Unlocking the Potential of Virtual Reality in Electric Motor Design

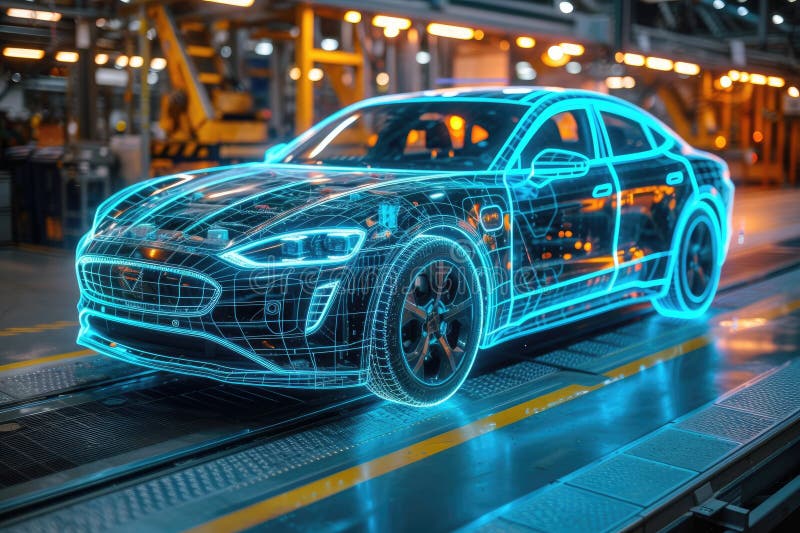

The electric vehicle (EV) industry is on the cusp of a revolution, driven by the increasing demand for sustainable and environmentally friendly transportation solutions. As EV manufacturers strive to improve the performance, efficiency, and range of their vehicles, they are turning to innovative technologies like virtual reality (VR) to transform the design process. Virtual reality for electric vehicle and electric motor design is becoming an essential tool, enabling designers and engineers to create, test, and iterate on virtual prototypes in a highly immersive and interactive environment.

By leveraging VR, EV manufacturers can enhance the design process in several ways. Firstly, VR enables designers to create highly detailed and accurate virtual models of electric motors and other components, allowing for precise testing and analysis. This reduces the need for physical prototyping, saving time and costs associated with building and testing multiple prototypes. Secondly, VR facilitates collaboration and communication among cross-functional teams, ensuring that all stakeholders have a shared understanding of design intent and requirements.

Moreover, VR enables designers to simulate real-world scenarios, testing the performance of electric motors under various conditions, such as different temperatures, loads, and speeds. This allows for the identification and addressing of design flaws early on, reducing the risk of costly rework and improving overall product quality. As the EV industry continues to evolve, the integration of VR into the design process is poised to play a critical role in driving innovation and competitiveness.

How to Leverage Virtual Reality for Electric Motor Design Optimization

To unlock the full potential of virtual reality for electric vehicle and electric motor design, it’s essential to follow a structured approach. Here’s a step-by-step guide on how to leverage VR for electric motor design optimization:

