Breaking Down the Barriers to Entry in the PCB Industry

The printed circuit board (PCB) industry is a highly competitive and complex field, with numerous challenges facing new PCB startups. One of the primary barriers to entry is the high development cost associated with designing and manufacturing PCBs. This can be a significant obstacle for startups with limited resources, as they must invest heavily in research and development, equipment, and personnel. Additionally, the PCB manufacturing process is intricate and requires specialized expertise, making it difficult for new companies to navigate.

Another significant challenge facing PCB startups is the intense competition in the market. Established companies have a strong foothold in the industry, and it can be difficult for new entrants to gain traction. Furthermore, the PCB industry is subject to rapid technological advancements, making it essential for startups to stay up-to-date with the latest developments and trends. However, this can be a daunting task, especially for companies with limited resources and expertise.

Despite these challenges, it is possible for PCB startups to overcome these barriers and achieve success. One key strategy is to develop a robust business plan that outlines the company’s goals, target market, and financial projections. This plan should also identify potential risks and opportunities, as well as outline a clear path for growth and development. By having a solid plan in place, PCB startups can better navigate the challenges of the industry and make informed decisions about their business.

In addition to a solid business plan, PCB startups can also benefit from seeking out resources and support from industry organizations, government agencies, and other stakeholders. For example, many countries offer grants and funding programs specifically for startups in the technology sector. Additionally, industry organizations such as the IPC (Institute for Printed Circuits) offer a range of resources and support for PCB startups, including training and education programs, networking opportunities, and access to industry experts.

By understanding the challenges facing PCB startups and developing strategies to overcome them, new companies can increase their chances of success in this complex and competitive industry. With the right combination of planning, resources, and support, PCB startups can break down the barriers to entry and achieve their goals.

How to Develop a Winning PCB Product Strategy

Developing a successful PCB product strategy is crucial for the success of any PCB startup. A well-crafted strategy can help a company to differentiate itself from competitors, meet the needs of its target market, and ultimately drive revenue growth. So, what are the key elements of a winning PCB product strategy?

First and foremost, it is essential to identify the needs of the target market. This involves conducting market research to understand the requirements and pain points of potential customers. PCB startups should also analyze their competitors, identifying gaps in the market and areas where they can differentiate themselves. By understanding the needs of the market, PCB startups can develop products that meet those needs and provide a unique value proposition.

Designing for manufacturability is another critical aspect of a successful PCB product strategy. This involves designing products that are easy to manufacture, test, and assemble. By doing so, PCB startups can reduce production costs, improve product quality, and increase efficiency. Additionally, designing for manufacturability can help to reduce the risk of product defects and improve overall product reliability.

A robust testing and validation process is also essential for ensuring the quality and reliability of PCB products. This involves testing products at various stages of development, from prototype to production, to identify and fix any defects or issues. By doing so, PCB startups can ensure that their products meet the required standards and specifications, reducing the risk of product failures and improving customer satisfaction.

In addition to these elements, PCB startups should also consider the importance of scalability and flexibility in their product strategy. This involves designing products that can be easily scaled up or down to meet changing market demands, as well as products that can be easily modified or customized to meet the needs of different customers. By doing so, PCB startups can improve their ability to respond to changing market conditions and improve their overall competitiveness.

By incorporating these elements into their product strategy, PCB startups can develop products that meet the needs of their target market, are easy to manufacture and test, and provide a unique value proposition. This can help to drive revenue growth, improve customer satisfaction, and ultimately contribute to the success of the business.

The Role of Prototyping in PCB Startup Success

Prototyping is a crucial step in the PCB development process, and it plays a vital role in the success of PCB startups. Prototyping allows startups to test and validate their ideas, identify potential problems, and make necessary changes before moving into production. In this article, we will discuss the importance of prototyping in PCB startup success, including the benefits of rapid prototyping, the use of PCB design software, and the value of testing and iterating on prototypes.

Rapid prototyping is a key aspect of the PCB development process. It allows startups to quickly create and test prototypes, reducing the time and cost associated with traditional prototyping methods. Rapid prototyping also enables startups to test multiple design iterations, identify potential problems, and make necessary changes before moving into production. This approach can help startups to reduce the risk of product failures, improve product quality, and increase customer satisfaction.

