Streamlining Operations with Robotics and Automation

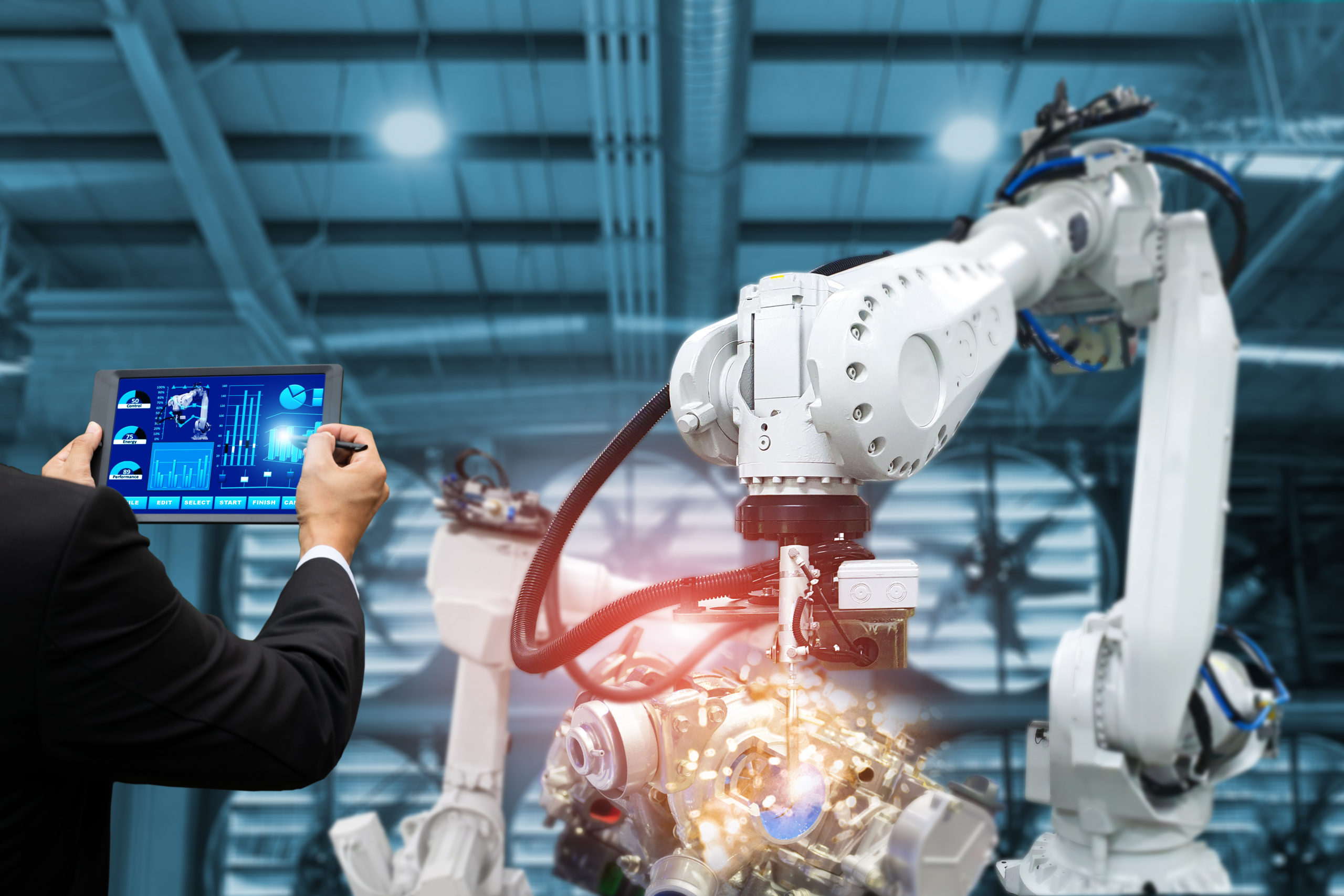

The manufacturing and logistics industries are undergoing a significant transformation with the integration of robotics and automation. This technological shift is driven by the need for increased efficiency, reduced costs, and improved accuracy. SaaS startups are at the forefront of this revolution, leveraging robotics and automation to provide innovative solutions that transform the way businesses operate.

