Why Thermal Management is Crucial for Electric Vehicles

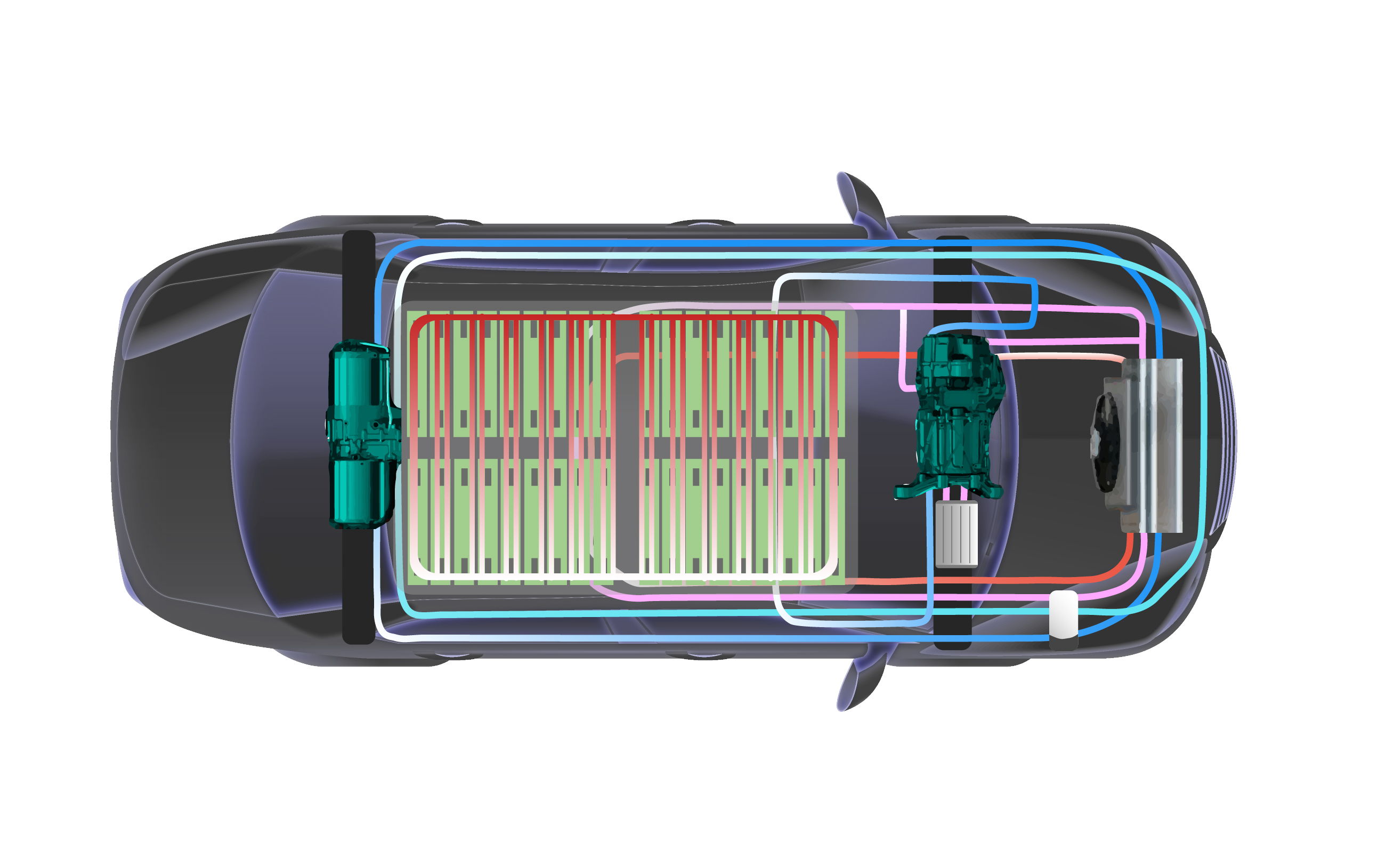

Electric vehicle thermal management is a critical aspect of ensuring the overall performance, efficiency, and reliability of electric vehicles. The management of heat within the vehicle’s systems is essential to prevent overheating, which can lead to reduced battery life, decreased performance, and increased risk of electrical fires. Effective thermal management is necessary to maintain optimal operating temperatures, ensuring the vehicle’s range, acceleration, and overall efficiency are not compromised.

The battery is a significant source of heat in electric vehicles, and its temperature has a direct impact on the vehicle’s performance and range. High temperatures can cause the battery to degrade faster, reducing its overall lifespan. Furthermore, excessive heat can also affect the electric motor, power electronics, and other components, leading to reduced efficiency and increased risk of failure.