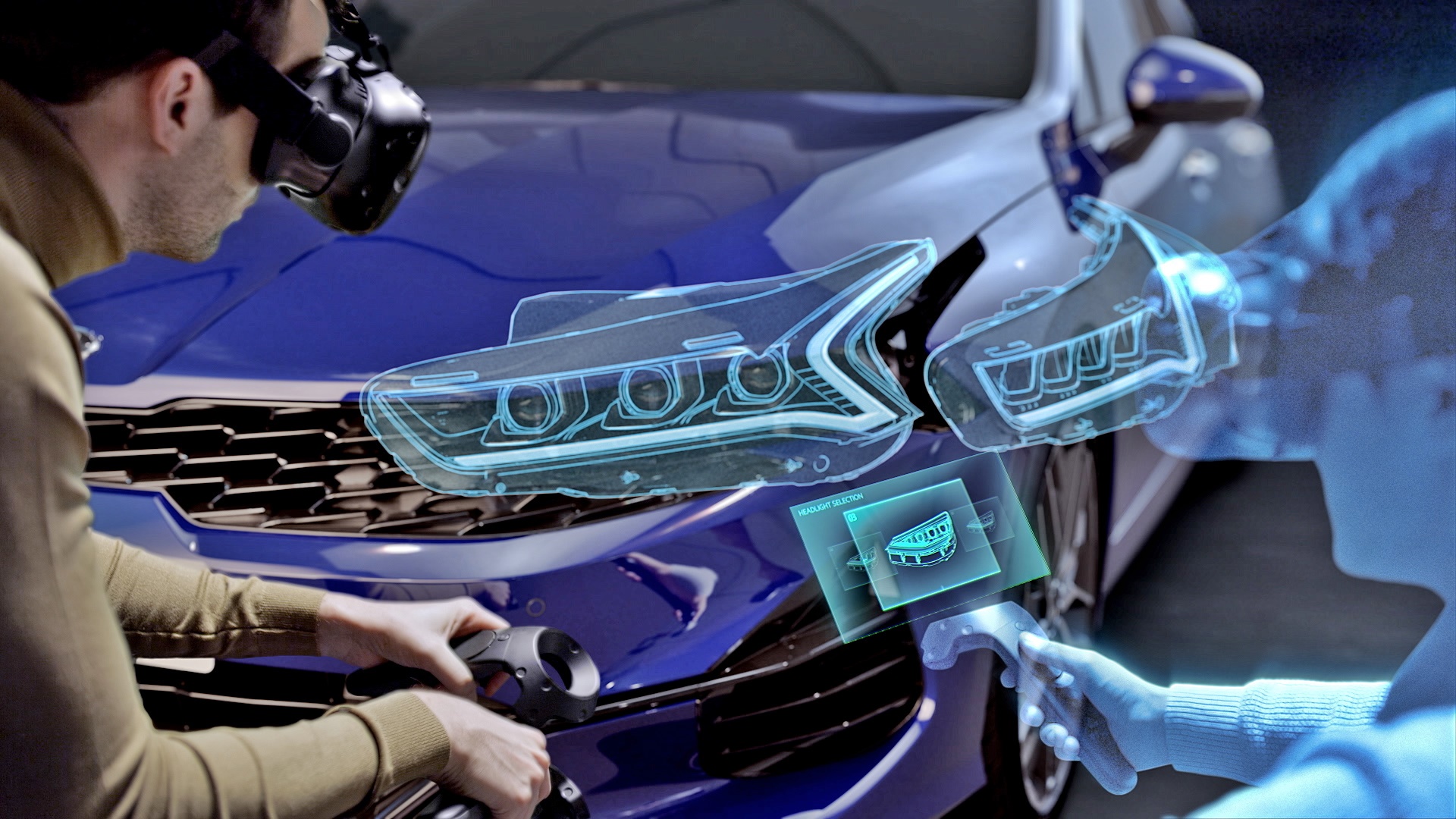

Step 1: Create a Virtual Prototype – The first step is to create a highly detailed and accurate virtual model of the electric motor. This can be achieved using computer-aided design (CAD) software and VR tools. The virtual prototype should include all the necessary components, such as the stator, rotor, and windings.

Step 2: Test and Iterate – Once the virtual prototype is created, it’s time to test and iterate on the design. VR enables designers to simulate real-world scenarios, testing the performance of the electric motor under various conditions. This allows for the identification and addressing of design flaws early on, reducing the risk of costly rework and improving overall product quality.

Step 3: Analyze and Optimize – The next step is to analyze the performance of the electric motor and optimize the design. VR enables designers to visualize complex data, such as electromagnetic fields and thermal distributions, allowing for a deeper understanding of the design. This information can be used to optimize the design, improving efficiency, reducing costs, and enhancing overall performance.