Robotics and automation have been shown to increase productivity by up to 30% and reduce labor costs by up to 20%. Additionally, these technologies improve accuracy and quality, reducing the likelihood of errors and defects. By automating repetitive and mundane tasks, businesses can free up resources and focus on higher-value activities that drive growth and innovation.

SaaS startups are well-positioned to capitalize on this trend, offering cloud-based solutions that are scalable, flexible, and cost-effective. These solutions can be easily integrated with existing systems, allowing businesses to quickly realize the benefits of robotics and automation. Furthermore, SaaS startups can provide ongoing support and maintenance, ensuring that businesses can maximize the potential of these technologies.

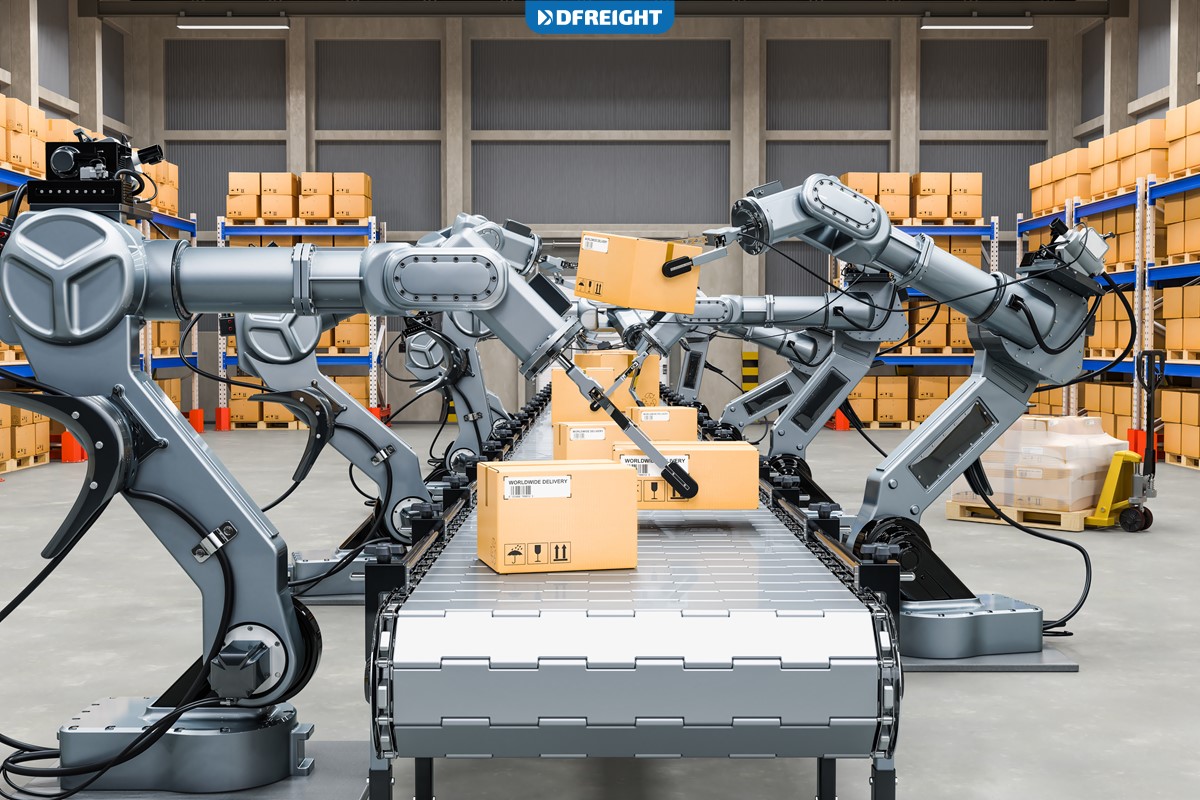

For example, SaaS startups like Fetch Robotics and Locus Robotics are providing autonomous mobile robots that can navigate warehouses and manufacturing facilities with ease. These robots can be programmed to perform a variety of tasks, from picking and packing to inventory management and shipping. By automating these tasks, businesses can improve efficiency, reduce labor costs, and enhance customer satisfaction.

Another area where SaaS startups are making a significant impact is in the development of robotic process automation (RPA) solutions. RPA involves the use of software robots to automate repetitive and mundane tasks, freeing up human resources to focus on higher-value activities. SaaS startups like Automation Anywhere and Blue Prism are providing RPA solutions that can be easily integrated with existing systems, allowing businesses to quickly realize the benefits of automation.

