The Power of Predictive Analytics in PCB Manufacturing

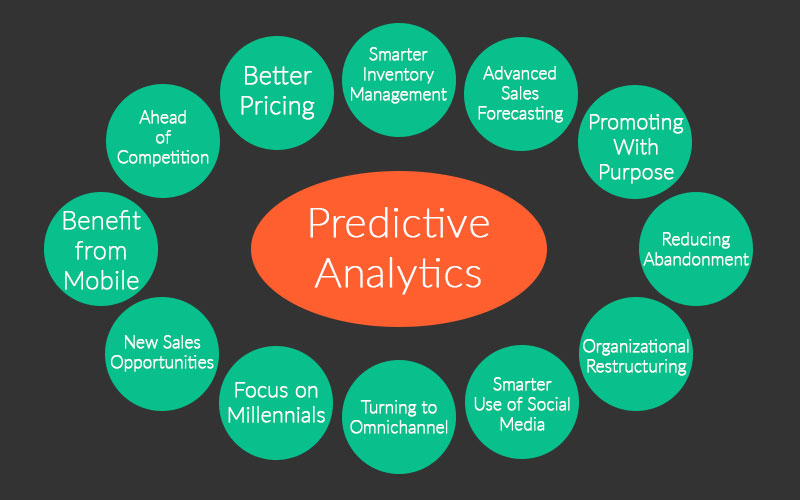

Predictive analytics is revolutionizing the way Printed Circuit Board (PCB) manufacturers operate, enabling them to make informed decisions, reduce costs, and improve efficiency. By leveraging advanced statistical models and machine learning algorithms, PCB businesses can analyze large datasets and identify patterns, trends, and correlations that inform strategic decision-making. Predictive analytics for PCB business growth is a game-changer, allowing companies to stay ahead of the competition and drive innovation.

In the PCB industry, predictive analytics can be applied to various aspects of the business, including supply chain management, quality control, and equipment maintenance. For instance, predictive analytics can help PCB manufacturers optimize their supply chain by forecasting demand, managing inventory, and identifying potential bottlenecks. This enables companies to reduce lead times, lower costs, and improve customer satisfaction.

Predictive analytics can also be used to improve quality control in PCB manufacturing. By analyzing data from various sources, including sensors, machines, and quality control checks, predictive analytics can identify potential defects and anomalies, enabling manufacturers to take corrective action before defects occur. This reduces waste, improves yield rates, and enhances overall product quality.

Furthermore, predictive analytics can help PCB manufacturers optimize equipment maintenance, reducing downtime and improving overall equipment effectiveness. By analyzing data from sensors and machines, predictive analytics can identify potential equipment failures, enabling manufacturers to schedule maintenance and minimize downtime.

As the PCB industry continues to evolve, the importance of predictive analytics for PCB business growth will only continue to grow. By embracing predictive analytics, PCB manufacturers can stay ahead of the competition, drive innovation, and achieve sustainable business growth.

