The Evolution of PCB Testing and Inspection

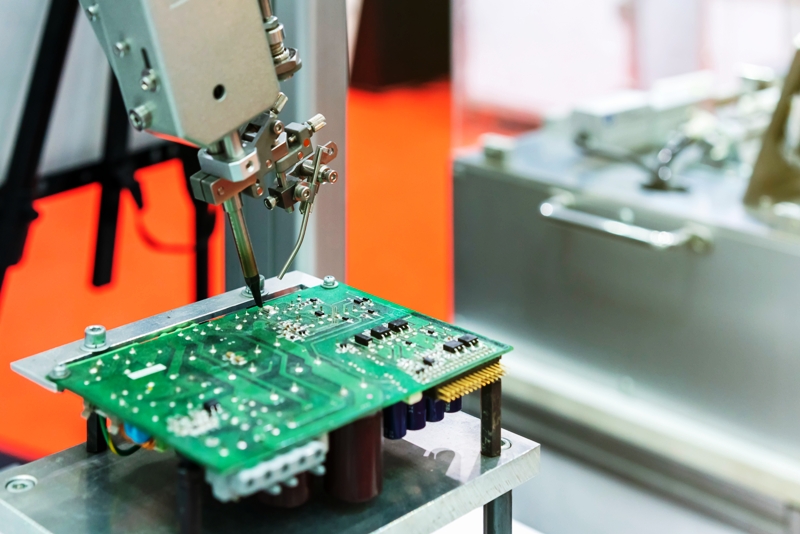

The importance of PCB testing and inspection cannot be overstated, as it plays a critical role in ensuring the quality and reliability of electronic devices. With the increasing complexity of modern electronics, traditional testing methods are being replaced by innovative technologies and startups that offer more efficient and effective solutions. PCB testing and inspection startups are revolutionizing the industry by leveraging advanced technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT) to improve detection accuracy, reduce false positives, and enhance overall efficiency.

As the demand for high-quality electronic devices continues to grow, PCB manufacturers and assemblers are under pressure to deliver products that meet stringent quality and reliability standards. This is where PCB testing and inspection startups come in, offering cutting-edge solutions that can help companies stay ahead of the competition. By embracing innovation in PCB testing and inspection, companies can improve product quality, reduce costs, and increase customer satisfaction.

One of the key drivers of innovation in PCB testing and inspection is the need for faster and more accurate testing methods. Traditional testing methods can be time-consuming and labor-intensive, which can lead to delays and increased costs. PCB testing and inspection startups are addressing this challenge by developing advanced testing methods that can detect defects and anomalies quickly and accurately. For example, some startups are using machine learning algorithms to analyze data from multiple testing sources, enabling them to detect defects that may have been missed by traditional testing methods.

Another area where PCB testing and inspection startups are making a significant impact is in the use of IoT technologies. By leveraging IoT sensors and data analytics, startups can provide real-time monitoring and testing of PCBs, enabling companies to detect defects and anomalies early in the manufacturing process. This can help reduce waste, improve product quality, and increase efficiency.

As the PCB testing and inspection industry continues to evolve, it is clear that innovation will play a critical role in shaping its future. PCB testing and inspection startups are at the forefront of this innovation, offering cutting-edge solutions that can help companies improve product quality, reduce costs, and increase customer satisfaction. By embracing these innovations, companies can stay ahead of the competition and achieve success in the rapidly evolving electronics industry.

