What is SaaS and How Does it Apply to PCB Design?

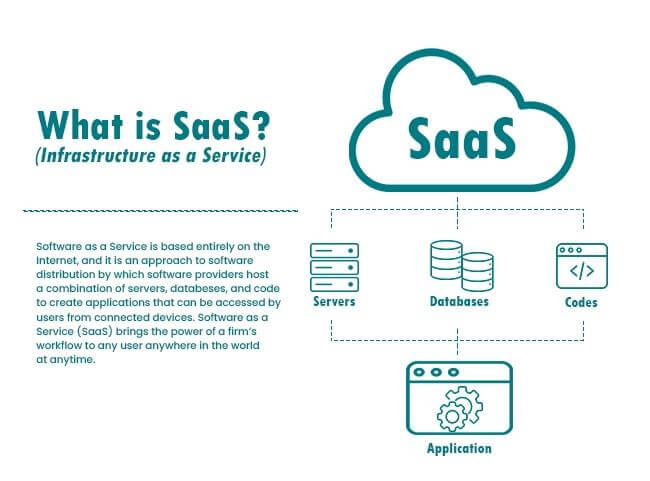

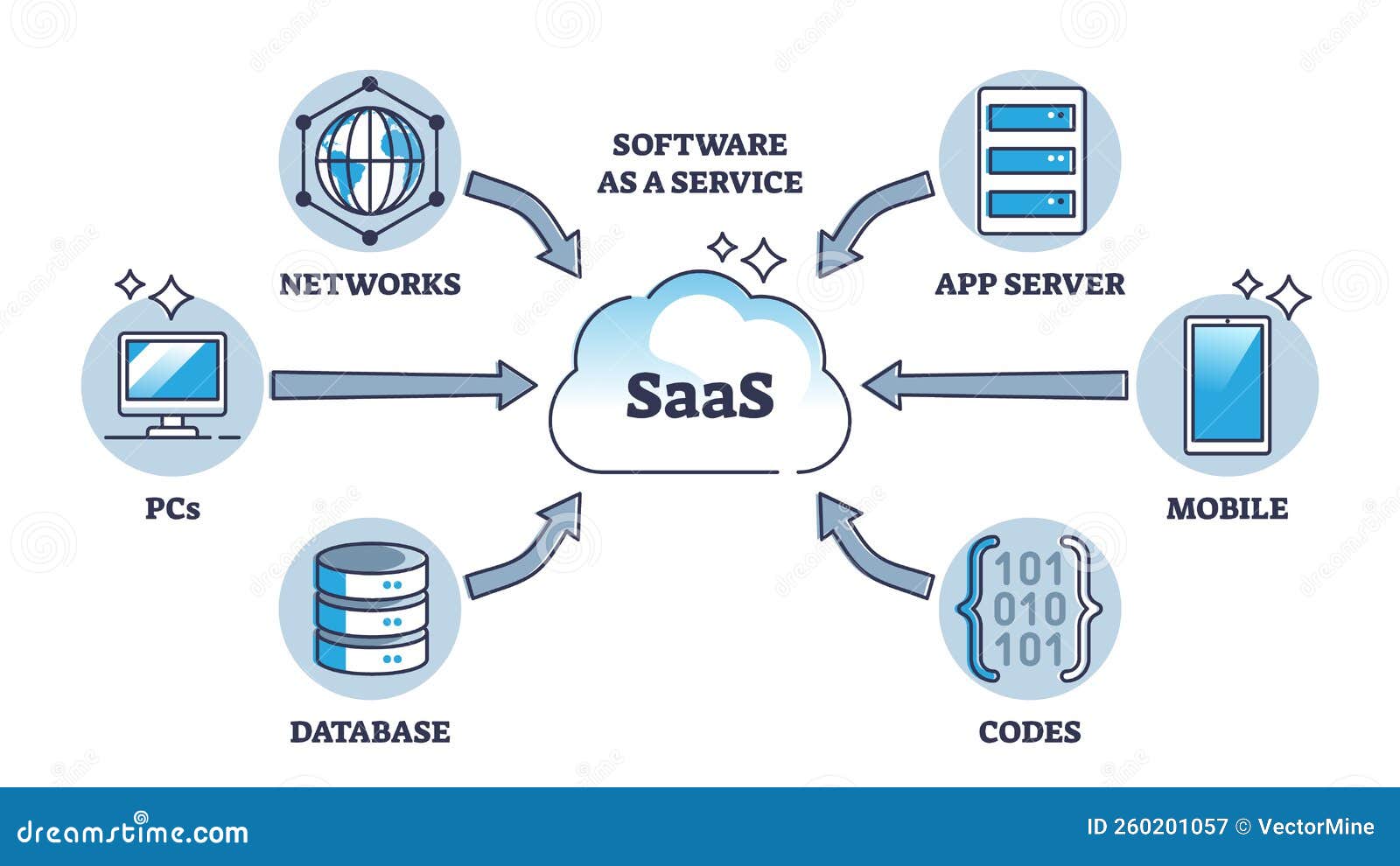

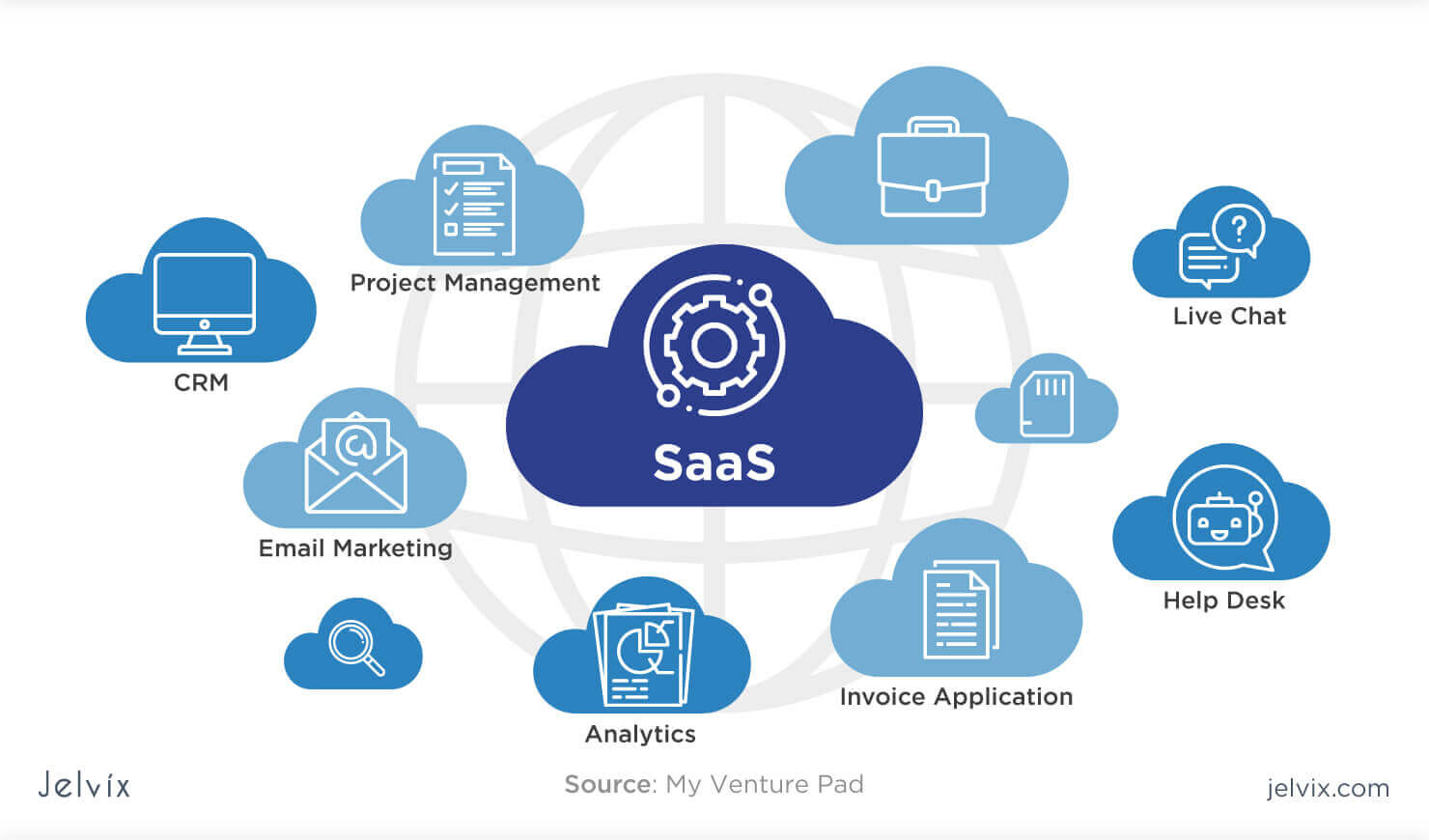

The rise of software as a service (SaaS) business models has transformed the way companies approach software solutions, and the printed circuit board (PCB) design industry is no exception. SaaS models provide scalable, cost-effective, and collaborative solutions for PCB designers and manufacturers, enabling them to streamline their design processes and improve productivity. In the context of PCB design, SaaS refers to a cloud-based software delivery model where users access PCB design tools and software applications over the internet, rather than installing and maintaining them on local computers.

This approach offers several benefits, including reduced upfront costs, increased flexibility, and enhanced collaboration. With SaaS-based PCB design tools, users can access the latest software versions and features without the need for manual updates or maintenance. Additionally, SaaS models enable real-time collaboration and data sharing among designers, engineers, and manufacturers, facilitating a more efficient and effective design process.

The SaaS model is particularly well-suited for the PCB design industry, where complex designs and multiple stakeholders are common. By providing a centralized platform for design collaboration and data management, SaaS-based PCB design tools can help