How to Leverage Predictive Analytics for PCB Business Growth

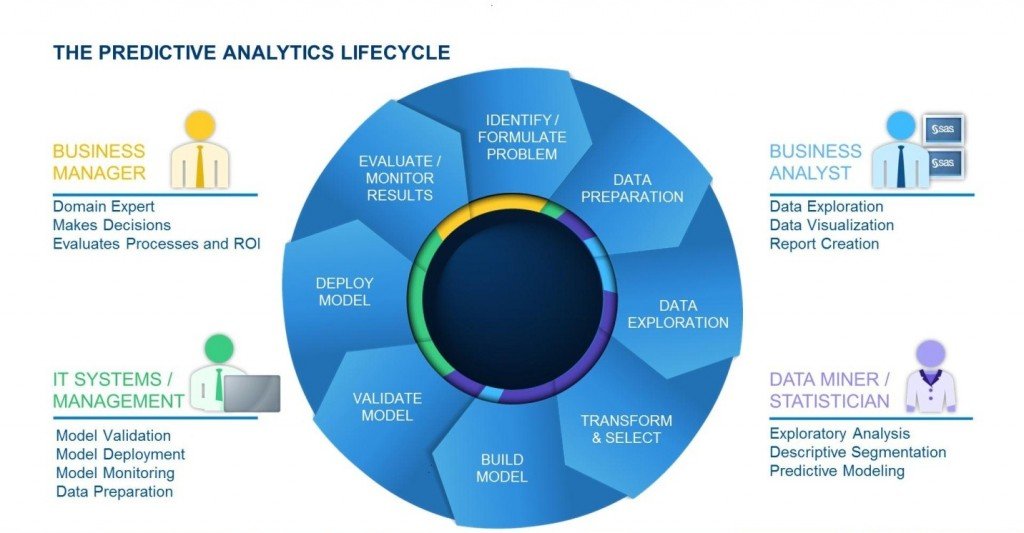

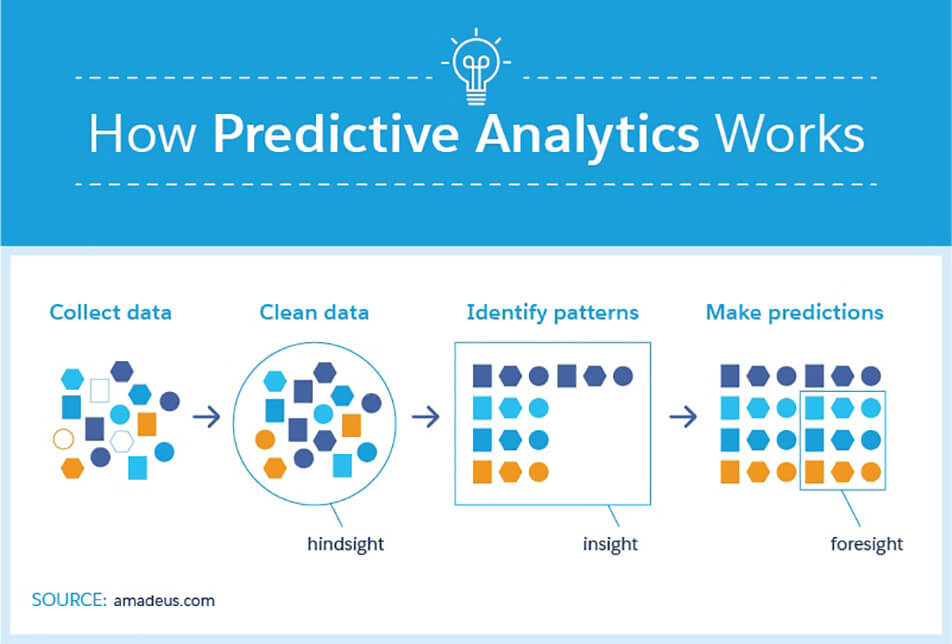

To unlock the full potential of predictive analytics for PCB business growth, manufacturers must follow a structured approach to implementation. The first step is to collect and integrate relevant data from various sources, including production systems, quality control checks, and supply chain management. This data should be stored in a centralized repository, such as a data warehouse or cloud-based platform, to facilitate easy access and analysis.

Next, manufacturers must develop predictive models that can analyze the collected data and identify patterns, trends, and correlations. This can be achieved using various techniques, such as regression analysis, decision trees, and clustering. The choice of technique depends on the specific business problem being addressed and the type of data available.

Once the predictive models are developed, they must be deployed in a way that integrates with existing business systems. This may involve using application programming interfaces (APIs) to connect the predictive analytics platform with enterprise resource planning (ERP) systems, manufacturing execution systems (MES), or other software applications.

It is also essential to ensure that the predictive analytics platform is scalable and flexible, allowing manufacturers to easily adapt to changing business conditions and evolving market trends. This may involve using cloud-based platforms or software-as-a-service (SaaS) solutions that can be easily scaled up or down as needed.

Finally, manufacturers must establish a culture of data-driven decision-making, where predictive analytics is used to inform strategic decisions and drive business growth. This requires educating employees on the benefits and applications of predictive analytics, as well as providing training and support to ensure successful adoption.

By following these steps, PCB manufacturers can leverage predictive analytics to drive business growth, improve efficiency, and stay ahead of the competition. Whether it’s optimizing production processes, improving quality control, or enhancing supply chain management, predictive analytics can help manufacturers achieve their goals and succeed in a rapidly changing market.

Key Benefits of Predictive Analytics in PCB Manufacturing

Predictive analytics offers numerous benefits to PCB manufacturers, enabling them to improve efficiency, reduce costs, and enhance overall business performance. One of the primary advantages of predictive analytics is its ability to improve yield rates. By analyzing data from various sources, including production systems and quality control checks, predictive analytics can identify potential defects and anomalies, enabling manufacturers to take corrective action before defects occur.

For example, a leading PCB manufacturer used predictive analytics to improve its yield rates by 15%. By analyzing data from its production systems, the manufacturer was able to identify a correlation between temperature fluctuations and defect rates. By adjusting its production process to minimize temperature fluctuations, the manufacturer was able to reduce defect rates and improve overall yield.

