successful in the PCB industry due to their innovative approaches to product development and their commitment to customer service and support. They have demonstrated that it is possible to succeed in the PCB industry with the right business model, marketing strategy, and product development approach.

Overcoming Common Challenges Faced by PCB Startups

PCB startups face a range of challenges, from funding and talent acquisition to competition and regulatory compliance. In this section, we will discuss some of the most common challenges faced by PCB startups and provide advice on how to overcome them.

One of the biggest challenges faced by PCB startups is funding. Starting a PCB business can be expensive, and many startups struggle to secure the funding they need to get off the ground. To overcome this challenge, PCB startups can consider alternative funding options, such as crowdfunding or angel investors.

Talent acquisition is another challenge faced by PCB startups. The PCB industry is highly specialized, and it can be difficult to find qualified employees with the right skills and experience. To overcome this challenge, PCB startups can consider partnering with universities or technical schools to access a pool of talented graduates.

Competition is also a major challenge faced by PCB startups. The PCB industry is highly competitive, and startups must differentiate themselves in order to stand out. To overcome this challenge, PCB startups can focus on developing a unique value proposition (UVP) that sets them apart from the competition.

Regulatory compliance is another challenge faced by PCB startups. The PCB industry is subject to a range of regulations, from environmental regulations to safety standards. To overcome this challenge, PCB startups can work with regulatory experts to ensure that they are compliant with all relevant regulations.

In addition to these challenges, PCB startups must also contend with the rapidly evolving nature of the PCB industry. New technologies and innovations are constantly emerging, and startups must stay ahead of the curve in order to remain competitive. To overcome this challenge, PCB startups can focus on staying up-to-date with the latest developments in the industry and investing in research and development.

Finally, PCB startups must also contend with the challenge of building a strong team. The PCB industry is highly specialized, and startups must attract and retain top talent in order to succeed. To overcome this challenge, PCB startups can focus on creating a positive company culture and offering competitive salaries and benefits.

By understanding the common challenges faced by PCB startups and developing strategies to overcome them, entrepreneurs can increase their chances of success in the PCB industry.

It’s also important for PCB startups to stay flexible and adapt to changing market conditions. This can involve pivoting their business model or adjusting their product offerings in response to changes in the market.

Additionally, PCB startups can benefit from seeking out mentorship and guidance from experienced professionals in the industry. This can involve working with a business incubator or accelerator, or seeking out advice from a seasoned entrepreneur.

By taking a proactive and adaptable approach to overcoming the challenges faced by PCB startups, entrepreneurs can set themselves up for success in the PCB industry.

Staying Ahead of the Curve: Trends and Innovations in PCB Technology

The printed circuit board (PCB) industry is constantly evolving, with new technologies and innovations emerging on a regular basis. To stay competitive, PCB startups must stay ahead of the curve and leverage these developments to improve their products and services.

One of the most significant trends in PCB technology is the increasing use of advanced materials. These materials, such as high-temperature laminates and low-loss dielectrics, offer improved performance and reliability compared to traditional materials. PCB startups can benefit from using these materials to develop high-performance PCBs that meet the demands of modern electronics.

Another trend in PCB technology is the adoption of automation and robotics in the manufacturing process. This can help to improve efficiency, reduce costs, and increase quality. PCB startups can benefit from investing in automation and robotics to streamline their manufacturing process and stay competitive.

In addition to these trends, there are also several innovations in PCB design and manufacturing that PCB startups can leverage to stay ahead of the curve. For example, the use of 3D printing and additive manufacturing can help to improve the complexity and density of PCBs, while also reducing costs and lead times.

PCB startups can also benefit from the use of advanced design tools and software. These tools can help to improve the design and simulation of PCBs, reducing the risk of errors and improving overall performance.

Furthermore, the use of artificial intelligence (AI) and machine learning (ML) is becoming increasingly prevalent in the PCB industry. These technologies can help to improve the design, manufacturing, and testing of PCBs, reducing costs and improving overall efficiency.

PCB startups can also benefit from the use of Internet of Things (IoT) technologies. These technologies can help to improve the connectivity and functionality of PCBs, enabling the development of smart and connected devices.

In order to stay ahead of the curve and leverage these trends and innovations, PCB startups must be willing to invest in research and development. This can involve partnering with universities and research institutions, as well as investing in internal R&D programs.

Additionally, PCB startups must also be willing to adopt new technologies and innovations quickly. This can involve staying up-to-date with the latest industry trends and developments, as well as being willing to take calculated risks to stay ahead of the competition.

By staying ahead of the curve and leveraging the latest trends and innovations in PCB technology, PCB startups can improve their products and services, reduce costs, and increase efficiency. This can help to drive growth and success in the competitive PCB industry.

Building a Strong Team: Hiring and Retaining Top Talent in the PCB Industry

Building a strong team is crucial for the success of any business, and PCB startups are no exception. In order to compete in the competitive PCB industry, startups need to attract and retain top talent in the field.

One of the most important things to consider when building a team for your PCB startup is the skills and experience of your employees. PCB design and manufacturing requires a high level of technical expertise, so it’s essential to hire employees with the right qualifications and experience.

In addition to technical skills, it’s also important to consider the soft skills of your employees. PCB startups need employees who are able to work well in a team, communicate effectively, and adapt to changing circumstances.

Another key consideration when building a team for your PCB startup is company culture. A positive company culture can help to attract and retain top talent, as well as improve employee morale and productivity.

To build a strong team for your PCB startup, it’s essential to have a clear understanding of your business goals and objectives. This will help you to identify the skills and experience you need to achieve your goals, and to develop a recruitment strategy that targets the right candidates.

Once you have identified the skills and experience you need, you can start to develop a recruitment strategy that targets the right candidates. This may involve advertising job openings on industry websites and job boards, as well as reaching out to professional networks and associations.

In addition to recruitment, it’s also important to consider employee retention. This involves creating a positive work environment, offering competitive salaries and benefits, and providing opportunities for career development and advancement.

By building a strong team with the right skills and experience, and creating a positive company culture, PCB startups can improve their chances of success in the competitive PCB industry.

It’s also important to consider the role of innovation and collaboration in building a strong team. PCB startups need employees who are able to think creatively and work collaboratively to develop new and innovative solutions.

By fostering a culture of innovation and collaboration, PCB startups can encourage their employees to think outside the box and develop new and innovative solutions that meet the needs of their customers.

In conclusion, building a strong team is crucial for the success of any PCB startup. By identifying the skills and experience you need, developing a recruitment strategy that targets the right candidates, and creating a positive company culture, you can improve your chances of success in the competitive PCB industry.