reduce errors, improve design quality, and accelerate time-to-market. Furthermore, SaaS models can be easily scaled up or down to meet the changing needs of businesses, making them an attractive option for companies of all sizes.

As the PCB design industry continues to evolve, the adoption of SaaS-based solutions is likely to play a key role in driving innovation and efficiency. By leveraging the benefits of cloud-based software delivery, PCB designers and manufacturers can focus on what matters most – creating high-quality designs and bringing products to market quickly and effectively. Whether you’re a small startup or a large enterprise, SaaS-based PCB design tools can help you unlock the full potential of your design team and stay ahead of the competition.

How to Choose the Right SaaS-Based PCB Design Tool for Your Business

With the growing adoption of software as a service (SaaS) business models for PCB design, selecting the right SaaS-based PCB design tool can be a daunting task. To make an informed decision, it’s essential to consider several key factors, including features, pricing, user interface, and customer support. In this section, we’ll explore these factors in detail and provide examples of popular SaaS-based PCB design tools.

Features are a critical consideration when choosing a SaaS-based PCB design tool. Look for tools that offer a comprehensive set of features, including schematic capture, PCB layout, simulation, and analysis. Additionally, consider the tool’s compatibility with your existing design workflow and its ability to integrate with other tools and software. For example, Altium 365 offers a robust set of features, including advanced simulation and analysis capabilities, while Autodesk Eagle provides a user-friendly interface and seamless integration with other Autodesk tools.

Pricing is another important factor to consider when selecting a SaaS-based PCB design tool. Look for tools that offer flexible pricing models, including pay-as-you-go and subscription-based options. Be sure to also consider the total cost of ownership, including any additional fees for support, training, or maintenance. For instance, Altium 365 offers a tiered pricing model, with options starting at $99 per month, while Autodesk Eagle provides a free version, as well as paid subscription options starting at $15 per month.

The user interface is also a critical consideration when choosing a SaaS-based PCB design tool. Look for tools that offer an intuitive and user-friendly interface, with features such as drag-and-drop functionality and real-time feedback. Additionally, consider the tool’s compatibility with your existing design workflow and its ability to integrate with other tools and software. For example, Autodesk Eagle offers a user-friendly interface and seamless integration with other Autodesk tools, while Altium 365 provides a robust set of features and advanced simulation and analysis capabilities.