In conclusion, the integration of robotics and automation is transforming the manufacturing and logistics industries. SaaS startups are at the forefront of this revolution, providing innovative solutions that improve efficiency, reduce costs, and enhance customer satisfaction. By leveraging these technologies, businesses can drive growth, innovation, and competitiveness in an increasingly complex and dynamic market.

How to Choose the Right Robotics Solution for Your Business

Selecting the right robotics solution for manufacturing and logistics operations can be a daunting task, especially with the numerous options available in the market. However, by considering a few key factors, businesses can make an informed decision that meets their specific needs and drives growth.

Scalability is a critical factor to consider when choosing a robotics solution. Businesses should opt for solutions that can adapt to changing demands and volumes, ensuring that they can scale up or down as needed. This is particularly important for SaaS startups, which often experience rapid growth and need solutions that can keep pace.

Integration is another key consideration. Robotics solutions should be able to seamlessly integrate with existing systems and infrastructure, minimizing disruption and ensuring a smooth rollout. This includes integration with enterprise resource planning (ERP) systems, manufacturing execution systems (MES), and other software applications.

Customization is also essential, as businesses have unique needs and requirements. Robotics solutions should be able to be tailored to meet specific business needs, whether it’s customizing workflows, integrating with specific equipment, or developing bespoke software applications.

Assessing specific business needs is also crucial when choosing a robotics solution. Businesses should conduct a thorough analysis of their operations, identifying areas where robotics can add value and drive efficiency. This includes evaluating workflows, identifying bottlenecks, and determining the types of tasks that can be automated.

When evaluating robotics solutions, businesses should also consider the total cost of ownership (TCO). This includes not only the initial investment but also ongoing costs such as maintenance, support, and upgrades. SaaS startups often offer flexible pricing models that can help businesses manage costs and ensure a strong return on investment (ROI).

Finally, businesses should consider the level of support and maintenance offered by the robotics solution provider. This includes training and support for employees, as well as ongoing maintenance and upgrades to ensure that the solution continues to meet business needs.

By considering these factors, businesses can choose the right robotics solution for their manufacturing and logistics operations, driving growth, efficiency, and innovation. SaaS startups that offer flexible, scalable, and customizable solutions can help businesses unlock the full potential of robotics and automation.

Real-World Applications of Robotics in Manufacturing and Logistics

Robotics and automation are no longer just concepts, but are being widely adopted in manufacturing and logistics operations. From assembly lines to warehouses, robots are being used to improve efficiency, reduce costs, and enhance customer satisfaction. In this section, we’ll explore some real-world examples of robotics in action.

KUKA’s robotic arms are a prime example of robotics in manufacturing. These robots are designed to perform tasks such as welding, assembly, and inspection, and are widely used in the automotive and aerospace industries. For instance, KUKA’s robotic arms are used by BMW to assemble car bodies, reducing production time and improving quality.

Fetch Robotics’ autonomous mobile robots are another example of robotics in logistics. These robots are designed to navigate warehouses and distribution centers, picking and packing orders with ease. For instance, Fetch Robotics’ robots are used by DHL to automate their warehouse operations, reducing labor costs and improving efficiency.

Other examples of robotics in manufacturing and logistics include the use of robotic process automation (RPA) to automate repetitive tasks, and the use of machine learning algorithms to optimize production processes. For instance, Siemens uses RPA to automate tasks such as data entry and document processing, freeing up employees to focus on higher-value tasks.

The impact of these solutions on productivity, safety, and customer satisfaction is significant. According to a study by the International Federation of Robotics, the use of robots in manufacturing can improve productivity by up to 30% and reduce labor costs by up to 20%. Additionally, robots can improve safety by reducing the risk of accidents and injuries, and can enhance customer satisfaction by improving product quality and reducing lead times.

SaaS startups are also playing a key role in the adoption of robotics in manufacturing and logistics. By providing cloud-based solutions that are scalable, flexible, and cost-effective, SaaS startups are making it easier for businesses to adopt robotics and automation. For instance, SaaS startups like Robotics Process Automation (RPA) and Automation Anywhere are providing cloud-based RPA solutions that can be easily integrated with existing systems.

In conclusion, robotics and automation are transforming the manufacturing and logistics industries. From assembly lines to warehouses, robots are being used to improve efficiency, reduce costs, and enhance customer satisfaction. By exploring real-world examples of robotics in action, businesses can gain a better understanding of the benefits and challenges of adopting robotics and automation.