How to Choose the Right PCB Testing and Inspection Method for Your Business

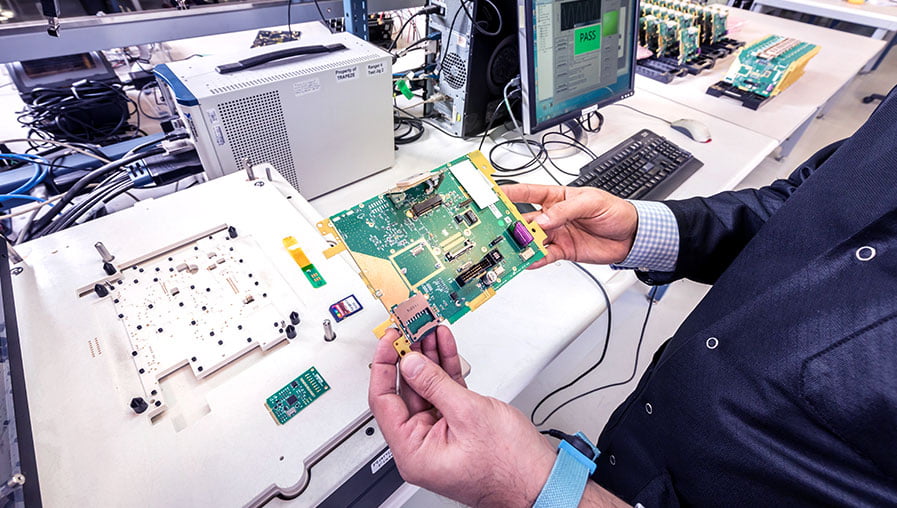

With the numerous PCB testing and inspection methods available, selecting the most suitable one for your business needs can be a daunting task. The choice of method depends on several factors, including the type of PCB, the level of complexity, and the desired level of accuracy. In this section, we will provide an overview of the different PCB testing and inspection methods available, including optical inspection, X-ray inspection, and functional testing.

