What is SaaS and How Does it Apply to PCB?

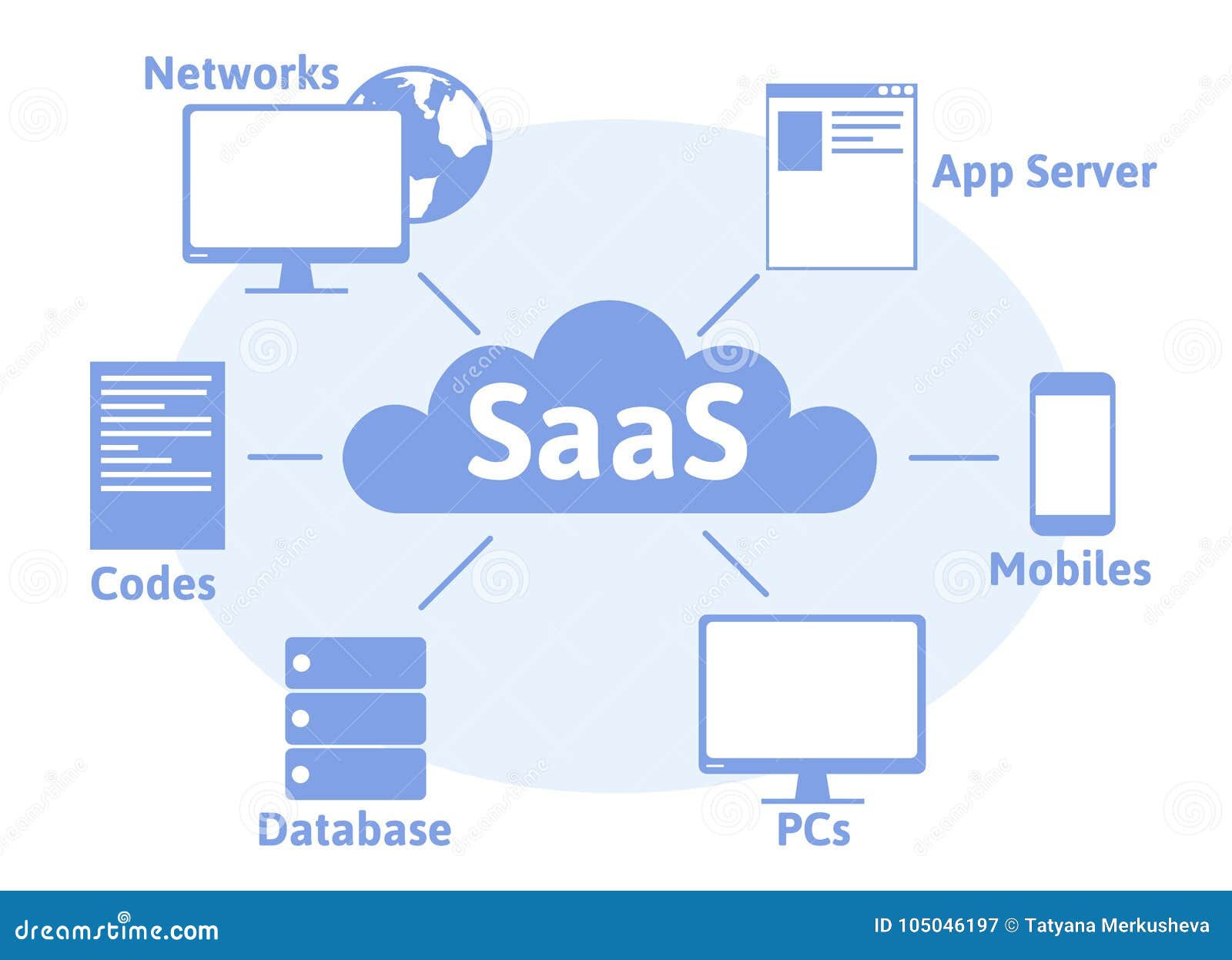

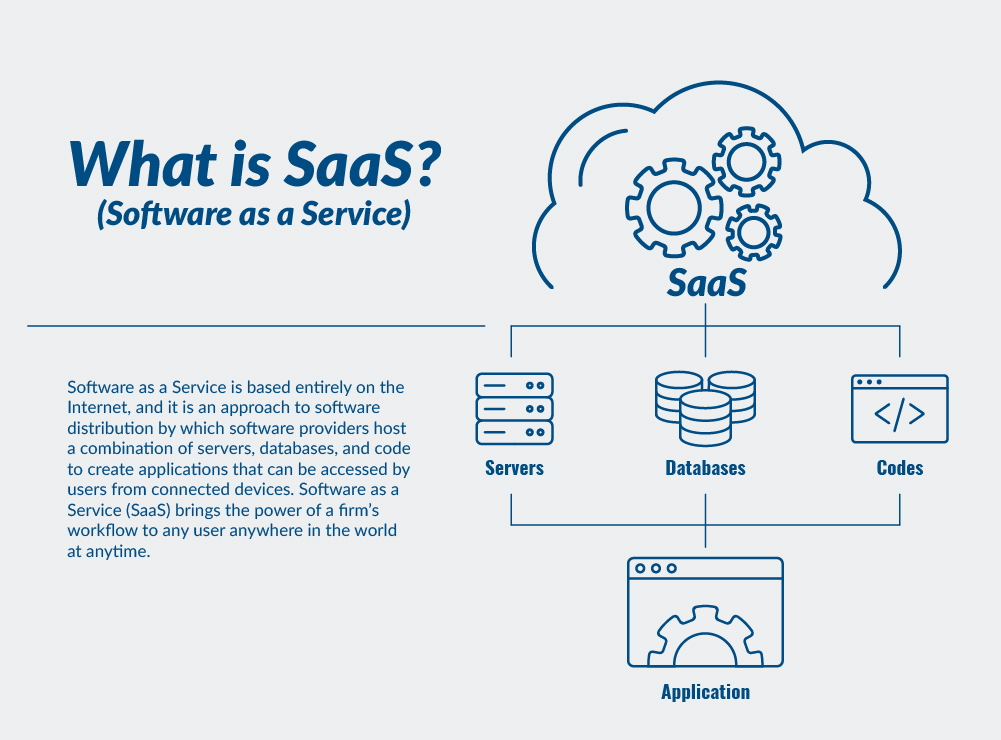

The concept of Software as a Service (SaaS) has revolutionized the way companies design, manufacture, and distribute Printed Circuit Boards (PCBs). SaaS business models for PCB have emerged as a game-changer in the industry, offering a cloud-based solution that enables companies to streamline their operations, reduce costs, and improve collaboration. In this article, we will explore the concept of SaaS and its relevance to the PCB industry, highlighting the benefits and advantages of adopting SaaS business models for PCB.