Real-world examples of successful VR implementation in electric motor design optimization include the use of VR by companies like Tesla and General Motors. These companies have leveraged VR to improve the design and development of their electric motors, resulting in improved performance, efficiency, and reduced costs.

By following these steps and leveraging the power of VR, electric vehicle manufacturers can optimize their electric motor designs, improving overall performance, efficiency, and reducing costs. Virtual reality for electric vehicle and electric motor design is a game-changer, and its potential to transform the industry is vast.

The Role of Virtual Reality in Electric Vehicle Prototyping and Testing

Virtual reality (VR) is revolutionizing the electric vehicle (EV) design process, and its impact is particularly significant in prototyping and testing. Traditional prototyping methods involve creating physical prototypes, which can be time-consuming and costly. VR, on the other hand, enables designers to create virtual prototypes, reducing the need for physical prototyping and accelerating the testing cycle.

One of the primary benefits of using VR in EV prototyping and testing is the reduction in physical prototyping costs. By creating virtual prototypes, designers can test and iterate on designs without incurring the costs associated with building and testing physical prototypes. This not only saves time and money but also enables designers to explore a wider range of design options, leading to improved overall performance and efficiency.

Another significant advantage of VR in EV prototyping and testing is the ability to identify and address design flaws early on. By simulating real-world scenarios, designers can test the performance of virtual prototypes under various conditions, identifying potential issues before they become major problems. This enables designers to make data-driven decisions, reducing the risk of costly rework and improving overall product quality.

Virtual reality for electric vehicle and electric motor design is also enabling the creation of more realistic and immersive testing environments. By simulating real-world scenarios, designers can test the performance of virtual prototypes in a highly realistic and immersive environment, reducing the need for physical testing and improving overall accuracy.

Companies like Volkswagen and BMW are already leveraging VR in their EV prototyping and testing processes, achieving significant reductions in costs and improvements in overall efficiency. By adopting VR, EV manufacturers can accelerate their design and testing processes, improving overall performance and reducing costs.

Real-World Applications: Virtual Reality in Electric Vehicle Design with Autodesk and Siemens