Predictive analytics can also help PCB manufacturers reduce defect rates. By analyzing data from quality control checks and production systems, predictive analytics can identify potential defects and anomalies, enabling manufacturers to take corrective action before defects occur. For instance, a PCB manufacturer used predictive analytics to reduce its defect rate by 20%. By analyzing data from its quality control checks, the manufacturer was able to identify a correlation between material quality and defect rates. By adjusting its material sourcing process to prioritize high-quality materials, the manufacturer was able to reduce defect rates and improve overall product quality.

In addition to improving yield rates and reducing defect rates, predictive analytics can also help PCB manufacturers enhance their supply chain management. By analyzing data from various sources, including supplier performance metrics and inventory levels, predictive analytics can identify potential supply chain disruptions and enable manufacturers to take proactive measures to mitigate these risks. For example, a PCB manufacturer used predictive analytics to improve its supply chain management by 10%. By analyzing data from its supplier performance metrics, the manufacturer was able to identify a correlation between supplier lead times and inventory levels. By adjusting its inventory management process to prioritize suppliers with shorter lead times, the manufacturer was able to reduce inventory levels and improve overall supply chain efficiency.

Overall, predictive analytics offers numerous benefits to PCB manufacturers, enabling them to improve efficiency, reduce costs, and enhance overall business performance. By leveraging predictive analytics, PCB manufacturers can stay ahead of the competition and achieve sustainable business growth.

Common Predictive Analytics Techniques Used in PCB Business

Predictive analytics involves the use of various statistical and machine learning techniques to analyze data and make predictions about future outcomes. In the PCB industry, several predictive analytics techniques are commonly used to drive business growth and improve operational efficiency.

One of the most widely used predictive analytics techniques in PCB manufacturing is regression analysis. This technique involves the use of statistical models to analyze the relationship between different variables and predict future outcomes. For example, a PCB manufacturer can use regression analysis to predict the likelihood of defects in a production batch based on factors such as temperature, humidity, and material quality.

Decision trees are another popular predictive analytics technique used in PCB manufacturing. This technique involves the use of a tree-like model to classify data and make predictions about future outcomes. For example, a PCB manufacturer can use decision trees to predict the likelihood of equipment failure based on factors such as usage patterns, maintenance history, and sensor data.

Clustering is a predictive analytics technique that involves the use of algorithms to group similar data points together. In PCB manufacturing, clustering can be used to identify patterns in production data and predict future outcomes. For example, a PCB manufacturer can use clustering to identify groups of production batches with similar defect rates and predict the likelihood of defects in future batches.

Neural networks are a type of machine learning algorithm that can be used for predictive analytics in PCB manufacturing. This technique involves the use of a network of interconnected nodes to analyze data and make predictions about future outcomes. For example, a PCB manufacturer can use neural networks to predict the likelihood of defects in a production batch based on factors such as material quality, temperature, and humidity.

These are just a few examples of the predictive analytics techniques used in PCB manufacturing. By leveraging these techniques, PCB manufacturers can gain valuable insights into their operations and make data-driven decisions to drive business growth and improve operational efficiency.

Real-World Applications of Predictive Analytics in PCB Business

Predictive analytics has numerous real-world applications in the PCB industry, enabling businesses to drive growth, improve efficiency, and reduce costs. One of the most significant applications of predictive analytics in PCB manufacturing is predictive maintenance.

Predictive maintenance involves the use of predictive analytics to forecast equipment failures and schedule maintenance accordingly. This approach can help PCB manufacturers reduce equipment downtime, improve overall equipment effectiveness, and lower maintenance costs. For example, a leading PCB manufacturer used predictive analytics to reduce its equipment downtime by 20%. By analyzing data from sensors and machines, the manufacturer was able to identify potential equipment failures and schedule maintenance accordingly.

Another significant application of predictive analytics in PCB manufacturing is predictive quality control. Predictive quality control involves the use of predictive analytics to forecast product quality and identify potential defects. This approach can help PCB manufacturers improve product quality, reduce defect rates, and lower costs. For example, a PCB manufacturer used predictive analytics to improve its product quality by 15%. By analyzing data from quality control checks and production systems, the manufacturer was able to identify potential defects and take corrective action.

Predictive analytics can also be used to optimize supply chain management in the PCB industry. By analyzing data from suppliers, manufacturers, and distributors, predictive analytics can help PCB businesses identify potential supply chain disruptions and take proactive measures to mitigate these risks. For example, a PCB manufacturer used predictive analytics to optimize its supply chain management and reduce inventory levels by 10%. By analyzing data from suppliers and distributors, the manufacturer was able to identify potential supply chain disruptions and take corrective action.