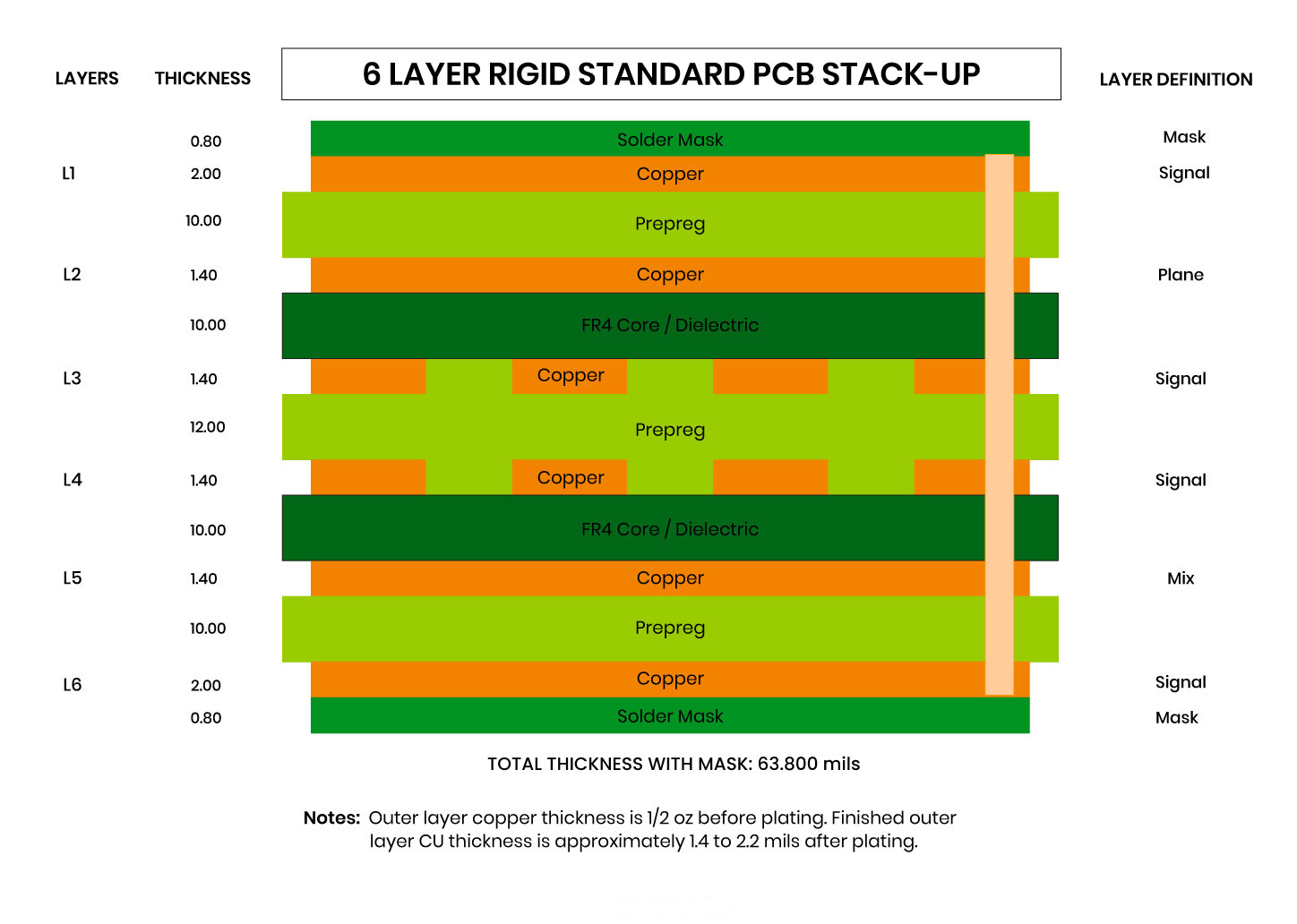

PCB design software is another essential tool for PCB startups. This software allows startups to design and simulate their PCBs, reducing the risk of errors and improving product quality. PCB design software also enables startups to create complex designs, including multi-layer boards, and to simulate the behavior of their PCBs under different operating conditions. This approach can help startups to improve product reliability, reduce production costs, and increase efficiency.

Testing and iterating on prototypes is also a critical aspect of the PCB development process. This approach allows startups to identify potential problems, make necessary changes, and validate their designs. Testing and iterating on prototypes can help startups to reduce the risk of product failures, improve product quality, and increase customer satisfaction. It can also help startups to identify areas for improvement, optimize their designs, and reduce production costs.

In addition to these benefits, prototyping can also help PCB startups to secure funding and attract investors. A working prototype can demonstrate the feasibility of a startup’s idea, and it can provide a clear vision of the product’s potential. This approach can help startups to build credibility, establish trust with investors, and secure the funding they need to move forward.

By incorporating prototyping into their development process, PCB startups can reduce the risk of product failures, improve product quality, and increase customer satisfaction. Prototyping can also help startups to secure funding, attract investors, and establish credibility in the market. Whether you are a seasoned entrepreneur or a newcomer to the PCB industry, prototyping is an essential step in the development process, and it can play a vital role in the success of your startup.

PCB Manufacturing Options for Startups: A Comparison

When it comes to PCB manufacturing, startups have several options to choose from, each with its own pros and cons. In this article, we will compare and contrast different PCB manufacturing options available to startups, including in-house manufacturing, contract manufacturing, and hybrid models.