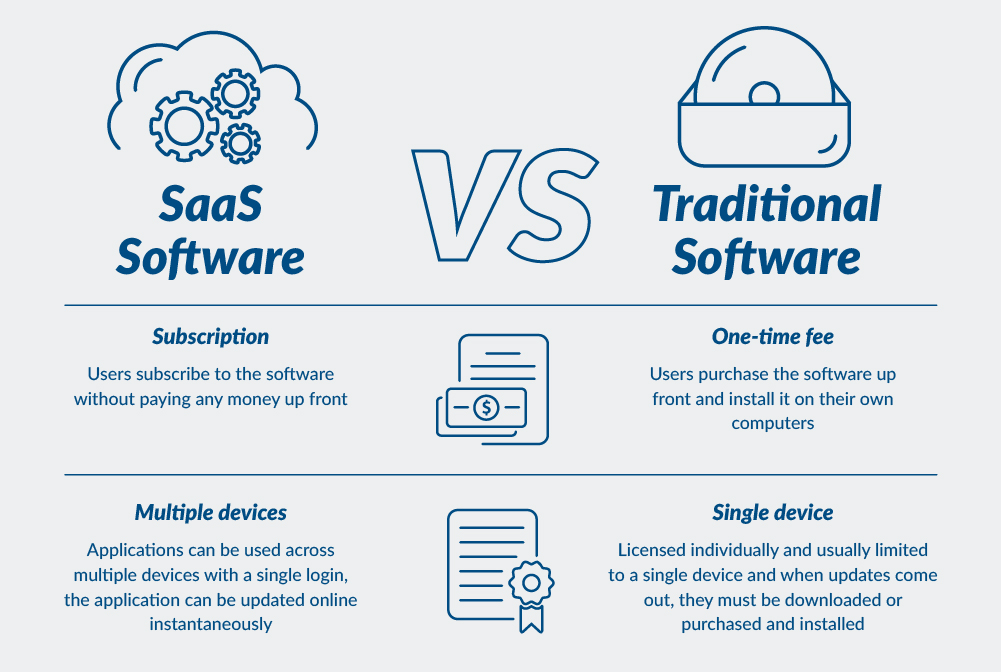

Traditionally, PCB design and manufacturing have been complex and time-consuming processes, requiring significant investments in software, hardware, and personnel. However, with the advent of SaaS, companies can now access a range of cloud-based tools and services that enable them to design, simulate, and manufacture PCBs more efficiently and effectively. SaaS solutions for PCB provide a scalable and flexible platform that can be easily integrated with existing systems, allowing companies to respond quickly to changing market demands.

The PCB industry is rapidly evolving, with increasing demands for smaller, faster, and more complex electronic devices. To stay competitive, companies must adopt innovative solutions that enable them to design and manufacture PCBs quickly and efficiently. SaaS business models for PCB offer a range of benefits, including reduced costs, improved collaboration, and increased scalability. By adopting SaaS solutions, companies can reduce their capital expenditures on software and hardware, while also improving their ability to collaborate with partners and suppliers.

In addition to the benefits, SaaS business models for PCB also offer a range of innovative features and functionalities that can improve the design and manufacturing process. For example, cloud-based design and simulation tools enable companies to test and validate their designs more quickly and accurately, reducing the risk of errors and defects. Similarly, manufacturing execution systems (MES) and supply chain management (SCM) solutions enable companies to streamline their production processes, improving efficiency and reducing costs.

As the PCB industry continues to evolve, it is clear that SaaS business models will play an increasingly important role in shaping the future of the industry. By adopting SaaS solutions, companies can improve their competitiveness, reduce costs, and improve collaboration. Whether you are a small startup or a large enterprise, SaaS business models for PCB offer a range of benefits and advantages that can help you achieve your goals.

The Benefits of SaaS Business Models for PCB

Software as a Service (SaaS) business models for Printed Circuit Boards (PCBs) offer a range of benefits that can improve the design, manufacturing, and distribution of PCBs. One of the primary advantages of SaaS business models for PCB is reduced costs. By providing a cloud-based solution, SaaS eliminates the need for companies to invest in expensive software and hardware, reducing capital expenditures and operational costs.

Another benefit of SaaS business models for PCB is increased scalability. SaaS solutions can be easily scaled up or down to meet the changing needs of companies, allowing them to quickly respond to changes in demand. This scalability also enables companies to reduce their environmental footprint, as they no longer need to maintain and upgrade their own hardware and software.

Improved collaboration is another key benefit of SaaS business models for PCB. SaaS solutions enable companies to collaborate more effectively with their partners and suppliers, improving communication and reducing errors. This collaboration also enables companies to respond more quickly to changes in the market, improving their competitiveness.

Several companies have successfully implemented SaaS solutions for PCB design and manufacturing, achieving significant benefits and improvements. For example, a leading electronics manufacturer was able to reduce its design and manufacturing costs by 30% by implementing a SaaS solution for PCB design. Another company, a small startup, was able to improve its collaboration with partners and suppliers by 25% by using a SaaS solution for PCB manufacturing.

