Unlocking the Potential of Virtual Reality in Electronics Design

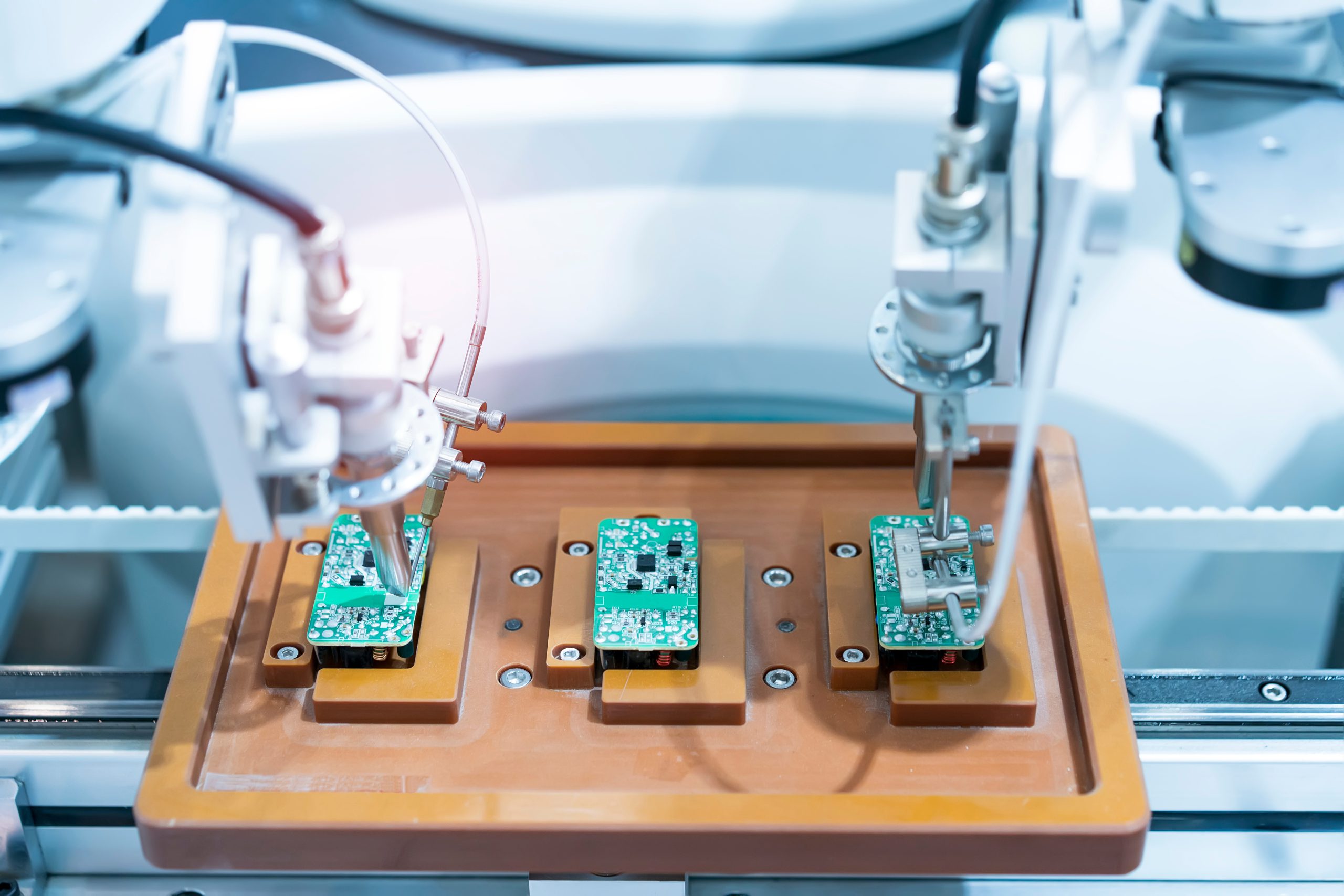

The integration of virtual reality (VR) in PCB design and manufacturing is revolutionizing the electronics industry. By providing an immersive and interactive environment, VR enables designers and manufacturers to work together more effectively, enhancing the design process, improving collaboration, and reducing errors. Virtual reality for PCB design and manufacturing offers a range of benefits, including increased accuracy, reduced material waste, and faster iteration.