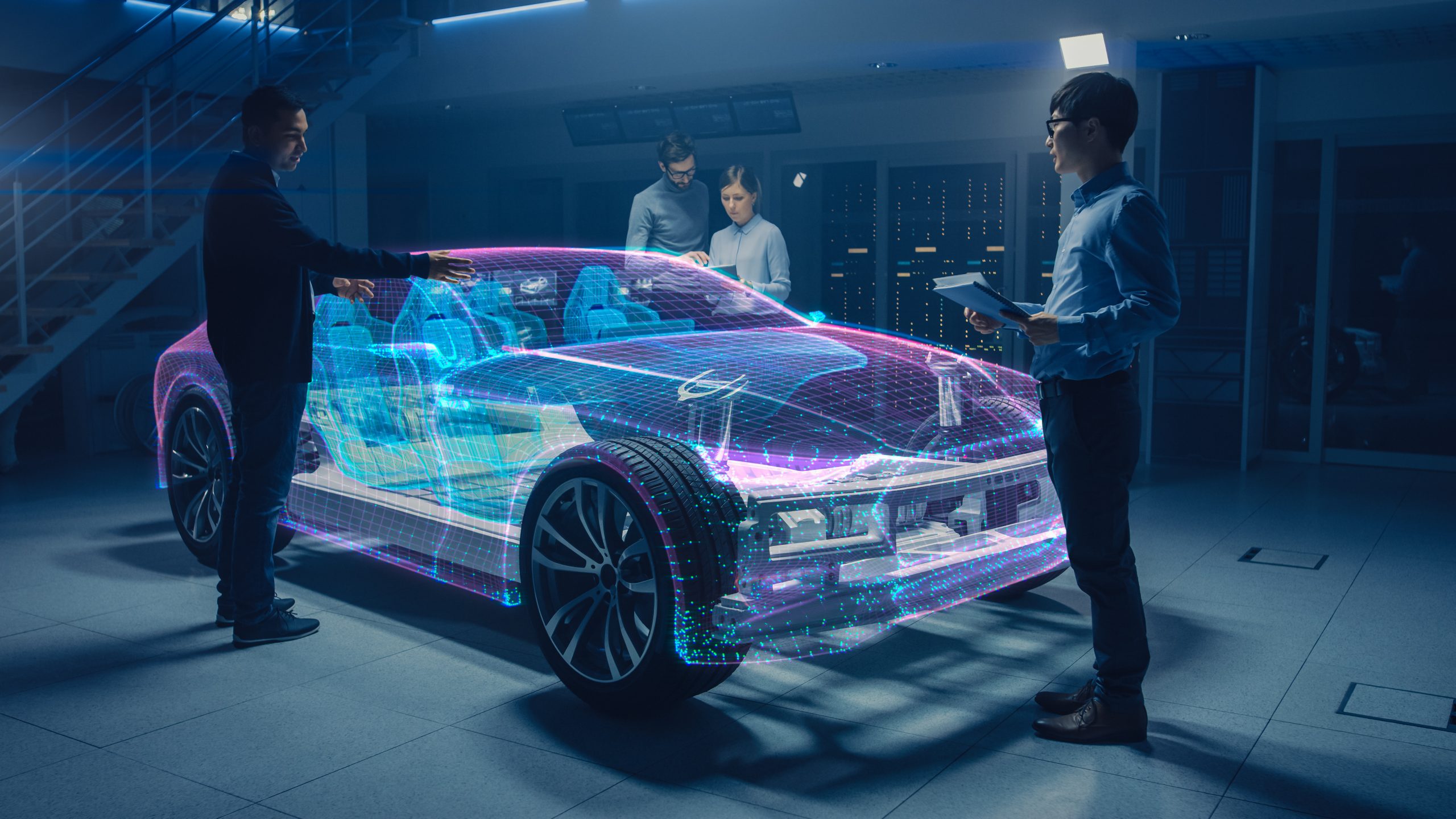

Several companies are already leveraging virtual reality (VR) in electric vehicle (EV) design, achieving significant benefits in terms of improved efficiency, reduced costs, and enhanced collaboration. Two notable examples are Autodesk and Siemens, which have successfully implemented VR in their EV design workflows.

Autodesk, a leading provider of design and engineering software, has developed a range of VR tools and solutions for EV design. Their software, such as Autodesk VRED, enables designers to create immersive and interactive 3D models of EVs, allowing for real-time testing and validation of designs. This has enabled Autodesk to reduce physical prototyping costs and accelerate the design process, resulting in faster time-to-market and improved overall efficiency.

Siemens, a global leader in industrial automation and software, has also implemented VR in their EV design workflows. Their software, such as Siemens NX, enables designers to create detailed and accurate 3D models of EVs, including electric motors, batteries, and other components. This has enabled Siemens to improve the accuracy and efficiency of their design process, reducing errors and improving overall product quality.

Both Autodesk and Siemens have achieved significant benefits through the implementation of VR in their EV design workflows. These benefits include reduced physical prototyping costs, accelerated design cycles, and improved collaboration among cross-functional teams. By leveraging VR, these companies have been able to improve the efficiency and effectiveness of their EV design processes, resulting in faster time-to-market and improved overall competitiveness.

Virtual reality for electric vehicle and electric motor design is a rapidly evolving field, with new applications and use cases emerging all the time. As the technology continues to advance, we can expect to see even more innovative and creative applications of VR in EV design, driving further improvements in efficiency, productivity, and competitiveness.

Overcoming Design Challenges with Virtual Reality in Electric Motor Development

Electric motor development is a complex and challenging process, requiring careful consideration of multiple design parameters, including thermal management, electromagnetic interference, and structural integrity. Virtual reality (VR) can help overcome these challenges by providing an immersive and interactive environment for designers to test and validate their designs.