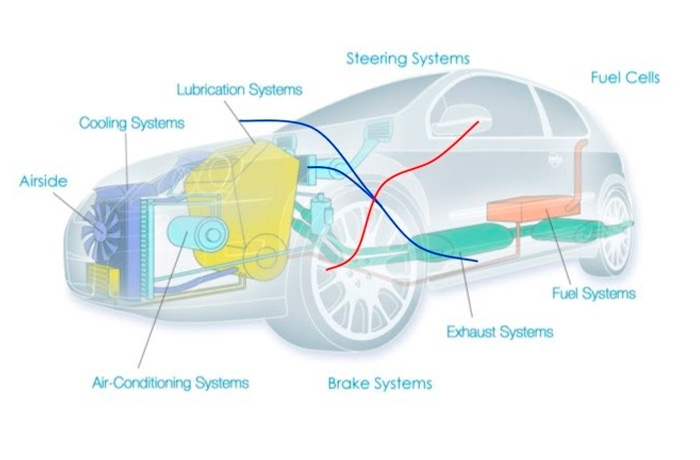

In addition to the battery, other components such as the electric motor, power electronics, and charging systems also generate heat. The management of this heat is crucial to prevent overheating, which can lead to reduced performance, decreased efficiency, and increased risk of electrical fires. Effective thermal management is necessary to maintain optimal operating temperatures, ensuring the vehicle’s range, acceleration, and overall efficiency are not compromised.

The importance of electric vehicle thermal management cannot be overstated. It is essential to ensure the overall performance, efficiency, and reliability of electric vehicles. By managing heat effectively, manufacturers can improve the range, acceleration, and overall efficiency of their vehicles, while also reducing the risk of electrical fires and improving the overall safety of the vehicle.

In the context of electric vehicle thermal management, it is essential to consider the various factors that affect the vehicle’s thermal balance. This includes the design of the vehicle’s cooling system, the materials used in the construction of the vehicle, and the driving habits of the user. By understanding these factors, manufacturers can design and develop more effective thermal management systems, improving the overall performance and efficiency of their vehicles.

Understanding the Sources of Heat in Electric Vehicles

The battery is a significant source of heat in electric vehicles, accounting for a substantial portion of the vehicle’s overall thermal load. During charging and discharging, the battery generates heat due to internal resistance, which can cause its temperature to rise. If left unmanaged, this heat can lead to reduced battery life, decreased performance, and increased risk of electrical fires.

The electric motor is another major source of heat in electric vehicles. As the motor converts electrical energy into mechanical energy, it generates heat due to electrical resistance and friction. This heat can be particularly problematic, as it can cause the motor to overheat, leading to reduced efficiency and increased risk of failure.

Power electronics, including the inverter and converter, also generate heat during operation. These components convert electrical energy from the battery to the motor, and in doing so, they produce heat due to electrical resistance and switching losses. If not properly managed, this heat can cause the power electronics to overheat, leading to reduced efficiency and increased risk of failure.

In addition to these primary sources of heat, other components such as the charging system, electrical wiring, and thermal management system itself can also generate heat. The charging system, for example, can generate heat during charging, particularly if the charger is not properly designed or maintained. Electrical wiring can also generate heat due to electrical resistance, particularly if the wiring is not properly sized or routed.

Understanding the sources of heat in electric vehicles is crucial for effective electric vehicle thermal management. By identifying and managing these sources of heat, manufacturers can design and develop more efficient thermal management systems, improving the overall performance, efficiency, and reliability of their vehicles.

The thermal balance of an electric vehicle is a delicate balance between heat generation and heat dissipation. If the heat generated by the vehicle’s components is not properly managed, it can lead to reduced performance, decreased efficiency, and increased risk of electrical fires. Effective thermal management is necessary to maintain optimal operating temperatures, ensuring the vehicle’s range, acceleration, and overall efficiency are not compromised.