One of the primary advantages of VR in electronics design is its ability to facilitate collaboration and communication among team members. By allowing designers and manufacturers to work together in a virtual environment, VR helps to ensure that all stakeholders are on the same page, reducing the risk of miscommunication and errors. Additionally, VR enables designers to create and test virtual prototypes, reducing the need for physical prototypes and minimizing material waste.

Virtual reality also offers a range of benefits for PCB manufacturing. By allowing manufacturers to simulate production lines and factory layouts, VR helps to optimize production processes, reduce costs, and improve product quality. Additionally, VR enables manufacturers to train employees in a virtual environment, reducing the risk of accidents and improving overall safety.

As the electronics industry continues to evolve, the use of virtual reality for PCB design and manufacturing is likely to become increasingly prevalent. By providing a range of benefits, including enhanced collaboration, improved accuracy, and reduced material waste, VR is poised to revolutionize the way electronics are designed and manufactured.

How to Leverage Virtual Reality for Enhanced PCB Design and Prototyping

Integrating virtual reality (VR) into the PCB design process can be a game-changer for electronics manufacturers. By providing an immersive and interactive environment, VR enables designers to create and test virtual prototypes, reducing the need for physical prototypes and minimizing material waste. Here’s a step-by-step guide on how to leverage VR for enhanced PCB design and prototyping:

Step 1: Choose the Right VR Software and Tools

There are several VR software and tools available for PCB design and prototyping, including Autodesk Live and SolidWorks Visualize. These tools enable designers to create and interact with virtual models of their PCB designs, allowing for real-time testing and iteration.

Step 2: Create a Virtual Prototype

Using VR software and tools, designers can create a virtual prototype of their PCB design. This virtual prototype can be used to test and iterate on the design, reducing the need for physical prototypes and minimizing material waste.

Step 3: Test and Iterate on the Design

Once the virtual prototype is created, designers can test and iterate on the design in real-time. This enables designers to identify and fix errors early in the design process, reducing the risk of costly rework and improving overall product quality.

Benefits of Using VR for Prototyping

The use of VR for prototyping offers several benefits, including reduced material waste and faster iteration. By creating and testing virtual prototypes, designers can reduce the need for physical prototypes, minimizing material waste and reducing the environmental impact of the design process. Additionally, VR enables designers to iterate on the design in real-time, reducing the time and cost associated with traditional prototyping methods.

Virtual reality for PCB design and manufacturing is a powerful tool that can enhance the design process, improve collaboration, and reduce errors. By following these steps and leveraging the benefits of VR, electronics manufacturers can improve their PCB design and prototyping processes, reducing costs and improving overall product quality.

Streamlining PCB Manufacturing with Virtual Reality

Virtual reality (VR) is not only revolutionizing the PCB design process, but also transforming the manufacturing process. By leveraging VR, manufacturers can optimize their production processes, reduce costs, and improve product quality. In this section, we’ll explore the applications of VR in PCB manufacturing and how it can benefit the industry.

Factory Planning and Layout

VR can be used to create a virtual replica of the factory floor, allowing manufacturers to plan and optimize their production layout. This can help reduce costs associated with physical prototyping and minimize the risk of errors during the manufacturing process.

Production Line Simulation

VR can also be used to simulate production lines, allowing manufacturers to test and optimize their production processes in a virtual environment. This can help identify bottlenecks and areas for improvement, reducing the risk of errors and improving overall efficiency.

Quality Control and Inspection

VR can be used to enhance quality control and inspection processes, allowing manufacturers to inspect and test products in a virtual environment. This can help reduce the risk of defects and improve overall product quality.

Benefits of VR in PCB Manufacturing

The use of VR in PCB manufacturing offers several benefits, including reduced costs, improved efficiency, and enhanced product quality. By leveraging VR, manufacturers can optimize their production processes, reduce the risk of errors, and improve overall productivity.