In-house manufacturing is a popular option for PCB startups that have the resources and expertise to produce their own boards. This approach allows startups to have complete control over the manufacturing process, from design to delivery. However, in-house manufacturing can be capital-intensive and requires significant investment in equipment, personnel, and facilities.

Contract manufacturing, on the other hand, involves outsourcing PCB production to a third-party manufacturer. This approach can be more cost-effective than in-house manufacturing, as startups do not have to invest in equipment and personnel. However, contract manufacturing can also involve a loss of control over the manufacturing process, and startups may have to compromise on quality and lead times.

Hybrid models, which combine elements of in-house and contract manufacturing, are also gaining popularity among PCB startups. This approach allows startups to maintain control over critical aspects of the manufacturing process while outsourcing non-core activities to third-party manufacturers. Hybrid models can offer the best of both worlds, but they can also be complex to manage and require significant coordination.

When choosing a PCB manufacturing option, startups should consider several factors, including cost, quality, lead time, and control. In-house manufacturing may be the best option for startups that require high-quality boards with complex designs, while contract manufacturing may be more suitable for startups that require high-volume production with shorter lead times. Hybrid models, on the other hand, may be the best option for startups that require a balance of control and cost-effectiveness.

Ultimately, the choice of PCB manufacturing option depends on the specific needs and goals of the startup. By carefully evaluating the pros and cons of each option, PCB startups can make informed decisions that support their business objectives and drive success.

In addition to the manufacturing option, PCB startups should also consider the importance of quality control, testing, and validation. Regardless of the manufacturing option chosen, startups should ensure that their PCBs meet the required standards and specifications, and that they are thoroughly tested and validated before delivery.

By choosing the right PCB manufacturing option and prioritizing quality control, testing, and validation, PCB startups can ensure that their products meet the highest standards of quality and reliability, and that they are well-positioned for success in the market.

Real-World Examples of Successful PCB Startups

While launching a successful PCB startup can be a challenging and daunting task, there are many examples of companies that have achieved success in this field. In this article, we will highlight several successful PCB startups, including companies like Adafruit, SparkFun, and Seeed Studio. We will analyze their strategies, products, and business models to identify key factors contributing to their success.

Adafruit is a well-known PCB startup that has achieved significant success in the industry. Founded in 2005 by Limor Fried, Adafruit has become a leading provider of DIY electronics and PCBs. The company’s success can be attributed to its focus on innovation, customer service, and community engagement. Adafruit’s products are designed to be easy to use and accessible to a wide range of customers, from hobbyists to professionals.

SparkFun is another successful PCB startup that has made a name for itself in the industry. Founded in 2003 by Nathan Seidle, SparkFun has become a leading provider of DIY electronics and PCBs. The company’s success can be attributed to its focus on innovation, customer service, and education. SparkFun’s products are designed to be easy to use and accessible to a wide range of customers, from hobbyists to professionals.

Seeed Studio is a Chinese PCB startup that has achieved significant success in the industry. Founded in 2008 by Eric Pan, Seeed Studio has become a leading provider of DIY electronics and PCBs. The company’s success can be attributed to its focus on innovation, customer service, and community engagement. Seeed Studio’s products are designed to be easy to use and accessible to a wide range of customers, from hobbyists to professionals.

While these companies have achieved success in the PCB industry, there are several key factors that have contributed to their success. These factors include a focus on innovation, customer service, and community engagement. Additionally, these companies have been able to identify and capitalize on emerging trends in the industry, such as the growth of DIY electronics and the Internet of Things (IoT).

By analyzing the strategies, products, and business models of these successful PCB startups, we can gain valuable insights into what it takes to succeed in this industry. Whether you are a seasoned entrepreneur or a newcomer to the PCB industry, these examples can provide valuable lessons and inspiration for your own startup.

In addition to these examples, there are many other PCB startups that have achieved success in the industry. These companies have been able to identify and capitalize on emerging trends, and have developed innovative products and business models that meet the needs of their customers. By studying these examples, we can gain a deeper understanding of what it takes to succeed in the PCB industry, and how to develop a successful PCB startup.

Building a Strong Team for Your PCB Startup

Building a strong team is crucial for the success of any PCB startup. A skilled and dedicated team can help to drive innovation, improve product quality, and increase customer satisfaction. In this article, we will discuss the importance of building a strong team for your PCB startup, including the roles of engineers, designers, and manufacturing experts.

Engineers play a critical role in the development of PCBs. They are responsible for designing and testing PCBs, as well as ensuring that they meet the required standards and specifications. Engineers should have a strong background in electrical engineering, as well as experience with PCB design software and manufacturing processes.

Designers are also essential for the development of PCBs. They are responsible for creating the visual design of the PCB, including the layout and appearance of the board. Designers should have a strong background in graphic design, as well as experience with PCB design software.