These examples demonstrate the potential of SaaS business models for PCB to improve the design, manufacturing, and distribution of PCBs. By reducing costs, increasing scalability, and improving collaboration, SaaS solutions can help companies achieve their goals and stay competitive in the market.

In addition to these benefits, SaaS business models for PCB also offer a range of innovative features and functionalities that can improve the design and manufacturing process. For example, cloud-based design and simulation tools enable companies to test and validate their designs more quickly and accurately, reducing the risk of errors and defects.

Overall, SaaS business models for PCB offer a range of benefits and advantages that can improve the design, manufacturing, and distribution of PCBs. By reducing costs, increasing scalability, and improving collaboration, SaaS solutions can help companies achieve their goals and stay competitive in the market.

How to Choose the Right SaaS Solution for Your PCB Needs

When selecting a Software as a Service (SaaS) solution for Printed Circuit Board (PCB) design and manufacturing, it is essential to consider several key factors to ensure that the chosen solution meets the company’s specific needs. In this article, we will discuss the key factors to consider when selecting a SaaS solution for PCB, including functionality, compatibility, and customer support.

Functionality is a critical factor to consider when selecting a SaaS solution for PCB. The solution should provide the necessary tools and features to support the company’s PCB design and manufacturing processes. This may include design and simulation tools, manufacturing execution systems, and supply chain management. It is essential to evaluate the solution’s functionality to ensure that it meets the company’s specific needs.

Compatibility is another key factor to consider when selecting a SaaS solution for PCB. The solution should be compatible with the company’s existing systems and software, including computer-aided design (CAD) software, enterprise resource planning (ERP) systems, and product lifecycle management (PLM) systems. Ensuring compatibility can help to streamline the implementation process and reduce the risk of integration issues.

Customer support is also an essential factor to consider when selecting a SaaS solution for PCB. The solution provider should offer reliable and responsive customer support to ensure that any issues or concerns are addressed promptly. This may include online support resources, phone support, and on-site support. Evaluating the solution provider’s customer support can help to ensure that the company receives the necessary support to implement and use the solution effectively.

In addition to these factors, it is also essential to consider the solution provider’s experience and expertise in the PCB industry. The solution provider should have a deep understanding of the PCB design and manufacturing process and be able to provide guidance and support to ensure that the company gets the most out of the solution.

By considering these key factors, companies can select a SaaS solution that meets their specific needs and helps to improve their PCB design and manufacturing processes. Whether you are a small startup or a large enterprise, selecting the right SaaS solution can help to improve your competitiveness and reduce costs.

When evaluating SaaS solutions for PCB, it is also essential to consider the solution’s scalability and flexibility. The solution should be able to grow and adapt with the company’s changing needs, providing a scalable and flexible platform for PCB design and manufacturing.

In conclusion, selecting the right SaaS solution for PCB requires careful consideration of several key factors, including functionality, compatibility, customer support, and the solution provider’s experience and expertise. By evaluating these factors, companies can select a solution that meets their specific needs and helps to improve their PCB design and manufacturing processes.

Key Features of SaaS Solutions for PCB

Software as a Service (SaaS) solutions for Printed Circuit Board (PCB) design and manufacturing offer a range of essential features that can improve the design and manufacturing process. In this article, we will discuss the key features of SaaS solutions for PCB, including design and simulation tools, manufacturing execution systems, and supply chain management.

Design and simulation tools are a critical feature of SaaS solutions for PCB. These tools enable companies to design and simulate PCBs in a virtual environment, reducing the risk of errors and defects. Design and simulation tools can also help companies to optimize their PCB designs, improving performance and reducing costs.