Virtual reality for PCB design and manufacturing is a powerful tool that can transform the manufacturing process. By leveraging VR, manufacturers can improve their production processes, reduce costs, and enhance product quality. As the technology continues to evolve, we can expect to see even more innovative applications of VR in the PCB manufacturing industry.

Real-World Examples of Virtual Reality in PCB Design and Manufacturing

Several companies have successfully implemented virtual reality (VR) in their PCB design and manufacturing processes, achieving significant benefits and results. Here are a few examples:

Intel’s VR-Enabled Design Process

Intel has leveraged VR to enhance its PCB design process, allowing designers to create and interact with virtual models of their designs. This has enabled Intel to reduce design errors, improve collaboration, and accelerate the design process.

Siemens’ VR-Based Manufacturing Simulation

Siemens has used VR to simulate its manufacturing processes, allowing the company to optimize its production lines and reduce costs. By simulating the manufacturing process in a virtual environment, Siemens has been able to identify and address potential issues before they occur.

Other Companies Using VR in PCB Design and Manufacturing

Other companies, such as Cisco and IBM, have also implemented VR in their PCB design and manufacturing processes. These companies have reported benefits such as improved design accuracy, reduced production time, and enhanced collaboration.

Benefits of VR in PCB Design and Manufacturing

The use of VR in PCB design and manufacturing offers several benefits, including improved design accuracy, reduced production time, and enhanced collaboration. By leveraging VR, companies can optimize their design and manufacturing processes, reduce costs, and improve product quality.

Virtual reality for PCB design and manufacturing is a powerful tool that can transform the industry. By providing an immersive and interactive environment, VR enables designers and manufacturers to work together more effectively, reducing errors and improving overall efficiency.

Overcoming Challenges and Limitations of Virtual Reality in PCB Design and Manufacturing

While virtual reality (VR) offers numerous benefits for PCB design and manufacturing, there are also challenges and limitations to consider. In this section, we’ll discuss some of the common challenges and limitations of implementing VR in PCB design and manufacturing, and provide tips and best practices for overcoming them.

Specialized Hardware and Software Requirements

One of the main challenges of implementing VR in PCB design and manufacturing is the need for specialized hardware and software. This can include high-performance computers, VR headsets, and specialized software tools. To overcome this challenge, it’s essential to invest in the right hardware and software, and to ensure that they are compatible with your existing systems and workflows.

User Fatigue and Eye Strain

Another challenge of using VR in PCB design and manufacturing is the potential for user fatigue and eye strain. To overcome this challenge, it’s essential to provide regular breaks for users, and to ensure that the VR environment is designed to minimize eye strain and fatigue.

Best Practices for Overcoming Challenges and Limitations

To overcome the challenges and limitations of implementing VR in PCB design and manufacturing, it’s essential to follow best practices and guidelines. This includes:

Investing in the right hardware and software

Providing regular breaks for users

Ensuring compatibility with existing systems and workflows

Designing the VR environment to minimize eye strain and fatigue

By following these best practices and guidelines, you can overcome the challenges and limitations of implementing VR in PCB design and manufacturing, and unlock the full potential of this technology.

Virtual reality for PCB design and manufacturing is a powerful tool that can transform the industry. By understanding the challenges and limitations of implementing VR, and by following best practices and guidelines, you can overcome these challenges and unlock the full potential of this technology.

The Future of Virtual Reality in PCB Design and Manufacturing

As virtual reality (VR) technology continues to evolve, we can expect to see even more innovative applications in PCB design and manufacturing. In this section, we’ll explore the future of VR in PCB design and manufacturing, including the potential for augmented reality (AR) and mixed reality (MR) applications.

Augmented Reality (AR) Applications

AR technology has the potential to revolutionize the PCB design and manufacturing process by providing a more immersive and interactive experience. AR can be used to enhance the design process, improve collaboration, and reduce errors. For example, AR can be used to create virtual prototypes, allowing designers to test and iterate on their designs in a more efficient and effective way.