Customer support is also an essential factor to consider when selecting a SaaS-based PCB design tool. Look for tools that offer comprehensive support options, including online documentation, tutorials, and customer support teams. Be sure to also consider the tool’s reputation for customer support, including reviews and ratings from existing customers. For instance, Altium 365 offers comprehensive support options, including online documentation and a customer support team, while Autodesk Eagle provides a robust set of resources, including tutorials and online forums.

In conclusion, choosing the right SaaS-based PCB design tool requires careful consideration of several key factors, including features, pricing, user interface, and customer support. By evaluating these factors and considering the needs of your business, you can select a tool that meets your needs and helps you achieve your design goals.

The Benefits of Cloud-Based PCB Design Collaboration

Cloud-based collaboration is a key benefit of software as a service (SaaS) business models for PCB design. By providing a centralized platform for design collaboration and data management, SaaS-based tools can facilitate collaboration among designers, engineers, and manufacturers. This can lead to improved design quality, reduced errors, and accelerated time-to-market.

One of the primary advantages of cloud-based collaboration in PCB design is real-time commenting. This feature allows multiple stakeholders to provide feedback and comments on designs in real-time, enabling faster and more effective communication. For example, a designer can share a design with a manufacturer and receive feedback on manufacturability and cost-effectiveness in real-time.

Version control is another critical aspect of cloud-based collaboration in PCB design. SaaS-based tools can provide automatic version control, ensuring that all stakeholders are working with the latest design version. This can help reduce errors and improve design quality by eliminating the risk of working with outdated designs.

Secure data storage is also a key benefit of cloud-based collaboration in PCB design. SaaS-based tools can provide secure and scalable data storage, ensuring that design data is protected and easily accessible. This can help reduce the risk of data loss and improve collaboration by providing a centralized platform for design data management.

Cloud-based collaboration can also facilitate collaboration among designers, engineers, and manufacturers. By providing a centralized platform for design collaboration and data management, SaaS-based tools can enable real-time communication and feedback. This can help improve design quality, reduce errors, and accelerate time-to-market.

In addition to these benefits, cloud-based collaboration can also improve the overall design process. By providing a centralized platform for design collaboration and data management, SaaS-based tools can help reduce the risk of errors and improve design quality. This can lead to faster and more effective design cycles, enabling businesses to bring products to market more quickly.

Overall, cloud-based collaboration is a key benefit of SaaS business models for PCB design. By providing a centralized platform for design collaboration and data management, SaaS-based tools can facilitate collaboration among designers, engineers, and manufacturers. This can lead to improved design quality, reduced errors, and accelerated time-to-market.

PCB Design and Manufacturing: A SaaS-Based Approach to Streamlining the Process

The integration of software as a service (SaaS) business models for PCB design with manufacturing processes can significantly streamline the design-to-manufacturing workflow. By providing a seamless data transfer and reducing errors, SaaS-based PCB design tools can help manufacturers improve their overall efficiency and productivity.

One of the key benefits of SaaS-based PCB design tools is their ability to integrate with manufacturing processes. This can be achieved through the use of APIs, which enable the transfer of design data from the SaaS-based tool to the manufacturer’s system. This integration can help reduce errors and improve the overall quality of the manufactured PCBs.

SaaS-based PCB design tools can also facilitate the use of digital twins, which are virtual replicas of the physical PCB. Digital twins can be used to simulate the behavior of the PCB under different conditions, allowing designers and manufacturers to identify and address potential issues before the physical PCB is manufactured.

The use of SaaS-based PCB design tools can also improve the prototyping process. By providing a cloud-based platform for design collaboration and data management, SaaS-based tools can enable designers and manufacturers to work together more effectively, reducing the time and cost associated with prototyping.

In addition to these benefits, SaaS-based PCB design tools can also improve the testing and production process. By providing a centralized platform for design data management, SaaS-based tools can help manufacturers reduce errors and improve the overall quality of the manufactured PCBs.

For example, a manufacturer can use a SaaS-based PCB design tool to design and simulate a PCB, and then transfer the design data to their manufacturing system for production. This can help reduce errors and improve the overall quality of the manufactured PCBs.