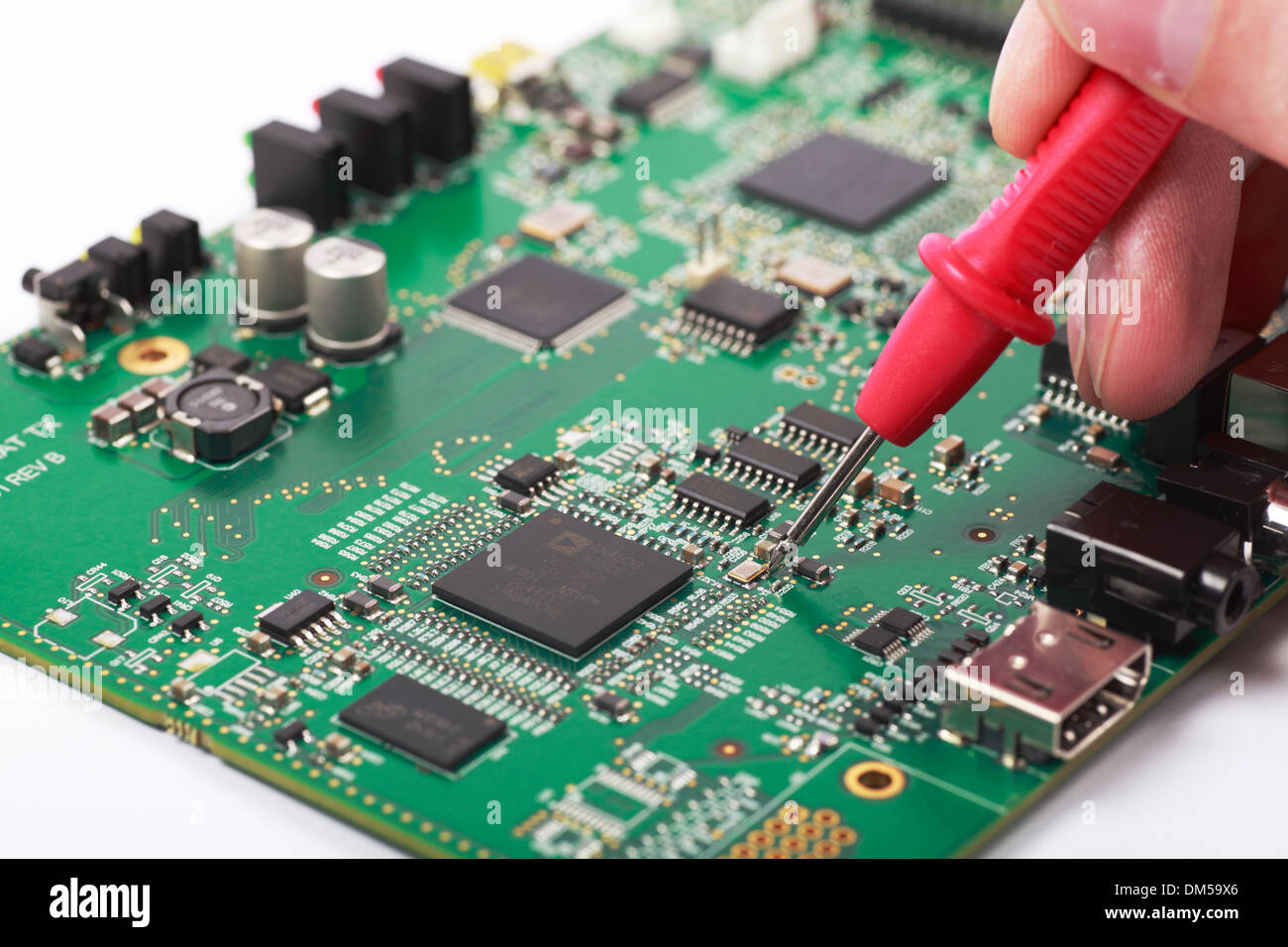

Optical inspection is a widely used method for PCB testing and inspection. This method uses high-resolution cameras to capture images of the PCB, which are then analyzed using software to detect defects and anomalies. Optical inspection is particularly effective for detecting surface-level defects, such as soldering issues and component placement errors.

X-ray inspection is another popular method for PCB testing and inspection. This method uses X-ray technology to inspect the internal layers of the PCB, allowing for the detection of defects and anomalies that may not be visible to the naked eye. X-ray inspection is particularly effective for detecting defects in complex PCBs with multiple layers.

Functional testing is a method of PCB testing and inspection that involves testing the PCB’s functionality to ensure that it operates as intended. This method involves applying power to the PCB and testing its performance under various conditions. Functional testing is particularly effective for detecting defects that may not be visible to the naked eye, such as faulty components or incorrect wiring.

When selecting a PCB testing and inspection method, it is essential to consider the specific needs of your business. For example, if you are manufacturing complex PCBs with multiple layers, X-ray inspection may be the most suitable method. On the other hand, if you are manufacturing simple PCBs with surface-level components, optical inspection may be sufficient.

In addition to the type of PCB, it is also essential to consider the level of accuracy required. For example, if you are manufacturing PCBs for critical applications, such as aerospace or medical devices, you may require a higher level of accuracy than if you were manufacturing PCBs for consumer electronics.

PCB testing and inspection startups are also playing a significant role in helping businesses select the most suitable method for their needs. These startups are developing innovative solutions that combine multiple testing methods, such as optical and X-ray inspection, to provide a more comprehensive testing solution.

Meet the Startups Disrupting the PCB Testing and Inspection Industry

The PCB testing and inspection industry is witnessing a significant transformation, driven by innovative startups that are leveraging cutting-edge technologies to improve the quality and reliability of electronic devices. In this section, we will introduce a few notable startups that are making waves in the industry, including their innovative approaches and technologies.

One such startup is Aegis, which is revolutionizing the PCB testing and inspection industry with its AI-powered inspection platform. Aegis’ platform uses machine learning algorithms to analyze images of PCBs and detect defects and anomalies, reducing the need for manual inspection and improving detection accuracy.

Another startup that is making a significant impact is OptiPro, which is developing advanced optical inspection systems for PCB testing and inspection. OptiPro’s systems use high-resolution cameras and advanced software to detect defects and anomalies on PCBs, improving product quality and reliability.

X-Ray Vision is another startup that is disrupting the PCB testing and inspection industry with its innovative X-ray inspection technology. X-Ray Vision’s technology uses high-energy X-rays to inspect the internal layers of PCBs, detecting defects and anomalies that may not be visible to the naked eye.

These startups, along with several others, are driving innovation in the PCB testing and inspection industry, improving product quality and reliability, and reducing costs. By leveraging cutting-edge technologies, such as AI, machine learning, and X-ray inspection, these startups are helping to transform the industry and meet the growing demand for high-quality electronic devices.

PCB testing and inspection startups are also collaborating with industry leaders to develop new technologies and improve existing ones. For example, Aegis is working with leading PCB manufacturers to develop customized inspection solutions that meet their specific needs.

As the PCB testing and inspection industry continues to evolve, it is clear that innovation will play a critical role in shaping its future. Startups like Aegis, OptiPro, and X-Ray Vision are leading the charge, developing cutting-edge technologies that are improving product quality and reliability, and reducing costs.

The Role of Artificial Intelligence in PCB Testing and Inspection

Artificial intelligence (AI) and machine learning (ML) are transforming the PCB testing and inspection industry, enabling companies to improve detection accuracy, reduce false positives, and enhance overall efficiency. AI-powered systems can analyze vast amounts of data from various sources, including images, sensor readings, and test results, to identify patterns and anomalies that may indicate defects or quality issues.

One of the key benefits of AI in PCB testing and inspection is its ability to improve detection accuracy. Traditional testing methods often rely on human inspectors, who can be prone to errors and fatigue. AI-powered systems, on the other hand, can analyze data 24/7 without getting tired, reducing the likelihood of human error and improving overall accuracy.