Mixed Reality (MR) Applications

MR technology combines the best of both worlds, blending the physical and virtual environments to create a more immersive and interactive experience. MR can be used to enhance the manufacturing process, providing a more efficient and effective way to assemble and test PCBs. For example, MR can be used to create virtual assembly instructions, allowing manufacturers to assemble PCBs more quickly and accurately.

Benefits of AR and MR in PCB Design and Manufacturing

The use of AR and MR in PCB design and manufacturing offers several benefits, including improved design accuracy, reduced production time, and enhanced collaboration. By leveraging these technologies, designers and manufacturers can work together more effectively, reducing errors and improving overall efficiency.

Future of Virtual Reality in PCB Design and Manufacturing

The future of VR in PCB design and manufacturing is exciting and full of possibilities. As VR technology continues to evolve, we can expect to see even more innovative applications in the industry. From AR and MR to other emerging technologies, the potential for VR to transform the PCB design and manufacturing process is vast.

Virtual reality for PCB design and manufacturing is a powerful tool that can transform the industry. By understanding the future of VR and its potential applications, designers and manufacturers can stay ahead of the curve and take advantage of the latest technologies to improve their workflows.

Best Practices for Implementing Virtual Reality in Your PCB Design and Manufacturing Workflow

Implementing virtual reality (VR) in your PCB design and manufacturing workflow can be a game-changer for your business. However, it’s essential to follow best practices to ensure a successful implementation. In this section, we’ll provide recommendations and guidelines for implementing VR in your workflow.

Training and User Adoption

Providing adequate training and support for users is crucial for a successful VR implementation. This includes training on VR software and tools, as well as best practices for using VR in the design and manufacturing process.

Ongoing Evaluation and Improvement

It’s essential to continuously evaluate and improve your VR implementation to ensure it meets your business needs. This includes monitoring user adoption, gathering feedback, and making adjustments as needed.

Best Practices for Implementing VR in PCB Design and Manufacturing

Here are some best practices for implementing VR in PCB design and manufacturing:

Start small and scale up

Begin with a small pilot project to test and refine your VR implementation before scaling up to larger projects.

Choose the right VR software and tools

Select VR software and tools that meet your business needs and are compatible with your existing workflows.

Provide ongoing training and support

Offer regular training and support to users to ensure they are comfortable and proficient using VR in the design and manufacturing process.

Monitor and evaluate user adoption

Continuously monitor and evaluate user adoption to identify areas for improvement and make adjustments as needed.

Virtual reality for PCB design and manufacturing is a powerful tool that can transform your business. By following these best practices and guidelines, you can ensure a successful implementation and unlock the full potential of VR in your workflow.

Conclusion: Revolutionizing PCB Design and Manufacturing with Virtual Reality

The integration of virtual reality (VR) in PCB design and manufacturing has the potential to revolutionize the electronics industry. By providing an immersive and interactive environment, VR enables designers and manufacturers to collaborate more effectively, reduce errors, and improve product quality. As the technology continues to evolve, it is likely that VR will become an essential tool in the PCB design and manufacturing workflow.

As demonstrated by real-world examples, the benefits of VR in PCB design and manufacturing are numerous. From enhanced design accuracy and reduced production time to improved collaboration and reduced material waste, VR has the potential to transform the way electronics are designed and manufactured. By leveraging VR software and tools, companies can streamline their production processes, reduce costs, and improve product quality.

While there are challenges and limitations to implementing VR in PCB design and manufacturing, these can be overcome with the right approach. By providing training and support, encouraging user adoption, and continuously evaluating and improving VR workflows, companies can unlock the full potential of VR. As the technology continues to advance, it is likely that we will see even more innovative applications of VR in the electronics industry.

As the electronics industry continues to evolve, it is clear that virtual reality for PCB design and manufacturing will play an increasingly important role. By embracing this technology, companies can stay ahead of the curve, improve their competitiveness, and drive innovation. Whether you are a designer, manufacturer, or simply interested in the latest developments in the electronics industry, it is time to explore the possibilities of VR and discover how it can revolutionize your workflow.