Overall, the integration of SaaS-based PCB design tools with manufacturing processes can significantly streamline the design-to-manufacturing workflow. By providing a seamless data transfer and reducing errors, SaaS-based tools can help manufacturers improve their overall efficiency and productivity.

As the PCB design industry continues to evolve, the use of SaaS-based tools is likely to play an increasingly important role in streamlining the design-to-manufacturing workflow. By providing a cloud-based platform for design collaboration and data management, SaaS-based tools can help designers and manufacturers work together more effectively, reducing the time and cost associated with PCB design and manufacturing.

Security and Data Management in SaaS-Based PCB Design

When it comes to software as a service (SaaS) business models for PCB design, security and data management are top concerns for designers and manufacturers. As SaaS-based tools store and manage sensitive design data in the cloud, it’s essential to ensure that this data is protected from unauthorized access, theft, and loss.

Reputable SaaS providers take data security seriously and implement robust measures to ensure the integrity and confidentiality of customer data. These measures include encryption, access controls, and backup procedures. For example, Altium 365 uses enterprise-grade encryption to protect design data, both in transit and at rest.

Access controls are another critical aspect of data security in SaaS-based PCB design. SaaS providers use role-based access controls to ensure that only authorized personnel can access and modify design data. This includes features such as user authentication, authorization, and auditing.

Backup procedures are also essential for ensuring data integrity and availability. Reputable SaaS providers implement regular backups of design data, which are stored in secure, off-site locations. This ensures that design data can be quickly recovered in the event of a disaster or data loss.

In addition to these measures, SaaS providers also implement robust data management practices to ensure the accuracy, completeness, and consistency of design data. This includes features such as data validation, data normalization, and data cleansing.

Designers and manufacturers can also take steps to ensure the security and integrity of their design data. This includes using strong passwords, enabling two-factor authentication, and regularly reviewing and updating access controls.

By implementing robust security and data management measures, SaaS providers can ensure the integrity and confidentiality of customer data. This provides designers and manufacturers with peace of mind, knowing that their sensitive design data is protected and secure.

In conclusion, security and data management are critical concerns for designers and manufacturers using SaaS-based PCB design tools. By implementing robust measures such as encryption, access controls, and backup procedures, SaaS providers can ensure the integrity and confidentiality of customer data.

Scalability and Cost-Effectiveness in SaaS-Based PCB Design

One of the primary benefits of software as a service (SaaS) business models for PCB design is their scalability and cost-effectiveness. SaaS-based tools can be easily scaled up or down to meet the changing needs of businesses, making them an attractive option for companies of all sizes.

Pay-as-you-go pricing models are a key feature of SaaS-based PCB design tools. This means that businesses only pay for the resources they use, rather than having to purchase and maintain expensive software licenses. This can help reduce costs and improve cash flow, making it easier for businesses to invest in other areas of their operations.

On-demand resource allocation is another benefit of SaaS-based PCB design tools. This means that businesses can quickly and easily access the resources they need, without having to worry about maintaining and upgrading their own infrastructure. This can help improve productivity and reduce downtime, making it easier for businesses to meet their design and manufacturing deadlines.

SaaS-based PCB design tools can also help businesses reduce their capital expenditures. By providing a cloud-based platform for design and manufacturing, SaaS-based tools can eliminate the need for expensive hardware and software purchases. This can help reduce costs and improve cash flow, making it easier for businesses to invest in other areas of their operations.

In addition to these benefits, SaaS-based PCB design tools can also help businesses improve their productivity and efficiency. By providing a centralized platform for design and manufacturing, SaaS-based tools can help businesses streamline their workflows and reduce errors. This can help improve the overall quality of their designs and products, making it easier for them to compete in the market.

For example, a small business that specializes in designing and manufacturing PCBs for the aerospace industry may use a SaaS-based PCB design tool to streamline their workflow and reduce costs. By providing a cloud-based platform for design and manufacturing, the tool can help the business quickly and easily access the resources they need, without having to worry about maintaining and upgrading their own infrastructure.