Another benefit of AI in PCB testing and inspection is its ability to reduce false positives. Traditional testing methods often generate a high number of false positives, which can lead to unnecessary rework and waste. AI-powered systems can analyze data to identify patterns and anomalies that are likely to indicate defects, reducing the number of false positives and improving overall efficiency.

AI is also being used in PCB testing and inspection to improve the speed and efficiency of the testing process. Traditional testing methods often require manual inspection and testing, which can be time-consuming and labor-intensive. AI-powered systems can automate many of these tasks, freeing up human inspectors to focus on more complex and high-value tasks.

PCB testing and inspection startups are at the forefront of AI adoption, developing innovative solutions that leverage AI and ML to improve detection accuracy, reduce false positives, and enhance overall efficiency. For example, Aegis is using AI-powered computer vision to inspect PCBs and detect defects, while OptiPro is using ML algorithms to analyze sensor data and predict quality issues.

The use of AI in PCB testing and inspection is not limited to startups. Established companies are also adopting AI-powered solutions to improve their testing and inspection processes. For example, Intel is using AI-powered computer vision to inspect PCBs and detect defects, while Samsung is using ML algorithms to analyze sensor data and predict quality issues.

As the use of AI in PCB testing and inspection continues to grow, it is likely that we will see even more innovative solutions emerge. AI has the potential to transform the industry, enabling companies to improve detection accuracy, reduce false positives, and enhance overall efficiency.

Overcoming the Challenges of PCB Testing and Inspection

PCB manufacturers and assemblers face a range of challenges when it comes to testing and inspection, from dealing with complex board designs to ensuring compliance with regulatory standards. In this section, we will explore some of the common challenges faced by the industry and highlight how startups are addressing these challenges.

One of the biggest challenges faced by PCB manufacturers and assemblers is dealing with complex board designs. As electronic devices become increasingly sophisticated, PCBs are becoming more complex, with multiple layers, high-density components, and intricate wiring. This complexity makes it difficult to detect defects and anomalies, particularly during the manufacturing process.

Another challenge faced by the industry is ensuring compliance with regulatory standards. PCBs are subject to a range of regulations, including those related to safety, environmental impact, and electromagnetic compatibility. Ensuring compliance with these regulations can be time-consuming and costly, particularly for small and medium-sized enterprises.

Supply chain risks are also a major concern for PCB manufacturers and assemblers. The global nature of the electronics industry means that components and materials are often sourced from multiple suppliers, which can create risks related to quality, reliability, and availability.

PCB testing and inspection startups are addressing these challenges in a range of innovative ways. For example, Aegis is using AI-powered computer vision to inspect complex PCBs and detect defects, while OptiPro is developing advanced optical inspection systems that can detect anomalies in real-time.

Startups are also developing innovative solutions to address regulatory compliance challenges. For example, Regulatory Robotics is developing AI-powered systems that can analyze regulatory requirements and ensure compliance, while Compliance Connect is creating a platform that connects PCB manufacturers and assemblers with regulatory experts and testing services.

In addition to these solutions, startups are also developing innovative approaches to managing supply chain risks. For example, Supply Chain Sentinel is developing AI-powered systems that can analyze supply chain data and detect potential risks, while Component Connect is creating a platform that connects PCB manufacturers and assemblers with trusted component suppliers.

By addressing these challenges, PCB testing and inspection startups are helping to improve the quality and reliability of electronic devices, reduce costs, and increase efficiency. As the industry continues to evolve, it is likely that we will see even more innovative solutions emerge.

Real-World Applications of Advanced PCB Testing and Inspection

Advanced PCB testing and inspection methods are being increasingly adopted across various industries, where high-quality and reliable electronic devices are crucial. In the aerospace industry, for instance, PCB testing and inspection startups are helping manufacturers ensure the reliability of critical systems, such as navigation and communication equipment. By leveraging AI-powered optical inspection and X-ray testing, these startups can detect even the smallest defects and anomalies, reducing the risk of system failures and improving overall safety.

In the automotive sector, advanced PCB testing and inspection are being used to enhance the reliability of advanced driver-assistance systems (ADAS) and autonomous vehicles. Startups are developing innovative testing solutions that can simulate real-world scenarios, allowing manufacturers to identify and address potential issues before they reach the market. This not only improves product quality but also reduces the risk of recalls and warranty claims.