Manufacturing execution systems (MES) are another key feature of SaaS solutions for PCB. MES provides real-time visibility into the manufacturing process, enabling companies to track and manage their PCB production in real-time. MES can also help companies to improve their manufacturing efficiency, reducing lead times and improving quality.

Supply chain management (SCM) is also an essential feature of SaaS solutions for PCB. SCM enables companies to manage their supply chain in real-time, tracking and managing their inventory, shipping, and logistics. SCM can also help companies to improve their supply chain efficiency, reducing costs and improving delivery times.

In addition to these features, SaaS solutions for PCB also offer a range of other benefits, including collaboration tools, data analytics, and security features. Collaboration tools enable companies to work together more effectively, improving communication and reducing errors. Data analytics provide companies with real-time insights into their PCB design and manufacturing process, enabling them to make data-driven decisions. Security features ensure that companies’ data is protected and secure, reducing the risk of data breaches and cyber attacks.

By providing these essential features, SaaS solutions for PCB can help companies to improve their design and manufacturing process, reducing costs, improving quality, and increasing efficiency. Whether you are a small startup or a large enterprise, SaaS solutions for PCB can help you to achieve your goals and stay competitive in the market.

In conclusion, SaaS solutions for PCB offer a range of essential features that can improve the design and manufacturing process. By providing design and simulation tools, manufacturing execution systems, supply chain management, collaboration tools, data analytics, and security features, SaaS solutions for PCB can help companies to reduce costs, improve quality, and increase efficiency.

Case Studies: Successful Implementation of SaaS Solutions for PCB

Several companies have successfully implemented software as a service (SaaS) business models for PCB, achieving significant benefits in terms of cost savings, increased efficiency, and improved collaboration. Here are a few examples:

Company A, a leading manufacturer of electronic components, implemented a SaaS-based PCB design and manufacturing solution to streamline its production process. The solution enabled the company to reduce its design-to-manufacturing cycle time by 30% and lower its production costs by 25%. Additionally, the SaaS solution allowed Company A to collaborate more effectively with its suppliers and customers, resulting in improved quality and reduced lead times.

Company B, a startup that specializes in designing and manufacturing IoT devices, adopted a SaaS-based PCB design solution to accelerate its product development process. The solution enabled the company to design and test its PCBs in a virtual environment, reducing the need for physical prototypes and speeding up the development cycle. As a result, Company B was able to bring its products to market 50% faster than its competitors.

Company C, a contract manufacturer of PCBs, implemented a SaaS-based manufacturing execution system (MES) to optimize its production process. The MES solution enabled the company to track its production workflows in real-time, identify bottlenecks, and make data-driven decisions to improve efficiency. As a result, Company C was able to increase its production capacity by 20% and reduce its lead times by 30%.

These case studies demonstrate the potential benefits of SaaS business models for PCB, including cost savings, increased efficiency, and improved collaboration. By adopting SaaS solutions, companies can streamline their PCB design and manufacturing processes, reduce costs, and improve their competitiveness in the market.

Overcoming Challenges in Implementing SaaS Solutions for PCB

While software as a service (SaaS) business models for PCB offer numerous benefits, companies may face several challenges during implementation. These challenges can be overcome with careful planning, execution, and support from the SaaS provider.

One of the primary concerns when implementing SaaS solutions for PCB is data security. Companies must ensure that their sensitive design and manufacturing data is protected from unauthorized access and breaches. To address this concern, companies should look for SaaS providers that offer robust security measures, such as encryption, firewalls, and access controls.

Another challenge is integrating SaaS solutions with existing systems and software. Companies may need to integrate their SaaS solution with computer-aided design (CAD) software, enterprise resource planning (ERP) systems, and other tools. To overcome this challenge, companies should select SaaS providers that offer application programming interfaces (APIs) and software development kits (SDKs) to facilitate integration.

Change management is also a significant challenge when implementing SaaS solutions for PCB. Companies must ensure that their employees are trained and comfortable using the new SaaS solution. To address this challenge, companies should provide comprehensive training and support to their employees, and encourage feedback and suggestions for improving the implementation process.