Overall, the scalability and cost-effectiveness of SaaS-based PCB design tools make them an attractive option for businesses of all sizes. By providing a cloud-based platform for design and manufacturing, SaaS-based tools can help businesses reduce costs, improve productivity, and improve the overall quality of their designs and products.

Real-World Examples of Successful SaaS-Based PCB Design Implementations

Several companies have successfully implemented software as a service (SaaS) business models for PCB design, achieving significant benefits and results. Here are a few examples:

Company A, a leading manufacturer of electronic components, implemented a SaaS-based PCB design tool to streamline their design and manufacturing process. The tool enabled real-time collaboration among designers, engineers, and manufacturers, reducing errors and improving productivity. As a result, the company was able to reduce their design-to-manufacturing time by 30% and improve their overall product quality.

Company B, a startup that specializes in designing and manufacturing PCBs for the aerospace industry, used a SaaS-based PCB design tool to reduce their costs and improve their scalability. The tool provided a pay-as-you-go pricing model and on-demand resource allocation, enabling the company to quickly and easily access the resources they needed without having to worry about maintaining and upgrading their own infrastructure. As a result, the company was able to reduce their costs by 25% and improve their productivity by 20%.

Company C, a leading provider of PCB design and manufacturing services, implemented a SaaS-based PCB design tool to improve their collaboration and communication with customers. The tool enabled real-time commenting and version control, reducing errors and improving the overall quality of their designs. As a result, the company was able to improve their customer satisfaction ratings by 15% and reduce their design-to-manufacturing time by 20%.

These examples demonstrate the potential of SaaS-based PCB design tools to drive significant benefits and results for companies of all sizes. By providing scalable, cost-effective, and collaborative solutions, SaaS-based tools can help companies improve their productivity, reduce their costs, and improve their overall product quality.

When implementing a SaaS-based PCB design tool, companies should consider several key factors, including the tool’s features, pricing, user interface, and customer support. They should also consider the potential challenges and lessons learned during the implementation process, such as the need for training and support, and the potential for cultural and organizational changes.

By carefully evaluating these factors and considering the potential benefits and challenges, companies can successfully implement SaaS-based PCB design tools and achieve significant benefits and results.

Future Directions for SaaS-Based PCB Design and Manufacturing

The future of software as a service (SaaS) business models for PCB design and manufacturing looks promising, with several emerging trends, technologies, and innovations on the horizon. As the demand for cloud-based solutions continues to grow, SaaS providers are expected to invest heavily in research and development, driving further efficiencies, productivity gains, and innovation in the PCB design industry.

One of the key trends expected to shape the future of SaaS-based PCB design and manufacturing is the increasing adoption of artificial intelligence (AI) and machine learning (ML) technologies. By leveraging AI and ML, SaaS providers can develop more sophisticated design and manufacturing tools, enabling designers and manufacturers to create more complex and sophisticated PCBs.

Another trend expected to impact the future of SaaS-based PCB design and manufacturing is the growing importance of cybersecurity. As more and more companies move their design and manufacturing processes to the cloud, cybersecurity will become an increasingly critical concern. SaaS providers will need to invest heavily in security measures, such as encryption and access controls, to protect customer data and prevent cyber threats.

The Internet of Things (IoT) is also expected to play a major role in shaping the future of SaaS-based PCB design and manufacturing. As more and more devices become connected to the internet, the demand for PCBs will continue to grow, driving innovation and growth in the industry.

In addition to these trends, several emerging technologies are expected to impact the future of SaaS-based PCB design and manufacturing. These include 5G networks, which will enable faster and more reliable data transfer, and the increasing use of autonomous vehicles, which will drive demand for more sophisticated PCBs.

Overall, the future of SaaS-based PCB design and manufacturing looks bright, with several emerging trends, technologies, and innovations on the horizon. As the demand for cloud-based solutions continues to grow, SaaS providers will need to invest heavily in research and development, driving further efficiencies, productivity gains, and innovation in the PCB design industry.

As the industry continues to evolve, it will be important for companies to stay ahead of the curve, investing in the latest technologies and innovations to remain competitive. By doing so, they can take advantage of the many benefits offered by SaaS-based PCB design and manufacturing, including increased productivity, reduced costs, and improved collaboration.