One of the most significant design challenges in electric motor development is thermal management. Electric motors generate heat during operation, which can affect their performance and lifespan. VR can help designers optimize thermal management by simulating the thermal behavior of the motor under various operating conditions. This allows designers to identify potential thermal issues early on and make data-driven decisions to improve the design.

Another significant design challenge is electromagnetic interference (EMI). EMI can affect the performance of the motor and other electrical systems in the vehicle. VR can help designers optimize EMI by simulating the electromagnetic behavior of the motor and identifying potential sources of interference. This allows designers to make data-driven decisions to improve the design and reduce the risk of EMI-related issues.

VR can also help designers optimize the structural integrity of the motor by simulating the mechanical behavior of the motor under various operating conditions. This allows designers to identify potential structural issues early on and make data-driven decisions to improve the design.

Virtual reality for electric vehicle and electric motor design is a powerful tool for overcoming design challenges. By providing an immersive and interactive environment for designers to test and validate their designs, VR can help reduce the risk of design-related issues and improve the overall performance and efficiency of the motor.

Companies like Tesla and General Motors are already leveraging VR in their electric motor development processes, achieving significant benefits in terms of improved design quality, reduced development time, and increased efficiency. By adopting VR, electric motor designers can overcome common design challenges and create more efficient, reliable, and sustainable motors.

Collaboration and Communication: The Social Benefits of Virtual Reality in Electric Vehicle Design

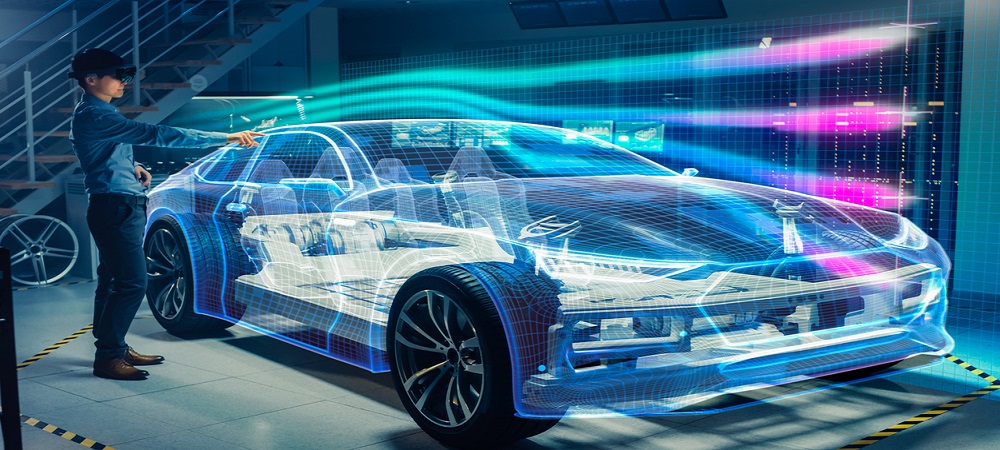

Virtual reality (VR) is not only a powerful tool for electric vehicle (EV) design optimization, but it also offers significant social benefits, including enhanced collaboration and communication among cross-functional teams. By providing an immersive and interactive environment, VR enables designers, engineers, and other stakeholders to share a common understanding of design intent and requirements.

One of the primary social benefits of VR in EV design is the ability to facilitate collaboration among cross-functional teams. By using VR, designers and engineers can work together more effectively, sharing a common understanding of the design and its requirements. This leads to improved communication, reduced errors, and faster time-to-market.

Another significant social benefit of VR in EV design is the ability to enhance communication among stakeholders. By providing an immersive and interactive environment, VR enables stakeholders to visualize and understand complex design concepts, leading to improved communication and reduced misunderstandings.