Additionally, companies may face challenges related to scalability and customization. As their business grows, companies may need to scale their SaaS solution to accommodate increased demand. To overcome this challenge, companies should select SaaS providers that offer scalable solutions and flexible pricing models. Companies may also require customization to meet their specific needs, which can be addressed by selecting SaaS providers that offer configuration options and customization services.

Finally, companies may face challenges related to vendor lock-in and dependence on the SaaS provider. To overcome this challenge, companies should select SaaS providers that offer flexible contract terms, data portability, and exit strategies.

By understanding these challenges and taking steps to address them, companies can ensure a successful implementation of SaaS solutions for PCB and unlock the full potential of software as a service (SaaS) business models for PCB.

The Future of SaaS Business Models for PCB

The future of software as a service (SaaS) business models for PCB is promising, with emerging trends and technologies set to transform the industry. One of the key trends is the increasing adoption of cloud-based platforms, which will enable greater collaboration and data sharing between designers, manufacturers, and suppliers.

Artificial intelligence (AI) and machine learning (ML) are also expected to play a significant role in the future of SaaS business models for PCB. AI-powered design tools will enable designers to create complex PCB designs more quickly and accurately, while ML algorithms will help optimize manufacturing processes and predict potential defects.

The Internet of Things (IoT) is another trend that will impact the future of SaaS business models for PCB. As more devices become connected, the demand for IoT-enabled PCBs will increase, driving the need for SaaS solutions that can support the design and manufacturing of these complex devices.

Additionally, the use of blockchain technology is expected to increase in the PCB industry, enabling secure and transparent data sharing between stakeholders. This will be particularly important for companies that need to comply with strict regulations and standards, such as those in the aerospace and defense industries.

Another emerging trend is the use of digital twins, which are virtual replicas of physical PCBs. Digital twins will enable designers and manufacturers to simulate and test PCB designs in a virtual environment, reducing the need for physical prototypes and speeding up the development process.

The future of SaaS business models for PCB will also be shaped by the increasing demand for sustainability and environmental responsibility. Companies will need to adopt SaaS solutions that enable them to design and manufacture PCBs in a more sustainable and environmentally friendly way, reducing waste and minimizing their carbon footprint.

Overall, the future of SaaS business models for PCB is exciting and full of opportunities for innovation and growth. As the industry continues to evolve, companies that adopt SaaS solutions will be well-positioned to take advantage of emerging trends and technologies, and to stay ahead of the competition.

Conclusion: Unlocking the Full Potential of SaaS for PCB

In conclusion, software as a service (SaaS) business models for PCB are revolutionizing the way companies design, manufacture, and distribute printed circuit boards. By adopting SaaS solutions, companies can reduce costs, increase scalability, and improve collaboration, ultimately leading to increased competitiveness and profitability.

Throughout this article, we have explored the benefits of SaaS business models for PCB, including reduced costs, increased scalability, and improved collaboration. We have also discussed the key features of SaaS solutions for PCB, including design and simulation tools, manufacturing execution systems, and supply chain management.

In addition, we have presented real-life examples of companies that have successfully implemented SaaS solutions for PCB design and manufacturing, highlighting the benefits and challenges of each case study. We have also discussed common challenges that companies may face when implementing SaaS solutions for PCB, such as data security and integration with existing systems, and offered advice on how to overcome these challenges.

Finally, we have explored the future of SaaS business models for PCB, including emerging trends and technologies, such as artificial intelligence, machine learning, and the Internet of Things. These developments are expected to have a significant impact on the PCB industry, enabling companies to design and manufacture PCBs more efficiently and effectively.

As the PCB industry continues to evolve, it is essential for companies to stay ahead of the curve by adopting SaaS solutions that can help them unlock the full potential of software as a service (SaaS) business models for PCB. By doing so, companies can improve their competitiveness, increase their profitability, and achieve long-term success in the market.