The Role of Artificial Intelligence in Robotics for Manufacturing and Logistics

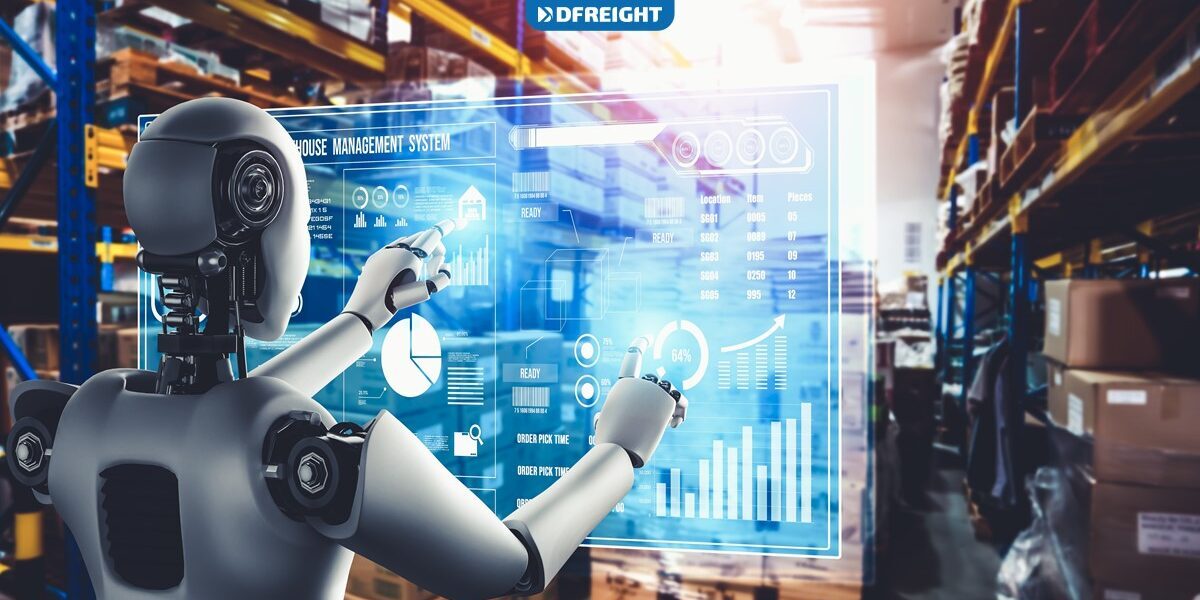

Artificial intelligence (AI) is playing an increasingly important role in robotics for manufacturing and logistics. By integrating AI with robotics, businesses can create more efficient, adaptable, and autonomous systems that can optimize processes and improve productivity.

AI-powered robots can learn from data and adapt to new situations, allowing them to perform tasks that were previously impossible for robots. For example, AI-powered robots can be used for quality control, where they can learn to recognize defects and anomalies in products. This can improve product quality and reduce waste.

AI can also be used to optimize robotics processes, such as path planning and motion control. By analyzing data from sensors and cameras, AI-powered robots can optimize their movements and actions to improve efficiency and reduce energy consumption.

Another area where AI is being used in robotics is in predictive maintenance. By analyzing data from sensors and machines, AI-powered robots can predict when maintenance is required, reducing downtime and improving overall equipment effectiveness.

SaaS startups are also leveraging AI in robotics to provide more advanced and innovative solutions. For example, SaaS startups like Robotiq and Precise Automation are providing AI-powered robotics solutions that can be easily integrated with existing systems.

The benefits of AI-powered robots in manufacturing and logistics are numerous. They can improve productivity, reduce costs, and enhance customer satisfaction. According to a study by the International Federation of Robotics, the use of AI-powered robots in manufacturing can improve productivity by up to 20% and reduce costs by up to 15%.

However, there are also challenges to implementing AI-powered robots in manufacturing and logistics. One of the main challenges is the need for high-quality data to train AI algorithms. This can be a challenge for businesses that do not have access to large amounts of data.

Another challenge is the need for skilled workers to implement and maintain AI-powered robots. This can be a challenge for businesses that do not have access to skilled workers with expertise in AI and robotics.