https://www.youtube.com/watch?v=GAklC6xYSEg

How to Design an Effective Thermal Management System

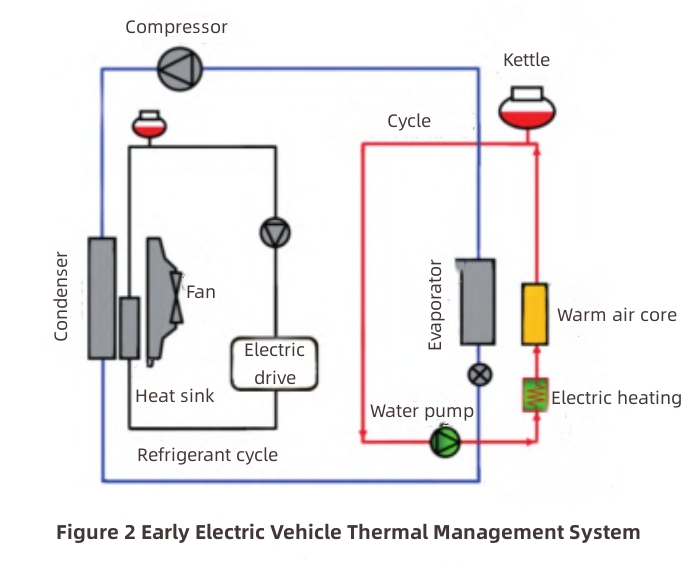

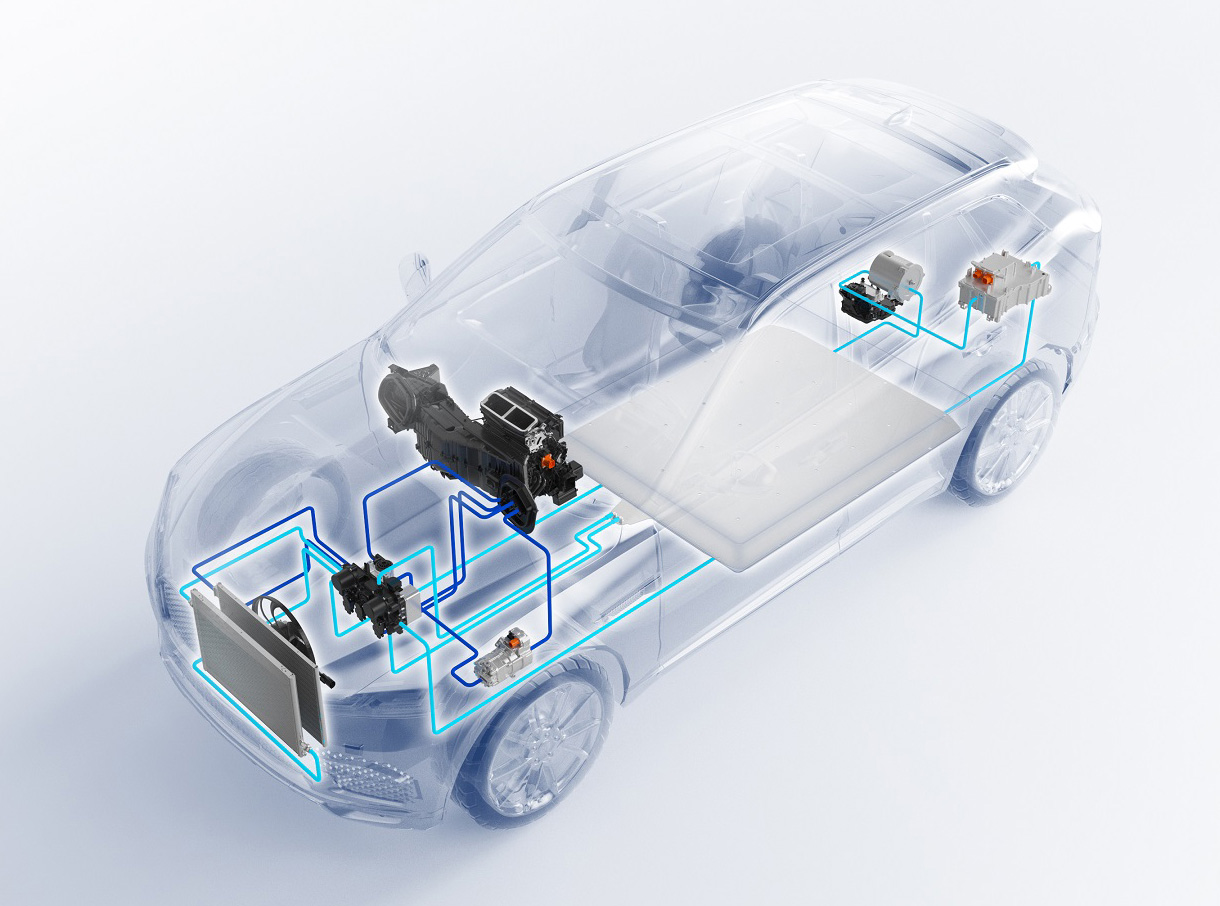

Designing an effective thermal management system for electric vehicles requires a comprehensive understanding of the vehicle’s thermal balance and the key components that contribute to it. The system should be designed to efficiently manage heat and maintain optimal operating temperatures, ensuring the vehicle’s range, acceleration, and overall efficiency are not compromised.