Virtual reality for electric vehicle and electric motor design also offers significant benefits in terms of training and education. By providing an immersive and interactive environment, VR enables designers and engineers to learn and practice new skills, leading to improved performance and reduced errors.

Companies like Volkswagen and BMW are already leveraging VR in their EV design workflows, achieving significant benefits in terms of improved collaboration, communication, and training. By adopting VR, EV manufacturers can improve the efficiency and effectiveness of their design processes, leading to faster time-to-market and improved overall competitiveness.

As the use of VR in EV design continues to grow, we can expect to see even more innovative and creative applications of this technology. By providing an immersive and interactive environment, VR has the potential to transform the way we design and develop electric vehicles, leading to improved performance, efficiency, and sustainability.

Future-Proofing Electric Vehicle Design with Virtual Reality and Artificial Intelligence

The electric vehicle (EV) industry is rapidly evolving, with new technologies and innovations emerging all the time. Two of the most significant trends in EV design are the use of virtual reality (VR) and artificial intelligence (AI). By combining these technologies, EV manufacturers can create more efficient, sustainable, and autonomous vehicles.

One of the primary benefits of combining VR and AI in EV design is the ability to optimize design processes. AI can be used to analyze vast amounts of data, identifying patterns and trends that can inform design decisions. VR can then be used to visualize and interact with these designs, allowing designers to test and validate their ideas in a highly immersive and interactive environment.

Another significant benefit of combining VR and AI in EV design is the ability to predict and prevent maintenance issues. AI can be used to analyze data from sensors and other sources, identifying potential issues before they become major problems. VR can then be used to visualize and interact with these issues, allowing designers to develop and test solutions in a highly immersive and interactive environment.

Virtual reality for electric vehicle and electric motor design is also being used in conjunction with AI to develop autonomous vehicles. By combining these technologies, EV manufacturers can create vehicles that are not only more efficient and sustainable but also safer and more autonomous.

Companies like Tesla and Waymo are already leveraging VR and AI in their EV design workflows, achieving significant benefits in terms of improved design quality, reduced development time, and increased efficiency. By adopting these technologies, EV manufacturers can future-proof their designs, creating vehicles that are more efficient, sustainable, and autonomous.

The potential of combining VR and AI in EV design is vast, and we can expect to see even more innovative and creative applications of these technologies in the future. By providing an immersive and interactive environment, VR can help designers to develop and test new ideas, while AI can help to analyze and optimize design processes.

Best Practices for Implementing Virtual Reality in Electric Vehicle Design Workflows

Implementing virtual reality (VR) in electric vehicle (EV) design workflows can be a complex process, requiring careful planning and execution. To ensure a successful implementation, it’s essential to follow best practices, including change management, training, and infrastructure requirements.

Change management is critical when implementing VR in EV design workflows. It’s essential to communicate the benefits and value of VR to all stakeholders, including designers, engineers, and management. This can be achieved through training and education programs, which can help to build a strong understanding of VR and its applications in EV design.

Training is also essential when implementing VR in EV design workflows. Designers and engineers need to be trained on how to use VR software and hardware, as well as how to integrate VR into their existing workflows. This can be achieved through on-site training, online tutorials, and workshops.

Infrastructure requirements are also critical when implementing VR in EV design workflows. This includes the need for high-performance computers, VR headsets, and software. It’s essential to ensure that the infrastructure is in place to support the use of VR, including the need for high-speed internet and data storage.

Virtual reality for electric vehicle and electric motor design is a rapidly evolving field, and it’s essential to stay up-to-date with the latest developments and trends. This can be achieved through industry events, conferences, and trade shows, as well as through online forums and communities.

By following these best practices, EV manufacturers can ensure a successful implementation of VR in their design workflows, leading to improved design quality, reduced development time, and increased efficiency.

Measuring the success of VR implementation is also critical, and this can be achieved through metrics such as design quality, development time, and cost savings. By tracking these metrics, EV manufacturers can ensure that VR is delivering the expected benefits and make adjustments as needed.