Manufacturing experts are responsible for overseeing the production of PCBs. They should have a strong background in manufacturing processes, as well as experience with quality control and assurance. Manufacturing experts should also be familiar with the latest manufacturing technologies and trends.

In addition to these roles, it is also important to have a strong management team in place. This includes a CEO or president, as well as other key executives who can provide strategic direction and guidance for the company.

To attract and retain top talent, PCB startups should offer competitive salaries and benefits, as well as opportunities for professional development and growth. They should also foster a positive and inclusive company culture, as well as provide a supportive and collaborative work environment.

By building a strong team, PCB startups can drive innovation, improve product quality, and increase customer satisfaction. They can also stay ahead of the competition and achieve long-term success in the industry.

In addition to building a strong team, PCB startups should also prioritize training and development. This includes providing ongoing training and education for employees, as well as opportunities for professional development and growth.

By prioritizing training and development, PCB startups can ensure that their employees have the skills and knowledge they need to succeed in the industry. They can also stay ahead of the competition and achieve long-term success.

Securing Funding for Your PCB Startup

Securing funding is a critical step for any PCB startup. Without sufficient funding, it can be difficult to develop and launch a product, hire a team, and grow the business. In this article, we will discuss the different funding options available to PCB startups, including venture capital, crowdfunding, and government grants.

Venture capital is a popular funding option for PCB startups. Venture capitalists invest money in startups in exchange for equity, and they often provide guidance and support to help the business grow. However, venture capital can be difficult to secure, and it often requires a strong business plan and a proven track record of success.

Crowdfunding is another funding option for PCB startups. Crowdfunding platforms, such as Kickstarter and Indiegogo, allow startups to raise money from a large number of people, typically in exchange for rewards or equity. Crowdfunding can be a good option for startups that have a strong product and a compelling story to tell.

Government grants are also available to PCB startups. Government grants can provide funding for research and development, product development, and business growth. However, government grants can be competitive, and they often require a strong application and a clear plan for how the funding will be used.

To secure funding, PCB startups should prepare a compelling pitch and business plan. The pitch should clearly explain the product and the market opportunity, and it should demonstrate a clear understanding of the business and the industry. The business plan should provide a detailed overview of the business, including the product, the market, the competition, and the financial projections.

PCB startups should also be prepared to answer questions from investors and to provide additional information as needed. This may include providing financial statements, product prototypes, and market research.

By securing funding, PCB startups can develop and launch their products, hire a team, and grow their business. With the right funding and support, PCB startups can achieve success and become leaders in the industry.

In addition to securing funding, PCB startups should also focus on building a strong team and developing a solid business plan. This will help to ensure that the business is well-positioned for success and that it can achieve its goals.

By following these tips and securing funding, PCB startups can overcome the challenges of launching a new business and achieve success in the industry.

Staying Ahead of the Competition in the PCB Industry

To stay competitive in the rapidly evolving PCB industry, startups must be proactive in their approach to innovation and growth. This involves staying up-to-date with the latest industry trends, investing in research and development, and building strategic partnerships. By doing so, PCB startups can differentiate themselves from competitors and establish a strong market presence.

One key trend in the PCB industry is the increasing demand for IoT-enabled devices. PCB startups that can design and manufacture boards that meet this demand are well-positioned for success. This may involve investing in new technologies, such as wireless connectivity and sensor integration, and developing expertise in areas like data analytics and machine learning.

Another important factor in staying competitive is investing in research and development. This can involve partnering with universities or research institutions to access new technologies and expertise, or establishing an in-house R&D team. By investing in R&D, PCB startups can develop new products and services that meet emerging market needs and stay ahead of the competition.

Building strategic partnerships is also critical for PCB startups. This can involve partnering with suppliers to access new materials and technologies, or collaborating with other companies to develop new products and services. By building a strong network of partners, PCB startups can access new markets, technologies, and expertise, and establish a strong competitive position.

In addition to these strategies, PCB startups must also focus on building a strong brand and establishing a robust online presence. This can involve developing a professional website, engaging with customers and partners on social media, and investing in targeted marketing campaigns. By building a strong brand and online presence, PCB startups can establish credibility and trust with customers, and differentiate themselves from competitors.

Finally, PCB startups must be prepared to adapt to changing market conditions and customer needs. This involves staying agile and responsive, and being willing to pivot or adjust strategies as needed. By being adaptable and responsive, PCB startups can stay ahead of the competition and establish a strong market position.

By following these strategies, PCB startups can stay competitive in the rapidly evolving PCB industry. By investing in innovation, building strategic partnerships, and establishing a strong brand and online presence, PCB startups can differentiate themselves from competitors and establish a strong market presence. With the right approach, PCB startups can achieve success and establish themselves as leaders in the industry.