Heat exchangers are a critical component of any thermal management system, responsible for transferring heat from the vehicle’s components to a cooling medium, such as air or liquid. The design of the heat exchanger should be optimized to maximize heat transfer, while minimizing pressure drop and flow resistance.

Cooling circuits are another essential component of a thermal management system, responsible for circulating the cooling medium through the heat exchanger and other components. The design of the cooling circuit should be optimized to minimize pressure drop and flow resistance, while ensuring adequate cooling capacity.

Thermal interfaces are also a critical component of a thermal management system, responsible for transferring heat between components and the cooling medium. The design of the thermal interface should be optimized to minimize thermal resistance, while ensuring adequate mechanical strength and durability.

In addition to these key components, the thermal management system should also be designed to integrate with other vehicle systems, such as the battery management system and the power electronics. This integration is critical to ensuring that the thermal management system operates effectively and efficiently, while minimizing the risk of electrical fires and other safety hazards.

When designing a thermal management system, it is essential to consider the vehicle’s operating conditions, including temperature, humidity, and altitude. The system should be designed to operate effectively in a wide range of conditions, while minimizing the risk of overheating and other safety hazards.

Advanced materials and technologies, such as advanced composites and phase-change materials, can also be used to improve the efficiency and effectiveness of the thermal management system. These materials can provide improved thermal conductivity, while minimizing weight and reducing the risk of overheating.

By following these design principles and considering the key components and operating conditions, it is possible to design an effective thermal management system for electric vehicles. This system can help to improve the vehicle’s range, acceleration, and overall efficiency, while minimizing the risk of electrical fires and other safety hazards.

The Role of Materials in Electric Vehicle Thermal Management

Materials play a crucial role in electric vehicle thermal management, as they can significantly impact the efficiency and effectiveness of the thermal management system. The thermal conductivity, density, and durability of materials are critical factors to consider when designing a thermal management system.

Graphite, for example, is a popular material used in electric vehicle thermal management due to its high thermal conductivity and low density. Graphite is often used in heat exchangers and thermal interfaces, where it can efficiently transfer heat and maintain optimal operating temperatures.

Copper is another material commonly used in electric vehicle thermal management, particularly in heat exchangers and cooling circuits. Copper has high thermal conductivity and is relatively inexpensive, making it an attractive option for many applications.

Advanced composites, such as carbon fiber and polymer matrix composites, are also being used in electric vehicle thermal management. These materials offer high thermal conductivity, low density, and excellent durability, making them ideal for use in heat exchangers, thermal interfaces, and other components.

In addition to these materials, phase-change materials (PCMs) are also being explored for use in electric vehicle thermal management. PCMs can absorb and release heat as needed, making them ideal for use in thermal energy storage applications.

The selection of materials for electric vehicle thermal management is critical, as it can significantly impact the efficiency and effectiveness of the thermal management system. By choosing materials with high thermal conductivity, low density, and excellent durability, manufacturers can design thermal management systems that are both efficient and reliable.

Furthermore, the use of advanced materials and technologies can also help to reduce the weight and size of the thermal management system, making it more compact and efficient. This can be particularly beneficial in electric vehicles, where space and weight are critical factors.

In conclusion, materials play a critical role in electric vehicle thermal management, and the selection of materials can significantly impact the efficiency and effectiveness of the thermal management system. By choosing materials with high thermal conductivity, low density, and excellent durability, manufacturers can design thermal management systems that are both efficient and reliable.

Real-World Examples: Thermal Management in Popular Electric Vehicles

The Tesla Model S is a prime example of a successful thermal management system in an electric vehicle. The Model S uses a combination of air and liquid cooling to manage heat, with a focus on maintaining optimal operating temperatures for the battery and electric motor. The vehicle’s thermal management system is designed to work in conjunction with its advanced battery management system, ensuring that the battery is always operating within a safe temperature range.

The Chevrolet Bolt is another example of a well-designed thermal management system in an electric vehicle. The Bolt uses a liquid cooling system to manage heat, with a focus on maintaining optimal operating temperatures for the battery and electric motor. The vehicle’s thermal management system is designed to work in conjunction with its advanced battery management system, ensuring that the battery is always operating within a safe temperature range.

The Nissan Leaf is a popular electric vehicle that uses a combination of air and liquid cooling to manage heat. The Leaf’s thermal management system is designed to work in conjunction with its advanced battery management system, ensuring that the battery is always operating within a safe temperature range. The vehicle’s thermal management system is also designed to optimize performance and efficiency, while minimizing the risk of overheating.