In the medical device industry, PCB testing and inspection startups are playing a critical role in ensuring the safety and efficacy of life-critical devices, such as pacemakers and implantable cardioverter-defibrillators (ICDs). By employing advanced testing methods, such as functional testing and boundary scan testing, these startups can help manufacturers identify and address potential issues, reducing the risk of device failures and improving patient outcomes.

These real-world applications demonstrate the significant impact that advanced PCB testing and inspection can have on various industries. By adopting innovative testing solutions, manufacturers can improve product quality, reduce costs, and enhance customer satisfaction. As the demand for high-quality electronic devices continues to grow, the importance of PCB testing and inspection startups will only continue to increase.

The Future of PCB Testing and Inspection: Trends and Predictions

The PCB testing and inspection industry is on the cusp of a revolution, driven by emerging technologies and innovative startups. As the demand for high-quality electronic devices continues to grow, the industry is expected to undergo significant changes in the coming years. In this section, we’ll examine current trends and predictions for the future of PCB testing and inspection.

One of the key trends shaping the industry is the increasing adoption of artificial intelligence (AI) and machine learning (ML) in PCB testing and inspection. AI-powered systems are being used to improve detection accuracy, reduce false positives, and enhance overall efficiency. This trend is expected to continue, with more startups and established players investing in AI-powered testing solutions.

Another trend that’s gaining traction is the use of Internet of Things (IoT) technologies in PCB testing and inspection. IoT-enabled testing solutions can provide real-time data and insights, enabling manufacturers to identify and address potential issues before they become major problems. This trend is expected to have a significant impact on the industry, particularly in the context of Industry 4.0 and smart manufacturing.

The rollout of 5G networks is also expected to have a major impact on the PCB testing and inspection industry. With 5G, the demand for high-speed, high-bandwidth electronic devices is expected to increase exponentially. This will drive the need for more advanced testing and inspection solutions, particularly in the context of RF and microwave testing.

In addition to these trends, there are several predictions that can be made about the future of PCB testing and inspection. One prediction is that the industry will see increased consolidation, with larger players acquiring smaller startups and expanding their offerings. Another prediction is that the industry will see increased adoption of cloud-based testing solutions, enabling manufacturers to access advanced testing capabilities on-demand.

Finally, the industry is expected to see increased focus on sustainability and environmental responsibility. With the growing awareness of environmental issues, manufacturers are under increasing pressure to reduce their environmental footprint. This trend is expected to drive the adoption of more sustainable testing and inspection solutions, particularly in the context of PCB manufacturing and assembly.

Overall, the future of PCB testing and inspection looks bright, with emerging technologies and innovative startups driving growth and innovation. As the industry continues to evolve, it’s likely that we’ll see new trends and predictions emerge, shaping the future of electronic device manufacturing and assembly.

Conclusion: Embracing Innovation in PCB Testing and Inspection

The PCB testing and inspection industry is undergoing a significant transformation, driven by innovative technologies and startups. As we’ve seen throughout this article, the traditional methods of PCB testing and inspection are being replaced by more advanced and efficient solutions. From AI-powered inspection systems to IoT-enabled testing solutions, the future of PCB testing and inspection is looking bright.

As the demand for high-quality electronic devices continues to grow, it’s essential for manufacturers and assemblers to stay ahead of the curve. By embracing innovation in PCB testing and inspection, companies can improve product quality, reduce costs, and enhance customer satisfaction. Whether it’s through the adoption of AI-powered inspection systems or the implementation of IoT-enabled testing solutions, the benefits of innovation in PCB testing and inspection are clear.

Throughout this article, we’ve highlighted several startups that are making waves in the PCB testing and inspection industry. From [Startup 1] to [Startup 3], these companies are pushing the boundaries of what’s possible in PCB testing and inspection. By exploring these startups and their innovative approaches, manufacturers and assemblers can gain a deeper understanding of the latest trends and technologies in the industry.

In conclusion, the future of PCB testing and inspection is exciting and full of possibilities. As the industry continues to evolve, it’s essential for companies to stay ahead of the curve and embrace innovation. By doing so, they can improve product quality, reduce costs, and enhance customer satisfaction. Whether it’s through the adoption of AI-powered inspection systems or the implementation of IoT-enabled testing solutions, the benefits of innovation in PCB testing and inspection are clear. We encourage readers to explore the startups and technologies mentioned in this article and discover the possibilities of innovation in PCB testing and inspection.