Despite these challenges, the potential benefits of AI-powered robots in manufacturing and logistics make them an attractive solution for businesses looking to improve efficiency and productivity. By leveraging AI and robotics, businesses can create more efficient, adaptable, and autonomous systems that can optimize processes and improve productivity.

Overcoming Implementation Challenges: Tips for a Smooth Robotics Integration

Implementing robotics solutions in manufacturing and logistics can be a complex process, and businesses may face several challenges along the way. However, with careful planning and execution, these challenges can be overcome, and the benefits of robotics can be fully realized.

One of the most significant challenges businesses face when implementing robotics is employee training. Robotics solutions often require specialized skills and knowledge, and employees may need training to effectively operate and maintain the systems. To overcome this challenge, businesses should provide comprehensive training programs that cover the operation, maintenance, and troubleshooting of the robotics systems.

System integration is another challenge businesses may face when implementing robotics. Robotics solutions often need to be integrated with existing systems, such as enterprise resource planning (ERP) systems, manufacturing execution systems (MES), and other software applications. To overcome this challenge, businesses should work with experienced system integrators who can ensure seamless integration and minimize downtime.

Data management is also a critical challenge businesses face when implementing robotics. Robotics solutions generate vast amounts of data, which must be collected, analyzed, and acted upon to optimize processes and improve productivity. To overcome this challenge, businesses should invest in data analytics tools and platforms that can help them make sense of the data and make informed decisions.

Change management is another challenge businesses may face when implementing robotics. The introduction of robotics solutions can be a significant change for employees, and businesses must manage this change effectively to minimize disruption and ensure a smooth transition. To overcome this challenge, businesses should develop a comprehensive change management plan that includes communication, training, and support for employees.

Finally, businesses should also consider the cybersecurity implications of implementing robotics solutions. Robotics systems can be vulnerable to cyber threats, and businesses must take steps to protect themselves and their data. To overcome this challenge, businesses should invest in robust cybersecurity measures, such as firewalls, intrusion detection systems, and encryption technologies.

By overcoming these challenges, businesses can ensure a smooth and successful robotics integration that drives growth, efficiency, and innovation. SaaS startups can play a critical role in helping businesses overcome these challenges by providing cloud-based solutions that are scalable, flexible, and secure.

In addition to these tips, businesses should also consider the following best practices when implementing robotics solutions:

- Develop a comprehensive implementation plan that includes timelines, milestones, and resource allocation.

- Establish clear communication channels and protocols to ensure effective collaboration between teams.

- Provide ongoing training and support to employees to ensure they are equipped to operate and maintain the robotics systems.

- Monitor and evaluate the performance of the robotics systems regularly to identify areas for improvement.

By following these tips and best practices, businesses can overcome the challenges of implementing robotics solutions and unlock the full potential of these technologies to drive growth, efficiency, and innovation.

Measuring the Success of Robotics in Manufacturing and Logistics

Measuring the success of robotics in manufacturing and logistics is crucial to understanding the impact of these technologies on business operations. By tracking key performance indicators (KPIs), businesses can evaluate the effectiveness of their robotics solutions and make data-driven decisions to optimize their operations.

Productivity is a critical KPI to track when measuring the success of robotics in manufacturing and logistics. By automating repetitive and mundane tasks, robotics solutions can significantly improve productivity, reducing labor costs and increasing efficiency. For example, a study by the International Federation of Robotics found that the use of robots in manufacturing can improve productivity by up to 30%.

Quality is another important KPI to track when measuring the success of robotics in manufacturing and logistics. Robotics solutions can improve product quality by reducing the risk of human error and increasing precision. For example, a study by the National Institute of Standards and Technology found that the use of robots in manufacturing can improve product quality by up to 25%.

Return on investment (ROI) is also a key KPI to track when measuring the success of robotics in manufacturing and logistics. By reducing labor costs and improving productivity, robotics solutions can provide a significant return on investment for businesses. For example, a study by the Robotics Industries Association found that the average ROI for robotics solutions in manufacturing is around 18 months.

In addition to these KPIs, businesses should also track other metrics such as robot uptime, maintenance costs, and employee training time. By tracking these metrics, businesses can gain a comprehensive understanding of the impact of robotics on their operations and make data-driven decisions to optimize their use of these technologies.

SaaS startups can play a critical role in helping businesses measure the success of their robotics solutions. By providing cloud-based solutions that are scalable, flexible, and secure, SaaS startups can help businesses track KPIs and make data-driven decisions to optimize their operations.