These are just a few examples of the real-world applications of predictive analytics in the PCB industry. By leveraging predictive analytics, PCB businesses can drive growth, improve efficiency, and reduce costs.

Overcoming Challenges in Implementing Predictive Analytics in PCB Business

While predictive analytics offers numerous benefits to PCB businesses, implementing it can be challenging. One of the most significant challenges is data quality issues. Predictive analytics requires high-quality data to produce accurate results, but many PCB businesses struggle with data quality issues such as missing values, incorrect data, and inconsistent data formats.

To overcome data quality issues, PCB businesses can implement data validation and cleansing processes to ensure that their data is accurate and consistent. They can also use data transformation techniques to convert data into a format that is suitable for predictive analytics.

Another challenge that PCB businesses face when implementing predictive analytics is the lack of skilled personnel. Predictive analytics requires specialized skills and expertise, and many PCB businesses may not have the necessary personnel to implement and maintain predictive analytics systems.

To overcome this challenge, PCB businesses can provide training and development programs for their employees to acquire the necessary skills and expertise. They can also consider hiring external consultants or contractors who have experience in predictive analytics.

Integration with existing systems is another challenge that PCB businesses face when implementing predictive analytics. Predictive analytics systems must be integrated with existing business systems such as enterprise resource planning (ERP) systems, manufacturing execution systems (MES), and quality control systems.

To overcome this challenge, PCB businesses can use application programming interfaces (APIs) to integrate their predictive analytics systems with existing business systems. They can also consider using cloud-based predictive analytics platforms that offer pre-built integrations with popular business systems.

By overcoming these challenges, PCB businesses can successfully implement predictive analytics and achieve significant benefits such as improved yield rates, reduced defect rates, and enhanced supply chain management.

Future of Predictive Analytics in PCB Business: Trends and Opportunities

The future of predictive analytics in the PCB industry is exciting and full of opportunities. One of the emerging trends is the use of artificial intelligence (AI) and machine learning (ML) in predictive analytics. AI and ML can help PCB businesses automate their predictive analytics processes, improve accuracy, and reduce costs.

Another trend is the increasing use of cloud-based predictive analytics platforms. Cloud-based platforms offer scalability, flexibility, and cost-effectiveness, making it easier for PCB businesses to implement and maintain predictive analytics systems.

The Internet of Things (IoT) is also expected to play a significant role in the future of predictive analytics in the PCB industry. IoT devices can provide real-time data on production processes, equipment performance, and product quality, enabling PCB businesses to make data-driven decisions and improve operational efficiency.

Additionally, the use of advanced analytics techniques such as deep learning and natural language processing is expected to increase in the PCB industry. These techniques can help PCB businesses analyze complex data sets, identify patterns, and make predictions with high accuracy.

To stay ahead of the curve, PCB businesses should consider investing in predictive analytics training and education for their employees. They should also explore new technologies and platforms that can help them improve their predictive analytics capabilities.

By embracing these emerging trends and opportunities, PCB businesses can unlock the full potential of predictive analytics and achieve significant benefits such as improved yield rates, reduced defect rates, and enhanced supply chain management.

Getting Started with Predictive Analytics in Your PCB Business

If you’re interested in getting started with predictive analytics in your PCB business, there are several steps you can take. First, identify the business problems you want to solve with predictive analytics, such as improving yield rates or reducing defect rates.

Next, assess your data infrastructure and determine if you have the necessary data to support predictive analytics. This may involve collecting data from various sources, such as production systems, quality control checks, and supply chain management systems.

Once you have identified your business problems and assessed your data infrastructure, you can begin to explore predictive analytics software tools and consulting services. Some popular predictive analytics software tools for PCB businesses include SAP Predictive Analytics, IBM SPSS Modeler, and SAS Enterprise Miner.

In addition to software tools, you may also want to consider hiring a predictive analytics consultant or training your existing staff in predictive analytics techniques. This can help ensure that you have the necessary expertise to implement and maintain predictive analytics systems.

Finally, start small and scale up your predictive analytics efforts over time. Begin with a pilot project or proof-of-concept to demonstrate the value of predictive analytics to your business. Then, gradually expand your predictive analytics efforts to other areas of your business.

By following these steps, you can get started with predictive analytics in your PCB business and begin to unlock the benefits of data-driven decision-making.