These examples demonstrate the importance of thermal management in electric vehicles, and how it can impact performance, efficiency, and reliability. By designing and implementing effective thermal management systems, manufacturers can ensure that their vehicles operate safely and efficiently, while minimizing the risk of overheating and other safety hazards.

In addition to these examples, other manufacturers such as BMW, Volkswagen, and Hyundai are also investing heavily in thermal management technology for their electric vehicles. These manufacturers are using advanced materials and technologies, such as advanced composites and phase-change materials, to improve the efficiency and effectiveness of their thermal management systems.

As the electric vehicle market continues to grow and evolve, the importance of thermal management will only continue to increase. Manufacturers will need to design and implement effective thermal management systems that can optimize performance, efficiency, and reliability, while minimizing the risk of overheating and other safety hazards.

Thermal Management Challenges and Future Directions

Despite the importance of thermal management in electric vehicles, there are still several challenges and limitations that need to be addressed. One of the main challenges is the need for more efficient cooling systems that can effectively manage heat in a wide range of operating conditions. Current cooling systems often rely on air or liquid cooling, which can be limited in their ability to manage high temperatures and heat fluxes.

Another challenge is the need for advanced materials that can provide improved thermal conductivity, density, and durability. Current materials often have limitations in terms of their thermal performance, which can impact the overall efficiency and reliability of the thermal management system.

Emerging technologies such as advanced composites and phase-change materials offer promising solutions to these challenges. Advanced composites, such as carbon fiber and polymer matrix composites, can provide improved thermal conductivity and density, while phase-change materials can absorb and release heat as needed, reducing the risk of overheating.

Future directions for thermal management in electric vehicles include the development of more advanced cooling systems, such as those using advanced heat exchangers and cooling circuits. The use of advanced materials and technologies, such as nanomaterials and metamaterials, is also expected to play a key role in improving the efficiency and effectiveness of thermal management systems.

In addition, the integration of thermal management systems with other vehicle systems, such as the battery management system and the power electronics, is expected to become more important in the future. This integration can help to optimize performance, efficiency, and reliability, while minimizing the risk of overheating and other safety hazards.

Overall, the future of thermal management in electric vehicles is expected to be shaped by the development of more advanced cooling systems, materials, and technologies. As the electric vehicle market continues to grow and evolve, the importance of thermal management will only continue to increase, driving innovation and advancement in this critical area.

Best Practices for Maintaining Your Electric Vehicle’s Thermal Management System

Regular maintenance is crucial to ensure the optimal performance and efficiency of your electric vehicle’s thermal management system. Here are some best practices to follow:

Regular Checks: Regularly check the thermal management system for any signs of damage or wear. Look for leaks, corrosion, or blockages in the cooling circuits and heat exchangers.

Software Updates: Keep your electric vehicle’s software up to date, as updates often include improvements to the thermal management system.

Driving Habits: Avoid extreme driving habits, such as rapid acceleration or braking, as these can put excessive stress on the thermal management system.

Cooling System Maintenance: Regularly check and maintain the cooling system, including the coolant level, coolant condition, and radiator condition.

Heat Exchanger Maintenance: Regularly clean and inspect the heat exchangers to ensure they are functioning properly.

Thermal Interface Maintenance: Regularly inspect and maintain the thermal interfaces to ensure they are functioning properly.

By following these best practices, you can help ensure the optimal performance and efficiency of your electric vehicle’s thermal management system, and extend its lifespan.

In addition to these best practices, it’s also important to be aware of the signs of a malfunctioning thermal management system. These can include:

Overheating: If the thermal management system is not functioning properly, the electric vehicle’s components can overheat, leading to reduced performance and efficiency.

Reduced Range: A malfunctioning thermal management system can also reduce the electric vehicle’s range, as the battery and electric motor may not be operating at optimal temperatures.

Increased Energy Consumption: A malfunctioning thermal management system can also increase energy consumption, as the electric vehicle’s components may not be operating at optimal temperatures.

By being aware of these signs and following the best practices outlined above, you can help ensure the optimal performance and efficiency of your electric vehicle’s thermal management system.

Conclusion: The Future of Electric Vehicle Thermal Management

In conclusion, thermal management is a critical aspect of electric vehicle performance, efficiency, and reliability. The importance of thermal management cannot be overstated, as it has a direct impact on the vehicle’s range, acceleration, and overall efficiency.

As the electric vehicle industry continues to evolve, the need for advanced thermal management systems will only continue to grow. Emerging technologies such as advanced composites and phase-change materials offer promising solutions to the challenges