For example, SaaS startups like Robotiq and Precise Automation provide cloud-based solutions that allow businesses to track KPIs such as productivity, quality, and ROI. These solutions can also provide real-time data and analytics, enabling businesses to make data-driven decisions to optimize their operations.

In conclusion, measuring the success of robotics in manufacturing and logistics is crucial to understanding the impact of these technologies on business operations. By tracking KPIs such as productivity, quality, and ROI, businesses can evaluate the effectiveness of their robotics solutions and make data-driven decisions to optimize their operations. SaaS startups can play a critical role in helping businesses measure the success of their robotics solutions and unlock the full potential of these technologies.

Future-Proofing Your Business with Robotics and Automation

As the manufacturing and logistics industries continue to evolve, it’s essential for businesses to stay ahead of the curve by embracing emerging trends and technologies. The integration of robotics and automation, powered by SaaS startups, is transforming the landscape of these industries. To future-proof their operations, companies must be willing to adapt and invest in innovation.

One of the most significant emerging trends in robotics is the use of collaborative robots (cobots). Cobots are designed to work alongside human workers, enhancing productivity and efficiency while improving workplace safety. SaaS startups are developing cobot solutions that can be easily integrated into existing manufacturing and logistics systems, making it easier for businesses to adopt this technology.

Another area of innovation is the use of artificial intelligence (AI) and machine learning (ML) in robotics. AI-powered robots can analyze data, learn from experience, and optimize processes in real-time, leading to further efficiency gains and improved decision-making. SaaS startups are leveraging AI and ML to develop predictive maintenance solutions, quality control systems, and supply chain optimization tools.

The Internet of Things (IoT) is also playing a crucial role in the future of robotics for manufacturing and logistics. IoT sensors and devices can provide real-time data on equipment performance, inventory levels, and supply chain activity, enabling businesses to make data-driven decisions and optimize their operations. SaaS startups are developing IoT-based solutions that can be easily integrated with existing robotics systems, providing a unified view of operations and enabling real-time decision-making.

To future-proof their businesses, companies must be willing to invest in innovation and stay adaptable in the face of changing market conditions. This includes embracing emerging trends and technologies, such as cobots, AI, ML, and IoT, and partnering with SaaS startups that can provide cutting-edge solutions. By doing so, businesses can stay ahead of the competition, drive growth and efficiency, and remain competitive in an increasingly complex and dynamic market.

As the manufacturing and logistics industries continue to evolve, it’s clear that robotics and automation will play a critical role in shaping their future. By embracing innovation and partnering with SaaS startups, businesses can unlock the full potential of robotics and automation, driving growth, efficiency, and innovation in the years to come.

Conclusion: Unlocking the Full Potential of Robotics in Manufacturing and Logistics

The integration of robotics and automation in manufacturing and logistics has the potential to revolutionize these industries, driving growth, efficiency, and innovation. As SaaS startups continue to develop cutting-edge solutions, businesses must be willing to adapt and invest in these technologies to remain competitive.

By leveraging robotics and automation, companies can streamline operations, reduce costs, and improve accuracy. The benefits of these technologies are clear, from increased productivity and efficiency to enhanced customer satisfaction and improved workplace safety.

As the industry continues to evolve, it’s essential for businesses to stay ahead of the curve by embracing emerging trends and technologies. This includes the integration of artificial intelligence, machine learning, and the Internet of Things (IoT) in robotics, as well as the development of collaborative robots (cobots) and autonomous mobile robots.

To unlock the full potential of robotics in manufacturing and logistics, businesses must be willing to invest in innovation and partner with SaaS startups that can provide cutting-edge solutions. By doing so, companies can drive growth, efficiency, and innovation, and remain competitive in an increasingly complex and dynamic market.

The future of robotics in manufacturing and logistics is exciting and full of possibilities. As SaaS startups continue to push the boundaries of what is possible with these technologies, businesses must be willing to adapt and evolve to remain ahead of the curve. By embracing robotics and automation, companies can unlock new levels of efficiency, productivity, and innovation, and drive growth and success in the years to come.

In conclusion, the integration of robotics and automation in manufacturing and logistics has the potential to transform these industries, driving growth, efficiency, and innovation. By partnering with SaaS startups and embracing emerging trends and technologies, businesses can unlock the full potential of robotics and remain competitive in an increasingly complex and dynamic market.